Maintenance professionals are feeling the squeeze. Rising costs for parts, labor, and downtime are pushing operational budgets to their limits. Limble recently surveyed hundreds of maintenance professionals and found that 88% of maintenance teams are experiencing cost increases across one or more of these areas.

But here’s the good news: while you can’t control external factors, you can control how efficiently you operate. Leading manufacturers are turning maintenance into a strategic advantage, using it to protect throughput, extend equipment life, and make data-driven decisions about where to cut costs and where to invest.

In this post, we’ll unpack survey insights and explore how maintenance leaders are navigating cost pressures.

Rising cost pressures and the need for efficient maintenance

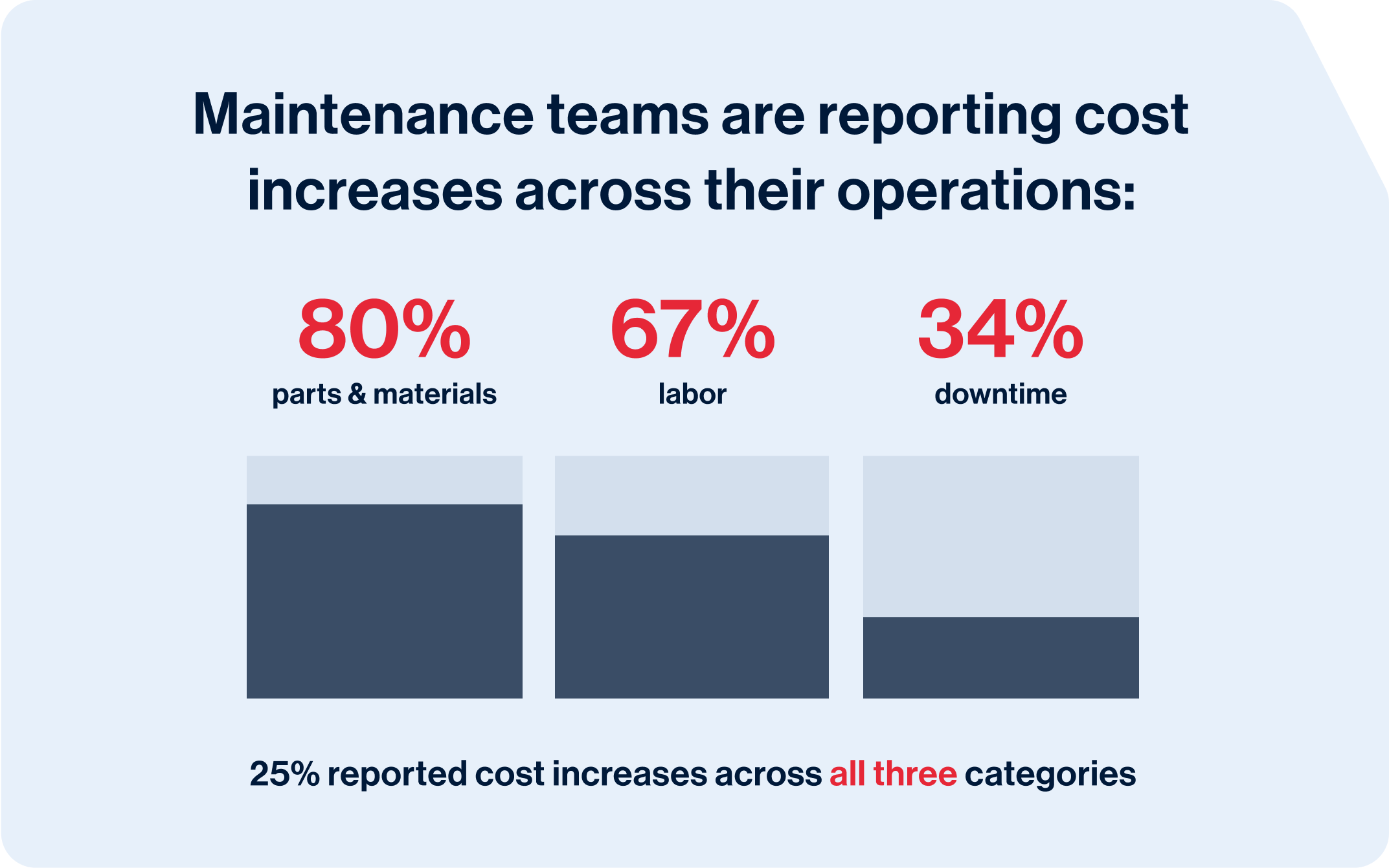

Maintenance teams highlight three key areas of their operations feeling the pressure on budgets and resources:

Parts and materials: Over 80% of survey respondents reported cost increases on parts and materials. Supply chain disruptions and inflation are already making critical parts more expensive, harder to find, and slower to arrive. And new tariffs could drive these costs even higher.

Labor expenses: Nearly 67% of teams are dealing with rising labor costs. With a continued shortage of skilled technicians, employers are paying more to attract and retain workers. At the same time, less than a third of teams are fully staffed, forcing smaller crews to absorb the workload and driving up premium labor costs from overtime, emergency call-ins, and off-hours coverage.

Downtime costs: 34% of teams report growing financial impacts from unplanned outages. Equipment failures delay production, drive up overtime costs, demand emergency spare part orders, and hurt profitability.

Many teams are seeing costs rise across the board, with 25% reporting hikes across all three categories.

The cost of inefficiency

Beyond external pressures, the survey also found several areas where maintenance teams have a clear opportunity to increase efficiency and reduce operational costs.

- Over 50% of teams regularly run out of critical spare parts, leading to emergency purchases, expedited shipping, and prolonged equipment downtime.

- More than 1 in 3 teams spend at least 60% of their time on reactive work, constantly putting out fires. This reactive cycle increases downtime, overextends technicians, and leaves little time for preventive work or long-term improvements.

- Over half of teams experience five or more hours of unplanned downtime each month, causing production delays and inflating labor and repair costs.

Reactive maintenance, part stockouts, and unplanned downtime don’t only disrupt daily operations, they carry real financial consequences. Maintenance teams are uniquely positioned to address operational inefficiencies and make a measurable impact on the company’s bottom line, helping to offset external pressures outside their control.

Strategies for cutting costs with smarter maintenance

Leading manufacturers are rethinking maintenance and making strategic investments to drive long-term efficiency and cost savings. Rather than viewing maintenance as a necessary expense to fix broken equipment, it’s being recognized as a competitive advantage. Operations leaders are investing in the tools, technology, and processes that empower maintenance teams to drive cost savings and build resilience against rising costs. By becoming more proactive, leveraging innovative technology, and implementing process improvements, maintenance can reduce capital expenses while maximizing uptime and productivity.

Here are three strategic areas to prioritize:

1. Prioritize preventive maintenance

Unplanned downtime is one of the biggest cost drivers for maintenance teams. By implementing or optimizing a preventive maintenance program, you can significantly reduce breakdowns, extend equipment lifespan, and improve team efficiency. A proactive approach also cuts costs by minimizing overtime, after-hours calls, and last-minute critical part needs.

Modern Computerized Maintenance Management Systems (CMMS) can automate your PM program, automatically generating and assigning PMs on a recurring schedule and even syncing with condition-monitoring sensors for timely proactive maintenance.

2. Optimize spare parts inventory

Avoid the vicious cycle of overstocking and stockouts by tracking spare parts usage in real time. Use a CMMS to alert you to low inventory and stale parts while monitoring usage trends for better planning. Smart inventory management helps balance availability with budget constraints, reducing emergency purchases, prolonged downtime, and excess capital tied up in stock.

3. Leverage data insights for better decisions

Track your maintenance costs closely to uncover cost-saving opportunities and address root issues instead of repeating quick fixes. CMMS platforms automatically track the data you need to improve capital planning and make informed decisions. Monitor costs across parts, labor, and invoices, so you can decide when to repair or replace equipment. Analyze maintenance history and performance to fine-tune preventive maintenance schedules, focusing on assets that need the most attention. Leverage task and backlog data to make informed hiring decisions and optimize resource allocation.

10 ways to reduce operational costs with smarter maintenance

For a full breakdown of maintenance strategies to boost efficiency, reduce waste, and drive resilience, download the free guide.

Building long-term resilience

Rising costs may seem daunting, but forward-thinking organizations are proving that challenges can be opportunities in disguise. By adopting smarter maintenance strategies, manufacturers can:

- Protect uptime and meet production goals more consistently

- Stretch the lifespan of critical assets, reducing capital expenditures

- Enable data-driven decision-making to allocate resources effectively

This isn’t just about tightening your belt. It’s about building a more agile, efficient operation that can weather economic storms and thrive in any market conditions.

Start building resilience today

Tackling rising costs and inefficiencies requires an actionable plan. Our guide, 10 ways to reduce operational costs with smarter maintenance, provides a tactical breakdown of strategies that can help your team reduce expenses, improve efficiency, and future-proof your operations. Learn how modern maintenance teams are streamlining daily workflows, implementing data-driven strategies, and aligning with production and finance to drive greater impact.

Get the guide and empower your team to thrive in the face of rising operational challenges.