-

Reduce downtime

Achieve significant cost savings with a proactive, preventive maintenance strategy and move fast when emergencies do happen.

LEARN MORE -

Increase productivity

Prioritize and complete work orders faster with efficient, collaborative software your team will love using.

LEARN MORE -

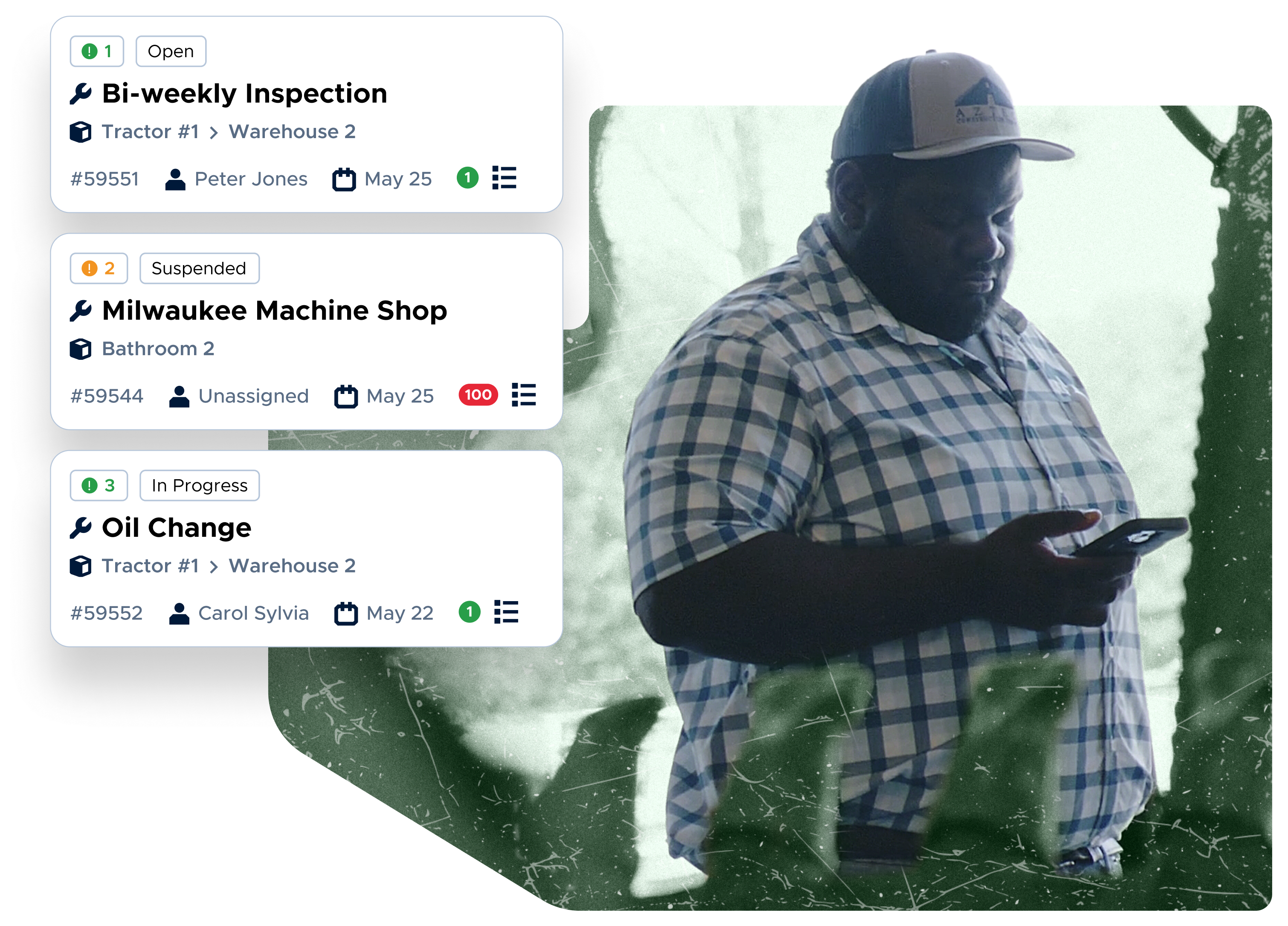

See every work order

Track open and historical work orders for full compliance, easier audits, and complete visibility into tasks at the individual staff level.

LEARN MORE

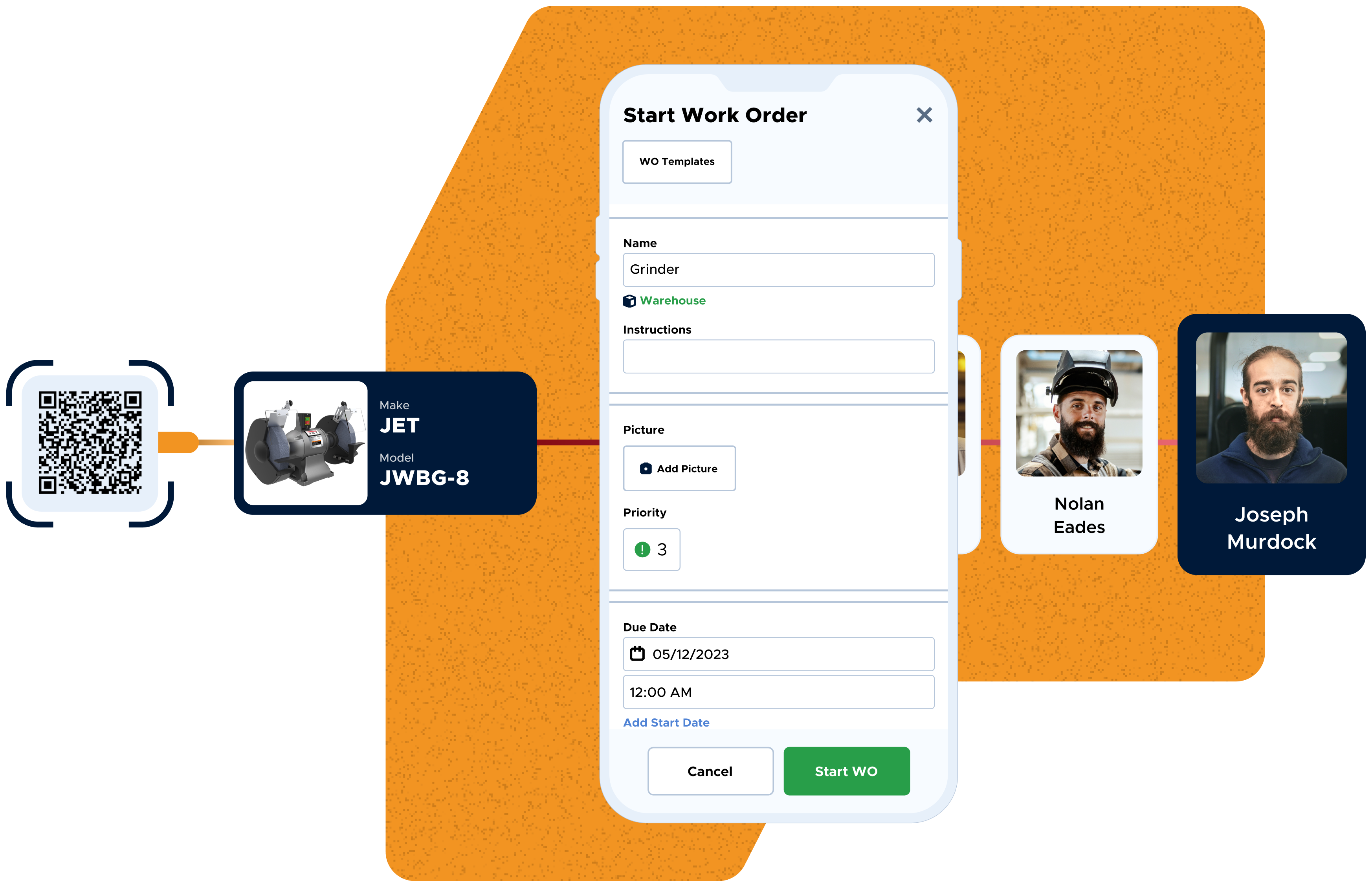

Set up a self-serve work request portal

Make it easier for people to request something from maintenance, whether they’re on-site or working remotely.

Personalize Your Preferences

Customize your portal by setting up the fields you’ll need for requests.

Publish and Share

Now you’re ready to receive and manage work requests with just a scan of the QR code - no app required.

The ability to get your maintenance scheduled and view it in a week or month outlook has helped us keep up with all the maintenance that needs to be done. The reporting gives more visibility to the work we do.

Sam Livingstone Maintenance Mechanic VIEW CASE STUDYLimble makes work order management easy and efficient.

Learn how with a personalized demo from our team.

Maintenance Work Order Software FAQs

What is a maintenance work order?

A work order is a formal authorization for a specific task or set of tasks, crucial for equipment maintenance, repairs, or operational needs. It acts as a central document within the management process, detailing the job scope, required materials, assigned team members, priority, deadlines, and often links to maintenance history for comprehensive tracking and execution.

What are the most important maintenance work order software features?

Important functionality of work order management software includes:

- Work order service requests: Simplify the submission and management of service requests with easy-to-use request forms, allowing users to create and track work orders efficiently.

- Work order creation and tracking: Streamline the creation, assignment, and real-time work order tracking, with customizable checklists and automated notifications.

- Maintenance scheduling and prioritization: Automate preventive maintenance scheduling and prioritize tasks effectively to optimize workflows.

- Mobile access: Empower teams, including field service workers, to manage work order statuses and updates remotely via mobile devices.

- Reporting and analytics: Configurable dashboards to monitor KPIs, costs, and performance metrics, providing actionable insights to enhance work order management and prepare for audits.

- Asset and inventory management: Link work orders directly to assets and parts inventory, reducing bottlenecks, managing spare parts, and improving resource allocation.

Who uses maintenance work order software?

Work order management systems, often integrated with maintenance software, are used by professionals across various industries—including manufacturing, healthcare, education, and energy—to streamline maintenance management and improve operational efficiency.

- Facility Managers: To track progress on facility maintenance tasks, repairs, and asset upkeep.

- Property Management Professionals: To coordinate repairs and upkeep across properties.

- Maintenance Teams: To manage maintenance work orders efficiently.

- Operations Managers: To ensure smooth workflows and minimize downtime.

- Asset Managers: To track the lifecycle of equipment and plan maintenance operations.

- Technicians: To access real-time updates, complete tasks, and report outcomes.

Does Limble have a mobile work order app?

Absolutely. Limble offers the industry’s #1 rated, easiest-to-use mobile CMMS app, designed specifically for technicians on the go. It puts everything your team needs right in their pocket – they can scan asset QR codes to instantly view history or start a work order request, receive real-time notifications, attach photos directly to tasks for clarity, and update job statuses in seconds. It’s built for the realities of field work, boosting efficiency from anywhere.

Learn more about our mobile app.

Is Limble able to integrate with other system?

Yes, Limble’s computerized maintenance management system (CMMS) is designed for integration. It can connect with ERP systems, IoT devices, and other software systems. This allows for seamless data flow, enabling real-time asset health monitoring for predictive maintenance strategies, automated parts procurement based on work order needs, and better overall financial tracking related to maintenance activities. Learn more about our integrations.

Can Limble manage different types of maintenance work orders?

Yes, Limble is built to handle the full spectrum of maintenance work:

- Preventive maintenance: Easily schedule recurring tasks based on time, meter readings, or events using our robust preventive maintenance scheduling features.

- Corrective maintenance: Quickly create and assign work orders for unexpected breakdowns or repairs identified during inspections.

- Emergency maintenance: Prioritize urgent tasks to ensure rapid response and minimize downtime.

- Maintenance inspections: Set up routine inspection routes and checklists.

Is Limble suitable for both small teams and large enterprises?

Limble is a scalable software solution. It’s simple enough for small businesses to adopt quickly but powerful enough to manage complex operations across multiple sites for larger organizations. Our flexible pricing and feature tiers allow you to choose the plan that fits your current needs and grows with you.

How easy is it to set up Limble and get my team started?

Limble is designed for rapid setup, often taking just hours, not weeks. Our user-friendly interface requires minimal training, and we offer resources like video tutorials, help articles, and dedicated support to ensure your team can start managing work orders quickly. We also provide options for importing existing asset and maintenance data to streamline the transition.