What is a CMMS?

CMMS Software Explained: Benefits, Features & Selection Guide

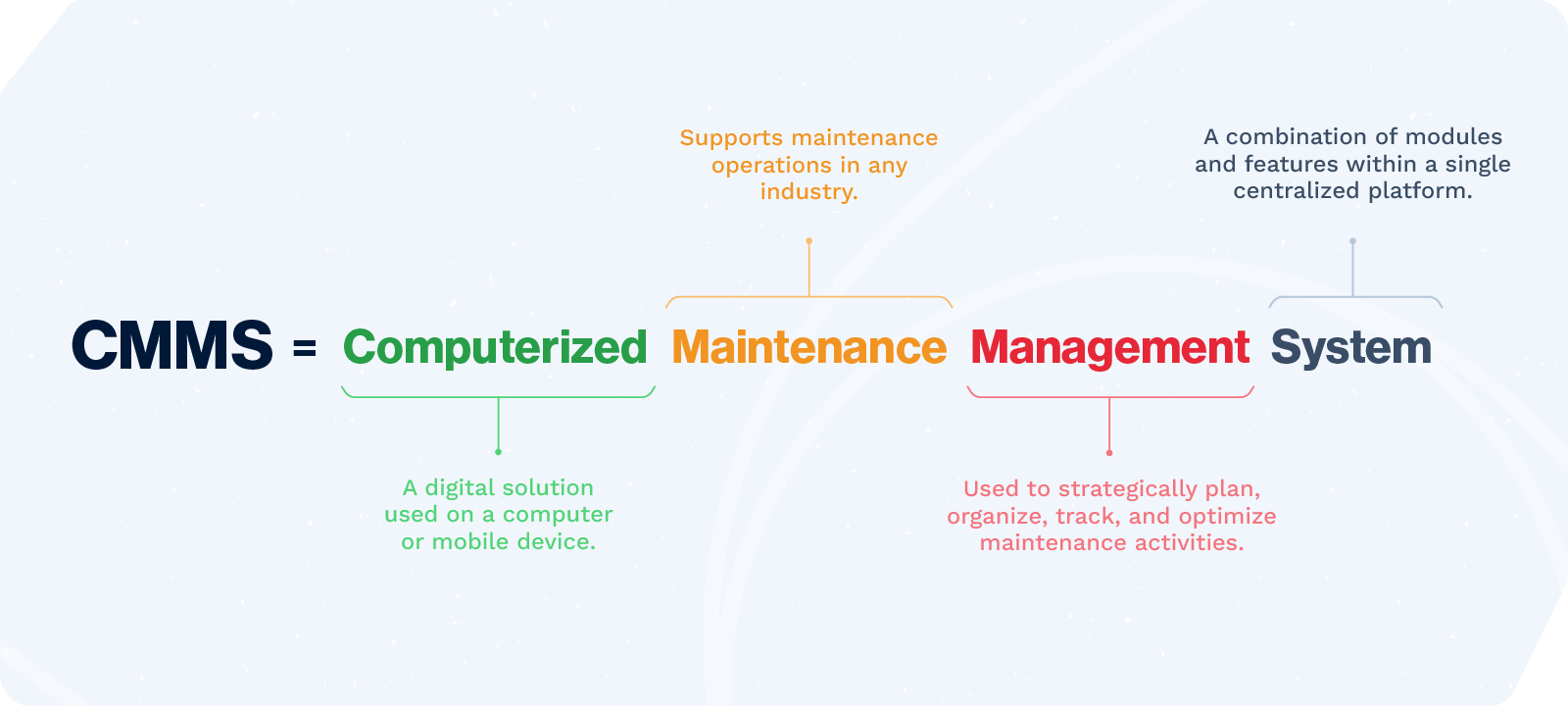

What is a Computerized Maintenance Management System (CMMS)?

A Computerized Maintenance Management System (CMMS) is software that helps businesses efficiently manage and coordinate maintenance operations.

Table of Contents

- CMMS Software Explained: Benefits, Features & Selection Guide

- What is a Computerized Maintenance Management System (CMMS)?

- Types of maintenance management software

- Industries that use CMMS/Who uses CMMS software

- Benefits of CMMS platforms

- How to make the transition to a CMMS

- Getting the most out of your CMMS

- FAQ

- Related Content

What does a CMMS do?

CMMS software can automate documentation and scheduling of maintenance tasks, provide technicians with easy access to information like maintenance histories, manuals, and checklists, and simplify the management of work orders and work requests for managers. They typically also include chat or communications functions that connect team members and reporting and dashboard capabilities for easier oversight of team activities.

In addition, most modern CMMS solutions come in the form of a dedicated mobile app that allows its features to be used from anywhere with an internet connection.

Download our Free CMMS Buyer's Guide!

Learn the questions to ask and the features to look for during the CMMS selection process - and find the right CMMS for you.

How does a CMMS work

By building a digital repository of maintenance information that can be used while work is completed, CMMS systems allow maintenance teams to perform more effective repairs and eliminate administrative tasks. Work orders can be received, opened, and completed – with the assistance of asset manuals and checklists – from wherever the technician is doing the work. Managers can assign tasks and manage team member workloads from one platform.

By eliminating the need to search for physical manuals or travel back to a central office to log activities, a CMMS both simplifies and improves the work of a maintenance team.

Functions a CMMS should have

Maintenance management software is a growing and quickly evolving technology. Different solutions will have their unique attributes and areas where they excel, but they will all offer many of the same core CMMS features and functions, such as:

- Spare parts inventory management

- Work order management

- Work request platform

- Dashboards and reporting

- Preventive maintenance scheduling

- Asset management

- Mobile CMMS app

- Sensor integrations that enable advanced maintenance strategies such as predictive and prescriptive maintenance and beyond

History of CMMS software

The foundations of CMMS technology originate with large enterprises, punch cards, and mainframe computers in the 1960s. These tools documented and tracked maintenance work, creating a comprehensive record. Eventually, punch cards became checklists, and mainframes became smaller computers.

The advent of networks is where things got interesting. Many organizations made custom internal solutions within applications like Microsoft Access, but they remained buggy, offered limited functionality, and were difficult to maintain.

The final significant evolution of CMMS was the transition from on-premise software to cloud-based solutions. This opened up the option of CMMS technology to a much broader range of organizations due to:

- Much lower implementation costs

- Improved access via mobile devices and widely available internet access

- Vendor-managed software updates

- Fewer points of failure and always-on capabilities

Today, CMMS solutions are practical, scalable, and affordable, which is why they are being adopted broadly among small and big businesses alike.

Types of maintenance management software

Many different types of maintenance management software offer slightly different areas of focus depending on the needs and goals of the team using them. Here are some of the most common.

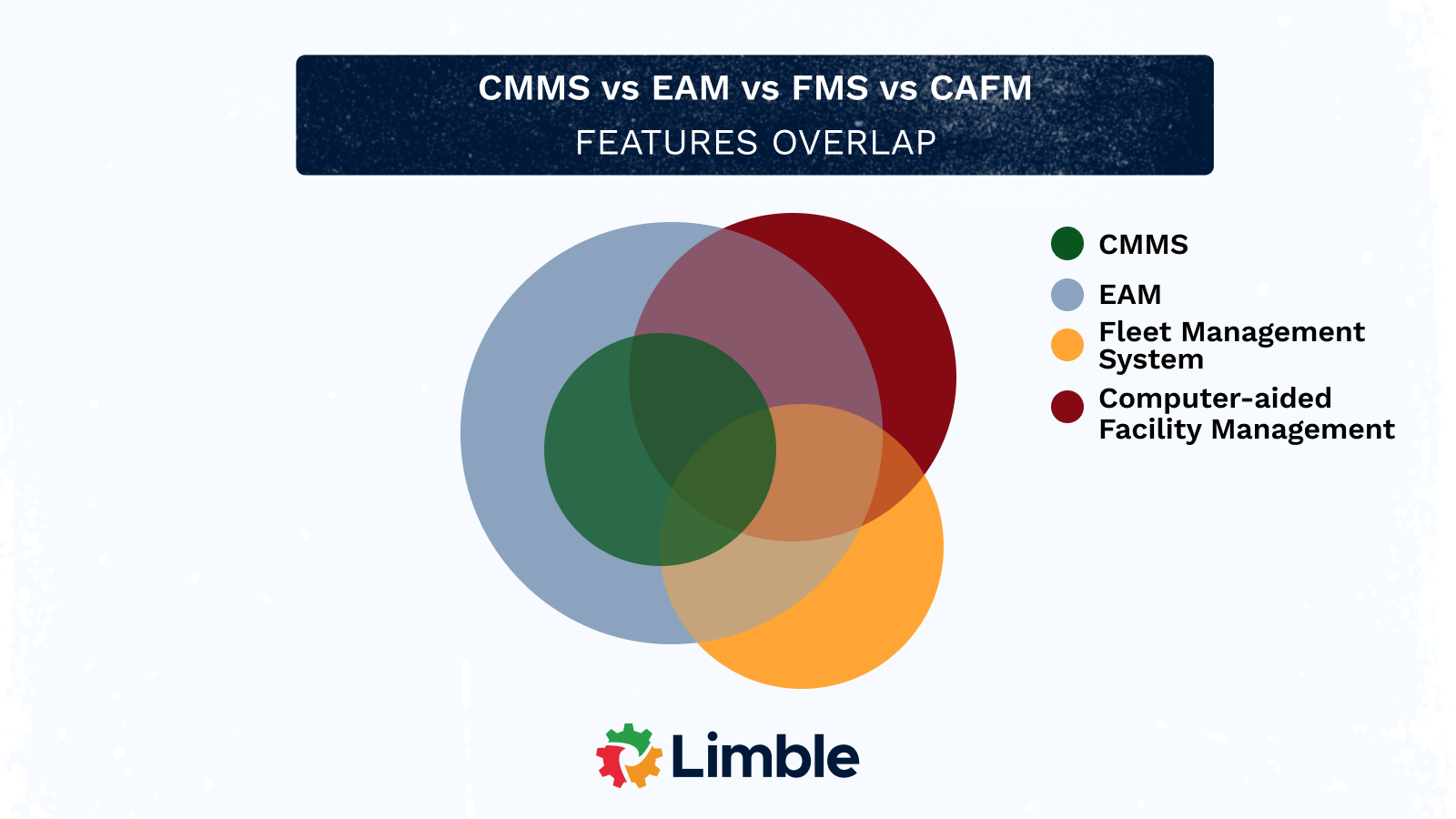

The difference between EAM, CAFM, FMS, and CMMS

While all of these systems provide some maintenance management functionalities, their use cases and modules will differ.

While all of these systems provide some maintenance management functionalities, their use cases and modules will differ.

- Enterprise Asset Management (EAM) solutions focus on functions that support the entire asset lifecycle, including procurement, but do not have broader maintenance functions. Large organizations typically use them as a supplement to other software solutions.

- Computer-Aided Facility Management (CAFM) solutions offer broad facility management functions, including space planning, room reservation, and administrative support.

- Fleet Management Software (FMS) is similar to a CMMS but with focused functions built for fleets, such as GPS tracking and fuel usage monitoring.

- CMMS Software solutions sit in the middle, with a broader range of functions to manage maintenance processes. Valuable for heavy equipment industries and facility maintenance alike, they offer comprehensive functionality to support all aspects of a strategic maintenance program.

What is a mobile CMMS?

Any cloud-based CMMS can be accessed from a mobile device through a browser. However, a truly mobile CMMS will offer a distinct mobile application that can be downloaded on your smartphone or tablet and used from anywhere.

CMMS mobile apps are built specifically to perform well on mobile devices, and the interface (the look, feel, and navigation) is designed to flow intuitively with minimal clicks or taps. This makes the system much easier to use while performing repairs in the field or facility.

Cloud-based SaaS versus on-premise software

While it can seem confusing, the choice between cloud-based versus on-premise software can be pretty simple once you consider your needs and capabilities.

Modern CMMS systems are cloud-based solutions. Cloud-based means that all the data stored in the system is saved in and accessed from one centralized spot (database) and can be accessed on any device with a simple username and password.

On-premise solutions, on the other hand, must be downloaded on individual devices. Data in these systems is stored on the company’s servers. Therefore, your internal technology team must be involved in system upgrades.

Cloud-based solutions are highly preferable for most mobile applications like CMMS. They are easier for your team to manage and feel more familiar to users. Most of the applications you use on your phone are cloud-based.

Industries that use CMMS/Who uses CMMS software

Every business with equipment or physical infrastructure can benefit from using a CMMS. For some organizations, the health of certain assets is critical to be able to operate at all. We can split the most common CMMS users into four groups.

CMMS for heavy industries

Heavy industries include any that rely on heavy machinery or equipment to function. This includes mining, construction, manufacturing, energy, and the airline industry which require thorough and strategic planning of preventive maintenance tasks to keep equipment running and meet strict regulatory requirements.

These industries spend a lot of resources on sophisticated maintenance strategies to get the most productivity out of their assets because more productivity directly leads to more revenue. They can use the features of a CMMS to continuously measure and improve their maintenance operations to maximize machine efficiency and asset performance, making it a worthwhile investment.

CMMS for facilities management

Facility maintenance is an integral part of facility management, ensuring that all building systems work properly and are comfortable for building occupants. That means taking care of the building infrastructure, electrical, plumbing, lighting systems, HVAC, and other building assets and equipment.

Various facility types like hotels, casinos, churches, fitness facilities, commercial buildings, museums, aqua parks, and more use CMMS software.

CMMS for fleet management

As its name suggests, fleet maintenance exists to keep the vehicles your organization relies on in top condition.

What sets fleet management apart is its emphasis on functions like asset tracking and fuel management. Trucking companies, car rental services, government organizations, farming operations, delivery services, and more use CMMS technology.

CMMS for field maintenance

Field maintenance is responsible for maintaining widespread assets that function independently of one another. Some recognizable examples include:

- Telecommunications infrastructure like cellphone towers

- Electrical grid components across a wide geographic area

- Residential and commercial HVAC repair

- Landscaping and grounds maintenance

CMMS technology helps field maintenance professionals manage maintenance activities across their wide-ranging areas of responsibility.

Benefits of CMMS platforms

When implementing a CMMS or any other technology solution, it is important to consider the advantages and disadvantages side by side to truly determine whether the benefits are worth the investment.

Advantages of using a CMMS

A CMMS can bring numerous positive changes to a maintenance team’s operations, and some of them can be experienced almost immediately. While they will impact different organizations to different degrees, here is a top ten list of the most significant.

- More efficient maintenance scheduling and operations: A CMMS will drastically reduce the administrative work needed to run an effective maintenance strategy.

- Streamlined work request and work order management: With a CMMS, all work requests and work orders are received and coordinated in a central location.

- Accurate and timely asset information: Maintenance histories, asset information, and task notes are available with the click of a button, enabling maintenance teams to perform their best work and inform decision-making with real data on key performance indicators (KPIs).

- Reduction in maintenance costs: When maintenance workflows take less time and are more efficient, labor costs decrease.

- Improved team communication: Computerized maintenance management software centralizes asset and maintenance information for maintenance team members. In addition, most programs will have functions dedicated to facilitating real-time team chats and communication.

- Easier vendor management: Most modern CMMS systems include features that enable easier vendor and contractor activities management.

- Increased operational efficiency and uptime: A CMMS helps automate sophisticated predictive maintenance and preventive maintenance strategies that help organizations avoid equipment failures.

- Reduction in planned and unplanned downtime costs: A CMMS-supported asset maintenance program can drastically reduce breakdowns and unplanned downtime, ensuring asset health and uninterrupted productivity while extending the lifespan of physical assets.

- More efficient and effective safety and regulatory compliance: Healthier equipment is safer equipment that reduces legal risk, and simpler documentation and centralized records ease the stress of audits.

- Improved employee productivity and morale: From less overtime due to fewer equipment emergencies to employee recognition made possible by productivity metrics, all the above benefits combine to lay the foundation for a great working environment.

Disadvantages of a CMMS

As with many other strategic initiatives, a CMMS implementation will only go well if there is a commitment to adopting it thoroughly in all aspects of your maintenance operation. The barriers that hold most organizations back from adding a CMMS mostly have to do with the time, money, and energy it takes to roll it out.

- Upfront costs: Technology can sometimes feel like an intangible cost when paying for user licenses and implementation fees, but before dismissing a CMMS because of the cost, take a careful look at the typical CMMS return on investment (ROI) achieved through time savings, reduced parts spend, and more.

- Setup and data migration: Especially for those starting from spreadsheets and paper forms, setting up a CMMS can seem daunting. Consider your organization’s true needs for migrating historical data, and weigh that against building your maintenance database from scratch as you begin using the system.

- Team adoption: It is easy to assume that beginning to use a mobile CMMS to log every task will be a difficult transition for seasoned maintenance professionals who aren’t used to working with computers. However, many modern maintenance systems were built with usability and adaptability in mind. Take advantage of free trials to find the right one for your team.

How to make the transition to a CMMS

Choosing the right CMMS for your maintenance team and investing in a thorough implementation will set your maintenance team – and your organization – up for success. Here is an overview of the steps to doing it right.

Critical steps in the CMMS selection process

Following the basic steps to choose the right CMMS will help match your organization’s maintenance needs with the best solution to solve them.

Step 1: Form a CMMS selection team

To fully understand all the considerations and ways a solution will impact your organization, you must include a variety of stakeholders and subject matter experts from within your organization. This will consist of maintenance managers and technicians, of course, but in addition, be sure to include other members of management, operations, and information technology.

Step 2: Conduct a needs assessment

Work with your selection team to evaluate what your organization needs in a CMMS. Determining the functions, characteristics, and specifications your organization requires will keep your selection process pointed in the right direction.

Step 3: Research the options that align with your needs

Conduct some high-level research to develop a shortlist of vendors that could meet your needs. You may include a CMMS RFP as part of your process; if so, these finalists are the organizations you will include in that sub-step.

Step 4: Test the finalists to make your final decision

To truly be confident in your choice, a testing phase is critical. Invest as much time as you can in testing your finalists with free trials and using real-life scenarios.

Key considerations for a CMMS transition

While your organization’s needs and the functions of the CMMS you choose are of the utmost importance, a few key considerations should always be included in any software search, regardless of the platform’s use or purpose. These considerations will ensure you achieve a baseline of quality in any software you choose.

- Usability: Is the system easy to learn and use?

- Customizability: Can the system’s fields and workflows be customized to your needs?

- Implementation: What is the vendor’s process and level of implementation support?

- Customer Support: What is the vendor’s track record for providing responsive and effective customer support?

- Security: Does the vendor follow data security best practices to keep your information safe?

- Scalability: Can the system handle whatever growth is in your organization’s future?

- Pricing: Does the vendor’s CMMS fit your budget, and can you be sure of a CMMS return on investment (ROI)?

The importance of CMMS implementation

For any organization making the transition, the CMMS implementation process can either make or break its success. Most CMMS implementation processes will include the following phases:

- Phase 1 – Preparation and planning: Plan the implementation to ensure sufficient time and resources to set up the system and train your team properly.

- Phase 2 – Data gathering: Pull together the information that will be imported into the system to inform your maintenance program, such as maintenance histories and manuals.

- Phase 3 – Produce and workflow implementation: Build the system around your workflows and put them into place within your team’s daily operations.

- Phase 4 – Post-implementation and continuous improvement: Implement processes for ongoing evaluation and improvement of maintenance effectiveness with the help of maintenance reports and dashboards.

Want to see Limble in action? Get started for free today!

Getting the most out of your CMMS

There is a lot to know about the history and applications of CMMS software. While researching all the details and completing all the key phases in the implementation process are essential, the most critical predictor of CMMS success is the consistency with which the system gets used.

The value of a CMMS is directly related to its role as a platform to access and analyze maintenance activity. So, the more it gets used, the better your experience will be.

The most user-friendly CMMS solutions will be simple enough to pick up and begin using on day one. Each work order and maintenance task that gets logged in the system builds more accurate schedules and analytics. If you’re ready to take the next step and try it for yourself, start a free trial or request a demo today.

FAQ

What does CMMS mean?

CMMS stands for Computerized Maintenance Management System. CMMS software helps businesses manage, automate, and streamline all of their maintenance operations.

Table of Contents

- CMMS Software Explained: Benefits, Features & Selection Guide

- What is a Computerized Maintenance Management System (CMMS)?

- Types of maintenance management software

- Industries that use CMMS/Who uses CMMS software

- Benefits of CMMS platforms

- How to make the transition to a CMMS

- Getting the most out of your CMMS

- FAQ

- Related Content

What does a CMMS do?

Maintenance teams use CMMS systems to help organize and document all the administrative aspects of their work in one centralized location.

Table of Contents

- CMMS Software Explained: Benefits, Features & Selection Guide

- What is a Computerized Maintenance Management System (CMMS)?

- Types of maintenance management software

- Industries that use CMMS/Who uses CMMS software

- Benefits of CMMS platforms

- How to make the transition to a CMMS

- Getting the most out of your CMMS

- FAQ

- Related Content

Is Limble Mobile CMMS app user friendly?

Limble is consistently rated Easiest-to-Use CMMS on review sites like G2, Capterra, and Software Advice. And our customers agree. With our mobile CMMS app, teams experience 30%+ better productivity, on average, requiring little to no training or ramp-up time. Our CMMS app can travel with your team, no matter where they go! Visit our App Store or Google Play for more information.

Table of Contents

- CMMS Software Explained: Benefits, Features & Selection Guide

- What is a Computerized Maintenance Management System (CMMS)?

- Types of maintenance management software

- Industries that use CMMS/Who uses CMMS software

- Benefits of CMMS platforms

- How to make the transition to a CMMS

- Getting the most out of your CMMS

- FAQ

- Related Content

Can I connect to other systems?

Limble provides seamless, pre-built CMMS Integrations with the most widely used software systems. That means no help from a developer or your IT team is required. Learn more about our integrations.

Table of Contents

- CMMS Software Explained: Benefits, Features & Selection Guide

- What is a Computerized Maintenance Management System (CMMS)?

- Types of maintenance management software

- Industries that use CMMS/Who uses CMMS software

- Benefits of CMMS platforms

- How to make the transition to a CMMS

- Getting the most out of your CMMS

- FAQ

- Related Content

How secure is the Limble CMMS platform?

At Limble, our world-class data security practices ensure your account information is safe. We use state-of-the-art technologies and industry best practices to maintain a secure infrastructure, including SOC-II Type II certification, regular penetration testing, and continuous security training for our staff.

Table of Contents

- CMMS Software Explained: Benefits, Features & Selection Guide

- What is a Computerized Maintenance Management System (CMMS)?

- Types of maintenance management software

- Industries that use CMMS/Who uses CMMS software

- Benefits of CMMS platforms

- How to make the transition to a CMMS

- Getting the most out of your CMMS

- FAQ

- Related Content

Is Limble CMMS software free?

Ditch paper work orders and increase your team’s productivity with Limble’s free Basic tier. Free today, tomorrow, and always. This is not a trial, and there are no strings attached. There are no set-up, update, or hardware fees. As long as you’re using Limble’s free CMMS software, we won’t charge you, ever.

Table of Contents

- CMMS Software Explained: Benefits, Features & Selection Guide

- What is a Computerized Maintenance Management System (CMMS)?

- Types of maintenance management software

- Industries that use CMMS/Who uses CMMS software

- Benefits of CMMS platforms

- How to make the transition to a CMMS

- Getting the most out of your CMMS

- FAQ

- Related Content