Asset Lifecycle Management

Everything you ever needed to know about asset lifecycle management.

What is asset lifecycle?

The asset lifecycle is a series of stages a company asset goes through that requires its own approach to management and maintenance. Be it a piece of equipment, a building, a vehicle, or any other item is used in the day-to-day operations, its productivity and maintenance needs will evolve as the asset ages.

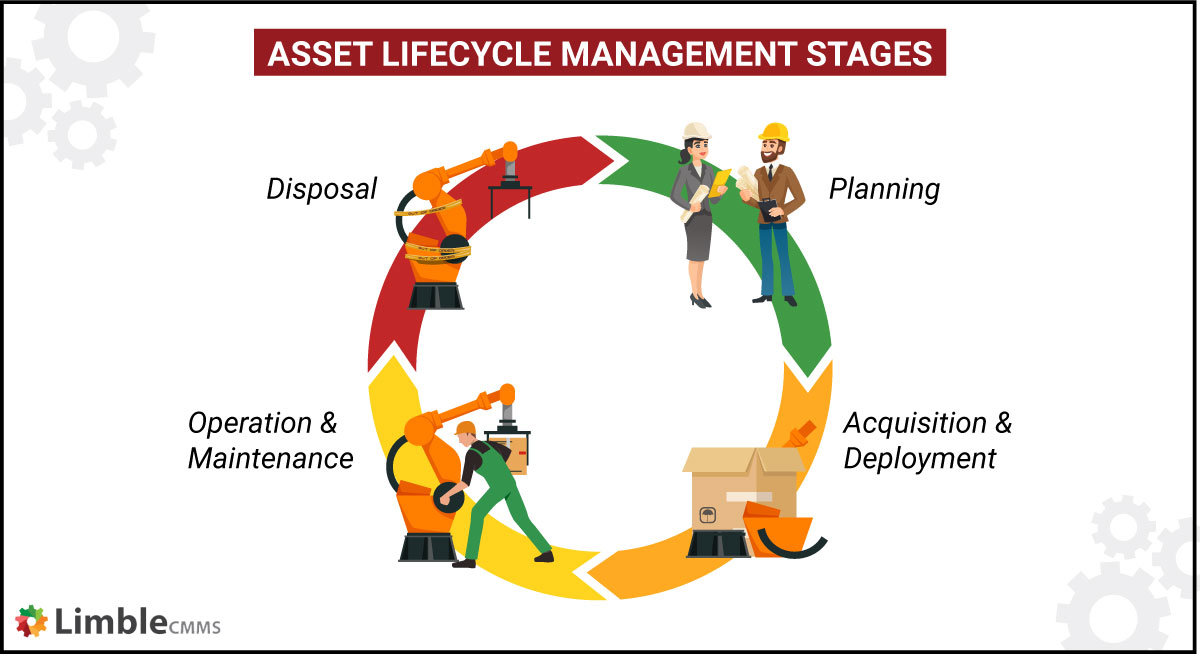

The lifecycle of all physical assets can be broadly classified into these major stages:

- Planning

- Acquisition and deployment

- Operation and maintenance

- Disposal

The lifecycle of an asset does not begin on the day it is acquired. Acquisition of assets is a major business decision, to be taken only after careful planning.

Purchasing inadequate assets can have major long-term repercussions. For instance, a costly machine that is not compatible with the existing plant facilities and business needs will quickly become a liability.

The cost of an asset, its role in the business, and other unique features will play a crucial role in how it is managed over the course of its useful life.

Checklist for Creating a Preventive Maintenance Plan

Following a consistent Preventive Maintenance Plan can make life easier. Use this checklist to create your own!

Table of Contents

- Everything you ever needed to know about asset lifecycle management.

- What is asset lifecycle?

- Checklist for Creating a Preventive Maintenance Plan

- What is asset lifecycle management (ALM)?

- The role of data in managing asset life

- Steps in the asset lifecycle management process

- Maximizing asset value

- Related Content

What is asset lifecycle management (ALM)?

Asset lifecycle management is the process of monitoring an asset’s use and performance over time to optimize how it is maintained and ultimately extend its useful life.

By keeping constant tabs on an asset throughout its lifecycle, a business will gain a lot of data and insight. It can learn how an asset’s physical condition is impacted by its use over time within a business’s specific application. It can also measure the contribution of the asset to productivity and revenue, its reliability and ongoing maintenance costs, and more.

Let’s take a look at how a company may use this information with an example of acquiring a new CNC machine:

Maximizing profit and revenue

With proper asset management processes in place, a business can learn how a CNC machine may handle faster production cycles, whether or not it is the best fit for its production requirements, and whether or not staff need training on machine operation to optimize productivity. All this information helps organizations efficiently increase productivity and revenue.

Minimizing the cost of ownership

Monitoring the investments of time and money made in an asset helps organizations understand the total cost of ownership for a CNC machine. Evaluating data on fuel and power usage, downtime events, and vendor spend for specialized repairs helps the business save a lot of money throughout the operating life of the asset.

Extending the operational life of the asset

With data on machine wear and tear, repair and maintenance schedules, and productivity levels over time, the business can optimize processes to keep the asset in working condition for as long as possible. This will help squeeze every bit of value from the asset and further improve overall ROI.

Asset lifecycle management comes with many additional benefits:

- Financial planning of acquisition cost

- Effective development of preventive maintenance strategies

- Reduction in depreciation, improving the resale value of an asset

- Improved productive efficiency

- Better safety and regulatory compliance

Without adequate lifecycle management, most assets will experience steady increases in maintenance expenses, reductions in productivity, and inefficient utilization of resources across the firm.

The role of data in managing asset life

Successful asset lifecycle management depends on the easy availability of information. For maximum impact, ALM planners need data from virtually every aspect of the organization. Given the amount of data and analysis required, analog or pen and paper systems simply do not provide the visibility a good asset lifecycle management process needs.

Modern CMMS (Computerized Maintenance Management System) and EAM (Enterprise Asset Management) software are sophisticated digital platforms that combine online systems and on-site tools (IoT integration) to streamline data collection. A CMMS/EAM platform gives businesses unprecedented control and visibility over all their operational assets, equipment, and departments.

Steps in the asset lifecycle management process

By providing a framework and digital platform to support each part of the ALM process, businesses can set themselves up for successful asset management practices. A customizable CMMS software gives businesses a critical edge in all stages of asset lifecycle management. Let’s take a look at how CMMS offers support at each stage.

1. Planning

Managers must make the case for the acquisition of a new asset. Many situations call for an asset investment:

- Replacing outdated equipment

- Improving efficiency/productivity

- Ensuring safety and environmental compliance

- Scaling-up production

Planning requires a thorough review of the technical aspects and cost of acquisition, as well as other critical inputs from all stakeholders – operators, on-site managers, financial/accounting, procurement, engineering, mid and high-level management, and more.

The asset is chosen after extensive research of options on the market, trialing and comparing them, and finally purchasing one that fits the business needs best.

The CMMS impact

To make a clear case for new asset acquisitions, management must review existing equipment and capital assets. With a mobile CMMS app, all the relevant asset data is available for quick and meaningful reporting.

Using custom KPIs, maintenance reports on asset performance can be shared with all major stakeholders across the organization, which streamlines the decision-making process.

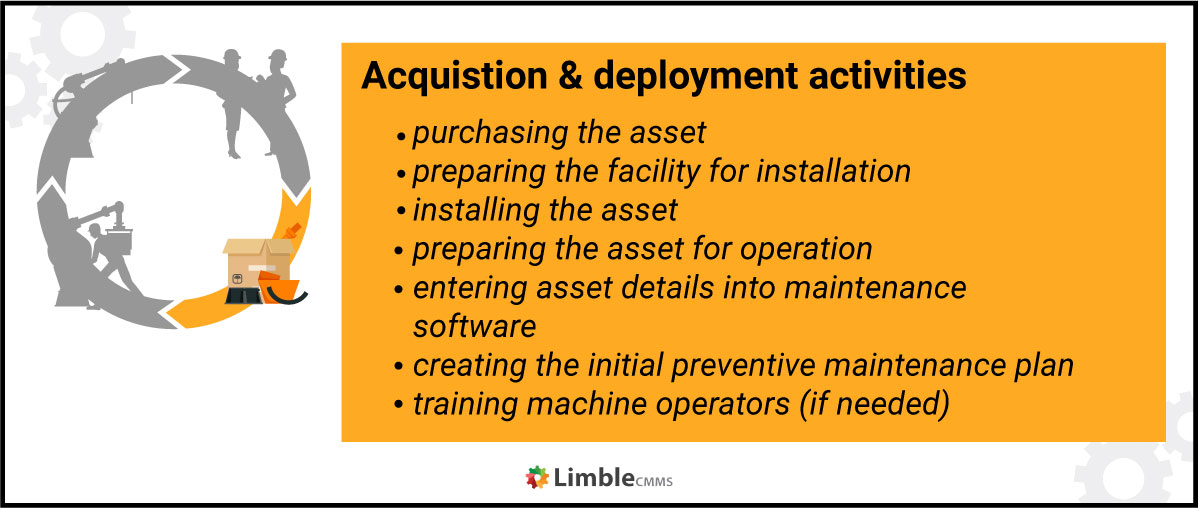

2. Acquisition & deployment

At this stage of the asset management process, the business will zero in on a specific product, based on the insights acquired during the planning stage – with the procurement department handling their part of the work.

Deployment involves essential tasks like asset delivery, on-site installation, and the training of operators (for equipment/machines/vehicles). This stage usually involves a high level of coordination between the business and the vendor of the product purchased.

The CMMS impact

The arrival of a new asset brings a whole set of essential tasks. Maintenance managers can use CMMS to allocate resources and schedule both the preparation work and the installation of the newly acquired asset.

While that is in process, they can enter the asset details into the CMMS database and create the initial preventive maintenance plan based on OEM recommendations and professional work experience. Depending on the type of asset and its importance, the organization might want to use maintenance software to set up asset tracking.

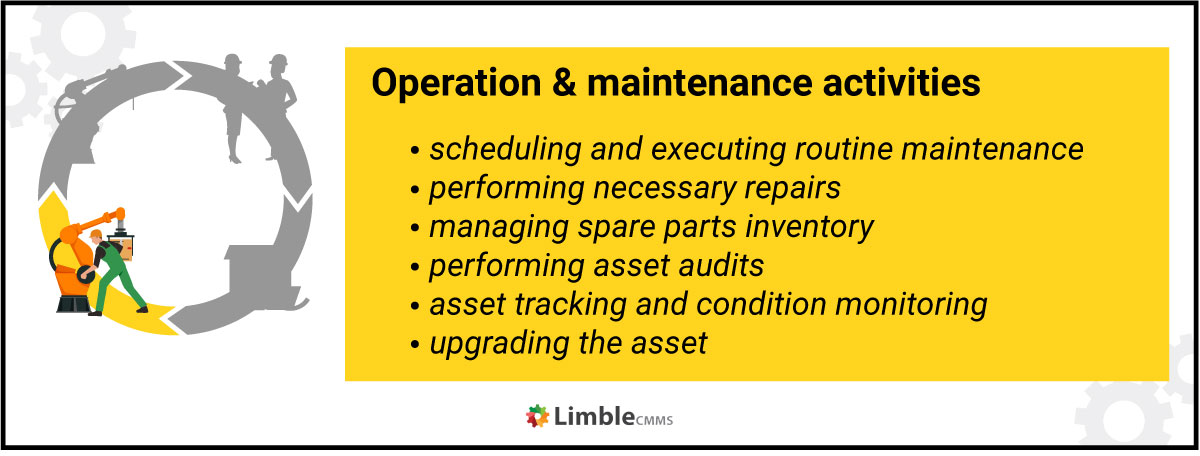

3. Operation & maintenance

This will be the longest stage in the life cycle of most assets. The primary focus of asset maintenance will be to extend it for as long as possible, while keeping the operational cost increases to a minimum.

Operation schedules should be created with the utmost care, based on vendor instructions and safety thresholds. Regular monitoring of the assets during operation is essential to detect any performance issues or parts wear and tear.

Proper maintenance schedules will reduce the risk of unexpected failures, emergency repairs, and unwanted downtimes. It will also contribute massively to increased uptimes and prolonged operational life of the asset, optimizing its functionality.

In this stage, businesses may also opt for modifications and upgrades to the asset. This is usually done in response to changes in production, compliance requirements, and other workplace conditions. Some upgrades can also help increase the longevity of the asset.

The CMMS impact

Modern CMMS/EAM software is crucial for keeping physical assets in good operating condition. They offer a variety of useful features that help maintenance teams organize all repair and maintenance work and stay on top of MRO inventory.

On top of that, a CMMS can link with cutting-edge IoT sensors connected to machines and equipment on the plant floor. These sensors can monitor asset status 24/7, detecting the potential for equipment failure well in advance. This is the foundation for running advanced maintenance strategies, such as prescriptive and predictive maintenance.

In other words, CMMS helps you plan for and execute any proactive maintenance strategy you want to use for your new assets. As an added bonus, you can use the asset data CMMS stores and generates to infer valuable insights for calculating asset productivity and its revenue generation potential. These can be leveraged to make further improvements in asset utilization.

4. Decommission & disposal

There comes a stage in the life of every asset where it is either obsolete, broken down, or just too inefficient to be profitable. At this point, the operational costs overrun the productivity gains from the asset – it is time to decommission the asset, dispose of it, and replace it.

After removal from service, the next step will be determined by the type of asset, its overall condition, and demand (if any) in the second-hand market. The business may opt to either sell/auction the asset, donate it, or just abandon it to a junkyard/recycling facility.

With due diligence and effective lifecycle management in the previous stages, a business can recoup a significant portion of its sunken costs in the asset. If the equipment or facility is in decent condition, it might fetch a high price through auction/resale.

The CMMS impact

Timely identification of the need for decommissioning and replacement of an asset is critical – it can reduce production inefficiencies and remove potential safety risks. By looking at maintenance history and reports, managers will have an easier time deciding if an asset should be repaired or replaced.

Furthermore, the disposal stage is also the time to reap the rewards of smart maintenance logs and digital record keeping – these can significantly improve the resale value of an asset.

Want to see Limble in action? Get started for free today!

Maximizing asset value

Businesses face a challenging future, with increasing effects of climate change, economic recession, and wider systemic shocks from the global pandemic. Financial discipline will be more important than ever in the coming years.

With less budgetary allocation for asset acquisition, firms will have to eke out more dollar value from existing asset inventories and try their best to prolong asset lifecycles. A modern, feature-packed, CMMS software like Limble will help you maximize asset value by guiding your actions at every stage of the asset lifecycle management process.