Among the many asset management challenges impacting a business, it’s easy to underestimate the importance of a comprehensive Leak Detection and Repair (LDAR) program. Yet, failing to implement one exposes your business to regulatory enforcement and financial penalties – especially if your plant handles liquids or gasses.

More than 50 federal regulations require businesses to have a formal LDAR program or mandate the use of an LDAR methodology. In the US, the Environmental Protection Agency (EPA) has oversight for compliance.

In the continuation of this article, we discuss how and why are leaks regulated, the most common causes of leaks you should watch out for, and how to develop a rigorous LDAR program.

Why are leaks regulated?

Governments globally are implementing LDAR regulations to combat the health and environmental impacts of liquid and gas leaks. The primary targets for these regulations are volatile organic compounds (VOCs) and hazardous air pollutants (HAPs) emitted from petroleum refineries and chemical manufacturing facilities.

EPA estimates that, in the US, approximately 70,367 tons per year of VOCs and 9,357 tons per year of HAPs are emitted from equipment leaks – with valves, pumps, and connectors being the largest source of fugitive emissions. In addition to protecting the environment and national health, such regulations reduce occupational exposure limits for those working in the facilities and living in the immediate neighborhood.

Initially aimed at the petrochemical industry, the regulations have expanded to include pharmaceuticals, polymer plants, dry cleaning, aerospace, and marine. Beyond EPA regulations, it’s not uncommon to find local governments including LDAR and emissions reduction into permit requirements to prevent groundwater contamination and reduce property damage.

What constitutes a leak under regulations?

Volatile organic compounds leak identification uses a vapor analyzer or VOC instrument detector calibrated for the substance being stored or transferred. This device will measure gas concentrations in parts per million by volume (ppmv).

VOC environmental meter. Source: PCE Instruments

Such detectors are sensitive and may identify the presence of VOC emissions, yet these may not constitute a leak under regulations.

What’s important is knowing the leak definition concentration specified in the regulations. It’s at this point that things can get tricky. There are numerous organizations that stipulate leak definition concentrations:

- New Source Performance Standards (NSPS)

- National Emission Standards for Hazardous Air Pollutants (NESHAP)

- State Implementation Plans (SIPs)

- Resource Conservation and Recovery Act (RCRA)

The problem? Their allowed concentration levels can differ.

To add to the confusion, many state and local agencies incorporate the LDAR requirements but stipulate even more stringent levels – asking businesses to further reduce VOC emissions – to improve local air quality.

Businesses need to be sure they are meeting the correct leak regulations. If there is a regulatory overlap, you must use the most stringent leak definition concentration. For example, many NSPS leak definitions use 10,000 ppm, while NESHAP can be as stringent as 500 to 1,000 ppm.

In addition to the VOC detector, many leak definitions also use sound, smell, and visual observations for gross leak rates. Be aware that some LDAR requirements require weekly visual inspections of specific components.

For water leaks, the target for leak reduction is usually the percentage of unaccounted water loss within a system, with private industrial water system permittees required to attain a 10 percent or less unaccounted water loss. The primary identification methods are visual inspection and sonic leak detection surveys.

Common causes and types of leaks

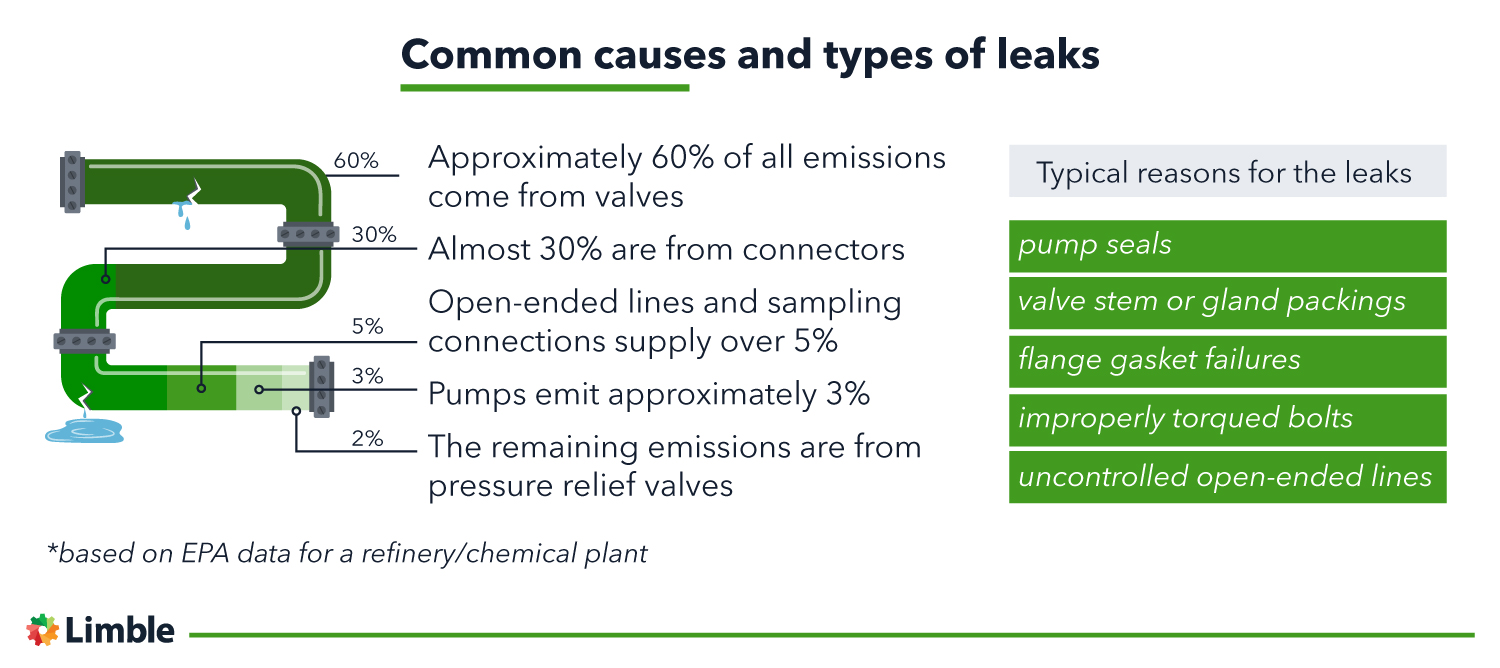

EPA produced a comprehensive 403-page protocol for estimating equipment leak emissions. When EPA used this data and applied it to the typical equipment at a refinery or chemical plant, they identified the following:

- Approximately 60% of all emissions come from valves

- Almost 30% are from connectors

- Open-ended lines and sampling connections supply over 5%

- Pumps emit approximately 3%

- The remaining emissions are from pressure relief valves

Typical reasons for the leaks include:

- Pump seals

- Valve stem or gland packings

- Flange gasket failures

- Improperly torqued bolts

- Uncontrolled open-ended lines

Now that we know why Leak Detection and Repair is so important, let’s see how to implement and execute a comprehensive LDAR program that satisfies all LDAR regulations.

The Essential Guide to CMMS

The Essential Guide to CMMS

5 steps for developing a rigorous LDAR program

While developing LDAR programs helps against enforcement action, emissions management is a smart tactical decision, even if your business is not regulated. EPA has estimated that the product lost from leaks averages a cost of $1,370 per ton. For a typical refinery or petrochemical plant, an LDAR program will reduce emissions by approximately 582 tons per year, saving almost $800,000.

While your business may be considerably smaller than a refinery, your revenue is too. If you’re 1/5th the size, you could still be saving almost $40,000 per year. Serious money that’s literally evaporating.

Follow these five steps to save money while helping the environment and people’s health.

Step #1: Identify problematic components

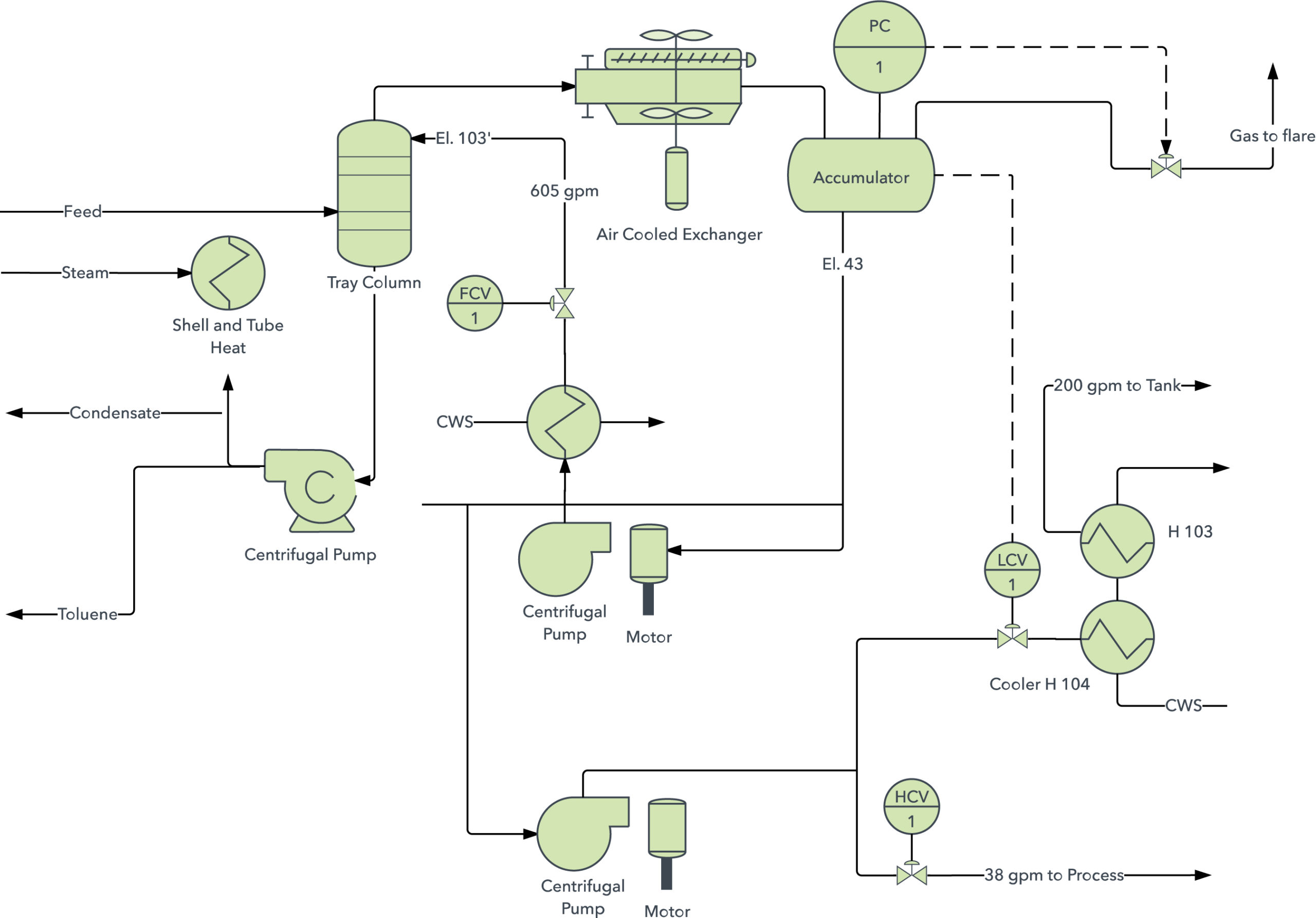

Use the relevant regulation or EPA guidance and physically locate each affected component in your facility. Check where the process equipment is located on your process flow or piping and instrumentation diagrams (P&IDs).

Example of a P&ID diagram. Source: LucidChart

Ensure these documents are up to date. Physically tag each component with a unique identification number and barcode, and enter the ID number onto the process flow or P&ID diagrams.

A computerized maintenance management system (CMMS) is the perfect data management method for capturing and controlling your LDAR program. Give each component an equipment record in the CMMS and record critical data.

Modern CMMS solutions like Limble allow you to generate a QR code, print it out, and paste it on your assets. Later on, anyone with access to the Limble app can scan the code and Limble will instantly pull the corresponding asset card which contains its maintenance history and condition data.

Step #2: Research the leak definition

Understand the regulations applicable to your industry. Where multiple regulations exist, identify the lowest leak definition. You may choose to set more severe limits for your facility to ensure you have a margin of safety. Try to be consistent in applying the limits across your plant. Use the same leak definition for similar components to avoid confusion and errors.

Be sure the equipment record cards within your CMMS are updated with the leak definition for each component and cite the relevant regulation and its version status. If challenged in an audit or in evaluations, the CMMS database ensures you have complete traceability of the information source, version, and the individual in your company who made the assessment.

Step #3: Implement a LDAR monitoring program

The regulation that stipulates the leak definition will also prescribe the monitoring frequency. These leak inspections might be annual, quarterly, monthly, or weekly. Again, you can choose to use increase the frequencies in your program development to be on the safe side. When writing a LDAR monitoring process, the primary document you should use is EPA Reference Method 21 (40 CFR Part 60, Appendix A).

Update the planned maintenance task for each affected component within the CMMS. Ensure that the LDAR technician completing the detection process has access to the relevant legislation and methodology by using a CMMS-connected device to gather needed technical data.

If the leaking component passes the leak test, the CMMS will update the task as acquitted and schedule the next inspection at the defined frequency. If the component leaks, CMMS can also initiate a work order for rectifying the defect.

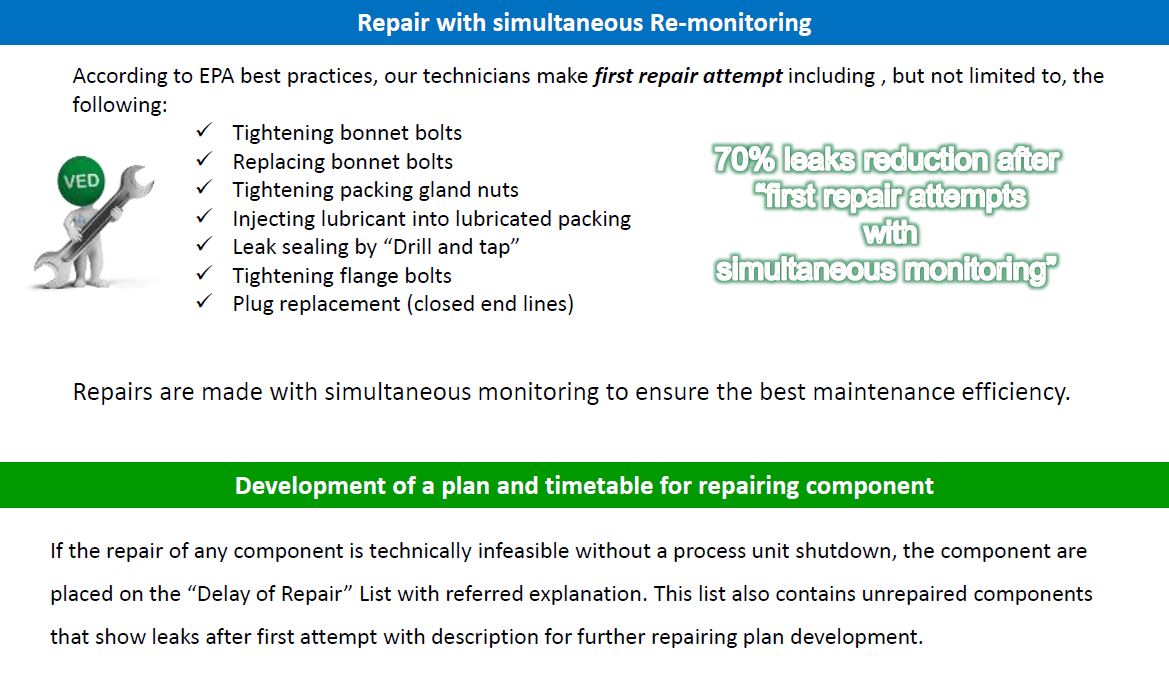

Step #4: Understand the leak repair process and LDAR regulations

The legislation will specify the number of days within which leaking components need to be addressed. The repairs usually need to be concluded in 5 to 15 days. It’s advisable to try and schedule the first repair attempt immediately to allow yourself sufficient time to escalate attempts should tightening, replacing, or lubricating the leaking equipment not work.

If you are likely to exceed the 15-day deadline, you must raise a Delay of Repair record. This record identifies the component and captures why you can’t repair it within the required time. You must also enter an estimated date for rectification.

Outsourcing Leak Detection and Repair to a contractor. Source: GFE

If you have an internal team that handles maintenance work related to leak detections and process units, you can load the 5/15-day deadlines into the planned maintenance schedule to ensure the CMMS prioritizes the work order appropriately. Once the deadlines have passed, the CMMS can create a Delay of Repair record which will prompt the technician on the reasons for the delay and set a new due date for completion.

Through all of this, the CMMS will track spares and dates to make sure you meet the repair commitment.

Step #5: Recordkeeping

As a regulated process, the expectation of rigorous recordkeeping is high as the records will form the basis of any audit. It’s important to maintain oversight of regulatory changes to ensure your business remains compliant. Process flow diagrams and P&IDs must be maintained to reflect the current plant status, and all inspections, tests, and repairs must be fully documented and up to date.

The EPA method recommends electronic monitoring and storage of LDAR data. Therefore, using a CMMS as a centralized repository for your LDAR programs will meet EPA expectations and severely reduce the administrative burden on your business. Technicians and auditors can access data from the field, each unique component ID has full traceability, and the Delay of Repair register may be easily accessed and evidenced.

Here is a short video that showcases how Limble CMMS helps our clients smash their audits!

Do not let leaks ruin your business

There is an ever-increasing legislative focus on environmental protection, improved occupational health, and harm reduction for the general population. Whether or not your business is affected by legislation, implementing a comprehensive Leak Detection and Repair program is best practice and shows a corporate commitment to sustainability.

There is also a considerable financial incentive from reducing raw material or product loss. Combine LDAR programs with a CMMS, and you have an unbeatable solution, easing program administration, providing centralized control, and ensuring compliance through task and work order scheduling.

To learn more about Limble CMMS, start a free trial or contact one of our CMMS specialists.