Corrective Maintenance

Everything you ever needed to know about corrective maintenance

What is corrective maintenance?

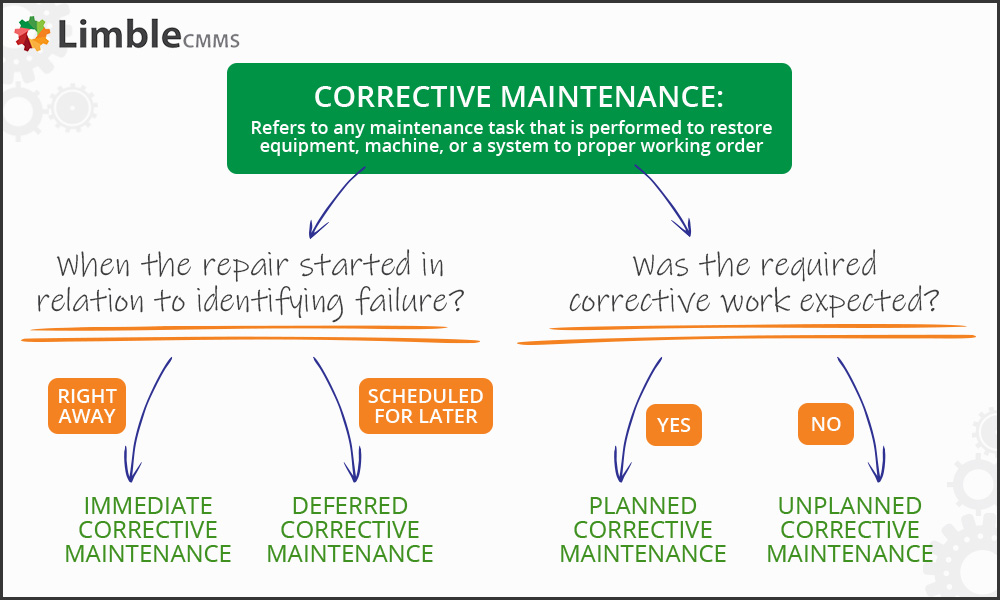

Corrective maintenance refers to any maintenance task a company performs to restore equipment, machines, or a system to proper working order.

Corrective maintenance is performed for several reasons:

- To resolve an issue spotted while doing other maintenance work

- When a machine operator spots an issue with the asset that needs to be corrected

- After condition-monitoring sensor sends an alert about a performance issue

- After a machine breakdown

In an ideal scenario, the majority of corrective maintenance work should focus on correcting minor issues on (partially) functional equipment, not addressing full-blown breakdowns.

Looking at the definition alone, someone might ask: Isn’t corrective maintenance just another one on the long list of synonyms for reactive maintenance (like breakdown and run-to-failure maintenance)?

While they are similar, they do not describe the same thing.

For instance, if someone asks which maintenance strategy a company is using, then the better answer would be reactive maintenance. This is because corrective maintenance isn’t a complete strategy in itself. It represents a type of maintenance action you are doing that is a part of every maintenance strategy.

Guide to Moving from Reactive to Preventive Maintenance

Want to transition away from costly reactive maintenance but don't know where to start? This guide has everything you need to know.

Types of corrective maintenance

Let’s break down a couple different ways to classify corrective maintenance tasks.

Immediate vs deferred corrective maintenance

Immediate vs deferred corrective maintenance helps technicians understand when to take corrective action in relation to when the problem of failure was detected.

Immediate corrective maintenance refers to corrective actions that take place immediately after failure. For example, a technician spots an issue during routine work and immediately corrects it.

Deferred corrective maintenance refers to corrective actions that are postponed/scheduled for later. Corrective maintenance might be deferred for many reasons, such as:

- Technicians are needed on a higher-priority case

- Replacement parts are not available

- A specialist is needed to perform the necessary corrective actions

Learn more about deferred maintenance here.

Planned vs unplanned corrective maintenance

People often think that reactive maintenance represents the lack of a maintenance plan, but that is not always the case.

Not all assets are worth putting on a preventive or predictive maintenance program. Sometimes, you consciously decide to let a machine run to failure and schedule corrective action when the failure occurs. This is called planned corrective maintenance. It can be applied to low-priority assets or those with high fault tolerance.

Unfortunately, things will not always go according to plan. A reality for many businesses is that unexpected breakdowns occur and must be resolved as soon as possible. These scenarios require sudden corrective actions to return the assets to operation. Hence the unplanned corrective maintenance.

Benefits of doing corrective maintenance the right way

Having an optimized corrective maintenance process provides multiple benefits:

- Reduced duration of both unplanned and planned maintenance

- Reduced need for emergency maintenance work by addressing minor problems before they cause functional failures, which, in turn, extends the lifespan of assets

- Better operating conditions for assets, which creates a safer work environment

The goal of every maintenance team is to be fast and effective, especially when dealing with unexpected breakdowns and machine malfunctions. That is reason enough for every maintenance department to take a closer look at how they are doing corrective maintenance.

The Essential Guide to CMMS

Download this helpful guide to everything a CMMS has to offer.

Corrective maintenance examples

Let’s discuss a few examples of corrective maintenance and see how it is applied in practice.

Example #1 – After asset breakdown

This is the most basic and common example of corrective maintenance action.

Within a production facility if one machine breaks down, the whole production line stops. A machine operator sends for someone on their maintenance team to inspect and fix the problem. The technician listens to the problem description and performs an inspection to see if it is a mechanical or electrical fault. They find the faulty part and replace it – which puts the asset back into the condition to perform its intended function.

The technician analyzed an unexpected breakdown, isolated the problem, and made the necessary corrections – in other words, they performed unplanned corrective work.

Example #2 – Problem noticed during preventive maintenance work

For this example, imagine a maintenance technician performing a scheduled maintenance task that consists of an oil change and a visual inspection. While doing that, they notice that one bearing is worn out and needs to be replaced. There were spare bearings in stock, so they can perform the replacement right away – doing, what we could call, immediate corrective maintenance.

Example #3 – Sensors show out-of-limit misalignment

Let’s put ourselves in the shoes of a maintenance manager who has all of their essential assets on a condition-based maintenance program. That means they retrofitted all critical assets with sensors to monitor the condition of their machines in real time.

For this example, we will throw around some arbitrary numbers.

After some time, a wireless sensor mounted on a rotating shaft of a pump signals that the shaft is out of alignment for 5 millimeters. In comparison, the safe operational conditions allow for only up to 3 millimeters of misalignment. This indicates that some corrective actions have to be scheduled as soon as possible.

Now, keep in mind that the equipment failure didn’t happen yet. The pump still performs as intended, but the loss can occur at any moment, which poses high cost and safety risks. Luckily, the technicians can immediately disassemble the pump and perform corrective actions – be it a simple tightening of loose parts or replacing cracked ones.

This example illustrates how to perform corrective maintenance on assets that didn’t yet reach functional failure. While failures are still the most common trigger of corrective maintenance, the increased use of condition-monitoring equipment and predictive analytics opens the door for other types of triggers.

Want to see Limble in action? Get started for free today!

Staying ahead

No company can eliminate corrective maintenance from their organization, but that shouldn’t stop them from reducing the number of unplanned corrective actions by employing proactive maintenance measures.

We hope that this guide will help you optimize corrective maintenance processes so you can properly handle unexpected work and speed up planned corrective tasks.

As always, if you have any questions, feel free to send us a message directly through our contact form.