Maintenance leaders are under constant pressure to reduce costs. This often pushes them to cut corners and chase short-term results.

The good news is that you don’t need to sacrifice reliability to lower costs. With the right strategy, tools, and mindset, you can streamline maintenance operations, extend asset life, and spend smarter — not just less.

In this article, we’ll give you an overview of typical maintenance costs, followed by eight cost-reduction strategies you can start implementing today.

Understanding manufacturing maintenance costs

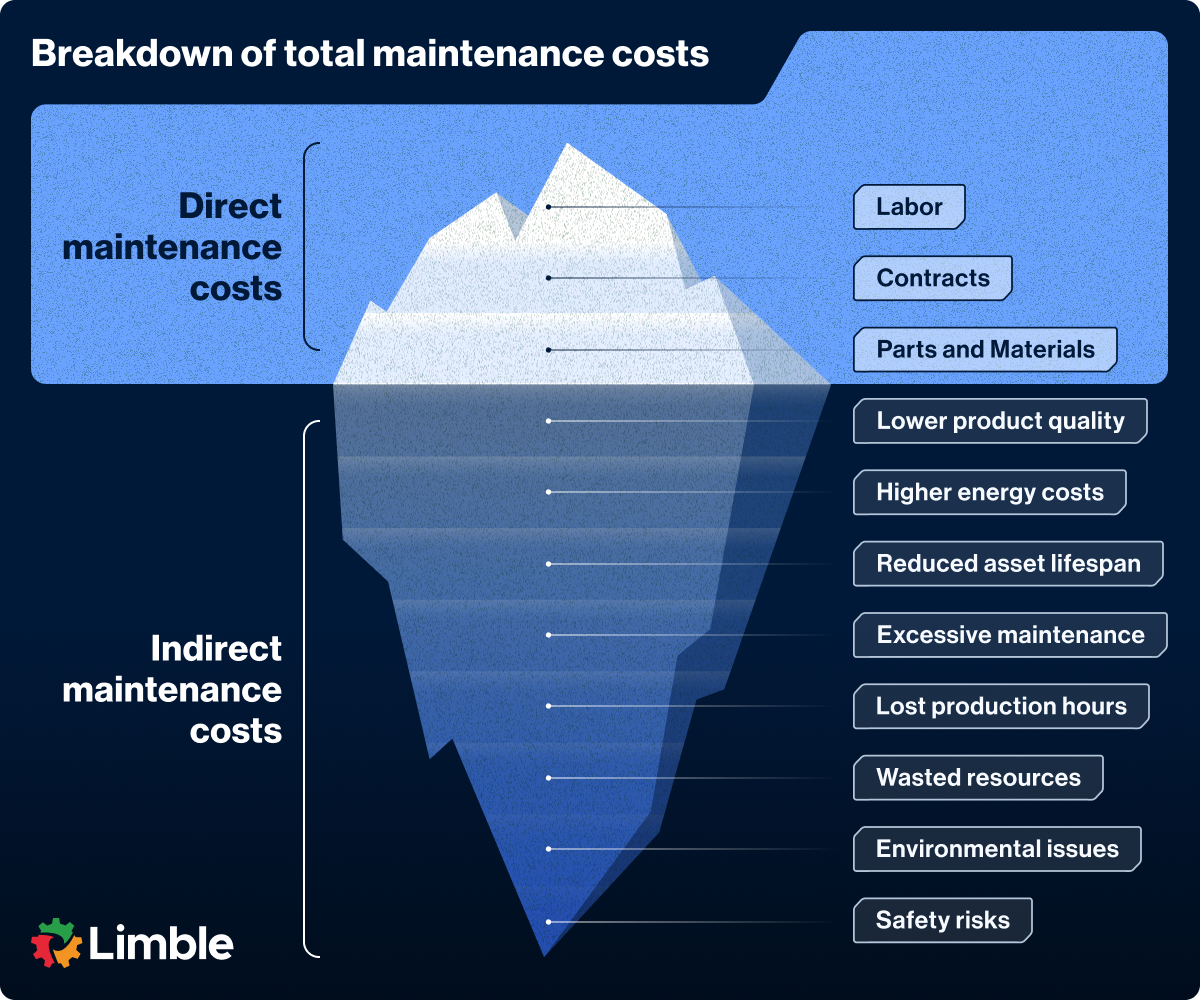

To start reducing maintenance costs, you first need a clear picture of what they actually include — and how they affect your entire operation. Maintenance spending touches everything from labor and spare parts to safety and productivity.

You need to go way beyond the price of a replacement part. Maintenance costs in a manufacturing plant are a combination of several major factors:

- Labor: One of the biggest cost drivers. Includes wages, overtime, and training for your in-house maintenance team, as well as fees for third-party contractors or specialists.

- Parts and materials: This bucket includes all physical items required for maintenance activities. It covers everything from consumables (such as lubricants, filters, and seals) to capital expenditures (like asset replacements).

- Downtime: While often tracked separately, downtime is the biggest indirect maintenance cost. Whether from planned repairs or surprise failures, every moment your equipment sits idle means lost productivity and revenue.

On top of that, poorly maintained equipment is a safety risk. It’s less efficient, more prone to failure, and can cause serious accidents. In fact, 15–20% of industrial accidents are related to maintenance operations. This puts your team at risk and can expose your business to fines or legal action.

Beyond safety, delayed maintenance drags down productivity. Asset performance declines. Failures increase. Downtime becomes more frequent and more expensive.

To manage costs effectively, you should stop viewing maintenance as a cost center and start seeing it as a strategic investment — one that protects your people, ensures compliance, and keeps your operation running at full capacity.

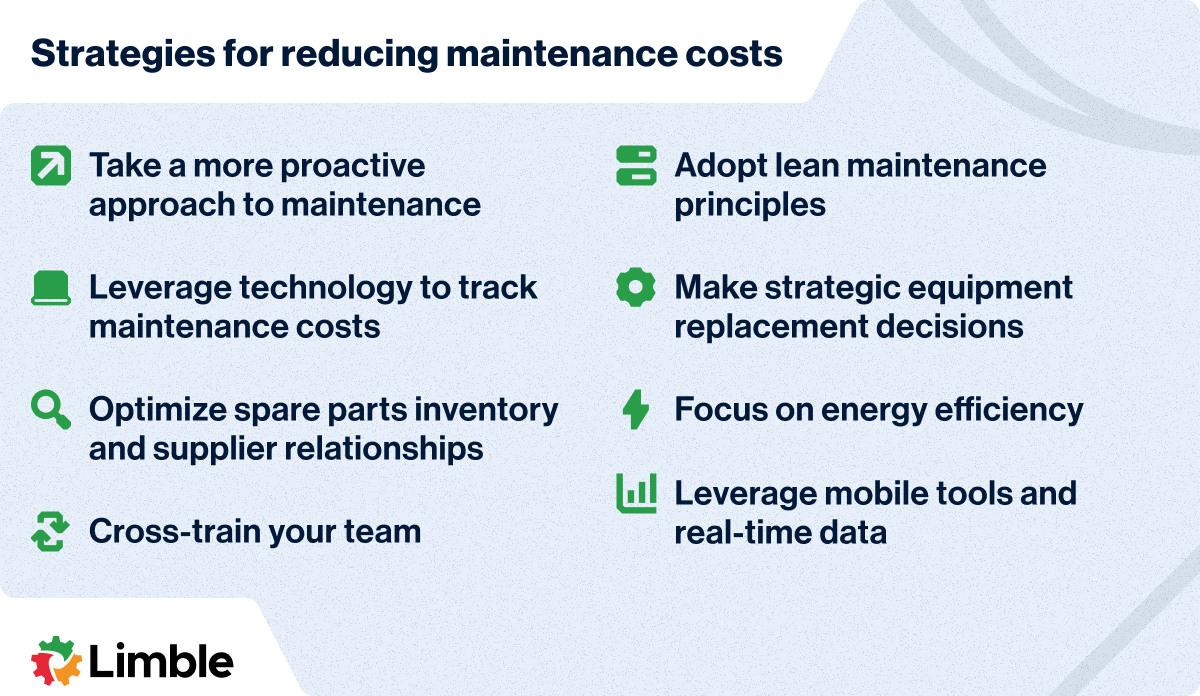

Proven strategies for reducing maintenance costs in manufacturing

Reducing maintenance costs requires a multifaceted approach that spans your entire operation. Real savings come from adopting smart, efficient strategies that boost reliability, leverage technology, and empower your team.

Here are eight changes you can make to build a more cost-effective maintenance program.

1. Take a more proactive approach to maintenance

One of the most effective ways to reduce maintenance costs is to move from reactive to proactive maintenance.

This approach can combine different elements:

- Scheduled preventive maintenance (PM): Regular tasks like inspections, cleaning, and lubrication help catch problems early and extend equipment life.

- Use of high-quality parts: While these cost more upfront, their durability and longer lifespan lead to fewer failures and lower labor costs over time.

- Condition-based monitoring: When possible, use real-time data to adjust maintenance activities based on the actual state of the equipment — not just the calendar.

- Predictive and prescriptive maintenance: Use sensor data and AI to detect early signs of failure, recommend precise interventions, and maximize uptime for your most critical (or most expensive) equipment.

The payoff? Fewer breakdowns, more predictable spending, and a more efficient use of both labor and parts.

2. Leverage technology to track maintenance costs

If you can’t track it, you can’t control it. A modern CMMS or EAM system helps you track where each of your maintenance dollars is being spent — in real time.

You can log every work order and its associated cost, track labor hours and parts usage by asset, monitor cost-related maintenance metrics, and automate preventive maintenance work to reduce unplanned, reactive expenses.

That is just the beginning. Based on historical data and recent trends, a CMMS like Limble will help you identify:

- Which assets are the most expensive to maintain

- Where you’re overspending on labor or inventory

- What are the common causes of downtime

- Opportunities to optimize scheduling and extend equipment life

With detailed KPI reporting and live dashboards, you can pinpoint cost drivers and make smarter decisions to improve your bottom line.

3. Optimize spare parts inventory and supplier relationships

Holding excessive inventory ties up cash and increases storage costs, while not having a critical part on hand leads to expensive downtime. Finding the right balance is key to keeping maintenance costs under control.

Start by using your CMMS to track part usage trends. With that data, you can apply just-in-time (JIT) inventory practices to reduce excess stock, lower carrying costs, and free up working capital. Your CMMS can also help you set smarter reorder points based on actual usage and lead times.

At the same time, focus on strengthening supplier relationships. By working closely with trusted vendors, you can:

- Negotiate better pricing and payment terms

- Leverage bulk ordering to reduce unit costs

- Secure faster, more reliable lead times

Having the right parts available when you need them — and fewer dollars tied up in storage — is a great way to make some room in a tight maintenance budget.

4. Cross-train your team

Cross-training maintenance technicians is a practical way to increase your in-house capabilities. You become less dependent on costly outside contractors and can respond to most issues immediately.

You can take this further by incorporating autonomous maintenance, where machine operators are trained to handle basic upkeep like cleaning, inspections, and minor adjustments. This lightens the load on your skilled technicians, allowing them to focus on more complex, high-value work while fostering a stronger sense of ownership across your workforce.

By investing in continuous development, you ensure that employees use machinery correctly, make fewer mistakes, and are more efficient in their roles.

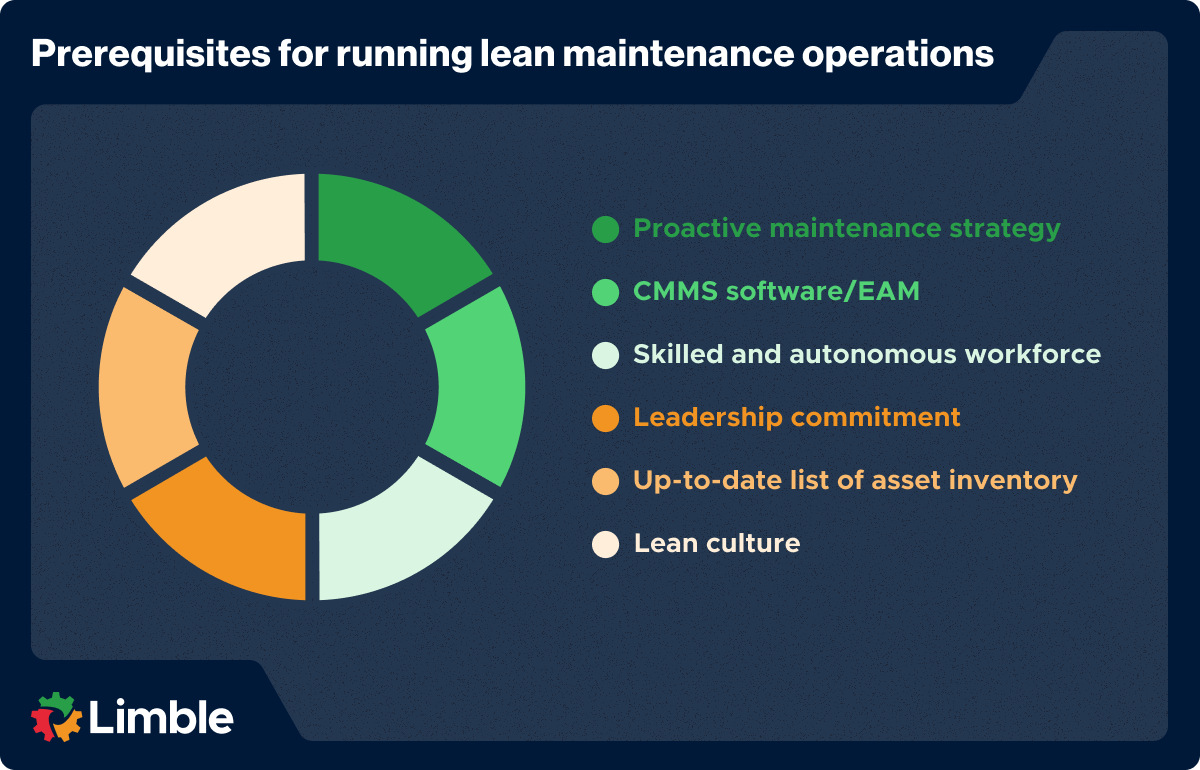

5. Adopt lean maintenance principles

Running a lean maintenance department is all about eliminating waste — wasted time, motion, inventory, and effort. When applied to your maintenance operations, lean principles help you streamline processes, improve efficiency, and ultimately reduce unnecessary costs.

That being said, implementing lean practices is much easier when you have certain things already in place:

Your best bet is to start by identifying your largest sources of inefficiency. Look for things like repeated breakdowns, poorly organized workspaces or tool storage, work orders with unclear instructions, and similar.

Next, implement lean practices that target these pain points:

- Standardize maintenance procedures with SOPs, digital checklists, and step-by-step instructions.

- Organize tools and parts storage for quick access to commonly used tools and parts.

- Reduce motion and downtime by planning work more effectively.

- Continuously review CMMS data to spot waste and track improvements.

Lean is not about doing more with less — it’s about doing only what’s needed, as efficiently as possible. This mindset leads to faster work execution, fewer errors, and lower labor and material costs.

6. Make strategic equipment replacement decisions

Sometimes, the most cost-effective move is to stop fixing and start replacing. Pouring money into aging, unreliable equipment can quickly become a major drain on your budget.

Use your CMMS to analyze the full cost and repair history of each asset. If a machine consistently breaks down, causes frequent production delays, or racks up maintenance costs that exceed its value, it’s time to consider a replacement. If you need help, check out our repair vs replace analysis guide.

While replacing assets can ruin your balance sheet for this month, it is worth it because of the improved reliability, better energy efficiency, fewer unplanned repairs, and warranty protection.

A strategic replacement plan ensures your resources are going toward assets that actually support productivity and profitability.

7. Focus on energy efficiency

Energy consumption is one of the largest and often most overlooked operational expenses in a manufacturing plant. A focus on energy efficiency can lead to savings of 10-30%.

This can be achieved through two main maintenance-related activities: ensuring all existing equipment is regularly maintained to run at peak efficiency, and strategically upgrading to more energy-efficient machinery and facility lighting.

8. Leverage mobile tools and real-time data

Equipping your team with mobile access to maintenance tools is a simple but powerful way to reduce delays, errors, and inefficiencies in the field.

With a mobile-enabled CMMS, technicians can:

- Access work orders, asset history, and manuals on the spot

- Log completed tasks and parts used in real time

- Capture photos, notes, and failure data for the reliability team

This leads to faster troubleshooting, fewer communication gaps, and less time spent on paperwork. Real-time data collection also improves reporting accuracy — giving you better visibility into costs, team performance, and asset reliability.

When your team has the right information at their fingertips, they can move faster, make smarter decisions, and keep equipment running at a lower cost.

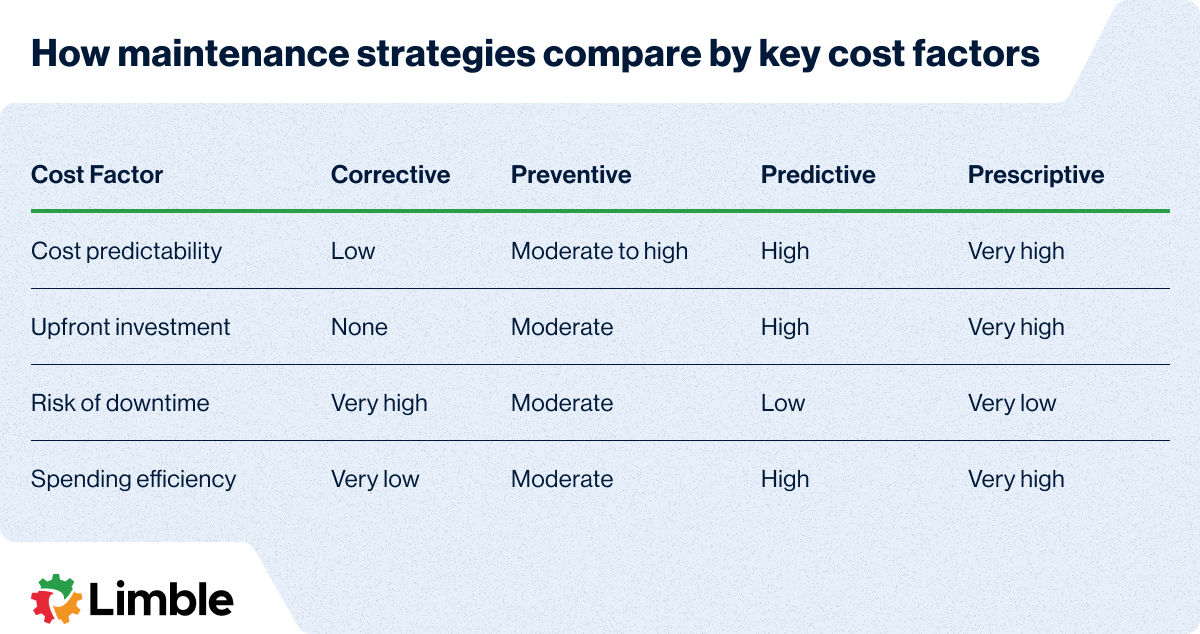

How your maintenance strategy defines your costs

The maintenance strategies you choose will be one of the biggest drivers of your budget. Each approach comes with a very different cost profile, directly impacting labor, parts, downtime, and profitability.

Before diving into each approach, here’s a side-by-side comparison of the most popular maintenance strategies and how they impact cost:

Corrective maintenance (the highest-cost model)

Corrective maintenance — also known as run-to-failure maintenance — waits for equipment to break before any action is taken. While it requires no upfront planning, it leads to sky-high operational costs.

You’ll pay premium prices for:

- Emergency parts

- Rush shipping

- Overtime labor

And that’s just the beginning. Unplanned failures cause significant downtime, which cuts deeply into production output and revenue. It’s a volatile, financially draining approach that’s rarely sustainable.

Preventive maintenance (predictable cost control)

Preventive maintenance is based on scheduled servicing. You perform tasks at regular intervals, which can be calendar-based or usage-based. This predictability allows for planned, more predictable spending.

Cost savings come from:

- Reducing the number of emergency repairs

- Using standard shipping when ordering parts

- Scheduling labor during regular shifts and avoiding overtime

The biggest financial tradeoff? Fixed schedules can lead to excessive maintenance, resulting in unnecessary spending on parts and labor.

Predictive maintenance (optimized spending)

Predictive maintenance (PdM) uses real-time asset data to monitor equipment condition and decide when service is actually required. That means you only spend when a machine shows signs of developing issues.

Benefits include:

- Eliminating excessive PM tasks

- Reduce the number and duration of both planned and unplanned downtime

- Lower inventory costs by being able to carry less stock

- Boosting ROI through targeted maintenance

This approach leverages sensors and analytics to ensure every maintenance dollar counts. It’s a powerful balance between cost control and equipment reliability.

Prescriptive maintenance (maximum ROI)

Prescriptive maintenance takes PdM to the next level. Using AI and machine learning, this strategy not only predicts issues — it also recommends the best course of action.

That means:

- Faster diagnostics

- Smarter labor allocation

- Highly efficient parts usage

This is the maintenance strategy with the highest ROI potential. It reduces your total cost of ownership (TCO), prevents catastrophic failures, and maximizes the value of every high-value asset.

Lower your maintenance costs with Limble

Here is how Limble helps you take control of your maintenance budget:

- Automate your reliability program: Easily schedule, assign, and track all your preventive maintenance tasks to prevent costly, unexpected failures before they happen.

- Optimize your spare parts inventory: Take control of your parts spending with our powerful inventory management system. Track usage, set automatic reorder points, and eliminate the waste associated with overstocking.

- Make data-driven financial decisions: Limble automatically captures the maintenance and cost data you need to make smart decisions. Justify repairs, prove the value of your PM program, and know exactly when it’s more cost-effective to replace an asset.

- Boost team efficiency: Empower your technicians with our user-friendly mobile app. They can access work orders, view SOPs, and log their work from anywhere, maximizing “wrench-on time” and reducing labor costs.

Stop letting your maintenance budget control you. Join the thousands of manufacturing teams that use Limble to cut costs, improve reliability, and prove the value of their maintenance operations.

Start for free today and take back control over your maintenance expenses.

Cost Reduction Strategy FAQs

What is the fastest way to start reducing maintenance costs?

Start by checking where your money is going. Track your maintenance activities — labor hours, parts used, and downtime causes. A CMMS can automate this process, but even basic tracking will reveal your biggest cost drivers. Once you know what’s costing you the most, you can focus on fixing those problems first.

Is preventive maintenance actually cheaper than just fixing things when they break?

Yes — overwhelmingly so in the long run. Reactive maintenance may seem cheaper upfront, but it comes with hidden costs: unplanned downtime, emergency part orders, and overtime labor. Preventive maintenance spreads costs out over time, keeps failures from escalating, and gives you more control over your budget and schedule.

What’s the most common mistake companies make when trying to cut maintenance costs?

The biggest mistake is cutting in the wrong places — like skipping preventive maintenance, buying low-quality parts, or reducing technician training. These short-term cuts often lead to larger failures and higher long-term costs. The key is to reduce waste, not capability.

How does a CMMS directly reduce maintenance costs?

A CMMS helps reduce costs in several critical ways:

- Automates preventive maintenance to reduce expensive unplanned disruptions.

- Optimizes spare parts inventory to prevent over-ordering and stockouts.

- Tracks repair history and asset performance, allowing you to make smarter replacement vs. repair decisions.

- Improves labor efficiency by giving technicians mobile access to work orders, manuals, and asset history in the field.

With a modern CMMS, you spend less time reacting and more time strategically managing your maintenance budget.

How can I get buy-in for maintenance cost reduction initiatives?

Start by showing the numbers. Use CMMS data to highlight wasted costs, repeat failures, or missed PMs, and tie those to downtime or lost production. When leadership sees the financial impact, it’s much easier to get support for implementing required changes.