Warehouse Maintenance Software

Maximize Fulfillment. Streamline Warehouse Maintenance.

Keep things running smoothly and on schedule from arrival and storage to distribution.

41%+

Increased team productivity

37%+

Reduced equipment downtime

29%+

Reduced labor costs

How Smart Facility Management Transforms Warehouse Operations

Limble is trusted by 50,000+ maintenance pros

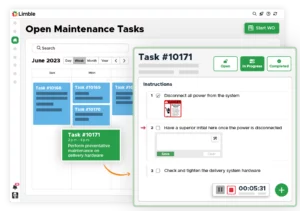

Boost Maintenance Efficiency & Productivity

Automate maintenance processes and save time on scheduling, inventory tracking, and generating reports

- Build and assign work orders with complete asset information, due date, priority and more

- Easily create a customizable work request portal that automates communications with your team and the requestor

- Track work order progress in real-time via mobile app when on the go

“It was relatively easy to say, ‘This is the right tool for us!…It is like taking your business from operating on a typewriter to operating on the latest iPhone.” – Samantha Murphy-Handy, Business Process Consultant, Aztec Construction

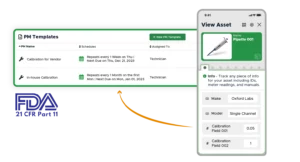

Automate Preventive Maintenance

Optimize your preventive maintenance program with PM templates, custom standard operating procedures, maintenance schedules, and more

- Automatically schedule and assign PMs to the right people at the right time

- Setup user-friendly preventive maintenance templates with SOPs, checklists, photos, and more

- Track completion rates on PMs in real-time to reduce costly unplanned downtime

“Over $100,000 saved with preventive maintenance.” – Ron McDowell, Association Manager for Sanctuary at False Cape

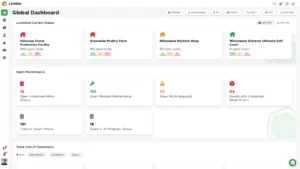

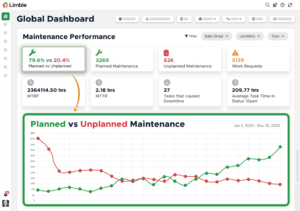

Make Data-Driven Decisions

Get complete reporting on all the data you and your leaders care about and confidently inform maintenance decisions

- Access maintenance history with work order tracking by asset, type, and location from multiple locations

- Track costs over time with labor and inventory spend reporting

- Report on preventive maintenance, project time and costs, parts spend and more

“The wonderful thing about Limble was it was just so darn easy to get implemented to a point where it really started adding value.” – Dustin Law, Engineering Manager, Western Pulp

Nail Regulatory Audits with Ease

Cut time on audit prep with full maintenance history at your fingertips

- Keep a detailed log of all asset and maintenance history in one place

- Schedule regular recurring inspections and PMs ahead of time to ensure all work is completed on time

- Verify all steps in a task are completed and documented with PM templates and checklists

“We’re staying above our service level expectations. And when people come into our facilities, all they see is everything working perfectly” – Justin Russell, Facility Manager, City of Lone Tree

Compare Pricing

Basic

Standard

Premium+

Enterprise

Aztec Construction Group

Limble helped Aztec Construction Group build preventive maintenance schedules, create templates to make future inspections easy, and improve team morale, leading to:

FAQ

What is warehouse maintenance software?

Warehouse maintenance software, often integrated with a CMMS, streamlines the maintenance of warehouse facilities, equipment, and systems. It enables businesses to schedule preventive maintenance, track work orders, and manage repairs efficiently. With CMMS features like asset tracking, inventory monitoring, and performance analytics, it helps reduce downtime, control costs, improve safety, and extend the lifespan of warehouse assets.

Why should I use warehouse maintenance software?

Using warehouse maintenance software offers key benefits to ensure efficient and reliable warehouse operations:

- Minimize Downtime: Preventive maintenance keeps equipment and systems running smoothly, avoiding disruptions.

- Reduce Costs: Early issue detection and streamlined repairs lower maintenance expenses.

- Optimize Efficiency: Automates work orders, schedules tasks, and tracks inventory in one platform.

- Enhance Safety: Regular maintenance ensures compliance with safety regulations and reduces risks.

- Extend Asset Lifespan: Proper upkeep maximizes the durability of warehouse equipment and infrastructure.

Who uses warehouse maintenance software?

Warehouse maintenance software is used by anyone who manages maintenance — facility managers, operations managers, and asset managers, and more — to manage assets, schedule maintenance, and ensure safety. It is widely employed in industries including manufacturing, education, energy & utilities, food & beverage, and many more to maintain infrastructure and manage resources effectively.

Is Limble Mobile CMMS app user friendly?

Limble is consistently rated Easiest-to-Use CMMS on review sites like G2, Capterra, and Software Advice. And our customers agree. With our mobile CMMS app, teams experience 30%+ better productivity, on average, requiring little to no training or ramp-up time. Our CMMS app can travel with your team, no matter where they go! Visit our App Store or Google Play for more information.

Can I connect to other systems?

Limble provides seamless, pre-built CMMS Integrations with the most widely used software systems. That means you won’t need help from a developer or your IT team to get started. Learn more about our integrations.

How secure is the Limble CMMS platform?

At Limble, our world-class data security practices ensure your account information is safe. We use state-of-the-art technologies and industry best practices to maintain a secure infrastructure, including SOC-II Type II certification, regular penetration testing, and continuous security training for our staff.

TRUSTED BY 50,000+ PROFESSIONALS AROUND THE WORLD

All-in-one CMMS for all your Maintenance Needs

Work Orders & Requests

Organize work orders, PMs and other tasks for your entire team. Easy-to-use mobile apps your technicians will actually use.

See Work Order SoftwarePreventive Maintenance Programs

Automate preventive maintenance scheduling, build simple checklists, and analyze team performance and efficiency.

See Preventive Maintenance SoftwareAsset Management

Intuitive and flexible asset management features make it easy to manage your assets, whether you have 10 or 10 million.

See Asset Maintenance Management SoftwareSpare Parts Inventory

Eliminate the guesswork and reduce the amount of time and money spent searching and managing your parts inventory.

See Parts Inventory Software