In manufacturing, the gap between market leaders and the rest isn’t usually one big invention — it’s the relentless push to get better every single day. While hitting daily production goals matters, true operational excellence comes from improving the processes that make those results possible.

That’s the heart of continuous improvement: ongoing, incremental progress that compounds over time.

In this guide, we’ll break down the principles of continuous improvement on the plant floor. You’ll see how to turn proven methods — like Kaizen, 5S, and the PDCA Cycle — into a practical framework your Production and Maintenance teams can use to cut waste, improve efficiency, and drive lasting progress in your facility.

What is continuous improvement in manufacturing?

Continuous improvement (CI) in manufacturing represents the ongoing effort to make processes, products, and workflows better over time. The focus is on small, consistent improvements that add up to major gains in quality, efficiency, and profitability.

The goals are simple:

- Eliminate waste

- Boost efficiency

- Improve product quality

- Increase customer satisfaction

- Lower costs without cutting corners

Modern continuous improvement grew out of post–World War II manufacturing, when Japanese companies like Toyota developed the Toyota Production System. Practices like Kaizen and 5S became the backbone of what we now call Lean Manufacturing. These methods later blended with concepts from Six Sigma and Total Quality Management (TQM) to form today’s CI strategies used worldwide.

TL;DR: Manufacturing continuous improvement isn’t a one-off project — it’s a mindset that turns “good enough” into “let’s make it even better.”

Is continuous improvement the same as manufacturing process improvement?

They’re closely related, but not quite the same.

Manufacturing process improvement usually refers to specific, targeted changes made to improve a single process or set of processes. Think cutting machine cycle time or reducing scrap in a production line. These improvements can be one-off projects with a clear start and end date.

Continuous improvement, on the other hand, is the ongoing culture and framework behind such projects.

In practice, process improvements are one of the many activities that happen within a continuous improvement program. Without the culture of CI, those process changes are less likely to stick and deliver long-term impact.

Popular tools and methods for continuous improvement on the plant floor

There’s no single “right” way to improve manufacturing processes. Over the years, manufacturers have developed a variety of tools and methods — most of them grouped under the umbrella of Lean Manufacturing, Six Sigma, and Total Quality Management initiatives.

Below, we are going to focus on the most popular methods that are relatively easy to implement.

The PDCA cycle (Plan-Do-Check-Act)

The PDCA cycle is a simple but powerful framework for making improvements and making sure they stick. It’s all about testing changes in a controlled way before fully committing to them.

How it works:

- Plan: Identify a problem or opportunity, set a goal, and plan your approach.

- Do: Test your idea on a small scale.

- Check: Review the results — did the change solve the problem or improve the process?

- Act: If it worked, standardize the new process. If it didn’t, make adjustments and run the cycle again.

Example: A maintenance team notices frequent downtime on a packaging line due to a loose sensor. They plan to install a different type of mounting bracket, do the change on one machine, check the results over two weeks, and then act by rolling the fix out to all lines after seeing a 90% drop in sensor issues.

Quality circles

Quality circles are small groups of employees — often from the same work area — who meet regularly to discuss and solve problems related to their work. The idea is to tap into the knowledge of the people closest to the process.

How it works:

- A group of 5–10 team members voluntarily meets to identify issues, brainstorm solutions, and recommend improvements.

- Meetings are structured and often follow a problem-solving process (like the PDCA mentioned above).

- Solutions are presented to management, who can approve and support implementation.

Example: A quality circle in the assembly department notices that a particular bolt is prone to stripping during installation. They investigate and recommend switching to a torque-limiting tool. Management approves, the tool is adopted, and defect rates drop by 11%.

Kaizen (continuous, incremental improvements)

Kaizen is a Japanese term meaning “change for the better” and is the backbone of continuous improvement. It encourages everyone to make small, daily improvements — from frontline operators to management.

How it works:

- Employees are encouraged to constantly look for small problems or inefficiencies.

- Improvements are quick to implement and often require little to no cost.

- Over time, these incremental changes compound into major performance gains.

Example: A technician suggests moving a commonly used tool from a cabinet across the shop to a magnetic holder next to the workbench. It’s a simple change, but it saves the team 10+ minutes a day — adding up to hours of productivity gained each month.

The 5S system

The 5S system is a workplace organization method that improves operational efficiency, safety, and quality by creating a clean and orderly environment. The name comes from five Japanese words, each starting with “S”:

- Sort: Remove unnecessary items.

- Set in order: Arrange items so they’re easy to find and use.

- Shine: Clean and inspect the work area regularly.

- Standardize: Create consistent processes and layouts.

- Sustain: Maintain and continuously improve the system.

How it works:

- Teams go through each “S” in sequence, eliminating clutter, organizing tools, cleaning work areas, and setting clear standards for upkeep.

- A visual and well-organized space makes problems easier to spot and reduces wasted time searching for tools or materials.

Example: A maintenance shop applies 5S by sorting old parts, labeling shelves, and creating shadow boards for tools. Meanwhile, a production team uses 5S to reorganize their workstation layout so that materials flow in sequence with the assembly process. Parts bins are color-coded, tools are placed at arm’s reach, and unnecessary items are removed.

Standard work

Standard work means documenting and following the best-known method for completing a task. It ensures every operator or technician performs the work the same way, every time — leading to consistent results, fewer errors, and easier training.

How it works:

- Break down each task into clear, step-by-step instructions. This should be done by experienced techs or operators — a person who knows both your plant floor and industry best practices for the task at hand.

- Include visuals, diagrams, or checklists to make the process easy to follow.

- Review and update the standard whenever a better method is found.

Example: A maintenance team creates a standard operating procedure for replacing a conveyor belt, including torque specs, alignment steps, and inspection points. This reduces variation between technicians and ensures the repair is done right the first time.

Six sigma (DMAIC and DMADV)

Six Sigma is a data-driven approach to improving quality by eliminating defects and reducing process variation. It uses structured problem-solving methods — most commonly DMAIC and DMADV — to make measurable improvements.

DMAIC (Define, Measure, Analyze, Improve, Control) is used to improve existing processes. DMADV (Define, Measure, Analyze, Design, Verify) is used to design new processes or products with quality built in from the start.

The easiest way to represent how these methods are applied is to use an example. Imagine a maintenance team using DMAIC to reduce unexpected breakdowns on a critical machine. They:

- Define the problem (frequent downtime).

- Measure breakdown frequency.

- Analyze vibration data to find bearing wear as the root cause.

- Improve by switching to higher-quality bearings and adjusting lubrication intervals.

- Control the process by implementing predictive maintenance to monitor equipment condition closely.

On the production side, DMADV could be used, for example, to design a new assembly line layout that minimizes product handling and defects compared to the current production process.

Challenges for establishing a continuous improvement culture

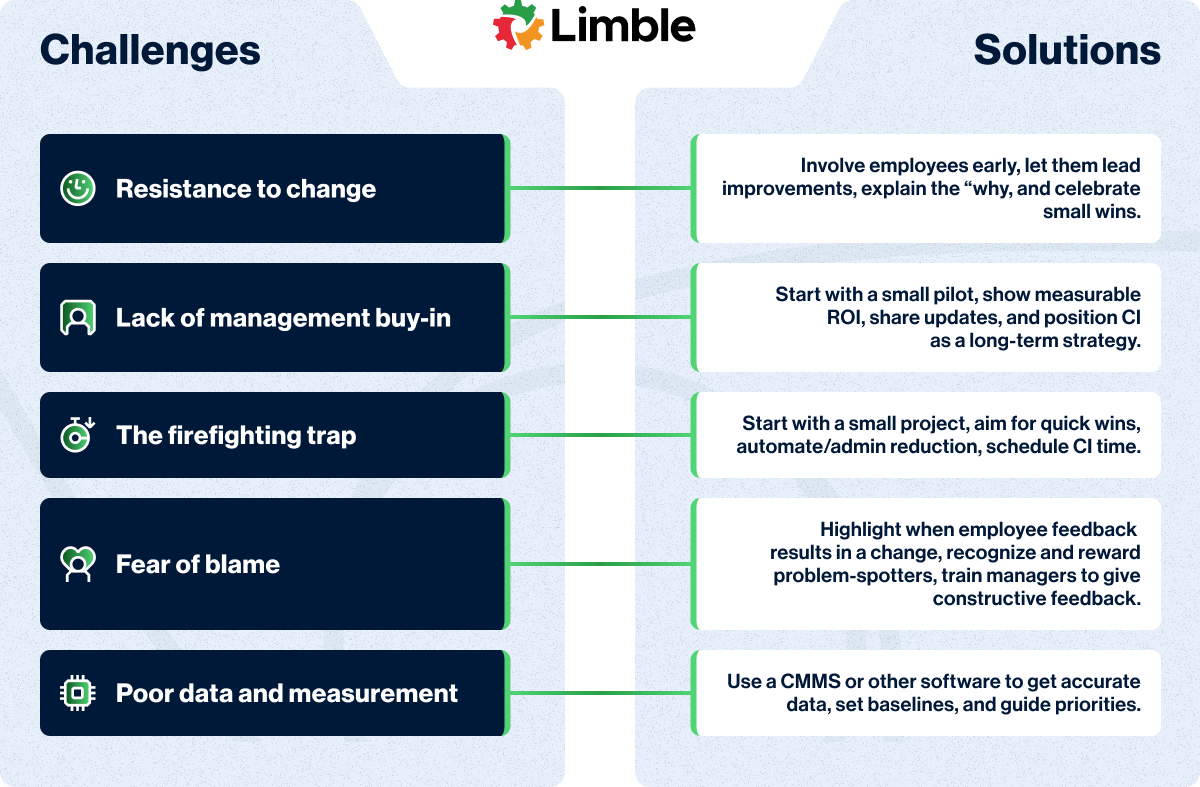

Building a culture of continuous improvement in any manufacturing facility is insanely beneficial — but it’s not easy. Below are some of the most common bottlenecks and ways to overcome them.

1. Resistance to change

One of the biggest hurdles to CI is people simply not wanting to change. Experienced team members may see new processes as extra work, or worse, as criticism of how they’ve been doing their job for years. With one-quarter of the manufacturing workforce being above 55 years old, some resistance to change is inevitable.

The “this is how we’ve always done it” mindset can stop an initiative like nothing else.

Overcome it by involving key employees from the start, so they have a say in the process and become advocates for change. Often, that means letting teams lead improvement efforts in their areas. Also, don’t forget to communicate the “why” behind each change, linking it to benefits for the team.

2. Lack of management buy-in

Without genuine support from leadership, continuous process improvements rarely last. If management isn’t willing to provide time, resources, and budget, these initiatives will be seen as a passing trend.

Continuous improvement should be pushed by top management as a long-term business strategy. Unfortunately, that is not always the case.

When trying to secure resources for your project, pitch a small pilot project that can show quick, measurable results. Quantify benefits in terms leadership cares about — cost savings, productivity gains, and reduced downtime.

3. The firefighting trap

It’s hard to focus on proactive improvements when you’re putting out fires left and right. This is especially true for maintenance teams on busy production floors that rely too much on reactive maintenance.

Here are some ways to break the firefighting cycle:

- Start with one small, manageable CI project that addresses a recurring problem.

- Use quick wins to free up time for bigger improvements.

- Leverage CMMS and maintenance automation to reduce admin tasks and streamline work orders.

- Make CI time part of the weekly schedule so it’s not sidelined by emergencies.

4. The fear of blame

A successful CI culture depends on open communication about problems. But if employees fear they’ll be blamed or punished for pointing out a flaw, they’ll stay silent. This creates blind spots and allows small issues to pester and grow.

The key is to build a blameless culture where the focus stays on fixing processes. Be sure to share examples of improvements that came directly from employee feedback, recognize and reward team members who identify problems early, and train managers to respond constructively. This way, issues are addressed without discouraging future input.

5. Poor data and measurement

Without reliable data, CI efforts are based on opinions instead of facts. You can’t track progress or prove results without a baseline. You will waste time on changes that don’t have measurable impact (or worse, abandon promising initiatives because you are unable to demonstrate benefits).

How to overcome it:

- Use a CMMS software or other tracking system to collect accurate, real-time data for the area you are trying to improve.

- Establish baseline performance metrics before making changes.

- Track results consistently and share them with the team.

- Use data to guide priorities and ensure resources go to the most impactful improvements.

When you recognize and address these challenges early, you give your continuous improvement efforts the best chance to take root and deliver lasting results.

Limble CMMS: Your engine for continuous improvement

The principles of continuous improvement give you the roadmap — but turning that plan into action requires the right tools.

For maintenance teams, a modern CMMS is the engine that powers their CI program. It helps standardize improvements, track results, and prove success with hard data.

We work with hundreds of manufacturers that use Limble CMMS to:

- Establish a data-driven culture: Automatically capture critical maintenance metrics and KPIs — from MTTR and MTBF to asset-level costs and failure frequency — so you can identify problems, measure improvements, and prove ROI to management.

- Standardize your best practices: When you find a better way to complete a PM or repair, instantly update digital checklists, procedures, and documentation so every technician follows the same method.

- Empower your team from the shop floor: Give technicians a mobile tool to report problems, suggest improvements, and access critical information on the spot — making it easy for the real experts to participate in CI.

- Break the reactive cycle: Streamline work orders and automate preventive maintenance schedules to free up time for high-impact improvement projects.

Want to see why Limble CMMS is the top-ranked maintenance software for teams looking to build a culture of continuous improvement?

FAQs about the continuous improvement process in manufacturing

How do I get my team on board with a new improvement initiative?

Start by involving your team early in the process. Ask for their input, let them identify problems, and encourage them to suggest solutions. Clearly explain the “why” — how the change will make their work easier, safer, or more efficient.

Start small with a quick-win project to build confidence and show results fast. Celebrate successes publicly, and recognize individual contributions so the team feels ownership over the improvements.

What are the 3C’s of continuous improvement?

The 3C’s stand for Concern, Cause, and Countermeasure—a simple problem-solving approach used in continuous improvement.

- Concern: Identify and clearly define the problem or opportunity.

- Cause: Find the root cause by asking “why” until you get to the underlying issue.

- Countermeasure: Implement a targeted solution to address the root cause and prevent it from recurring.

This method helps teams focus on solving the real problem instead of just treating symptoms.

Where is the best place for a maintenance team to start with continuous improvement?

Begin with a small, high-impact project that addresses a recurring problem. This could be something like reducing downtime on a critical machine, organizing tools with 5S, or standardizing a common inspection procedure (you can use your CMMS to find a preventive maintenance procedure that takes longer than it should).

What does a simple Kaizen event look like for a maintenance team?

A Kaizen event is a short, focused improvement workshop. For a maintenance team, a great example would be tackling a Preventive Maintenance (PM) procudere that takes too long:

- Team: The technicians who actually perform the PM.

- Process: The team physically walks through the entire PM, timing each step and mapping the workflow. This is a simple form of value stream mapping. They identify waste, such as time spent walking back and forth to the tool crib.

Solution: They re-organize a dedicated PM cart with every necessary tool and consumable. Using visual management tools like Kanban boards, they create a standardized kit that cuts down on wasted motion and ensures the job is done the same way every time.