Facility Maintenance

Everything you ever needed to know about facility maintenance.

What is facilities maintenance?

Facility maintenance is all maintenance activities that are taken within and outside of commercial buildings to keep the area safe, presentable, and most importantly, functional. It is often used interchangeably with building maintenance.

The most common types of maintenance activities include:

- Maintenance of equipment inside the building (HVAC, certain office equipment and furniture, building-specific equipment like medical equipment in hospitals)

- Maintenance of all building systems (plumbing, electrical systems, lighting, fire safety systems, elevator systems)

- Upkeep of the building infrastructure itself (roofing, windows, doors and door locks, exterior and interior painting)

- Upkeep of the space around the building (landscaping and grounds maintenance, pest control, snow removal, parking lots)

Facility managers often operate with limited budgets, but are still expected to deliver initiatives and programs focused on sustainability and energy efficiency. This is due to research indicating that buildings are responsible for 40% of total energy consumption in the United States.

Property maintenance is used when referring to residential buildings. Industrial maintenance is used when referring to manufacturing and other industrial facilities. Facility maintenance, on the contrary, is generally used to refer to all other commercial buildings.

The role of maintenance in facility management

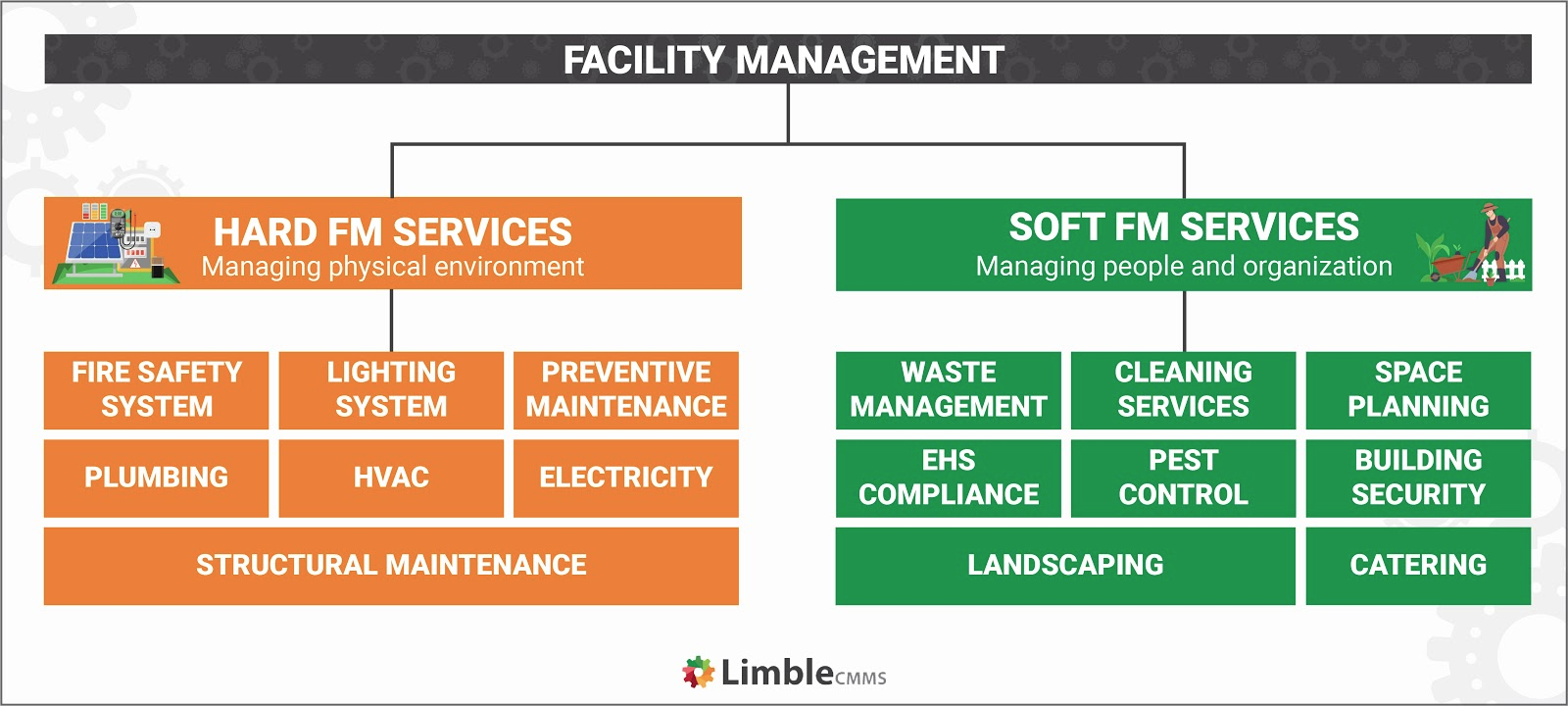

Facility maintenance is a part of facilities management. Facilities management can be broken down into hard and soft facilities management services:

In this categorization, facility management covers all hard FM services, plus landscaping, cleaning, and pest control from the side of soft FM services. In other words, a big chunk of facility management revolves around maintenance.

Types of buildings that rely on facilities maintenance

Organizations require facility maintenance at a wide variety of facilities:

- Offices

- Schools and university campuses

- Hotels and casinos

- Hospitals

- Property

- and many more…

While the type of equipment at each facility may differ, the core range of maintenance responsibilities is more or less the same.

Certain businesses might have a highly specialized piece of equipment. If it breaks down, the facility manager usually outsources the repair to a specialized maintenance vendor with the necessary tools and knowledge.

Checklist for Creating a Preventive Maintenance Plan

Following a consistent Preventive Maintenance Plan can make life easier. Use this checklist to create your own!

In-house vs outsourcing of facilities maintenance work

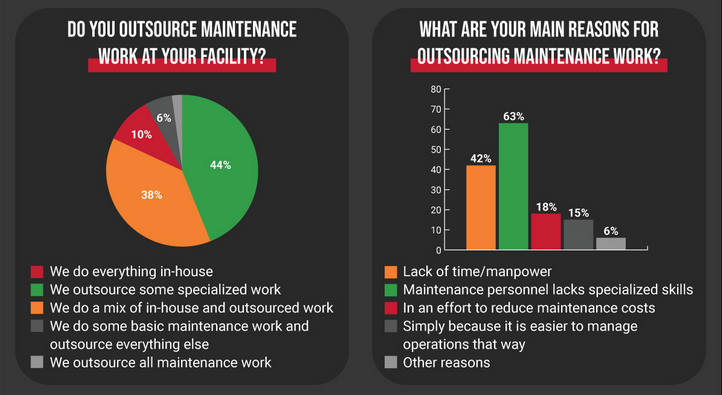

This is not an either/or question. Most facility managers take a middle-of-the-road approach when it comes to utilizing in-house resources versus outsourcing maintenance work. In fact, according to our latest research, 82% of facility and maintenance managers have a strong mixed strategy:

Often, they form a small internal maintenance team to take care of routine maintenance work and perform simple repairs and corrective actions. Other maintenance tasks get outsourced for various reasons.

A few examples include:

- Facility managers in hospitals and casinos often have a dedicated vendor they can call in to repair equipment that requires specialized knowledge.

- Building systems like plumbing, which only need sporadic attention, are cheaper to manage with an outside vendor. It doesn’t make fiscal sense to pay a full salary to a plumber to work a couple of days each month.

- Tasks like landscaping and pest control are easier to outsource to companies that offer professional grounds maintenance services.

- Janitorial tasks are regularly outsourced to companies providing professional cleaning services.

While there are many legitimate reasons to outsource maintenance work, this shouldn’t be taken for granted. There is still a lot that goes into outsourcing. Companies must keep track of the vendor’s contact information, invoices, work history, and schedules, not to mention ensuring that the required work is performed properly.

A good CMMS with a vendor management module can help companies seamlessly integrate vendors into their maintenance systems.

Facilities maintenance may also be outsourced as part of a broader facility management outsourcing agreement. In this scenario, all aspects, including facilities maintenance, are entrusted to facility management companies. This arrangement is commonly employed when a business rents a portion of a building (such as a few offices or floors), and the building owner has engaged a facility management company to oversee the entire building’s operations.

How to automate and streamline facilities maintenance

Keeping a facility clean, organized, and efficient is not the sole responsibility of the maintenance team. However, the maintenance department does shoulder most of that responsibility.

Here are three bulletproof ways to organize, automate, and streamline facility maintenance operations.

1) Use facility maintenance software

There is no better way to streamline facility maintenance work than to use capable facility maintenance software.

Maintenance has too many moving interconnected parts to be tracked and managed manually, even for small teams, including:

- Schedule and track a wide variety of maintenance activities

- Adjust schedules and workload based on the number of maintenance technicians, available resources, and incoming maintenance tickets

- Ensure the necessary spare parts are in stock to perform maintenance work

- Manage multiple vendors and contracts

- Accurately track maintenance expenses and generate recurring reports

Some companies try to manage all of this with spreadsheets, but that is a subpar solution when compared to mobile maintenance software. Spreadsheets still require a lot of manual work, which is slower, more prone to human error, hard to use on mobile devices, and severely limits reporting capabilities.

A Computerized Maintenance Management System (CMMS) offers real-time insight into all maintenance activities, automates a big chunk of the maintenance workflow, and holds a centralized repository of data on parts and equipment, which maintenance teams can quickly access from anywhere.

A CMMS provides deep insight into maintenance metrics and other benchmarks for performance and also enormously speeds up the overall maintenance workflow.

Lastly, it is important to mention that CMMS solutions can often be integrated with IWMS, CAFM, and other facility management software.

2) Outline clear procedures and responsibilities

A great way to streamline any type of recurring work is to outline the proper way to execute it. A proper procedure has many benefits, including, most importantly, achieving consistent quality work.

Companies can standardize many different aspects of facility maintenance, including:

- Writing clear standard operating procedures

- Creating preventive maintenance checklists

- Setting up an onboarding process for new hires and outside contractors

- Setting up technician training/mentorship processes

- Outlining procedures for taking tools and spare parts out of inventory and returning them back

- Implementing strong safety guidelines and safety training process for both facility maintenance workers and other employees (when needed)

It’s also a good idea to review (and update) these procedures on a yearly basis. A lot can change in a year, and maintenance teams will learn new and more efficient ways to update their processes. Updating SOPs based on new information is a prime example of continuous improvement.

3) Commit to proactive maintenance

It is much easier to manage maintenance tasks when they are planned ahead. It is easier to manage workloads, it is easier to keep MRO inventory in check, and it is easier to control maintenance expenses.

When technicians are continually responding to emergency work requests and breakdowns due to lack of planned maintenance, routine scheduled tasks will only get deferred, resulting in more reactive work, downtime, and emergency repairs later down the road.

It is a vicious cycle that can only be stopped by a hard commitment to preventative maintenance and other proactive maintenance programs.

Want to see Limble in action? Get started for free today!

Implement Limble CMMS as your facilities maintenance software

Limble CMMS was designed with a single purpose: to help maintenance and facilities managers streamline their maintenance activities. That can be done only when you have a deep insight into every aspect of your maintenance operations: assets, spare parts inventory, work orders, maintenance schedule, and vendors.

To learn more about each category and associated features Limble offers, click on the links below:

- Asset management

- Work orders

- Maintenance schedule

- Spare parts management

- Vendor management

- Managing reports

If you want to test Limble CMMS, you have three options:

Try a self-demo (a simulated environment where you can test Limble’s features for yourself)