A few months ago, I bought into the CMMS promise. Our facility was growing, work orders were piling up, and I needed something better than our Excel tracking system.

After three months of demos and trials, we picked what seemed like the perfect platform. Leadership approved the budget, and I was confident we’d finally get our maintenance operations under control.

The honeymoon lasted about three weeks.

- Our PM schedules got completely messed up because the system couldn’t handle our rotating equipment properly

- Simple tasks like searching for a specific asset took multiple steps through different menus

- When corporate asked for MTBF metrics, I spent two days manually calculating them in Excel because the built-in reports were useless

I knew there had to be better options out there. So, I decided to dig deeper.

Over the next 30+ hours, I dug through G2 reviews, watched platform demos on YouTube, and read Reddit threads where people shared their unfiltered experiences.

After all that research, I narrowed it down to a list of 9 potential CMMS platforms to go with. They have good reviews, useful features, and maintenance teams seem happy with them.

9 Best CMMS & maintenance software solutions for 2025: my top picks

- Limble CMMS – The most comprehensive all-in-one platform I found. The best mobile experience of all platforms I researched, and the implementation process seems to be the most organized.

→ BEST FOR: Teams that want all the key CMMS features in one system without compromises.

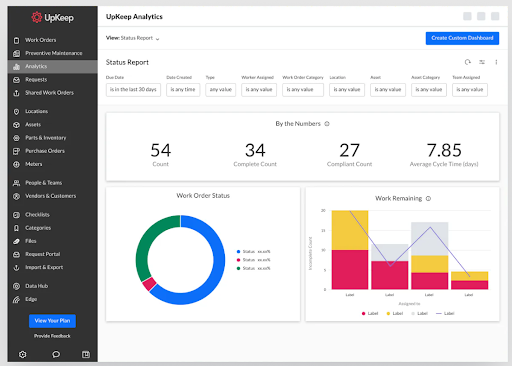

- UpKeep – Simple, user-friendly platform with a reliable mobile app and straightforward work order management.

→ BEST FOR: Small to mid-sized maintenance teams that need a mobile-first solution.

- Fiix CMMS – I like that it comes with strong data tracking and analytics through a clean, single-screen interface for all maintenance operations.

→ BEST FOR: Teams that need detailed MTBF/MTTR metrics and historical data tracking to prove maintenance ROI.

- MaintainX – AI-powered PM creation with excellent multi-site standardization through Enterprise mode.

→ BEST FOR: Multi-site operations that need identical procedures and PM schedules everywhere.

- Accruent FAMIS 360 – Powerful data consolidation and reporting flexibility built for complex facility operations.

→ BEST FOR: Universities, hospitals, or government facilities with complex compliance.

- eMaint CMMS – Robust inventory management with automatic reordering and multi-plant oversight from one dashboard.

→ BEST FOR: Manufacturing and industrial facilities that manage parts inventory across multiple plants or warehouses.

- Eptura Asset (formerly Hippo CMMS) – Flexible work order system that doesn’t require asset connections. It seems perfect for general facilities management tasks.

→ BEST FOR: Facilities teams manage both equipment and general maintenance tasks (moves, cleaning, repairs).

- Brightly Asset Essentials – Easy-to-adopt platform with strong mobile photo documentation and responsive customer support.

→ BEST FOR: Multi-location facilities that prioritize quick implementation.

- Fracttal One – Web-based platform that feels intuitive even for non-tech users, with strong analytics that bring all maintenance data together.

→ BEST FOR: Teams that want maintenance KPI tracking and analytics without building custom reports from scratch.

How did I find and evaluate the best CMMS software?

Let me be upfront about my research process. I didn’t sit through sales calls or test every platform firsthand – that would have taken months.

Instead, I looked for real user experiences and publicly available information.

I started with G2 and Capterra, and read through 400+ reviews to see what maintenance teams loved and hated about their CMMS.

The negative reviews were especially useful. When someone takes time to write a 1-star review, they’re usually describing a major problem that drove them crazy.

Reddit was where I found the most honest discussions. In r/maintenance, r/FacilityManagement, and r/manufacturing, people regularly ask for CMMS recommendations. And the responses get straight to the point. Maintenance managers share which systems they use and what they wish they’d known before buying.

YouTube walkthroughs helped me understand how these platforms work day-to-day. I could see the interface, watch some real workflows, and get a feel for how intuitive each system was.

I even printed out pricing pages and feature comparisons for the top contenders. Sounds old-school, but I needed to see everything side-by-side without switching between browser tabs.

From there, I narrowed the list based on what I’d learned matters for modern maintenance operations — reliable mobile apps, intuitive work order creation, flexible PM scheduling, accurate inventory tracking, and reporting tools.

After filtering through all the options against these criteria, I ended up with 9 CMMS platforms that get the job done.

My take on what makes CMMS software worth it

All this research taught me something important. A good CMMS doesn’t need to do everything. It just needs to handle the daily maintenance issues without making your life harder.

These are the things I’d look for in any system worth buying:

It has to be incredibly easy for technicians to use

The best maintenance software gets out of your technicians’ way.

They should be able to pull up their work orders, update status, log time, and close jobs without hunting through menus or remembering which buttons to press.

This isn’t just my experience. I found maintenance managers on Reddit saying the same thing:

(Source)

If it takes more than a few taps to complete basic tasks, you’ll probably end up with incomplete data and frustrated employees. And once techs start using paper or WhatsApp instead of your CMMS software, you’ve lost.

It must provide clear, accessible reports

Too many CMMS platforms make you export everything to Excel just to calculate basic metrics like MTBF or PM compliance. That’s not reporting.

Good reporting means that you get metrics without jumping through hoops.

Equipment downtime trends, technician productivity, parts usage – all in formats you can screenshot and send to management. If I need to explain why that compressor keeps failing, the data should be right there.

The best CMMS platforms have pre-built reports for the things maintenance teams track most often. Pull them up, filter by date, and share them directly. No Excel gymnastics.

It needs a powerful preventive maintenance engine

PM scheduling is where most CMMS platforms show their true colors. You need a system that handles your actual PM complexity. This includes equipment that runs on hours, seasonal tasks, and all the weird exceptions that pop up.

Too many systems that can only do basic calendar scheduling. What happens when your backup generator needs service every 200 run hours OR annually, whichever comes first?

The good platforms let you build PM schedules that match how your equipment actually runs. They track completion rates and automatically adjust for missed PMs. When you’re managing hundreds of assets, you can’t babysit the schedule every week.

This comment from r/maintenance gets right to why PMs matter:

(Source)

Exactly. We all know PMs are important. But if your CMMS makes scheduling and tracking them a nightmare, they won’t get done.

It should connect with your other business tools

Most facilities already run accounting software, ERP systems, and maybe some IoT sensors.

A good CMMS needs to connect to these tools through APIs, webhooks, or at least CSV imports. You don’t want to waste hours every week copying information between systems

Without proper integrations, you end up being a data entry clerk instead of a maintenance manager. Every part order, every cost update becomes manual work.

9 Best CMMS software solutions I evaluated in detail

1. Limble CMMS

From all my research, Limble stood out as the most comprehensive solution I found.

While other platforms excel in specific areas, Limble seems to have built everything maintenance teams need in one system, without making it too complicated.

The mobile app works exactly like you’d want it to. Real-time notifications keep everyone updated, work orders sync instantly between devices, and techs can access asset histories, parts inventory, and repair manuals from their phones.

The work request portal simplifies things for non-maintenance staff too – they scan a QR code on broken equipment and submit a request without an account or app download.

The preventive maintenance engine handles complex scheduling scenarios that trip up other systems. You can set PMs based on meter readings, calendar dates, or conditional triggers, and the system automatically generates work orders without creating duplicates.

Implementation and support also caught my attention. The platform offers expert-guided onboarding with custom implementation plans, 24/7 support through chat, email, or phone, and response times under 60 seconds on weekdays.

Plus, Limble also includes comprehensive asset management, spare parts inventory tracking, integrations with ERPs and IoT sensors, advanced reporting tools, and more.

Verdict ⚖️: Best all-around option for teams that want a complete CMMS solution with strong support and don’t want to compromise on any core CMMS features.

What I like about Limble CMMS

- Mobile app provides real-time notifications and instant syncing between devices, with offline capability and QR code scanning

- Preventive maintenance scheduling manages meter-based, calendar-based, and conditional triggers without any duplicate work orders

- Comprehensive asset management combines equipment histories, spare parts inventory, and vendor information in one centralized platform

What G2 users like about Limble CMMS

“The ease of use and the intuitive feel of the software. The ticket cataloging and searchability of each item. It was easy to implement and integrate into our team and throughout the company. We use it all day, every day to manage all of our maintenance needs, from work tickets to PM to parts inventory.

They reach out to me several times a year to check in and make sure that Limble is meeting my specific needs, and are always available through email to your rep or through online chat to address an issue that you may have.”

– Limble CMMS G2 Review, Robert T.

What I dislike about Limble CMMS

- Loading images and files can sometimes take longer than expected, though this isn’t a constant issue

- Some minor features take a few extra steps, but nothing that affects daily operations

What G2 users dislike about Limble CMMS

“The only feature of Limble that I have found to dislike is load time. This is not a constant, but sometimes loading images and/or files can take longer than I would like.”

– Limble CMMS G2 Review, Hunter M.

2. UpKeep

UpKeep consistently showed up in my research as one of the more user-friendly CMMS options, especially for teams that need something straightforward without excessive complexity.

The work order system is simple to navigate, and techs can pull up assignments, log time, and close jobs without hunting through multiple screens. The mobile app is also reliable, which isn’t something you can say about every CMMS platform.

The preventive maintenance scheduling handles routine tasks well across multiple buildings and equipment types. Teams can track vendor work, parts usage, and recurring maintenance without the usual headaches.

However, some reviews complained about not being able to customize work order formats to match existing processes.

There’s also frustration around work orders getting closed without required information (apparently, the system doesn’t ask techs to complete all necessary fields before marking jobs done).

Verdict ⚖️: UpKeep seems like a solid choice for teams that value simplicity over advanced features, but it might feel limiting if you need heavy customization or strict workflow controls.

What I like about UpKeep

- The mobile app works seamlessly offline and syncs when the connection returns

- Preventive maintenance scheduling handles meter-based, calendar-based, and conditional triggers without duplicating work orders

- Reports generate MTBF, MTTR, and PM compliance metrics without Excel exports or custom queries

What G2 users like about UpKeep

“UpKeep has been an invaluable asset to our maintenance team. The most helpful feature for us has been the work order management system. It allows us to easily create, assign, and track work orders, ensuring that nothing falls through the cracks. The ability to attach photos and documents to work orders has significantly streamlined our communication and documentation process.

Additionally, the mobile app has been a game-changer. Our technicians can access and update work orders on the go, which has greatly increased our efficiency and reduced downtime. The real-time notifications keep everyone informed and up-to-date, which is crucial for our fast-paced environment.”

– UpKeep G2 Review, Verified Anonymous User.

What I dislike about UpKeep

- You can’t customize work order formats to match how your team currently operates

- Technicians can close work orders without filling in required information, like time logs or notes

- Reporting features are basic compared to some alternative platforms

What G2 users dislike about UpKeep

“I would prefer that the work orders cannot be closed without completing the required fields, similar to how the requests are. For example, techs should have to enter a note, log their time, and check off tasks and checklists.”

– UpKeep G2 Review, Antwain H.

3. Fiix CMMS

Fiix strikes a balance between simplicity and functionality that maintenance teams seem to appreciate. The interface puts everything on one screen – work orders, inventory, asset maintenance, and dashboards.

The work order management works well for basic needs. Techs can see their assigned tasks, update progress, and add notes that the whole team can access. The system tracks parts, quantities, and completion steps, which helps with shift handoffs.

The main advantage is how Fiix handles data and reporting. Reviews kept mentioning the historical tracking and analytics tools as major improvements over basic CMMS platforms. You can see which work orders belong to whom, track progress in real-time, and get facility performance data from one dashboard.

The mobile app has problems, though. Technicians can’t search by manufacturer part numbers. The workflow for creating and closing work orders is clunkier than the web version. Techs often have trouble moving through work orders and completing tasks properly.

Other complaints are about scheduling and customization limits. You can’t sort work orders by multiple criteria at once. The analytics are useful, but you can’t customize data analysis as much as most maintenance managers want.

Verdict ⚖️: Fiix works for teams that want comprehensive tracking with a clean interface, but the scheduling limitations and mobile app issues might be deal-breakers.

What I like about Fiix CMMS

- Historical data tracking and analytics provide clear insights into maintenance processes and asset performance

- The interface is simple and organized, whether you’re managing work orders, inventory, or asset registers

- Real-time work order progress updates keep everyone informed about task status and ownership

What G2 users like about Fiix CMMS

“I like using the Fiix system to be able to identify pertinent work orders and their priorities, and it keeps me informed about which belong to me and which to my team members. I am able to update work order progress, and others are able to see my updates, too.

It’s useful in the event I go home and do not complete a task. In addition, I can also add notes and other important information, such as parts, quantities, steps, etc. I find it easy to understand and navigate through the menus and options.”

– Fiix CMMS G2 Review, Rigo S.

What I dislike about Fiix CMMS

- Maintenance planning and scheduling tools are weak compared to other platforms in this category

- The mobile app lacks key features like manufacturer part number search and has a clunky workflow

- Limited customization options for data analysis, and you can’t sort work orders by multiple criteria simultaneously

What G2 users dislike about Fiix CMMS

“The least helpful part of FIIX is the limitations of the app. It is very easy to use the app, but it isn’t as versatile as the web-based applications because of the workflow to create and close work orders.

It is also a little complicated for the technicians to navigate through the work orders and complete some of the tasks properly. They also have a hard time maximizing the data and information inputs.”

– Fiix CMMS G2 Review, Carlos F.

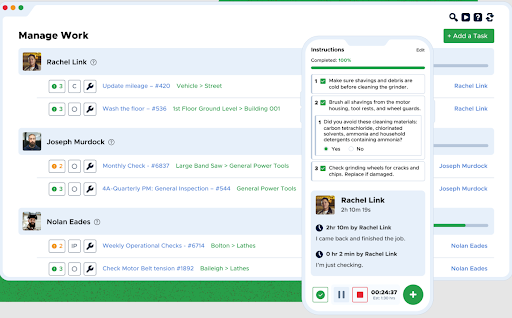

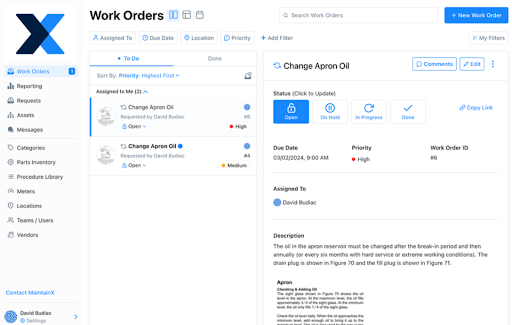

4. MaintainX

The AI-powered PM creation caught my attention here. Users report that it saves hours during implementation with automatic preventive maintenance tasks.

There are also QR codes on equipment that provide instant access to machine history. It makes it simple for techs to see what’s been done before.

For companies with multiple sites, the Enterprise mode lets you create procedures and PMs once, then push them to all locations without information loss.

Asset metering and data tracking seem strong as well. Teams use inspection data to forecast major repairs and schedule them proactively. The system centralizes everything – work orders, vendor contacts, parts info, labor tracking – in one place that works on any device.

The downsides are complexity and incomplete features. While basic functions are easy, advanced reporting and dashboards have a steep learning curve.

Plus, the spare parts inventory module isn’t as developed as the work order and asset tracking features. Several users mentioned that, because the system is so easy to customize, busy or inexperienced users can accidentally mess up workflows or data.

Verdict ⚖️: Great for multi-site operations that need standardized processes, but avoid if you need robust inventory management or have concerns about users accidentally changing key workflows.

What I like about MaintainX

- New users can start working with the system on day one with minimal training

- AI-powered tools for creating preventive maintenance tasks save hours during implementation

- QR code integration makes it easy to access machine histories and asset information instantly

What G2 users like about MaintainX

“MaintainX is intuitive and easy to adopt, even for teams who aren’t tech-savvy. The mobile and desktop interfaces are straightforward and easy to use.

The AI tools for building preventive maintenance tasks are a game-changer. This was a deciding factor for me. This saved us hours during implementation. I also appreciate how customizable the system is to fit our workflows.”

– MaintainX G2 Review, Todd E.

What I dislike about MaintainX

- Advanced reporting and dashboard features have a steep learning curve compared to the basic functions

- Spare parts inventory tracking isn’t as developed as the core work order and asset management modules

- The system is so easy to modify that inexperienced or busy users can accidentally mess up workflows and data

What G2 users dislike about MaintainX

“While I appreciate how fluid and easy the use is, it’s quite easy for someone less experienced in the field who is very busy to move things around incorrectly.

Whilst I recognize this is partially a user and training issue, time is a resource we do not have much of.”

– MaintainX G2 Review, Isaiah S.

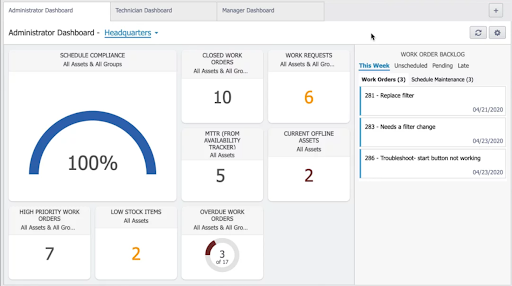

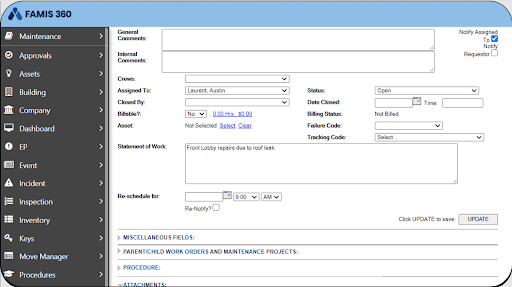

5. Accruent FAMIS 360

FAMIS 360 didn’t have as many user reviews as other platforms, but it kept appearing in G2 alternative lists and ChatGPT recommendations, so I decided to investigate.

What users talk about most is the data consolidation and reporting flexibility. They mention how FAMIS integrates multiple data entry points. The system is configurable enough to collect the specific data you need in the format you want, which helps avoid unnecessary information down the line.

FAMIS handles large amounts of information well across different screens and modules. Once users get familiar with the system, they find work order searches fairly straightforward. The program seems built for organizations that manage complex facility operations with lots of moving parts.

But there seem to be some major downsides. The interface tells you this is older software. While it holds lots of information across different screens, you need to know exactly where to look to find what you need.

The system lacks modern features like photo and document attachments – users still need to send these via separate emails.

Updates also seem problematic. Some users mentioned that system updates delete custom reports without warning. For a platform that prioritizes reporting, losing your configured reports during routine updates is a serious issue.

Verdict ⚖️: Consider for large institutions that need powerful reporting and data configuration, but avoid if you want modern features, intuitive interfaces, or reliable system updates.

What I like about Accruent FAMIS 360

- The system consolidates multiple data entry points and creates configurable reports for informed facility management decisions

- You can run several reports simultaneously, which saves time when pulling comprehensive data

- The platform handles large amounts of information well across different screens and modules

What G2 users like about Accruent FAMIS 360

“Famis allows us to integrate and consolidate our maintenance management data entry points to develop reports that enable our managers to make informed decisions to more effectively deliver facility management services on campus.

The system is configurable to ensure that we get the data we need/want, in the format we need, on the “front side” to avoid collecting information we don’t want down the line.”

– FAMIS 360 G2 Review, Stephen M.

What I dislike about Accruent FAMIS 360

- The interface feels outdated, and you need to know exactly where to look for specific information

- System updates often delete custom reports without warning users beforehand

- The client self-service portal is confusing with too many options and lacks basic features like photo uploads

What G2 users dislike about Accruent FAMIS 360

“It would be nice if it had more features. It’s not the most user-friendly program. I think it would be useful if clients could see more information on work orders. When clients use FAMIS self-serve to submit requests, they have too many options to choose from.

It would be great if it were more simplified because clients are constantly getting confused about which options they should choose. It would also be nice if you could add photos or documents to it so people wouldn’t have to send an email separately.”

– FAMIS 360 G2 Review, John Doe.

6. eMaint CMMS

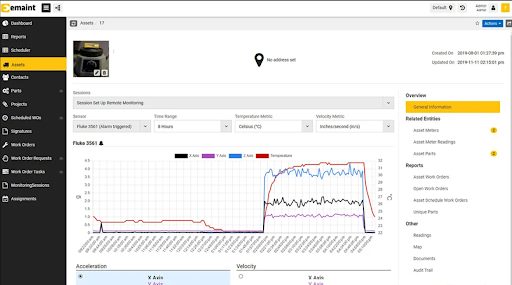

eMaint (now part of Fluke Reliability) came up a few times in my research as a solid choice for teams that manage multiple facilities or complex inventory control.

Users love the inventory management tools. The system tracks parts usage in real-time, automatically removes items as they’re consumed, and populates reorder lists when stock gets low.

For organizations that manage multiple plants or facilities, eMaint provides a centralized overview of PMs and spare parts across all locations from one dashboard.

However, while the custom reporting function works well for basic needs, you need JSON coding knowledge if you want to build more advanced reports. This can be a major barrier for most maintenance teams.

Managing reports and workflows gets messy, too. Reports display in one long alphabetical list with no grouping options, so it’s harder to find what you need as your report library grows.

Verdict ⚖️: Great for multi-site operations with strong inventory needs and teams comfortable with Excel-like interfaces, but skip if you need advanced reporting without coding skills.

What I like about eMaint CMMS

- Inventory management automatically tracks parts usage, removes consumed items, and generates reorder lists when stock runs low

- Custom reporting is intuitive and can be set up quickly to auto-generate and distribute to teams

- The system provides centralized insights for managing PMs and spare parts across multiple plants or facilities

What G2 users like about eMaint CMMS

“eMaint makes managing our maintenance system very easy, whether it be the ability to directly send work orders to a worker’s phone or having a self-generated report on a wide range of information gathered from within eMaint.”

– eMaint CMMS G2 Review, Anonymous Verified User.

What I dislike about eMaint CMMS

- You need JSON coding experience if you want to build more advanced reports

- The system lacks bulk operations like closing multiple work orders at once or deleting multiple procedure steps simultaneously

- Document and photo uploading is cumbersome, and barcode integration for parts checkout needs improvement

What G2 users like about eMaint CMMS

“Building advanced reports in eMaint can be a bit of a challenge for those without JSON coding experience. The ability to close out multiple work orders at once would be a helpful feature, as it would be a major time saver when cleaning up a backlog.

Similarly, the ability to delete multiple steps in a task procedure at once would be a huge time saver when implementing large changes to several procedures at one time.”

– eMaint CMMS G2 Review, Anonymous Verified User.

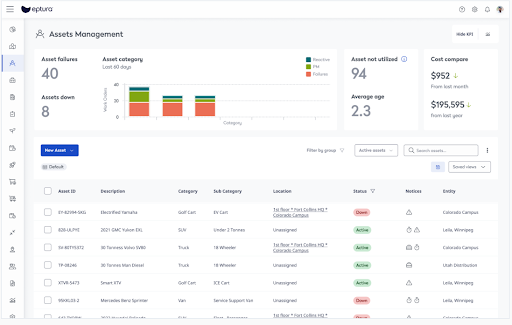

7. Eptura Asset (formerly Hippo CMMS)

Eptura Asset (which many users still call Hippo) has a good reputation for facilities management.

Work order flexibility is the biggest selling point. While many CMMS systems force every work order to connect to a specific asset, Eptura lets you categorize work types without these restrictions. This works well for facilities management, where much work doesn’t involve tracked equipment.

The system also handles multi-location management smoothly. Managers like having work orders and asset costs in one place for budget decisions. Both scheduled and unscheduled maintenance flows through the platform without issues.

Problems seem to show up with integrations and customization. Parts inventory won’t integrate with ERP systems like Infor, so teams manage two separate purchasing systems.

You can’t customize priority fields, and the QR code requests have gaps – if you move equipment daily, you can’t add location fields to track where things are.

Customer support is also weak. Multiple reviews mention they can’t reach anyone for help with questions or problems.

What I like about Eptura Asset

- Work orders don’t need to be tied to specific assets, which works well for facilities management tasks

- Cloud-based system provides reliable connections and stable performance across multiple locations

- A centralized platform that combines maintenance costs and asset information to help managers make budgeting decisions

What G2 users like about Eptura Asset

“Having a one-stop shop for our users to find what they need is fantastic. The information obtained via assets and work order costs assists our managers and supervisors with budgeting decisions regarding various assets.”

– Eptura Asset G2 Review, Brooke A.

What I dislike about Eptura Asset

- ERP integration for parts inventory can be problematic

- Some basic customization options are missing (e.g., modifying priority fields or adding custom fields to QR code requests)

- Customer support is difficult to reach when you need help with questions or system issues

What G2 users dislike about Eptura Asset

“The need to integrate parts inventory into our ERP system is a hurdle now, and it is almost impossible to manage two purchasing systems and inventory. A few little issues, such as the inability to customize the priority field (I think it once did allow this).

Inability to add fields to the QR code for requests is frustrating. We move many assets around on the plant floor almost every day, so a water heater, for example, might be moved 3-4 times a week. We added a custom field to the request portal for users to simply tell us what line the asset is on at the time of request.”

– Eptura Asset G2 Review, Daniel B.

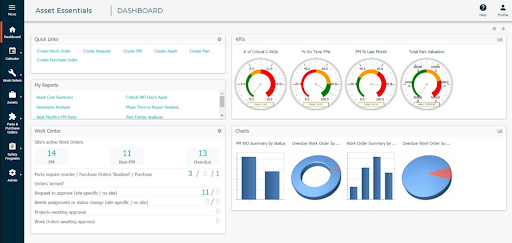

8. Brightly Asset Essentials

Brightly Asset Essentials keeps showing up when facilities teams discuss easy-to-adopt CMMS platforms. The system centralizes work order management and asset tracking for multi-location operations.

The mobile device functionality works well for basic needs. Teams can submit work requests with photos directly from their phones, which helps when you need to document problems on the spot.

Asset management and preventive maintenance seem to be well organized through the platform. It can handle multiple locations smoothly, and managers can assign different people to assess problems across sites.

The workflows are customizable enough for most standard operations. The big problem is that simple tasks require too many clicks, and you can’t shorten decision trees even when they don’t make sense for your workflow.

Plus, setup takes much longer than most teams expect, and some features don’t always work properly during rollout.

Verdict ⚖️: Good for multi-location facilities that need photo documentation and easy adoption, but avoid if you have complex approval workflows or unique processes.

What I like about Brightly Asset Essentials

- Mobile work order requests with photo attachments work well for documenting problems directly from the field

- Customer support offers multiple contact options, including chat, phone, and email

- Most users can start working with the system quickly without extensive training

What G2 users like about Brightly Asset Essentials

“The ability to have all the different locations use the program and attach pictures to the work order request so that we know where the problem is.

I love the option that you can use your cell phone as well, which makes it easier for the requester to be able to be at the specific area that needs attention and not have to go to a computer to write up what’s wrong.”

– Brightly Asset Essentials G2 Review, Regina C.

What I dislike about Brightly Asset Essentials

- Simple tasks require too many clicks, and decision trees can’t be shortened due to program limitations

- Customization options are limited, which creates problems for teams with specific operational needs

- You can’t see work requests on the mobile app, which defeats the purpose of mobile functionality

What G2 users dislike about Brightly Asset Essentials

“Feels less flexible when you’re dealing with highly specific or unique operational needs, as customization options have their limits.”

– Brightly Asset Essentials G2 Review, Mohammad N.

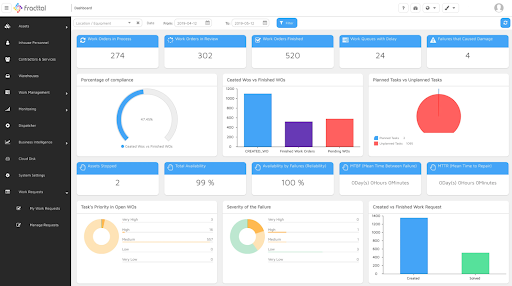

9. Fracttal One

Based on reviews, Fracttal One focuses heavily on user experience and comprehensive asset management in one package.

Teams mention how intuitive the platform feels, even for people who aren’t particularly tech-savvy. The web-based system lets you access everything with just a username and password from anywhere.

The system also has centralized facility maintenance data and analytics. It brings together asset information, maintenance history, and performance metrics in one place. And mobile access lets techs update work orders and check asset information in real-time from the field.

Company-level customizations are frustrating because they go through some type of approval process, and you can’t just change functionality on your own. Users mention that you can’t save filter settings and have to reconfigure them every time.

Training is another weak spot. While they offer webinars and videos, there’s no interactive, step-by-step training within the platform itself.

Verdict ⚖️: Strong choice for data-driven teams with standard maintenance workflows, but avoid if you need platform customization or self-paced training modules.

What I like about Fracttal One

- The intuitive, web-based interface works for users at all tech levels and requires only a username and password to access from anywhere

- Centralizes all maintenance data with strong analytics and reporting tools for tracking KPIs and historical trends

- Mobile access brings real-time work order updates and asset information checks directly from the field

What G2 users like about Fracttal One

“What I find most impressive about Fracttal One is its comprehensive approach to asset maintenance management. Its user-friendly interface and easy navigation make it accessible to users of all levels.”

– Fracttal One G2 Review, Romina A.

What I dislike about Fracttal One

- Company-level customizations demand voting processes (which prevent quick functionality changes)

- You can’t save request filters and have to reconfigure their view settings every time they update

- Lacks interactive, step-by-step training modules within the platform

What G2 users dislike about Fracttal One

“I think it lacks dedicated, step-by-step training modules. For example, if you want to learn how to create a work order, this shouldn’t be done solely through a webinar or video lecture, but through very brief, specific interactive modules on the software’s own screens. This would be very helpful for technical profiles, for example.”

– Fracttal One G2 Review, Verified Anonymous User.

My advice on how to find the right CMMS tool for your team

After spending 30+ hours on this research, I realized there’s no single best solution.

You need something simple enough that techs will use it, flexible enough to match your processes, and support that responds when problems come up.

For me, I kept coming back to platforms that had everything built in (not pieced together through add-ons), worked reliably offline, and didn’t nickel-and-dime you for basic features like reporting.

If your priorities are similar – especially if you want everything in one system without piecing together multiple tools – Limble CMMS checked all the boxes that mattered most in my research.

They also offer a live 1:1 demo where you can see how it would work specifically for your operation before making any commitment.

CMMS software: frequently asked questions (FAQs)

What’s the #1 mistake people make when choosing a CMMS?

From what I’ve seen, the biggest mistake is picking a CMMS based on what looks good rather than what works for your team’s daily routine.

People get excited about fancy features and dashboards, then realize their maintenance crew finds the system too complicated for daily use.

What is the single biggest advantage of implementing a CMMS?

You get all your maintenance information in one place instead of scattered across spreadsheets, emails, and people’s heads.

Teams can see what needs fixing, when it was last serviced, and who’s responsible for it. It stops the constant scrambling to figure out basic information about your equipment.

Beyond the feature list, what truly differentiates one CMMS from another?

Apart from the feature list, it comes down to how the software works with your team’s daily routine. Here’s what matters:

- User adoption: Does your maintenance crew actually want to use it, or do they see it as extra work piled on top of their real job?

- Implementation speed: Can you get up and running in weeks, not months? Some systems have extensive customization that can take forever to set up.

- Support quality: When something breaks or you’re confused, can you reach someone who knows the product and can solve your problem in a timely manner?

What’s the difference between a CMMS and an EAM?

CMMS (computerized maintenance management system) and EAM (enterprise asset management) sound similar and overlap in many areas, but they’re two different approaches to managing your asset lifecycle and maintenance.

- CMMS handles the day-to-day maintenance work. It streamlines work orders, schedules repairs, tracks parts inventory, and makes sure your equipment keeps running.

- EAM does everything a CMMS does, but it also takes a bigger-picture view. It manages the entire asset lifespan, financial planning, compliance tracking, and strategic decisions about when to repair versus replace equipment.

The key difference: CMMS focuses on keeping things running today, while EAM helps you plan for tomorrow. If you’re mainly concerned with work orders and maintenance schedules, a CMMS works fine. If you need to make long-term asset decisions and manage complex compliance requirements, EAM gives you the broader tools you need.

Which industries use CMMS software the most?

Maintenance management software gets heavy use across industries where equipment downtime costs serious money or creates safety risks:

- Manufacturing: Production lines can’t afford unexpected breakdowns, so predictive maintenance activities and quick repairs are critical to keeping operations running.

- Healthcare: Hospitals need medical equipment, HVAC systems, and backup power working 24/7 since equipment failure can directly impact patient care.

- Facilities management: Office buildings, schools, small businesses, and large complexes use CMMS to handle everything from elevator maintenance to HVAC repairs across multiple locations.

- Utilities: Power plants, water treatment facilities, and energy companies rely on CMMS to maintain the infrastructure that serves entire communities.

- Transportation: Airlines, railways, and fleet operators use CMMS to automate vehicle maintenance, comply with safety regulations, and minimize service disruptions.

The common thread is that these industries can’t afford to wing it when it comes to maintenance. The stakes are too high.