Routine Maintenance

Everything you ever needed to know about routine maintenance.

What is routine maintenance?

Routine maintenance is the regular maintenance a company performs to keep assets in good operating condition and reduce unexpected breakdowns. These tasks are carried out regularly to identify and address issues before they lead to equipment failure.

Be it a truck, a building, a CNC machine, or a forklift, no asset is exempt from the wear and tear that comes with daily use. Routine maintenance activities are the single most effective way to deal with equipment deterioration before it leads to serious issues.

But how does routine maintenance fit into a business’s overall maintenance strategy? What are its upsides and downsides? And how can a CMMS maximize the value of routine maintenance?

Depending on the equipment in question and the type of maintenance work required, routine maintenance can be performed on a time-based schedule (daily/weekly/monthly) or a usage-based schedule (cycles performed/miles driven/hours in use). Time-based maintenance schedules are the most common.

In general, routine maintenance consists of simple tasks that require minimal training. Thus, these tasks are sometimes carried out by machine operators, which frees maintenance technicians to focus on more complex tasks. This practice forms the basis of autonomous maintenance.

Advantages of routine maintenance

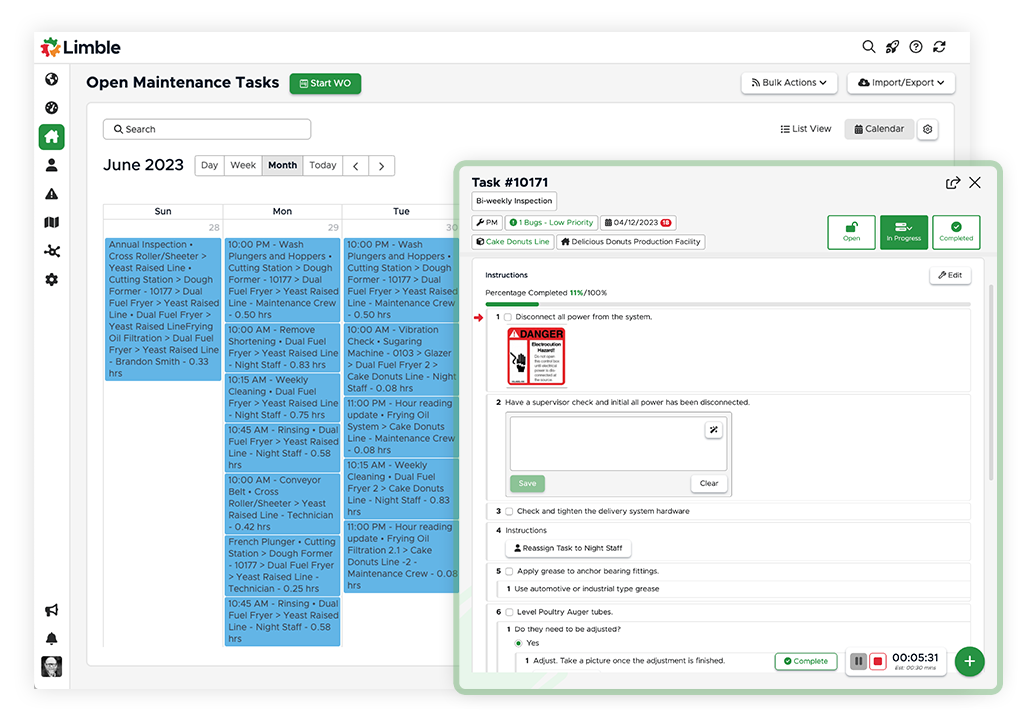

If you run a preventive maintenance (PM) schedule, you’ve likely noticed that routine maintenance tasks take quite a few spots on your maintenance program calendar (marked blue in the illustrative example below).

Since routine maintenance is an integral part of all preventive maintenance efforts, it brings the same set of benefits:

- Improves equipment lifespan

- Reduces the number of unexpected equipment failures

- Keeps a piece of equipment in good operating condition

- Helps better estimate spare parts inventory needs

- Can be standardized and optimized

While routine maintenance is crucial in keeping breakdowns at bay, one downside frequently comes up: It often spends resources on maintenance work that might not be needed yet, increasing maintenance costs.

That is a valid concern, but it can be addressed by optimizing maintenance schedules.

When first creating a PM plan, a business generally follows the guidelines outlined in an equipment manual.

Depending on a variety of factors (the accuracy of the manufacturer’s recommendations, the conditions in which the machine works, replacement parts used, how hard the machine is pushed, etc.), the need for routine tasks may be higher or lower than what is currently recommended.

The best way to approach this problem is to use CMMS software to keep detailed maintenance logs and track metrics, like MTBF (Mean Time Between Failures), that will send a notification to perform maintenance work on specific assets when it is needed.

To learn more about a CMMS and how it can improve maintenance processes, check out this guide: What is a CMMS System and How Does it Work

Checklist for Creating a Preventive Maintenance Plan

Following a consistent Preventive Maintenance Plan can make life easier. Use this checklist to create your own!

Examples of routine maintenance

Here are some maintenance tasks that can be classified under routine maintenance:

- Equipment inspections

- Simple maintenance tasks that are done on a regular basis like lubrication, filter changes, parts replacements, etc.

- Cleaning-related tasks (mopping the floor, cleaning equipment, washing windows, mowing the lawn, etc.)

- Testing safety equipment

This is not a definitive list; just a few examples to provide a better understanding of what routine maintenance covers.

Routine Maintenance Workflow

Each company’s routine maintenance workflow may vary, but the following process gives a general idea of what that should look like.

1. Identify Assets Suitable for Routine Maintenance

Not all assets require the same maintenance approach. To determine which assets are best suited for routine maintenance, consider the following criteria:

- Repairable Assets: Routine maintenance is most effective for repairable assets that demand minimal intervention between repairs. These assets benefit from regular inspections and minor adjustments to extend their life and prevent sudden failures.

- Time-Tested Assets: Assets with a history of predictable wear and tear are ideal candidates for routine maintenance. When historical data indicates when maintenance is typically required, a routine schedule becomes advantageous.

- Cost-Effective Maintenance: High-value assets that necessitate complex inspections or substantial adjustments may be better suited to preventive maintenance. Preventive maintenance focuses on comprehensive measures and can involve disassembly, in-depth inspections, and overhauls, making it more appropriate for critical assets.

2. Establish Time-Based Maintenance Intervals

Determining the optimal maintenance schedule is crucial to strike a balance between maintenance costs and savings. Setting time-based maintenance intervals ensures that maintenance tasks occur at predictable, regular intervals.

However, it’s important to be mindful of over-maintenance, which can lead to diminishing returns on investment. The ‘law of diminishing returns’ occurs when more and more resources are allocated to maintenance, while each investment earns a smaller and smaller return. Therefore, finding the right frequency for routine maintenance is essential for optimizing asset performance while managing costs effectively.

3. Develop Checklists for Each Asset

A fundamental component of routine maintenance is the use of checklists. These checklists enumerate every step of the maintenance task, serving as a comprehensive guide for maintenance technicians. Checklists help ensure that no essential steps are overlooked during the maintenance process, promoting consistency and thoroughness.

4. Execute Routine Maintenance

When the scheduled time interval is reached, it’s time to put the routine maintenance workflow into action.

Guide to Moving from Reactive to Preventive Maintenance

Want to transition away from costly reactive maintenance but don't know where to start? This guide has everything you need to know.

How a good CMMS supports routine maintenance

Scheduling and tracking routine maintenance works best when paired with a CMMS, a mobile-enabled CMMS to be exact.

Here are a few ways in which a mobile CMMS app supports routine maintenance efforts:

#1) Scheduling & managing maintenance work

It is crucial to stay on top of routine maintenance tasks. To maintain an effective maintenance schedule, there are three conditions that every maintenance task (or any other task for that matter) needs to satisfy:

- It needs to be assigned to a specific person

- It needs to have a due date

- Managers must have the ability to easily track if tasks are being finished on time

Mobile CMMS supports that activity because it helps:

- Define balanced maintenance schedules

- Issues push notifications to quickly communicate task reassignments and priority changes

- Provide instant access to all active and finished maintenance tasks (all it needs is internet access)

- Optimize maintenance schedules using detailed maintenance logs and reports

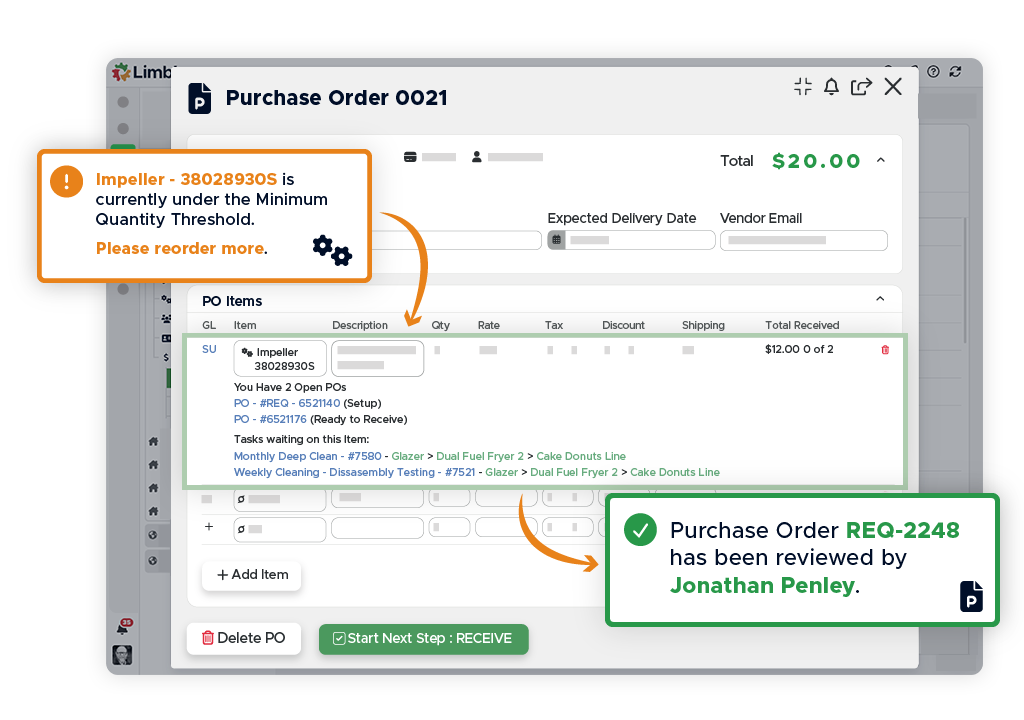

#2) Controlling spare parts inventory

Visual inspections aside, maintenance teams can’t perform routine maintenance if they don’t have the right tools or spare parts available.

This is why many software solutions will have a distinct spare parts inventory module that allows you to:

- Set up email notifications when stock quantity for a certain part is low

- Automatically track usage of spare parts by making them a required item on every Work Order and PM

- Accurately forecast parts usage and budget for the next quarter/year

#3) Storing maintenance data

A CMMS is very handy for optimizing maintenance schedules. In the context of routine maintenance, that means optimizing the frequency of routine maintenance tasks.

The logic is simple. If a company performs routine maintenance on a machine and it still regularly breaks down, in the majority of cases, there are three reasons why that is happening:

- Routine maintenance tasks are too far apart

- The routine work being performed is subpar

- The machine is being misused

Using a CMMS, techs can drill down into maintenance history and maintenance reports to find the root causes of these breakdowns. This is important because addressing the issue is usually the easier part.

When facing regular breakdowns, there are a few solutions for resolving these problems:

- If routine maintenance tasks are too far apart, the company needs to increase the volume of routine maintenance tasks on that asset.

- If the routine work is subpar, then the company should look to define clear preventive maintenance checklists.

- If the machine is misused, then the company needs to ensure that the machine is working in proper conditions, uses OEM-approved replacement parts, and is used by sufficiently trained machine operators.

To apply the right solution, it’s important to first identify the problem correctly.

Want to see Limble in action? Get started for free today!

Where to start?

It’s encouraging to see that even businesses that are still caught up in reactive maintenance perform a decent volume of routine maintenance tasks. We see that clearly when we’re helping them implement Limble into their organization.

The main problem is that they lack a proper structure, inventory control, and strong maintenance schedules – basically everything that comes with having a modern CMMS system. This results in lower productivity, excessive maintenance on some assets and not enough attention placed on others, bloated deferred maintenance backlog, and – in worst-case scenarios – it leads to a constant tug of war with unplanned machine breakdowns.

If you’re in a similar situation and looking to change that trend, let’s chat and see how we can help you out.