Mean Time Between Failures (MTBF) is more than a maintenance metric—it’s a barometer for how efficiently your organization manages asset reliability, technician time, and long-term operational costs. And as maintenance and manufacturing costs increase, improving MTBF is no longer a nice-to-have. It’s essential.

Limble’s 2024 industry survey revealed that 88% of maintenance professionals have seen rising costs in parts, labor, or downtime, and over 25% are seeing increases in all three. What’s driving that? Tariffs and changing employee costs both play a role but one culprit is much more in the control of operations and maintenance leaders: too much reactive work and not enough visibility into asset performance.

Across our customer community, we’ve seen five proven tactics that directly increase MTBF while helping teams reduce emergency repairs, improve uptime, and gain control over maintenance costs.

1. Make root cause analysis part of the maintenance culture

Recurring failures are often symptoms of a deeper problem rooted in flawed repair processes, missing data, or overlooked design issues. Teams that treat every failure as a learning opportunity, backed by clear data trails, are the ones improving MTBF fastest.

Corey Stone, Processing Manager at Caglia Recycling (read the case study) shared how they transformed a recurring jam issue:

“We were seeing a large rise in jams with the glass breaker. Through downtime analysis in Limble, we narrowed it down to a specific part of the machine. We tore it apart and found a warped spindle causing the jams. After fixing it, performance dramatically improved.”

With fewer unknowns and better documentation, maintenance teams can break the reactive cycle and extend the runtime between breakdowns.

2. Make accountability easy with real-time documentation

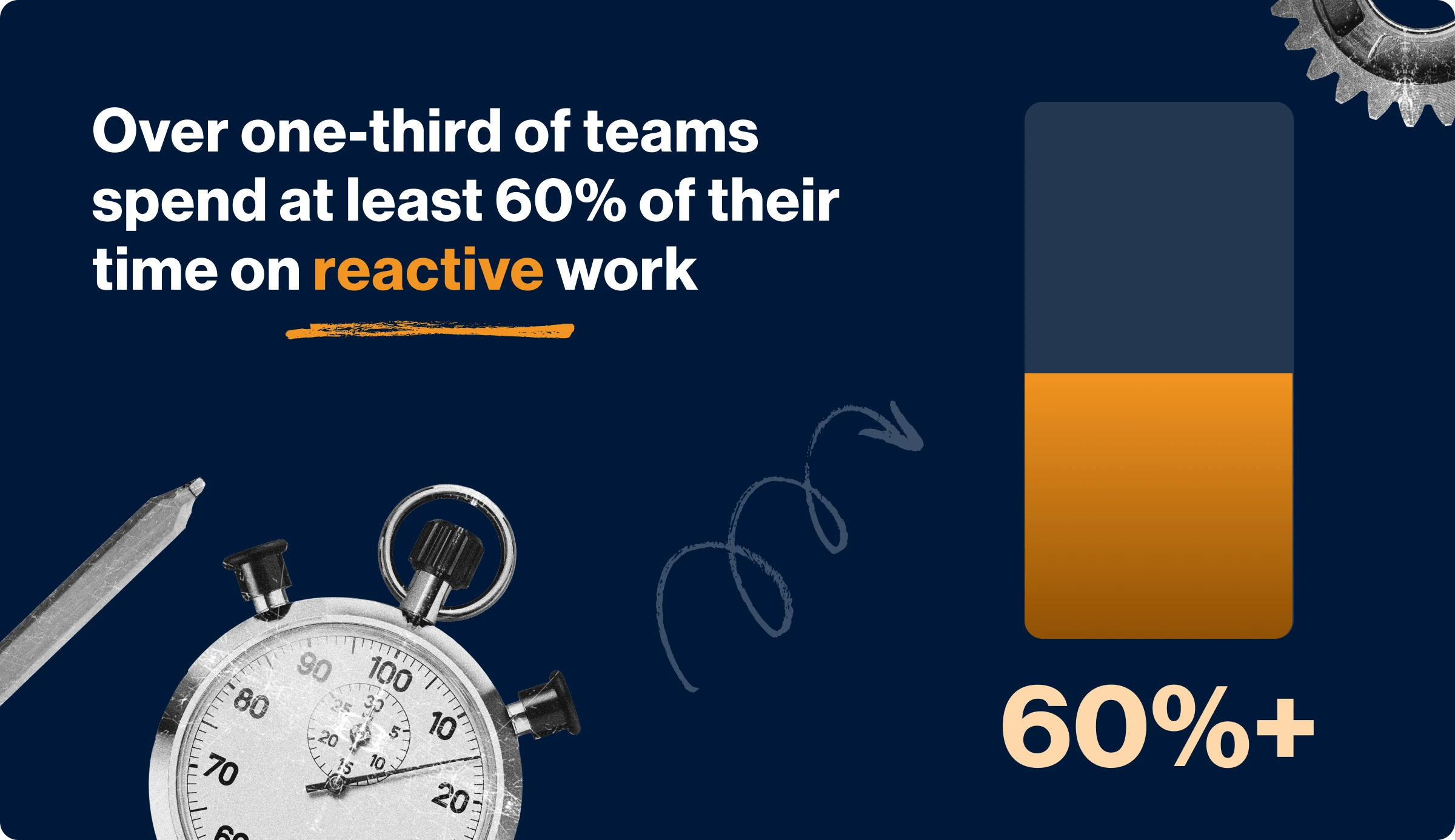

MTBF improvements rely on data, but many organizations still collect that data manually or after the fact. Our survey found that over one-third of teams spend at least 60% of their time on reactive work, often because failure insights are lost in paperwork or delay.

Josh Galer at Island Abbey Nutritionals (read the case study) has explained how switching to real-time mobile documentation changed their workflow:

“The way that the old system would work is that it was printing off a piece of paper that then that pamphlet of papers would be given to a technician each morning and they would have to hand write onto the piece of paper what work they’d done…[With Limble] they could fill the work orders in live… It just took away all of the manual errors and manual entry of data that we did not want to do.”

Simplifying how your team captures maintenance history boosts accountability and builds a reliable foundation for preventive planning.

3. Right-size your preventive maintenance strategy

Over-servicing can waste technician time and introduce unnecessary wear. Our data shows that optimizing PMs is one of the most cost-effective ways to reduce downtime and labor hours without compromising reliability. One food manufacturer helped by using Limble, saw the impact of focusing their efforts on preventive maintenance.

“They were doing weekly PMs, no matter the usage. We helped them shift to usage-based scheduling and they reduced PMs by 30%. And they saw fewer mid-run failures.”

Adapting your PM strategy to real-world asset performance ensures you’re putting effort where it counts—and extending equipment life in the process.

4. Improve inventory visibility to reduce unplanned delays

Nothing tanks MTBF like waiting days for a missing part. Yet over 50% of maintenance teams report running out of critical spares, according to Limble’s survey. That leads to longer downtimes, rush shipping fees, and stalled repair timelines.

Josh Galer at Island Abbey Nutritionals (read the case study) shared a cautionary tale:

“We were down for a week because we didn’t have a particular part… we were losing parts because they wouldn’t always get captured on a piece of paper. That was catastrophic for us.”

Maintaining visibility into stock levels and tying parts directly to work orders is essential for sustaining high MTBF across your operation.

5. Focus resources on the assets that matter most

Trying to manage everything equally spreads your team too thin. High-MTBF teams take a strategic approach: they focus on the assets that drive production and create plans around their criticality, cost, and history.

Micah Crawshaw, Maintenance Coordinator at Panorama Mountain Resort (read the case study), uses asset-level insights to justify smarter investments:

“We now track hours spent on assets… that makes it easier to justify when you need to replace or upgrade something. It forces leadership to plan ahead, not just react when it fails.”

This level of planning ensures that resources are used on the equipment that delivers the most value. Maintenance then becomes a strategic driver, not a cost center.

Final thoughts

With parts, labor, and downtime costs rising, improving MTBF isn’t just about efficiency. It’s about protecting your bottom line. The most effective teams are using data to reduce failure frequency, streamline PM programs, and make smarter decisions about where and when to act.

These five strategies are helping organizations simplify operations, build visibility, and increase asset reliability – all without increasing headcount or spend.

If your team is navigating cost pressure and rising failure rates, these are the places to start.