Smarter maintenance for beverage operations

From production to packaging, Limble helps beverage teams maximize uptime, standardize processes, and drive technician efficiency.

SEE LIMBLE CMMS IN ACTION

Improve productivity by more than 40%

Built for the demands of beverage production

Streamline preventive maintenance, track work, and keep bottling, brewing, and packaging on schedule.

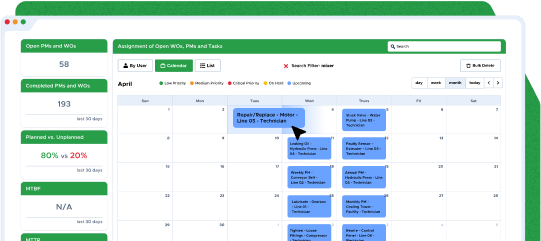

Prevent unplanned downtime

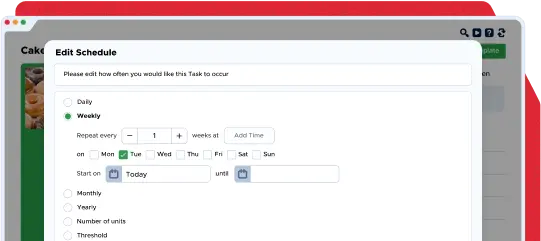

- Automate PMs based on schedules, runtime, or meter readings

- Monitor PM completion to catch gaps before they cause downtime

- Catch issues early to prevent breakdowns and keep production on track

Improve technician productivity

- Mobile work orders technicians can use at the line or in the field

- QR codes for instant asset details, maintenance history, and work requests

- Offline mode for seamless work in any location

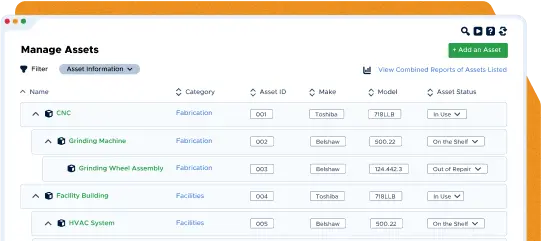

Standardize across teams and sites

- Create custom asset hierarchies by location, line, or component

- Define SOPs and workflows for labelers, CIP skids, and other key systems

- Route requests, assign work, and report progress automatically

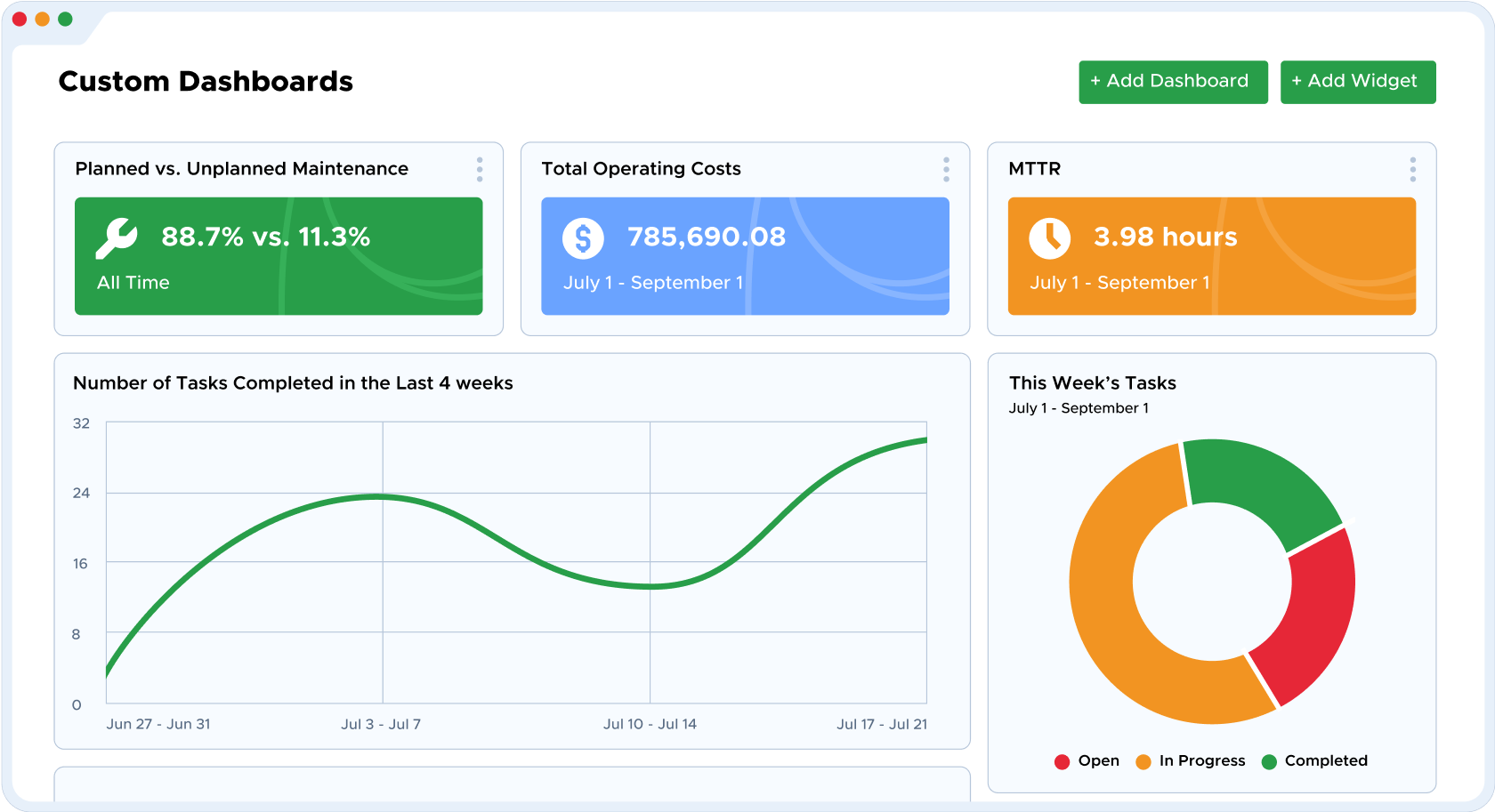

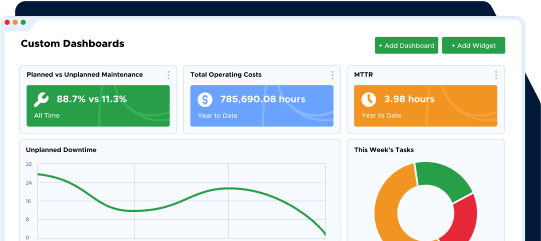

Get the visibility to optimize costs

- Track labor, downtime, and parts by machine or asset group

- Easily surface recurring issues and identify root causes

- Justify spending and staffing with real-time data across your sites

“We're finding that we don't need to be at the pieces of equipment as much as we used to. We're actually using the data to point where we put the technicians to work.”

Sean Diffley Director of Engineering VIEW CASE STUDYReady to learn more about Limble?

Schedule a demo or calculate your price right away.