Downtime is the most expensive problem in manufacturing. Every hour a critical asset is offline leads to lost production, missed deadlines, and wasted labor — costing manufacturers between $39k and 1.3 million

The good news? Most downtime isn’t random. With the right systems, strategies, and tools in place, you can systematically reduce downtime instead of just reacting to it.

In this guide, we’ll walk through six tried-and-tested strategies that help maintenance and production teams work together to reduce both planned and unplanned downtime.

1. Actively track downtime events

To make targeted improvements and reduce downtime, maintenance and reliability teams need timely, accurate, and consistent information about every downtime event.

The only way to ensure that is to start collecting detailed downtime data. While this can be done manually, using a CMMS or other automated system is the most reliable way to ensure data consistency and accuracy on a large scale.

For each downtime occurrence, try to capture:

- The exact duration of the event

- The specific machine or process area affected

- The product being run at the time

- The shift or crew on duty

- A clear, symptom-based reason for the failure (e.g., “Jammed conveyor belt”)

Tip: Start with a predefined list of downtime categories (equipment failure, material shortage, operator error, etc.) to get clean data. This ensures that technicians and operators use consistent terminology when reporting downtime.

2. Implement proactive maintenance strategies

If you want to reduce unplanned downtime, the most effective (and obvious) step you can take is to shift from reactive to proactive maintenance.

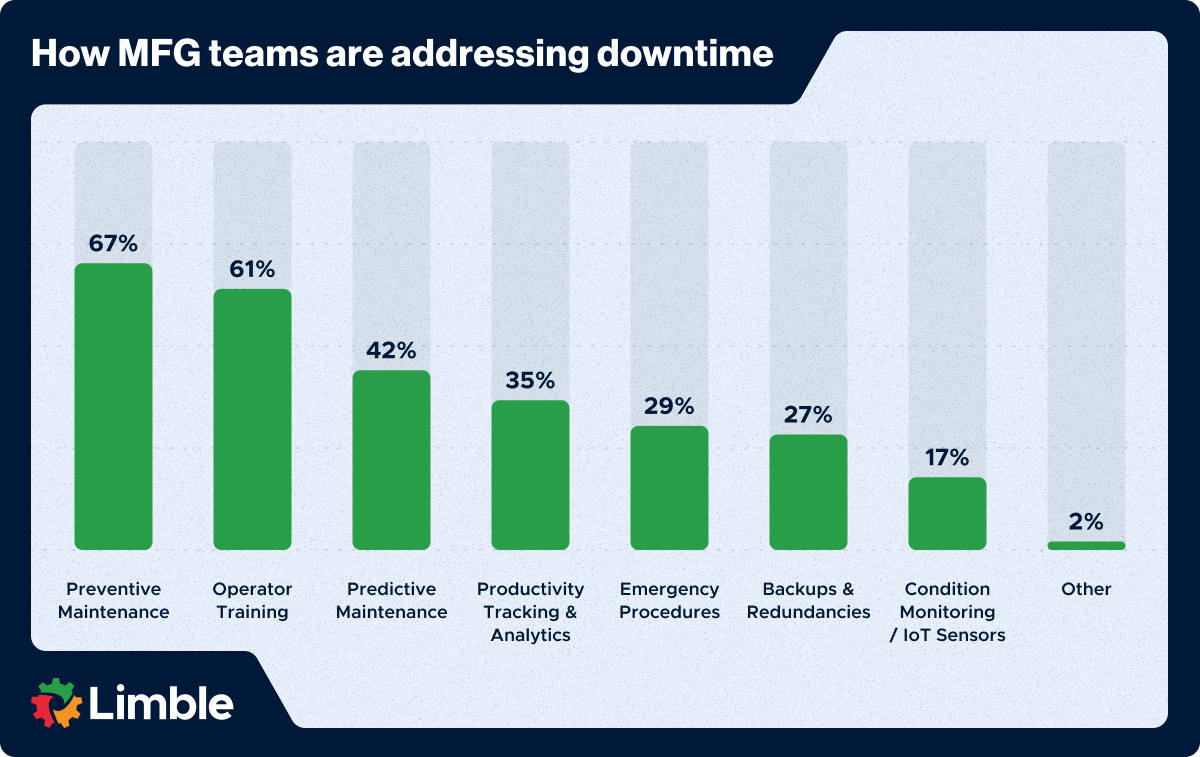

Alongside operator training, our 2024 Maintenance Industry report shows that this is the most popular way manufacturing teams are addressing downtime.

Do not get misled into thinking that there is a universally best maintenance strategy. Successful maintenance teams use a mix of proactive strategies, depending on the criticality, age, and complexity of their assets:

- Preventive maintenance: Scheduled tasks like inspections, cleaning, and lubrication. Best suited for non-critical assets or equipment with simple, well-understood failure modes.

- Condition-based maintenance (CBM): Triggered by real-time indicators like vibration, pressure, or temperature. Ideal for assets where failure conditions are easy to monitor and don’t require predictive modeling.

- Predictive maintenance (PdM): Uses IoT sensor data and analytics to forecast failures. Best for high-value or high-risk assets where unexpected machine downtime has a major impact on safety or production.

- Prescriptive maintenance (RxM): Goes a step further by using AI to recommend the best response when a potential issue is detected. Most useful for complex, critical assets with expensive failure modes and multiple repair options.

If you are still deep in the “fix-it-when-it-breaks” model, use a CMMS to start scheduling more PMs, centralize asset history, and begin tracking failure reasons. Once your team becomes accustomed to the new workflow and adopts a proactive mindset, you can start incorporating more advanced strategies listed above.

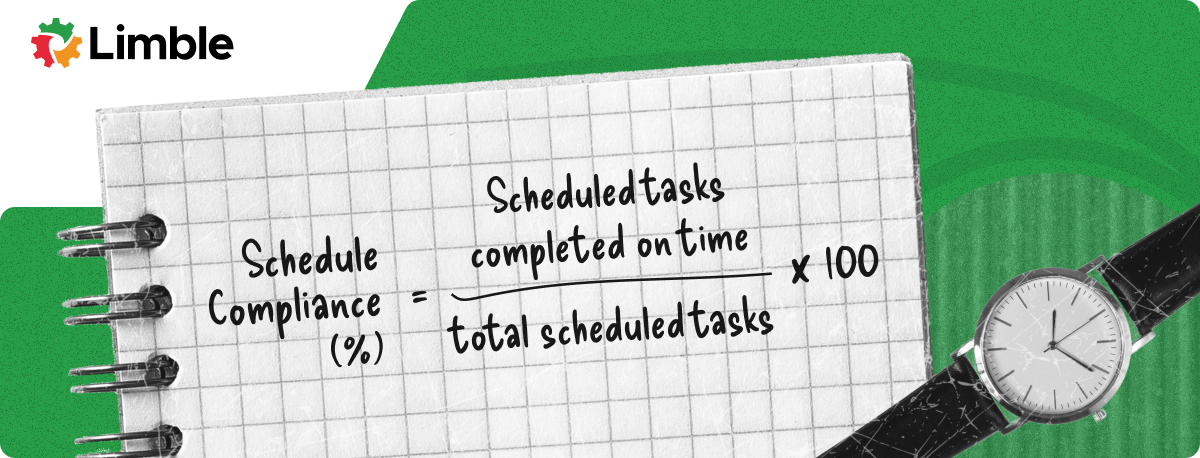

3. Improve PM schedule compliance

A well-built PM schedule only delivers results if the work actually gets done as planned. When tasks are delayed, skipped, or rushed, the risk of equipment failure increases — and so does unplanned downtime.

Improving PM schedule compliance ensures that your maintenance program delivers the reliability and performance it was designed for.

Here are a few ways to boost on-time completion rates:

- Keep workloads realistic so technicians aren’t overloaded.

- Prioritize PMs based on asset criticality and condition, not just calendar dates.

- Automate reminders and assignments using your CMMS.

- Give technicians mobile access to SOPs and checklists so they can efficiently complete tasks in the field.

- Review open work orders regularly to identify and address the increasing backlog.

- Track delay reasons for each postponed PM.

- Track schedule compliance as a KPI to monitor progress and accountability.

Want to dive deeper? Check out our full guide on how to improve PM schedule compliance for more practical strategies and examples.

4. Optimize production processes

Reducing downtime isn’t just about maintenance; it’s also about how the equipment is operated day-to-day. By optimizing your production processes and empowering your operators, you can prevent many of the issues that lead to equipment failure and line stoppages.

There are many different improvements you can make here:

- Monitor production in real time: Give operators the visibility they need to catch problems early. Use automated alerts and digital dashboards to display live process trends (equipment status, cycle/takt time, speed, etc.) at workstations. This allows operators to spot deviations as early as possible.

- Improve production line flow: Bottlenecks and backpressure — especially on conveyor systems — can lead to jams, damaged goods, and equipment strain. Consider adding pressureless accumulation tables or other buffering systems to smooth transitions between stages and reduce turbulence.

- Streamline product changeovers: Frequent product changes can lead to extended planned downtime. Implement modular, flexible equipment setups that reduce adjustment time and help your team switch over quickly without sacrificing quality or consistency.

- Standardize and mark optimal equipment settings: Identify ideal machine settings for speed, pressure, and other variables — and mark them clearly on the equipment. This prevents operators from making unnecessary tweaks that can destabilize the manufacturing process and lead to avoidable downtime.

- Run scheduled maintenance blitzes: A maintenance blitz is a focused, high-intensity effort to complete a large number of maintenance tasks in a short period — often during a planned shutdown or slow production window. Use these blitzes to clear backlogs, perform deep preventive maintenance, or prepare equipment for peak production seasons.

- Hold hourly standup reviews: Use a simplified version of Short Interval Control by running quick, five-minute meetings at the beginning of each shift. Review the biggest downtime event from the previous day and choose one improvement to focus on for the next. This creates a continuous, real-time feedback loop that drives rapid problem-solving.

Maintenance and operations teams must work together to optimize how equipment is used. It’s a great way to reduce stress on your assets and extend the time between failures.

5. Invest in your maintenance team

Your most valuable asset in the fight against downtime isn’t a machine — it’s your people. However, they need to have the right skills and tools for the job at hand.

Maintenance training should go beyond basic operation and include best practices, troubleshooting tips, and equipment-specific guidance.

To reduce disruptions, implement upskilling and cross-training programs for both technicians and operators. This improves the chances that equipment can be serviced quickly, no matter who is on shift.

Lastly, you’ll want to define clear roles and responsibilities. Everyone on the team should know exactly how they contribute to reducing downtime. For example:

- Managers lead improvement programs, define success metrics, and ensure the team has the right tools and resources.

- Supervisors maintain downtime codes, run maintenance blitzes, lead daily standups, and follow up on corrective actions.

- Technicians perform advanced troubleshooting, carry out scheduled work, and write helpful completion notes when closing out work orders.

- Operators capture accurate downtime reasons, respond to alarms, verify optimal equipment settings, and implement quick-fix actions when safe to do so.

When every person knows their role, has the right tools, and is given the trust and training to act, your downtime numbers are bound to drop.

6. Chip away at downtime systematically

Reducing downtime is a part of continuous improvement. To ensure your efforts are sustainable, it’s crucial to use structured, repeatable methodologies.

Use the DMAIC process to analyze and reduce downtime

A core tool in lean manufacturing, DMAIC provides a five-step, data-driven approach to solving downtime issues with precision:

- Define: Clearly outline what qualifies as a downtime event. Build a shared understanding across teams. Brainstorm a comprehensive list of both planned and unplanned downtime reasons.

- Measure: Capture the “who, what, when, where, and why” of each event. This is the same structured data collection covered in Strategy 1, supported by your CMMS.

- Analyze: Use tools like Pareto charts or fishbone diagrams to identify which issues have the biggest impact. Go beyond duration — consider safety risks, material waste, and incurred costs.

- Improve: Brainstorm solutions to address root causes. This might include adjusting inspection intervals, updating PM checklists, retraining staff, or redesigning high-failure components.

- Control: Monitor your improvements over time. Create SOPs, assign task ownership, and use your CMMS to ensure new processes are followed consistently.

DMAIC gives your team a clear framework to work within — turning data into action and action into permanent results.

Perform regular root cause analysis (RCA) to eliminate downtime causes

Equipment failures are a common cause of production downtime. This is why your reliability team needs to take a close look at your most problematic assets and identify the underlying reasons they keep failing.

To be effective, RCA should be:

- Timely (conducted soon after a failure)

- Collaborative (involve technicians, operators, and supervisors)

- Documented and repeatable (so insights aren’t lost over time)

There are various root cause analysis techniques that can be used to get the job done. However, they all benefit from having accurate historical equipment and failure data that is easily accessible — yet another reason to have a CMMS.

Additional tips for reducing manufacturing downtime

Beyond the core strategies, there are many other actions you can take to protect uptime and improve your facility’s long-term reliability:

- Perform regular equipment risk audits: Take a proactive look at all your assets. Identify obsolete equipment that’s hard to repair, lacks available spare parts, or poses a safety risk. In many cases, replacing a high-risk machine is more cost-effective than continuing to fix it after each failure.

- Consider Total Productive Maintenance (TPM): TPM empowers operators to take ownership of basic maintenance on their machines. It also includes structured processes designed to eliminate the Six Big Losses (like unplanned downtime, changeovers, and minor stops) and build a path toward zero breakdowns.

- Make downtime highly visible: When a line goes down, everyone should know it. Use clear visual signals — like lights, screen alerts, or status boards.

- Distinguish between quick fixes and long-term solutions: Not every issue requires root cause analysis. Train your team to decide whether a situation calls for a “quick fix” to restore flow or a “100-year fix” that needs engineering input.

- Treat downtime as a key performance indicator: Make downtime metrics visible and meaningful. Use real-time dashboards or scoreboards to show operators and technicians how their actions affect uptime.

- Calculate the true cost of downtime: To get leadership buy-in for maintenance investments, learn how to speak money. Include not just lost production, but also labor costs, overtime, expedited parts, and missed opportunities. Knowing your hourly downtime cost makes it easier to justify the budget for prevention.

- Track the bigger picture with OEE: Downtime is only part of the story. Use Overall Equipment Effectiveness to capture losses from availability, performance, and quality. For an even deeper view, consider Total Effective Equipment Performance (TEEP) to measure capacity utilization across all available time.

- Standardize every improvement: When your team finds a better way to work, don’t let it disappear. Document it as standardized work (SOPs, checklists, etc.) so others can repeat it consistently. This ensures best practices become shared practices.

At the end of the day, reducing downtime in manufacturing isn’t about one big fix — it’s about layering small, smart actions that build long-term reliability.

Take control of your downtime with Limble

The strategies in this guide give you a clear path to reducing downtime — but to put them into action, you need the right tools. Managing maintenance using spreadsheets and paper work orders makes it nearly impossible to stay proactive.

That’s where Limble comes in.

Limble is built to help manufacturing maintenance teams like yours move from reactive chaos to proactive control. With our platform, you can easily apply the strategies you just read — and get the visibility and efficiency needed to reduce downtime on your plant floor.

Here is how Limble helps you take control:

- Build a rock-solid proactive maintenance program. Effortlessly schedule, assign, and track preventive maintenance tasks. Leverage your own asset data to support predictive maintenance and get ahead of failures before they cause downtime.

- Automate your downtime tracking. Make it easy for your team to log downtime events accurately. Limble automatically calculates key metrics like MTTR and MTBF, turning raw data into actionable insights.

- Empower your team on the floor. With Limble’s top-rated mobile app, technicians have everything they need at their fingertips. They can access work orders, view standardized procedures, and log issues instantly, right from their mobile device.

Don’t stay stuck in a cycle of endless repairs. Start your free trial and join the thousands of maintenance teams that use Limble to reduce downtime, streamline workflows, and take complete control of their operations.

FAQs

What is downtime?

Downtime is any period when a machine, production line, or entire facility is not in operation and producing goods. It is the opposite of uptime. Downtime can be broken down into two main categories: planned and unplanned.

What is planned downtime?

Planned downtime is a deliberate and scheduled interruption of production to perform necessary activities. Because it is scheduled, it can be managed to minimize its impact on overall operations.

Common reasons for planned downtime include:

- Preventive maintenance: Performing routine inspections, cleanings, lubrications, and part replacements to keep equipment in optimal condition.

- Upgrades and installations: Installing new equipment, software, or system upgrades.

- Changeovers: Retooling a production line to switch from one product to another.

- Scheduled calibrations and testing: Performing quality checks to ensure equipment is operating to specification.

What is unplanned downtime?

Unplanned downtime is an unexpected stoppage in production caused by an unforeseen event. It is the most disruptive and costly type of downtime because it occurs without warning, leading to production losses, schedule delays, and often, expensive emergency repairs.

Common causes of unplanned downtime include:

- Equipment failure: A machine or critical component breaks down unexpectedly.

- Operator error: Mistakes made during operation that cause a shutdown.

- Material shortages: Running out of raw materials needed for production.

- Power outages: Loss of electricity to the facility or key equipment.

How do you calculate downtime?

Downtime is typically calculated as the total time a machine or process is not operating during scheduled production hours.

Downtime % = (Downtime minutes ÷ Total scheduled production minutes) × 100

You can also track downtime frequency, mean time between failures (MTBF), and mean time to repair (MTTR) to better understand performance over time.