Over 50,000 maintenance professionals rank Limble #1

Flexible maintenance management for busy teams

Limble’s versatile CMMS and EAM software is user-friendly, feature-rich, and backed by enterprise-grade support. Enjoy total clarity and control with a seamlessly integrated maintenance system that grows with you.

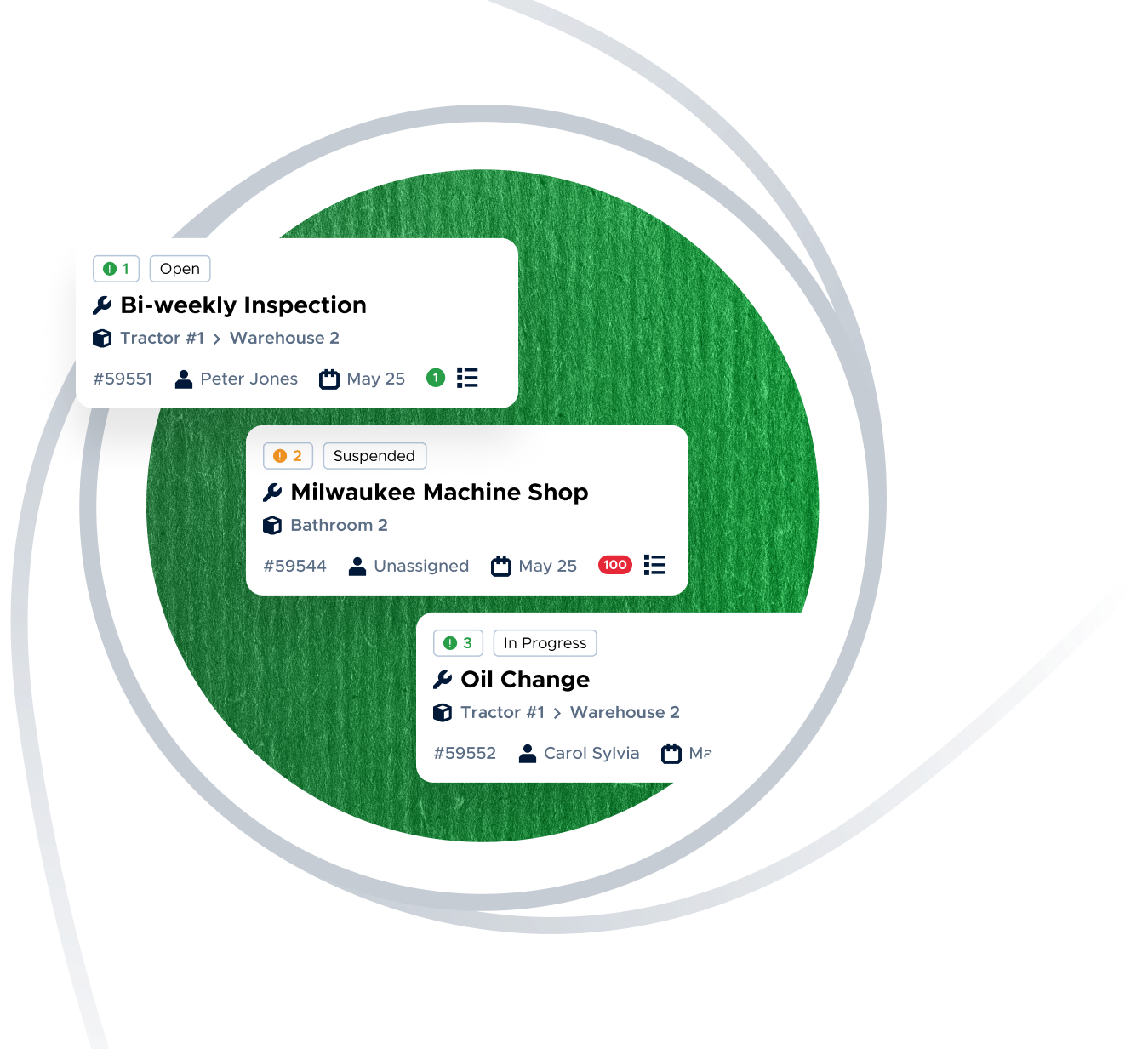

Work Orders

Work orders, asset management, PMs, and reporting that get you out of the spreadsheet era and on to modern maintenance management. Get started fast and make it your own as you grow.

Asset Management

Track and associate your assets with work orders, parts, vendors, and preventive maintenance tasks.

Preventive Maintenance

Plan repeatable PM tasks, automate scheduling and assignment, and avoid unplanned downtime.

Automate maintenance reporting

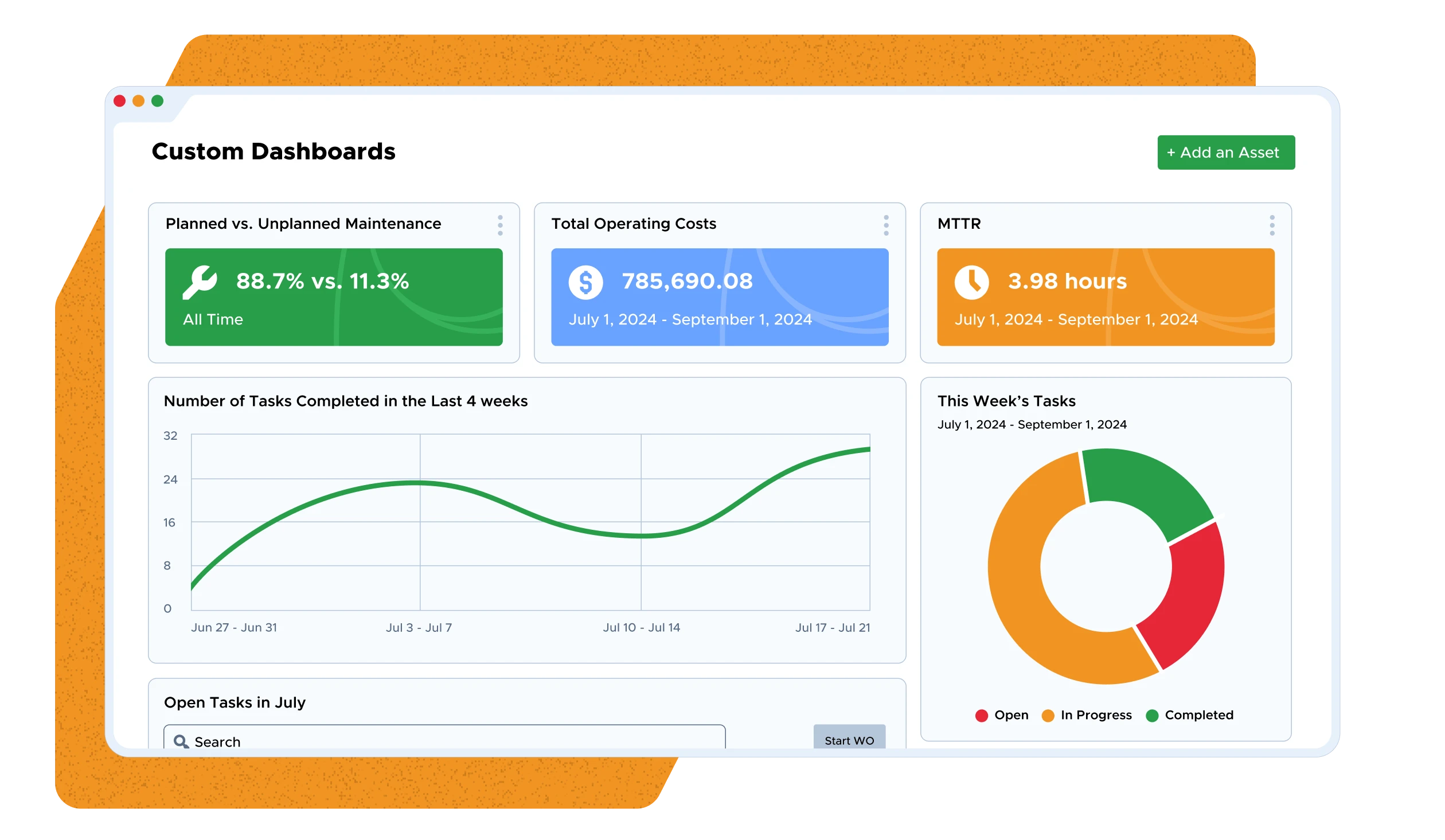

Use Limble’s customizable, user-friendly dashboards and reporting to track maintenance activity, share updates on work orders and assets, and get insights on your team’s performance.

Parts inventory management

Make sure you always have the parts you need, with a searchable, filterable database of parts and automatic reordering.

The ability to get your maintenance scheduled and view it in a week or month outlook has helped us keep up with all the maintenance that needs to be done. The reporting gives more visibility to the work we do.

Sam Livingstone Maintenance Mechanic VIEW CASE STUDY

Complete visibility and control

Work orders, asset management, PMs, and reporting that get you out of the spreadsheet era and on to modern maintenance management. Get started fast and make it your own as you grow.

Learn More

Configure and customize to fit your needs

It’s easy to start seeing success and grow with Limble. Our onboarding team gets staff trained up quickly and helps configure the platform to meet requirements across multiple use cases and locations, so you can make fast, impactful changes to the way you manage maintenance.

-

Set up fast

Get started quickly with one-click work orders, a library of templates, and a helpful support team.

-

Make it your own

Customize your dashboards, user settings, templates, and automations to match your SOP and reporting needs.

-

Grow your program

Add limitless custom assets, parts, and tasks to scale across multiple locations.

Track your team’s success with reporting and dashboards

Showcase the results of your hard work, justify spend on maintenance resources, and get your team the resources and recognition they deserve with accurate reporting on key maintenance metrics.

Learn MorePowerful enterprise solutions

-

EAM

Enterprise asset management that gives you a 360° view of your assets across many locations, teams, and vendors.

LEARN MORE -

Compliance and audits

Robust compliance features and audit trails to keep you in line with applicable standards.

LEARN MORE -

Seamless migration

Tools and support for an easy, successful migration from another CMMS or EAM solution.

LEARN MORE -

Powerful integrations

Connect to your ERP, IoT ecosystems, and other enterprise business solutions for silo-free maintenance.

LEARN MORE

Ready to learn more about Limble?

Schedule a demo or start your free trial right away.