Choosing a Computerized Maintenance Management System (CMMS) is one of the most important decisions a maintenance leader will make.

The right platform can streamline your operations, cut costs, and keep your team motivated. The wrong one can drain your budget, frustrate technicians, and make you worse off than where you started.

With hundreds of options out there, the process can feel overwhelming. This guide breaks it down into simple, actionable steps. Use it to confidently evaluate and select the right CMMS software for your specific operational needs.

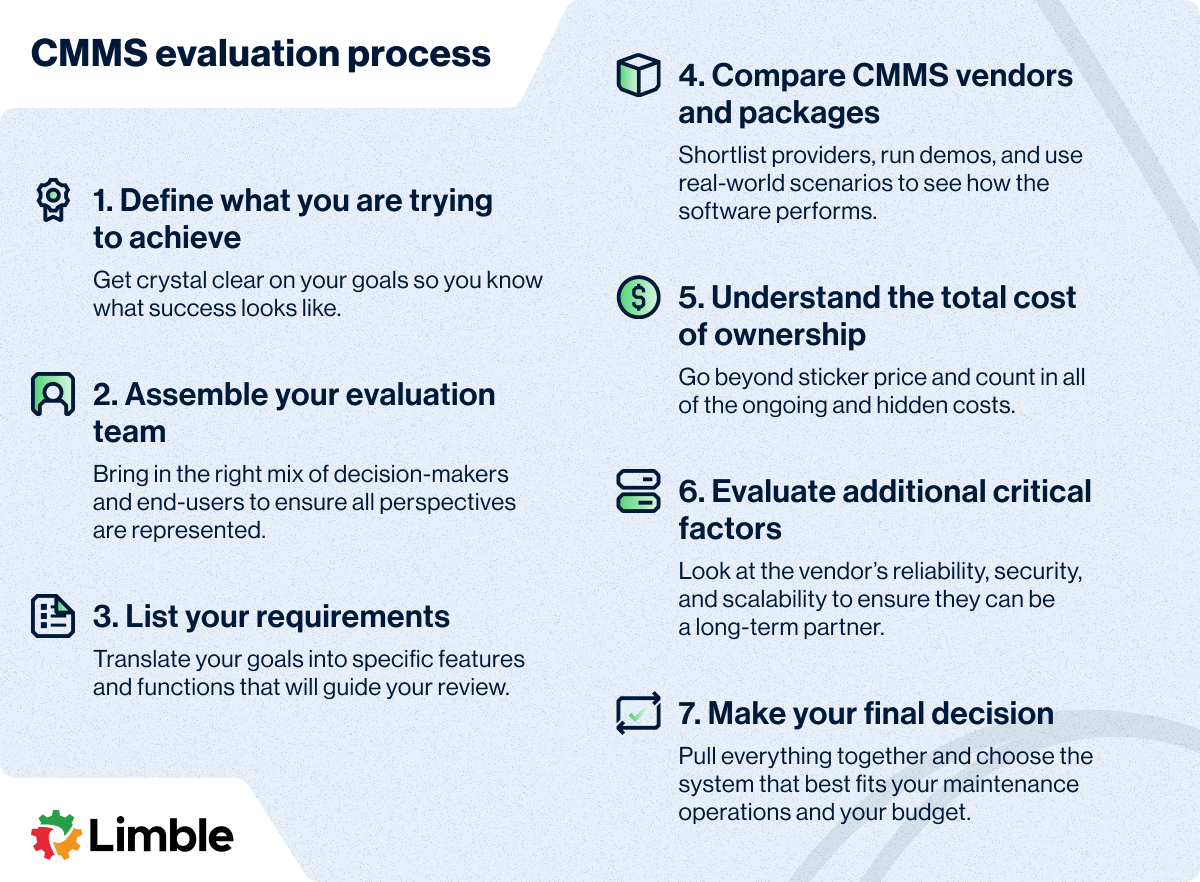

A typical CMMS platform evaluation process

From exact features to ease of use and security considerations, there’s a lot to look at when evaluating a CMMS platform. The good news is that the process can be significantly streamlined — as long as you just approach it in a structured way.

We recommend following these steps:

Step 1: Define what you are trying to achieve

Step 1: Define what you are trying to achieve

Before looking at any CMMS software, you need to know what success looks like for your team. A CMMS is a tool, and tools are only effective when they have a clear purpose.

Gather your team leads and start by answering questions like:

- What problems are we trying to solve?

- What goals are we aiming for in the next 12–24 months?

- How will we measure success once the system is in place?

Your answers might revolve around reducing downtime, extending asset life, cutting down on administrative work, or simply getting better visibility into work orders.

Whatever your priorities are, write them down. And be specific. For example, instead of “decrease downtime,” set a goal like: “reduce unplanned downtime on critical assets by 30% within 12 months.”

This will become the foundation for your evaluation — and later, the checklist you’ll use to see if a CMMS truly delivers what you need.

Avoid this trap: Don’t start by making a long list of features you think you need. This is the #1 mistake teams make. It often leads to paying for advanced CMMS features you’ll never touch — while some of your core business problems remain unsolved.

Step 2: Assemble your evaluation team

Evaluating a CMMS isn’t a one-person job. The system will impact multiple departments, so it’s important to bring the right people into the process from the start.

Here’s who typically gets a set at the table:

- Maintenance managers: They understand the big-picture goals and long-term needs.

- Technicians: They’ll use the system daily, so their input on usability is crucial.

- IT: They’ll help assess integration, security, and technical requirements.

- Finance: They can evaluate budget impact and long-term cost considerations.

- Operations: They’ll provide insight into how maintenance affects production and service delivery.

You’ll want to designate one person to be your project lead. They will be responsible for organizing the evaluation process, keeping the project on schedule, and making sure feedback is collected from all stakeholders.

For everyone else, the role is simple: understand what is expected of you and provide timely input when asked.

Step 3: List your requirements (must-haves vs. nice-to-haves)

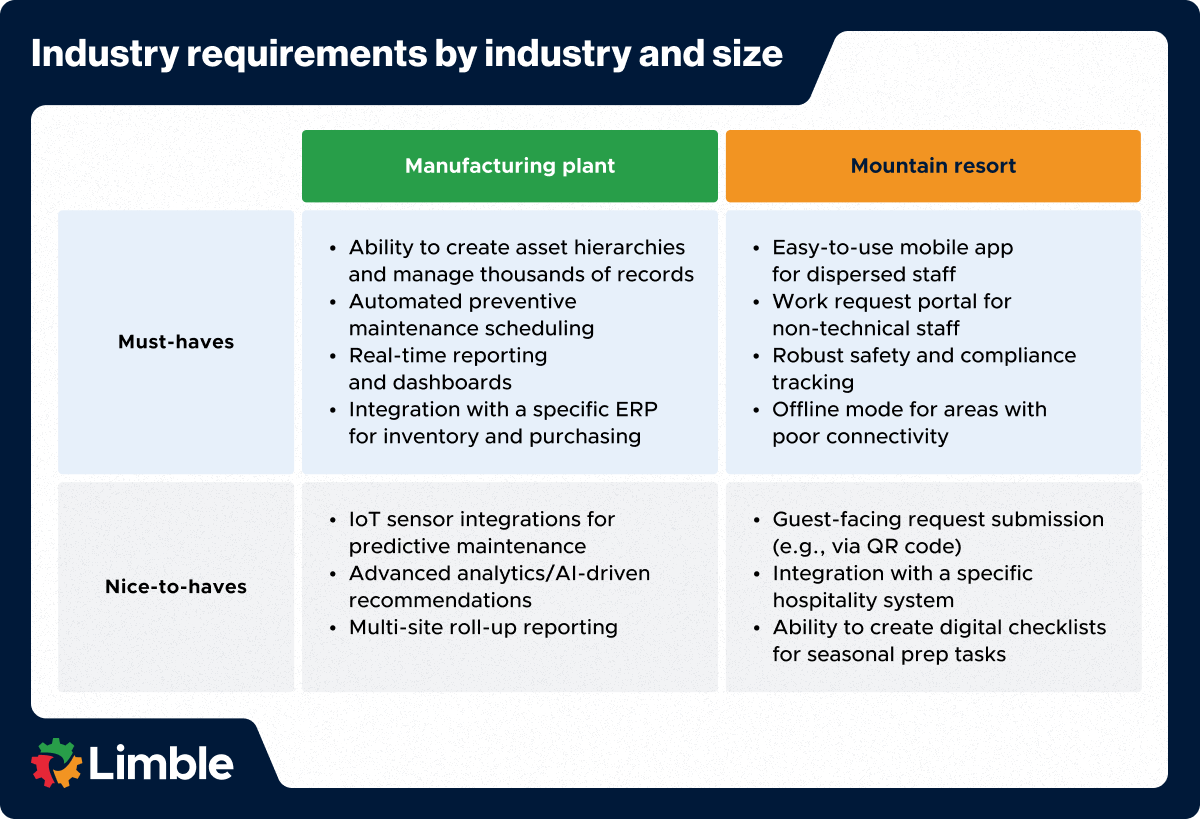

The next step is to look at your objectives, maintenance requirements, and operational needs — and translate them into specific software requirements.

This is about defining exactly what you need the CMMS to do to help you reach your goals. Separating your needs into must-haves and nice-to-haves is one way to simplify the process.

Must-haves are features or capabilities you cannot operate without. If a platform is missing even one, it should be cut from your list. Nice-to-haves are useful additions that could make your daily maintenance tasks easier, but aren’t deal-breakers if absent.

Let’s look at two example organizations to show how requirements can vary by industry and size.

Scenario 1: Large manufacturing plant [INDUSTRIAL MAINTENANCE]

- Size: 1,200 employees, 3 production lines, 10,000+ assets

- Asset types: Production machinery, conveyors, forklifts, HVAC systems

- Primary goals: Reduce unplanned downtime, improve preventive maintenance compliance, and gain real-time visibility into maintenance KPIs

Scenario 2: Mountain resort [FACILITY MANAGEMENT]

- Size: 250 employees, spread across multiple facilities

- Asset types: Guest cabins, ski lifts, snowmaking machines, restaurants, vehicles

- Primary goals: Ensure guest safety, streamline work requests, and extend asset life through preventive maintenance

Your best bet is to identify 3–5 providers that meet all of your must-have requirements from Step 3. Use a mix of independent software review sites (like G2 and Capterra) and vendor websites to build your initial shortlist. The goal isn’t to find every option — it’s to narrow your search to a handful of strong contenders worth deeper evaluation.

Next, schedule demos and see how each solution handles your real-world workflows. To get the most out of this process, don’t sit back for a generic presentation. Instead, provide their sales team with a short script of your common scenarios, such as:

- “Show me how a technician would find an asset, open a work order, and log their time on the mobile app.”

- “Walk me through creating a new PM schedule for a critical piece of equipment.”

- “Show me how I would build an automatic report that tracks our team’s PM compliance rate for the last quarter.”

Pro tip: Create a simple evaluation scorecard to compare vendors against your must-have requirements. Scoring each platform from 1–5 after every demo prevents you from being swayed by a polished presentation and keeps the focus on what actually matters to your operation.

Here is a practical example of a scorecard you could use:

Once demos are complete, you’ll have a clearer picture of which solutions are practical, easy to use, and aligned with your team’s goals.

Once demos are complete, you’ll have a clearer picture of which solutions are practical, easy to use, and aligned with your team’s goals.

However, if the demos aren’t enough, take advantage of free trials or free accounts that most vendors offer. This gives your evaluation team extra time to test the software in real-world conditions and get more hands-on experience.

If you’re up for it, you can jumpstart the evaluation process by opening a free CMMS account at Limble.

Step 5: Understand the total cost of ownership (TCO)

A CMMS’s price is more than just the number on a subscription plan or license agreement. To make a fair comparison — and avoid unpleasant surprises — you need to calculate the Total Cost of Ownership (TCO) over the long term.

Your deployment type will shape the cost structure:

- Cloud-based CMMS: Typically subscription-based (monthly or annual) and treated as an operational expense (OpEx). These plans usually bundle in software access, updates, security, and customer support, making costs predictable.

- On-premise CMMS: Usually purchased through a perpetual license and treated as a capital expense (CapEx). While you “own” the software, you’re responsible for paying extra for updates, annual support contracts, an internal IT team, and the server infrastructure needed to host it.

When reviewing quotes, make sure you ask about all potential expenses. Use a checklist like this to keep things transparent across vendors:

- Software subscription or license fees: The core cost of the software itself.

- CMMS implementation and onboarding fees: These often cover setup, configuration, and data migration.

- Training costs: Initial training for your team, plus training for future hires.

- Ongoing support fees: They can be included in the subscription or sold as an extra annual contract.

- Customization: Will you need any additional development to create custom workflows or integrations with existing software? This can be very expensive.

- Hardware costs: Servers or devices required for on-premise installations (if you decide to go this way). Possibly mobile devices if technicians do not have them already, but need mobile access.

Taking the time to map out these costs ensures you’re comparing solutions on a level playing field.

Tip: Some vendors offer calculators you can use to estimate costs or get a custom quote. Check out Limble’s pricing calculator if you want to give this a try.

Step 6: Evaluate the vendor as a partner

The final step is to look beyond the software itself and evaluate the vendor as a long-term partner. A great product backed by a reliable company is what makes a CMMS investment successful over the long haul.

Here are the key factors to weigh:

- Data security: Ask about security protocols, encryption, and backup procedures. If you operate in a regulated industry, confirm compliance with standards like SOC 2 or ISO 27001.

- Ease of use: Even the most powerful CMMS fails if people don’t adopt it. Confirm the interface is intuitive and that technicians can get up to speed quickly.

- Scalability: Can the platform grow with you? Look for flexibility in adding new facilities, users, or advanced modules without breaking your budget.

- Vendor stability: Consider the company’s track record. Are they established, financially stable, and actively investing in product improvements?

- Customer support quality: A strong support team can make or break your experience. Check support channels (chat, phone, email), and whether support is included or an extra cost. Usually, you will want a dedicated account manager you can reach out to.

Evaluating these factors helps you avoid “paper-perfect” solutions that look great in demos but fall short in day-to-day use.

With all this information in hand — your goals, requirements, vendor scorecards, costs, and critical factors — you’re ready for the final step.

Making your final decision

Choosing a CMMS is a critical decision, but it doesn’t have to be complicated. Having a structured process will help you cut through the marketing noise and focus on features and usability that will make a difference for your operation.

If your evaluation has highlighted ease of use, a powerful mobile app, and a strong preventive maintenance engine as top priorities, we’d love to show you what Limble can do. Schedule a personalized demo to see how we can help you achieve your maintenance goals.

FAQs about CMMS solution evaluations

What are the most common mistakes to avoid when evaluating a CMMS?

The most common mistake is focusing on a long list of features instead of the core usability for your team members. This often leads to choosing a system that looks impressive on paper but doesn’t actually solve your core problems.

Other common pitfalls include:

- Involving too few stakeholders, which creates blind spots during evaluation.

- Ignoring the total cost of ownership and getting caught off guard by hidden expenses.

- Relying only on scripted demos without testing the software through free trials or pilot programs.

- Underestimating the importance of ease of use, which can lead to poor adoption.

How do I calculate the potential ROI of a new CMMS?

You can estimate ROI by focusing on how the software will impact your core business metrics. Start by calculating potential cost savings from reduced equipment downtime and lower overall maintenance expenses. Then, factor in additional savings from better spare parts management — less money tied up in excess inventory and fewer emergency orders.

When you compare these savings against the total cost of ownership, you’ll have a realistic picture of your potential return.

Should I be evaluating an EAM system instead of a CMMS?

It depends on your goals. If you want to automate and optimize the day-to-day work of your maintenance team — work order management, preventive maintenance scheduling, and tracking spare parts — a CMMS is the right tool. If you need to manage the entire financial lifecycle of assets from procurement to disposal, then an Enterprise Asset Management (EAM) system is likely the better fit.

What is the best CMMS software?

The best CMMS is the one that fits your specific maintenance processes and goals. Instead of looking for a universal “best platform”, focus on which software aligns with your needs. Top solutions excel at core functionalities like asset tracking to monitor the entire asset lifecycle and provide real-time data through dashboards. This data is critical for optimizing your maintenance strategies over time.