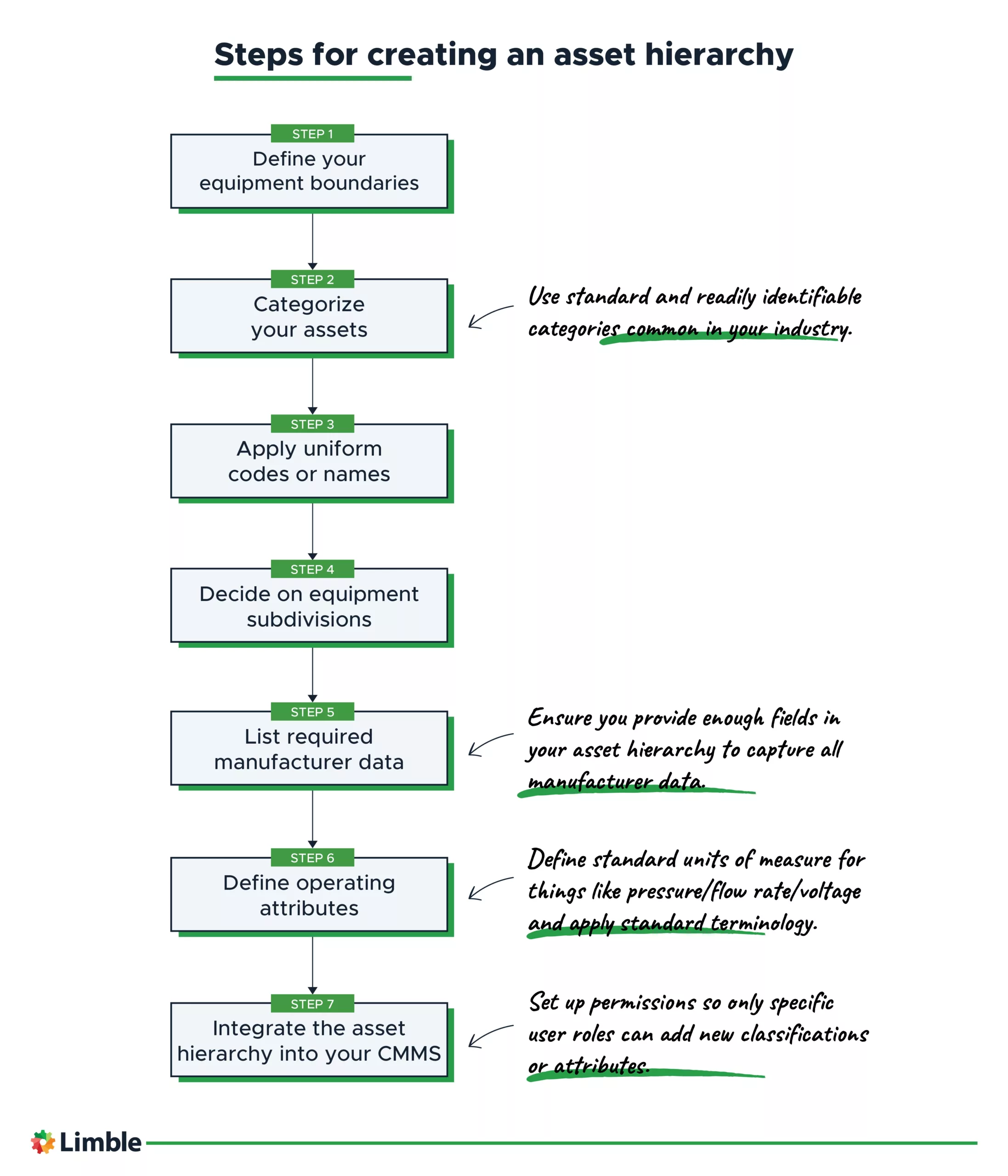

Defining your asset hierarchy is not difficult, but it requires a systematic approach and consideration of several important points.

It helps if you already have an existing (and accurate) asset register.

Step 1: Define your equipment boundaries

Clearly define the rules by which you categorize a system.

Imagine you have two departments that share the same compressed air system. You need to consider:

- Where are the boundaries at which the change in department occurs?

- If you have an electric motor driving a pump, does a motor form part of the electrical system or the pumping circuit?

- If a leak occurs at a boundary connection, does it belong to the connected device or is it within the system boundary?

You must clearly identify and define these rules to prevent user confusion and data corruption.

Step 2: Categorize your assets

You can use a system to categorize your assets as we did in the diagram above, or to create a class of assets — like Pumps.

Use standard, readily identifiable categories common in your industry. Trying to personalize categories to your business will introduce jargon and confusion, making it hard to integrate new hires, and causing outside contractors to be less efficient.

In our example asset hierarchy, we defined HVAC as the system, with pumps as one of the children. Three different pump types are sub-units of the generic “pump” category, with each of them composed of individual components.

Step 3: Apply uniform codes or names

Create standardized names and codes for your equipment to allow easy identification and meaningful analysis. Adherence to a naming convention prevents people from inventing their own abbreviations or failure codes that will ruin your data integrity.

Your CMMS can enforce this discipline by forcing technicians to select names/codes from a predefined list.

ISO 14224 has some helpful naming examples in Appendix A you can use as a reference.

Step 4: Decide on equipment subdivisions

Use a standard list of equipment sub-units. For instance, you may decide a generic compressor has the following sub-units:

- Compressor

- Control and monitoring

- Receiver

- Air treatment

- Power transmission

- Miscellaneous.

In your CMMS, be sure to apply these sub-units to all compressors, even if the compressor is a simple unit that doesn’t have great complexity.

You may not use the sub-units entries, but maintaining the attributes is important for data integrity. Avoid devising different sub-units with customized attributes for equipment in the same category.

Step 5: List required manufacturer data

Ensure you provide enough fields in your asset hierarchy to capture all manufacturer data. Some manufacturers use part and serial numbers to identify their components; others add a model number. Some even include codes to indicate component modification states.

This information is critical when analyzing failure modes, calculating reliability, or understanding maintenance costs.

Step 6: Define operating attributes

There will be specific data that applies to a sub-unit. This data might include pressure and flow rates for hydraulic components, or voltage and current for electrical devices.

Define standard units of measure you’ll need to enter for such information. Is the energy consumption in watts, kilowatts, or megawatts, or will all three need to be offered as a choice? There is a standard terminology that you should use: W, kW, or MW.

Where units are case-sensitive, having one component shown as 10 kW and another incorrectly as 10 KW counts as two different units, with any search or analysis potentially missing one component.

Step 7: Integrate the asset hierarchy into your CMMS

Once the asset hierarchy is in your CMMS, it becomes the standard to which everyone must conform. When a new asset is purchased and loaded into the system, the only selections you can make will be those identified in the hierarchy.

The CMMS will not allow everyday users to invent new classifications or attributes. Those permissions can be enabled/disabled for different CMMS user roles.

For this reason, be rigorous in designing the structure to encompass all current requirements. An administrator will have to edit the structure if you buy new equipment that doesn’t fit into the current hierarchy.

In these cases, review the entire asset hierarchy to avoid isolated changes to the existing structure.

Optimize your asset management hierarchy with Limble CMMS

The combination of a well-structured asset hierarchy and a CMMS is important for every business seeking to optimize its asset management processes.

While creating an asset hierarchy involves forethought and rigorous discipline, flexible CMMS software like Limble makes sure the whole process is very straightforward.

Don’t hesitate to reach out or schedule a quick product demo to learn more about Limble CMMS and its ability to simplify and streamline your asset management operations.

Comments are closed.