Failure analysis techniques vary widely based on the specific use cases. That being said, steps for conducting failure analysis follow the same pattern.

Step #1: Define the problem

A well-defined problem statement is essential for any deep analysis. Failure analysis requires the engineers to define the problem as clearly and concisely as possible. The problem statement should contain details about:

- The failure that occurred

- The data that needs to be collected

- The failure analysis technique to be used

- The expectations for the failure analysis (goals)

Step #2: Collect failure data

All relevant data has to be collected. This includes both quantitative data and qualitative data.

Quantitative data refers to the operations data, maintenance data, age of the machine, etc. It can be obtained:

- From maintenance records

- From the CMMS database or any other tool used to monitor asset health and performance

- Through troubleshooting

- By performing a visual inspection (as a part of failure investigation)

Qualitative data cannot be easily quantified. Such data is obtained by interviewing machine operators, maintenance technicians, operations managers, etc. All relevant data concerning the failure should be collected.

Step #3: Create a failure timeline

Root causes result in a chain reaction that forms the surface-level failures we observe. The collected failure data can shed light on the event sequences that happened. With enough information, the team performing the analysis can create a failure timeline. This serves as a visual and mental aid to the analysis process.

Hopefully, the timeline will provide clarity into the cause-and-effect relationship between the events.

Step #4: Select useful data and discard the rest

The timeline created in the previous step is also used to identify useful data. Quantitative and qualitative data collected in step #2 is mapped to the events in the timeline. The data that finds a place in the timeline is useful for the final analysis.

The rest of the data can be discarded as it is not relevant to the events that caused the failure. This way, failure analysis teams won’t waste time and effort analyzing irrelevant information.

Step #5: Administer the chosen failure analysis technique

The next step is to conduct the chosen failure analysis technique (we will discuss them in the next section). The method selected depends on the specific use case, industry, and the experience of failure analysis engineers conducting the analysis.

Step #6: Review results, test and apply a solution

The result of failure analysis is studied in detail. In most instances, the purpose of failure analysis is to implement remedies that can prevent future failures. Different solutions proposed are tested and the best solution is used to improve the system/machine.

How to write your failure analysis report

After you’ve done the analysis, it is time to write the report. While administrative work is nobody’s favorite job, documenting used procedures, tested solutions, and found conclusions can be extremely useful for future failure analysis.

How exhaustive your failure analysis report is going to be will depend on the type and scope of the analysis you are performing.

For example, an in-depth field failure analysis performed after a product recall needs to have very detailed documentation. In this case, it is recommended to slowly gather documentation and records as you go through the process. Later on, you can ask all involved teams to send over what they have, merge it, and finalize your failure analysis document.

In stark contrast, for a quick analysis performed to analyze the breakdown of conveyor belt #3, a single-page report might suffice.

What to include in the failure analysis report

There is no universal report you can follow as every organization has its own procedures and goals.

We recommend that you use good old common sense. When someone looks at the report 15 months later when troubleshooting a similar problem, which information will make their job safer/faster/easier? Of course, the purpose of the report and how “official” it needs to be will also have an impact on its structure and things that need to be included.

In general, look to cover the following:

- Introduction (why the analysis is performed, the scope of the analysis…)

- Problem description (what happened, the chronology of events that created the issue…)

- General information (who performed the analysis, failure analysis techniques, and tests used to gather data and analyze the problem)

- Findings (what was the root cause, as well as any other notable findings that might not necessarily be related to the initial purpose of this investigation)

- Recommendations for corrective actions (a good report should focus on solutions and prevention more than assigning blame)

This might still sound rather abstract so let’s look at some templates.

Checklist for Creating a Preventive Maintenance Plan

Following a consistent Preventive Maintenance Plan can make life easier. Use this checklist to create your own!

A few failure analysis report examples

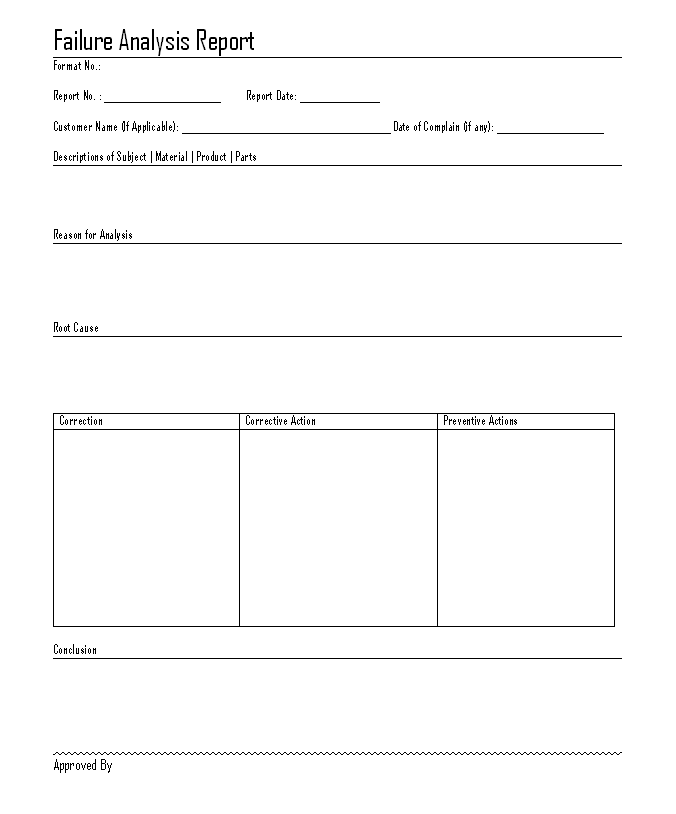

A sample of a basic failure analysis report. Source: Inpaspages

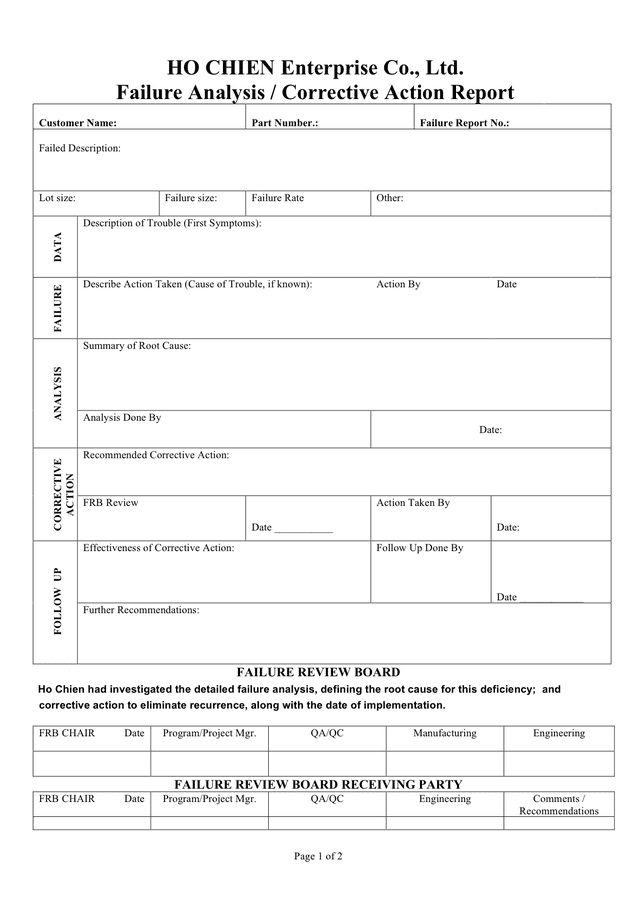

More comprehensive failure analysis report form. Source: Dexform

More comprehensive failure analysis report form. Source: Dexform

You can find many other examples on the web by searching for “failure analysis report” and taking a look at Google’s “Images” section.

Key takeaways

Failure analysis is a versatile tool that has many purposes. It can be used to investigate past failures, understand failure mechanisms, and predict the modes of future failures.

There is no “one size fits all” solution to conducting failure analysis. The technique selection will depend on the goal of the analysis, available resources, access to relevant data, and what the failure analysis team knows and prefers to use.