Reduce Downtime by 30%

Hit Your Uptime Targets &

Maximize Your Profits

Conquer downtime with a proactive maintenance strategy supported by world-class software.

$479M

Saved in annual downtime costs

30%

Avg. downtime reduction

$281M

Saved in annual parts spend

Learn How Limble Reduces Downtime

Limble is trusted by 50,000+ maintenance professionals globally

Modernize Preventive Maintenance

Stop breakdowns before they happen with preventive maintenance workflows

- Automate preventive maintenance scheduling and assign tasks to the right people at the right time

- Report on user performance KPIs to reduce reactive maintenance and increase uptime

- Track metrics like MTTR & MTBF simply by completing PMs and work orders

“It saves us money on wait time, downtime, parts, not paying employees when their machine is down…when you do all the numbers, it’s over probably a couple hundred thousand dollars Limble has helped us save.” – Carlos Melendez, Maintenance Supervisor, Tara Manufacturing

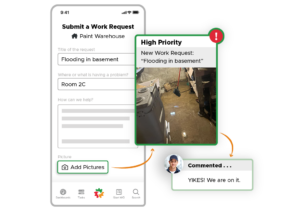

Streamline Communication

Centralize and simplify communication for a unified team

- Real-time organization, communication, and access to information

- Anyone can scan a QR code or barcode, or visit a URL to submit an issue

- Automatically update work requesters on the status of their tickets via simple, customizable workflows

“Being able to put everything in Limble and have that accessible out on the floor has been huge.” – Matt Burtz, Maintenance Director, Preferred Popcorns

Improve Asset Management

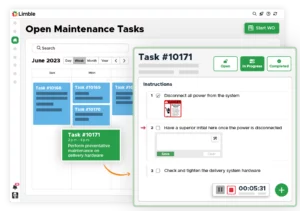

Easily organize work orders, PMs, and other maintenance tasks for your entire team

- Organize physical asset records in a searchable hierarchy

- Create custom fields to track each asset however you need

- View asset cards with essential information like WOs, PM schedules, parts, reports, and more; all in a single location

“The wonderful thing about Limble was it was just so darn easy to get implemented to a point where it really started adding value.” – Dustin Law, Engineering Manager, Western Pulp

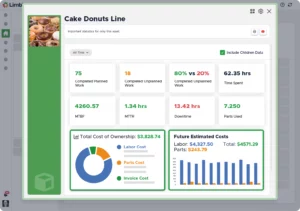

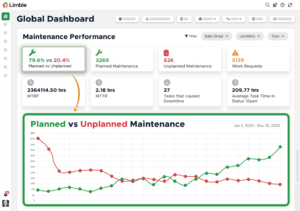

Make Data-Driven Decision

Transform your maintenance operations with data-driven insights at your fingertips

- Real-time reporting on the status of all your operations

- Report time, parts, and money spent by asset to make equipment management more proactive and strategic

- Analyze and forecast your use of maintenance resources

“Limble simplifies life as a maintenance supervisor!” – Robert Stricklin

Maintenance Supervisor, City of Lompoc Water Treatment Plant

Compare Pricing

Basic

Standard

Premium+

Enterprise

Tara Manufacturing

This family-owned manufacturing company turns the tide on downtime with a maintenance program powered by Limble.

FAQ

What is CMMS software?

CMMS (Computerized Maintenance Management System) software helps businesses manage, automate, and streamline all of their maintenance operations. Learn more about CMMS.

Who uses CMMS software?

CMMS software is used by anyone who manages maintenance — facility managers, operations managers, and asset managers, and more — to manage assets, schedule maintenance, and ensure safety. It is widely employed in industries including manufacturing, education, energy & utilities, food & beverage, and many more to maintain infrastructure and manage resources effectively.

Is Limble Mobile CMMS app user friendly?

Limble is consistently rated Easiest-to-Use CMMS on review sites like G2, Capterra, and Software Advice. And our customers agree. With our mobile CMMS app, teams experience 30%+ better productivity, on average, requiring little to no training or ramp-up time. Our CMMS app can travel with your team, no matter where they go! Visit our App Store or Google Play for more information.

Can I connect to other systems?

Limble provides seamless, pre-built CMMS Integrations with the most widely used software systems. That means you won’t need help from a developer or your IT team to get started. Learn more about our integrations.

How secure is the Limble CMMS platform?

At Limble, our world-class data security practices ensure your account information is safe. We use state-of-the-art technologies and industry best practices to maintain a secure infrastructure, including SOC-II Type II certification, regular penetration testing, and continuous security training for our staff.

TRUSTED BY 50,000+ PROFESSIONALS AROUND THE WORLD

All-in-one CMMS for all your Maintenance Needs

Work Orders & Requests

Organize work orders, PMs and other tasks for your entire team. Easy-to-use mobile apps your technicians will actually use.

See Work Order SoftwarePreventive Maintenance Programs

Automate preventive maintenance scheduling, build simple checklists, and analyze team performance and efficiency.

See Preventive Maintenance SoftwareAsset Management

Intuitive and flexible asset management features make it easy to manage your assets, whether you have 10 or 10 million.

See Asset Maintenance Management SoftwareSpare Parts Inventory

Eliminate the guesswork and reduce the amount of time and money spent searching and managing your parts inventory.

See Parts Inventory Software