From manufacturing and mining to hospitality and healthcare, Computerized Maintenance Management Systems (CMMS) have become all but essential. Wherever there are assets to maintain, a CMMS plays a critical role in reducing downtime, controlling costs, and keeping operations running smoothly.

But not all CMMS platforms are created equal. Legacy systems, while groundbreaking in their time, were often clunky, hard to use, and limited in scope.

Today, organizations demand something more. A modern CMMS is built on cloud technology, designed for mobile teams, and connected to the larger tech ecosystem you rely on.

Let’s explore what sets modern CMMS solutions apart from traditional ones, and highlight the must-have features you should find in every modern system.

The differences between traditional and modern CMMS platforms

CMMS software has been around for decades. The gap between older, legacy systems and today’s modern platforms is huge. Here are the key differences you’ll notice:

- Technology stack: Legacy systems were often installed on-premise and required heavy IT involvement. A modern CMMS is cloud-based, mobile-friendly, and continuously updated with little to no downtime.

- User experience: Traditional CMMS tools have outdated, complex interfaces. Modern platforms focus on ease of use and accessibility, taking cues from the consumer apps people use every day.

- Integration: Older systems usually operated in silos, making data hard to share. A modern CMMS connects seamlessly with IoT sensors, ERP systems, and BI tools to create a unified view of your operations.

- Data and analytics: Legacy systems typically store only the basic maintenance records. Today’s solutions automatically track a large number of data points, which can be transformed into predictive insights and custom dashboards.

- Maintenance approach: In the past, CMMS only supported reactive and preventive maintenance. A modern CMMS extends that support to predictive and even prescriptive maintenance strategies.

Together, these differences explain why upgrading isn’t just about convenience — modern solutions enable teams to run more efficiently and put their maintenance data to work.

Next, let’s look at characteristics that make a CMMS “modern.”

What makes a modern CMMS system deserving of that title

If your CMMS is only suitable for creating work orders and recordkeeping, then it’s not good enough. Below are the core qualities that separate a truly modern CMMS from everything that came before.

Cloud-based and accessible anywhere

The biggest shift from legacy to modern CMMS is the move from on-premise servers to the cloud. This has eliminated the heavy upfront investment in servers and ongoing IT maintenance.

What this means for you:

You get a system that is always up-to-date, secure, and accessible in real time from any device. Your entire maintenance operation is connected and manageable from anywhere, whether you’re on the shop floor, in the office, or traveling. And no more waiting for manual upgrades or worrying about backups — the provider handles it all.

Mobile-first, not just mobile-friendly

Legacy systems were designed for desktop use, with mobile access added as an afterthought (if at all). A modern CMMS, by contrast, is built mobile-first. The mobile app is as important as the desktop interface, designed to make life easier for technicians who spend their days away from a desk.

What this means for you:

Your technicians can manage their entire workflow from their phones or tablets. Receiving work orders, pulling up asset histories and manuals, attaching photos and completion notes — everything can be done on the go. This dramatically improves data accuracy and operational efficiency across your entire team.

User-friendly by design

Old(er) CMMS platforms are notoriously difficult to navigate. They require extensive training because even simple actions (e.g. rescheduling a work order) force you to click through several different screens.

A modern CMMS flips that experience. Ease of use is a top priority, as CMMS is only useful if people use it. The platform that isn’t intuitive isn’t modern.

What this means for you:

Everyone on your team — from seasoned supervisors to less tech-savvy technicians — can quickly learn the system. A high adoption rate leads to consistent, reliable data collection, which is the foundation for smarter maintenance decisions. When your maintenance team actually enjoys using the tool, the value of your CMMS multiplies.

Built to integrate

Traditional CMMS systems often acted as closed-off silos where data remained trapped. A modern CMMS is built to connect. Through open APIs and pre-built integrations, it seamlessly exchanges information with other business systems you rely on — think ERP, purchasing, BI tools, and IoT sensors.

What this means for you:

You get a single source of truth. For example, you might sync your CMMS with your ERP to keep inventory and procurement aligned, or connect to IoT devices that automatically trigger work orders when equipment conditions change. The result is a smarter, more proactive operation where maintenance works in tandem with other departments.

Fast and secure

Speed and security are non-negotiable for a modern CMMS. Legacy systems often struggled with performance issues and required manual security updates. A modern CMMS is supposed to be fast and come with enterprise-grade protection. With cloud infrastructure, providers can continuously optimize speed, apply patches, and keep your data safe.

What this means for you:

You can rely on quick load times, even when handling large data sets. With security features like data encryption, role-based access, and automatic backups, you can be confident that your sensitive maintenance and asset information is protected. All of that without extra work for your IT team.

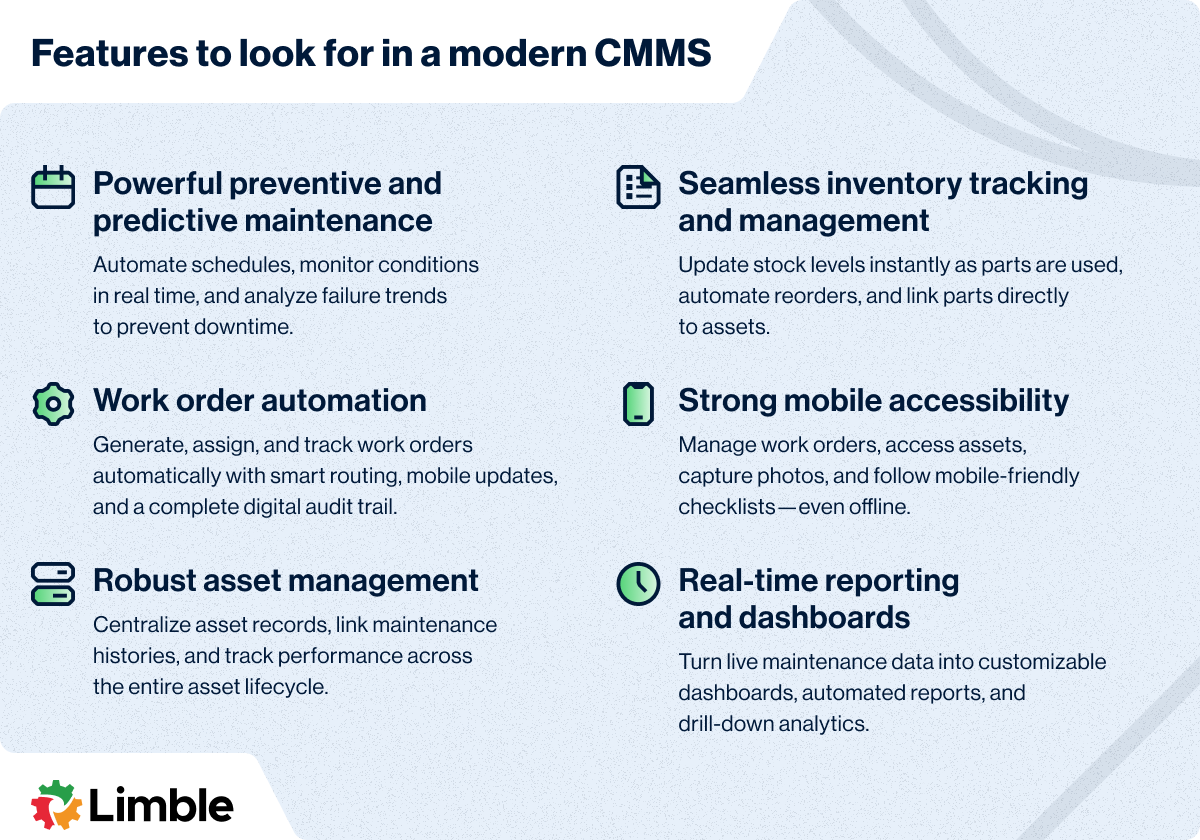

Key features a modern CMMS should include

So far, we have talked about underlying characteristics. Let’s switch gears to something more practical — specific CMMS features you should expect to find in modern software.

1. Powerful preventive and predictive maintenance

It’s no longer just about scheduling tasks on a calendar. A modern system should help you move beyond reactive fixes by enabling both preventive and predictive maintenance.

Key features to look for:

- Automated scheduling: Automatically generate and assign preventive maintenance tasks based on time, usage, or condition.

- Condition monitoring: Collect real-time data from IoT sensors to track equipment performance and anticipate issues.

- Predictive maintenance analytics: Integrate with data analytics platforms to get predictive and prescriptive insights.

- Failure trend analysis and reporting: Identify recurring breakdowns and use data to eliminate root causes.

- Flexible maintenance plans: Create tailored schedules for different asset types to balance workloads and costs.

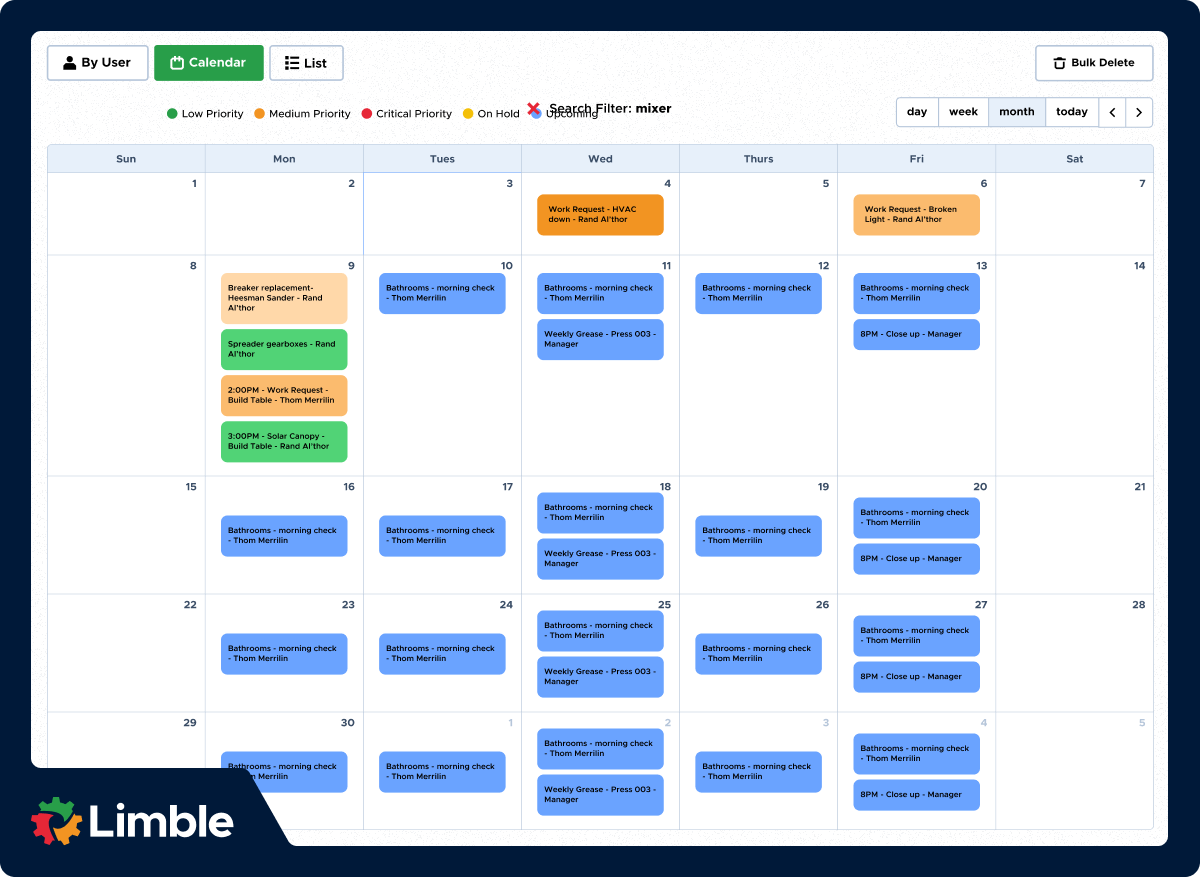

- Visual maintenance calendar: Visualize all maintenance work in a calendar; drag-and-drop tasks to reschedule work.

2. Work order automation

A modern CMMS should make creating and assigning work orders effortless. Not manually. Not after cross-referencing with a spreadsheet. Not after clicking through seven different screens. Automation should do all of the heavy lifting for you.

Key features to look for:

- Automated work order creation: Generate work orders instantly based on preventive schedules, sensor alerts, or user requests.

- Smart assignment rules: Route work orders to the right technician based on skills, availability, or location.

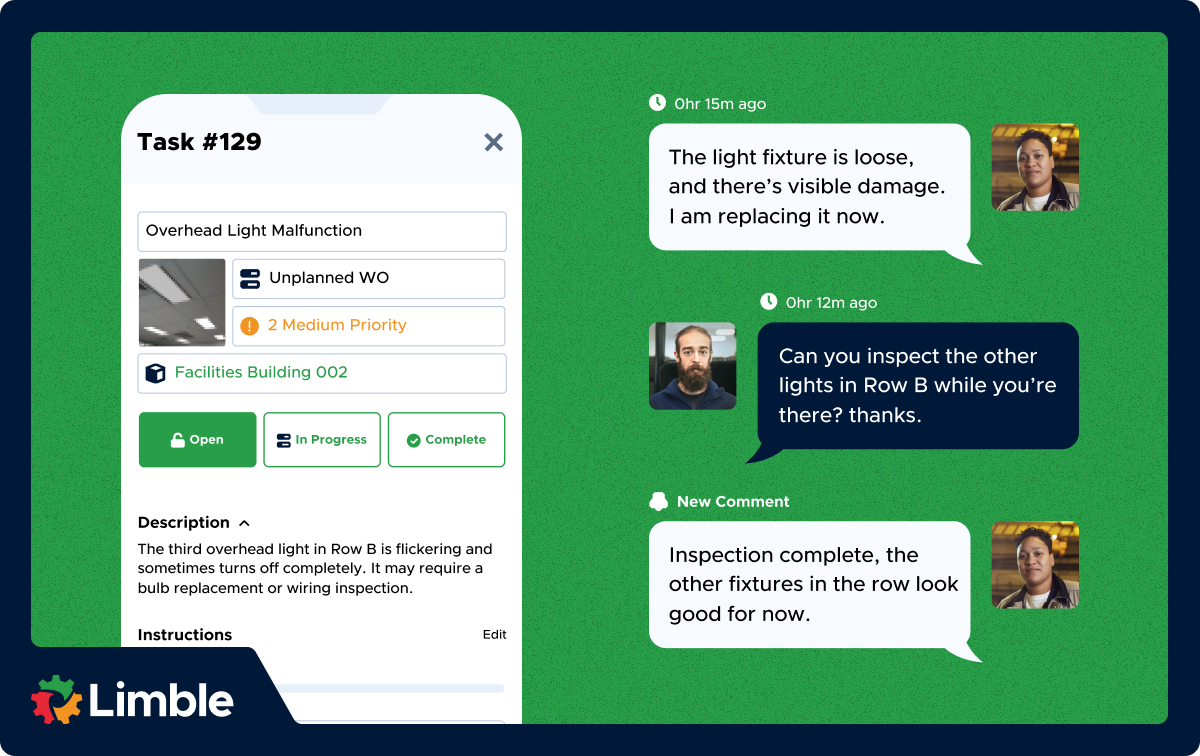

- Mobile work order updates: Let technicians update status, add notes, and attach photos directly from the field.

- Digital audit trail: Keep a complete record of every action taken on each work order for accountability and compliance.

Tip: Be sure the system allows you to customize workflows. A rigid automation process that cannot be adjusted will create more headaches than it solves.

3. Robust asset management

Managing assets effectively means more than just keeping a list of equipment. A modern CMMS should provide a complete, connected view of every asset. This includes history, performance, and cost. That’s how you make smarter decisions about repair, replacement, and optimization.

Key features to look for:

- Centralized asset database: Store detailed records for every asset, from location and manuals to warranties, service history, asset tags, and QR codes.

- Lifecycle tracking: Monitor performance, costs, and downtime across the whole lifespan of each asset.

- Linked maintenance history: Access a complete log of past work orders, inspections, and repairs in one place. Utilize the smart search functionality to quickly find the information you need.

- Hierarchical asset structure: Organize equipment into parent-child relationships for better visibility into complex systems.

4. Seamless inventory tracking and management

Keeping the right parts on hand is critical for minimizing downtime and avoiding costly delays. A modern CMMS should give you full visibility into your spare parts inventory and tie it directly to your maintenance workflows.

Key features to look for:

- Real-time parts tracking: Inventory levels update automatically the moment a WO or a PM task is closed, reflecting exactly what was used and keeping stock levels accurate.

- Automatic reorder points: Trigger purchase requests when inventory falls below set thresholds.

- Linked parts-to-assets: Assign parts to specific assets so technicians always know what they need for a job.

- Vendor and purchase history: Keep a record of past orders, suppliers, and costs to simplify procurement.

Tip: Your CMMS should be able to integrate with your purchasing or ERP system. Without this connection, you risk duplicate records, and you will make life significantly harder for your procurement team.

5. Strong mobile accessibility

Maintenance work happens in the field, not behind a desk. A modern CMMS must provide a full-featured mobile app that allows technicians to communicate and do their jobs as efficiently as possible.

Key features to look for:

- Full work order management: Create, update, and close work orders directly from a phone or tablet.

- Asset and parts lookup: Scan QR codes or barcodes to instantly pull up asset histories and related parts.

- Digital checklists: Standardize work for technicians and operators by building and attaching mobile-friendly checklists to WOs and PMs.

- Offline functionality: Continue working even without internet access, with data syncing once a connection is restored.

- Photo and note capture: Document work with images, voice notes, or typed comments on the spot.

Tip: Don’t settle for a “mobile-friendly” website. Insist on a dedicated app that techs and operators can install on their phone. The app does not need to support all of the features of a desktop version, but should have most.

6. Real-time reporting and dashboards

A modern CMMS turns raw maintenance activity into clear, real-time insights through reports and dashboards. This allows managers and supervisors to track performance, spot problems early, and track KPIs.

Key features to look for:

- Customizable dashboards: Tailor views to show KPIs like downtime, work order completion, and asset costs.

- Live data updates: See metrics update instantly as work orders are created, closed, or modified.

- Automated reporting: Use existing templates or build custom reports that can be sent to different stakeholders on a recurring schedule.

- Drill-down analytics: Move from high-level KPIs into detailed asset or technician-level data with one click.

What is the process to migrate from legacy maintenance systems to a modern CMMS?

Switching from a legacy CMMS to a modern platform is probably the biggest upgrade you can make to your maintenance program. Done right, migration ensures your team doesn’t just move data, but also adopts better processes.

The migration can be time-consuming, but it is pretty straightforward:

- Get buy-in from relevant departments: Involve Maintenance, IT, and Finance early so everyone understands the goals and benefits of the migration.

- Audit your current data: Review existing work orders, asset records, and inventory lists to clean up duplicates, outdated entries, or missing details before migration.

- Define workflows and requirements: Document how you want preventive schedules, work orders, and reporting to function in the new system. This ensures the setup matches your team’s needs.

- Import and configure: Upload cleaned data into the new CMMS, set up user roles, and configure integrations with other systems like ERP or IoT tools.

- Train your team: Provide hands-on training for managers and technicians, with a focus on using the mobile app in day-to-day workflows.

- Launch in phases: Start with a pilot group or a single site before rolling out company-wide. This lets you troubleshoot issues and build momentum.

- Monitor and optimize: After launch, track adoption and performance metrics. Adjust workflows, reports, and automations as you identify opportunities for improvement.

Download our CMMS migration guide if you want to dive deeper and learn best practices from thousands of successful CMMS rollouts.

Is your CMMS built for the future?

The best CMMS systems are easy to use, mobile-first, and built to turn maintenance data into actionable insights. They empower technicians in the field and give managers the clarity they need to make confident decisions.

If your current system feels like more of a roadblock than a tool — hard to use, lacking a real mobile app, and locking up your data in confusing reports — it may be time to see what a truly modern CMMS looks like.

Limble was built on these modern principles to help teams get ahead of failure and boost operational efficiency.

Ready to see the difference? Start by creating your free Limble account.

Modern CMMS FAQs

What are two types of CMMS?

CMMS platforms generally fall into two categories:

- On-premise CMMS: Installed on local servers and managed by your IT team. These systems were the standard for decades but require ongoing maintenance, manual updates, and higher upfront costs.

- Cloud-based CMMS: Delivered as Software-as-a-Service (SaaS). These modern systems are accessible from anywhere, updated automatically, and typically come with mobile apps that make them far easier to adopt and scale.

Most organizations today choose cloud-based CMMS because of its flexibility, lower costs, and ability to integrate with other tools.

What is the typical pricing structure for modern CMMS solutions?

Most modern CMMS platforms use a subscription-based model, usually billed monthly or annually. Pricing typically ranges from $50–$150 per user per month, with higher tiers unlocking advanced features like analytics, integrations, or IoT support. Some vendors also offer flat-rate or asset-based pricing for large operations.

How is a CMMS different from an EAM system?

A CMMS is focused on managing maintenance operations to maximize uptime. An EAM (Enterprise Asset Management) system has a broader scope, covering the entire asset lifecycle from procurement and financial planning to disposal. Learn more in our CMMS vs EAM guide.

What types of industries benefit from a modern CMMS?

Any industry that relies on physical assets or equipment can benefit from a modern CMMS. This includes manufacturing, healthcare, hospitality, utilities, oil and gas, facilities management, logistics, and more. Any organization looking to streamline its maintenance operations and reduce downtime can see significant value.

How does a modern CMMS help with regulatory compliance?

A modern CMMS helps with regulatory compliance by creating a permanent, auditable, time-stamped record of all maintenance work. An auditor needs service records for a specific asset? You can instantly generate a report showing every PM and repair performed, proving compliance with safety and industry standards.