Simplify and streamline warehouse maintenance management

Limble CMMS helps you manage everything—from forklifts and conveyor belts to HVAC systems and safety inspections—by automating maintenance schedules and tracking tasks in one easy-to-use platform.

Preventive maintenance

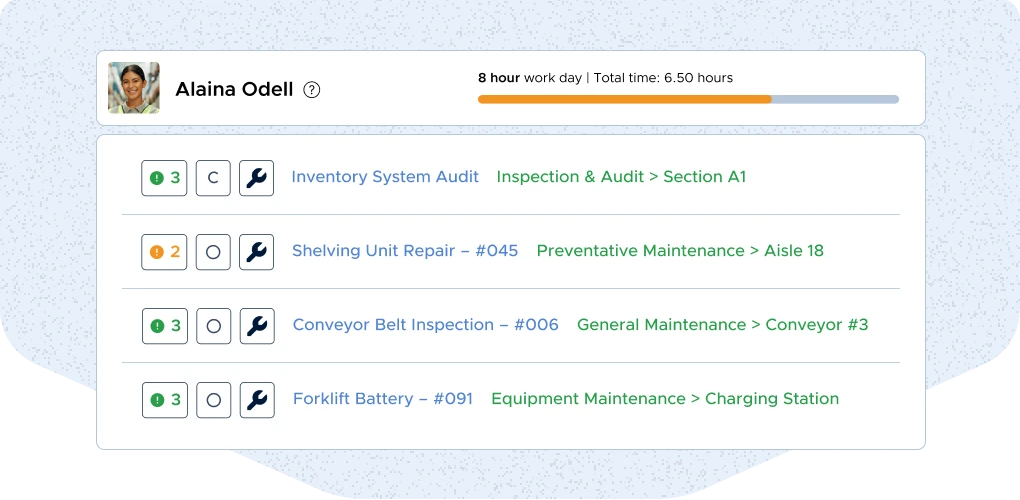

Use Limble to automate preventive maintenance schedules for critical assets based on time, usage, or condition. With detailed checklists, your team can complete tasks faster and with fewer errors, reducing downtime and extending the lifespan of your equipment.

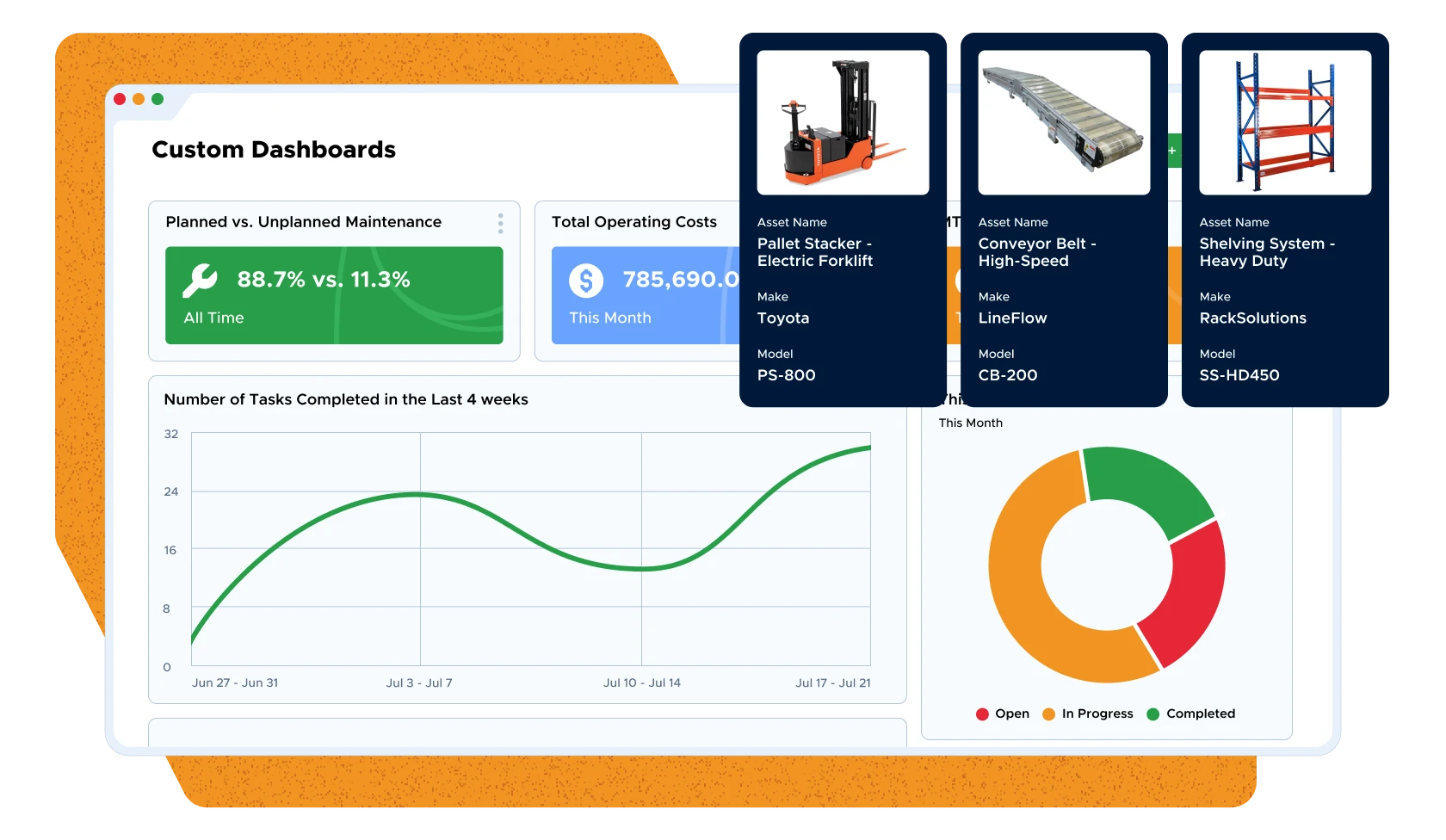

Insights that power better decisions

Limble’s robust reporting and analytics tools provide complete visibility into your warehouse operations. Use real-time dashboards to:

- Monitor downtime trends, asset performance, and maintenance costs.

- Spot inefficiencies and optimize processes for better results.

- Generate detailed reports for stakeholders, ensuring transparency and accountability.

With actionable insights, you’ll always have the data you need to improve operations and maximize efficiency.

Never worry about safety or compliance issues

Safety and compliance are critical in warehouse operations. Limble CMMS helps you:

- Log inspections and follow all safety protocols.

- Schedule and track repairs for essential systems like fire alarms, HVAC, and loading dock equipment.

- Keep documentation organized for audits and regulatory requirements.

- Protect your team, equipment, and operations from unnecessary risks by staying compliant and proactive.

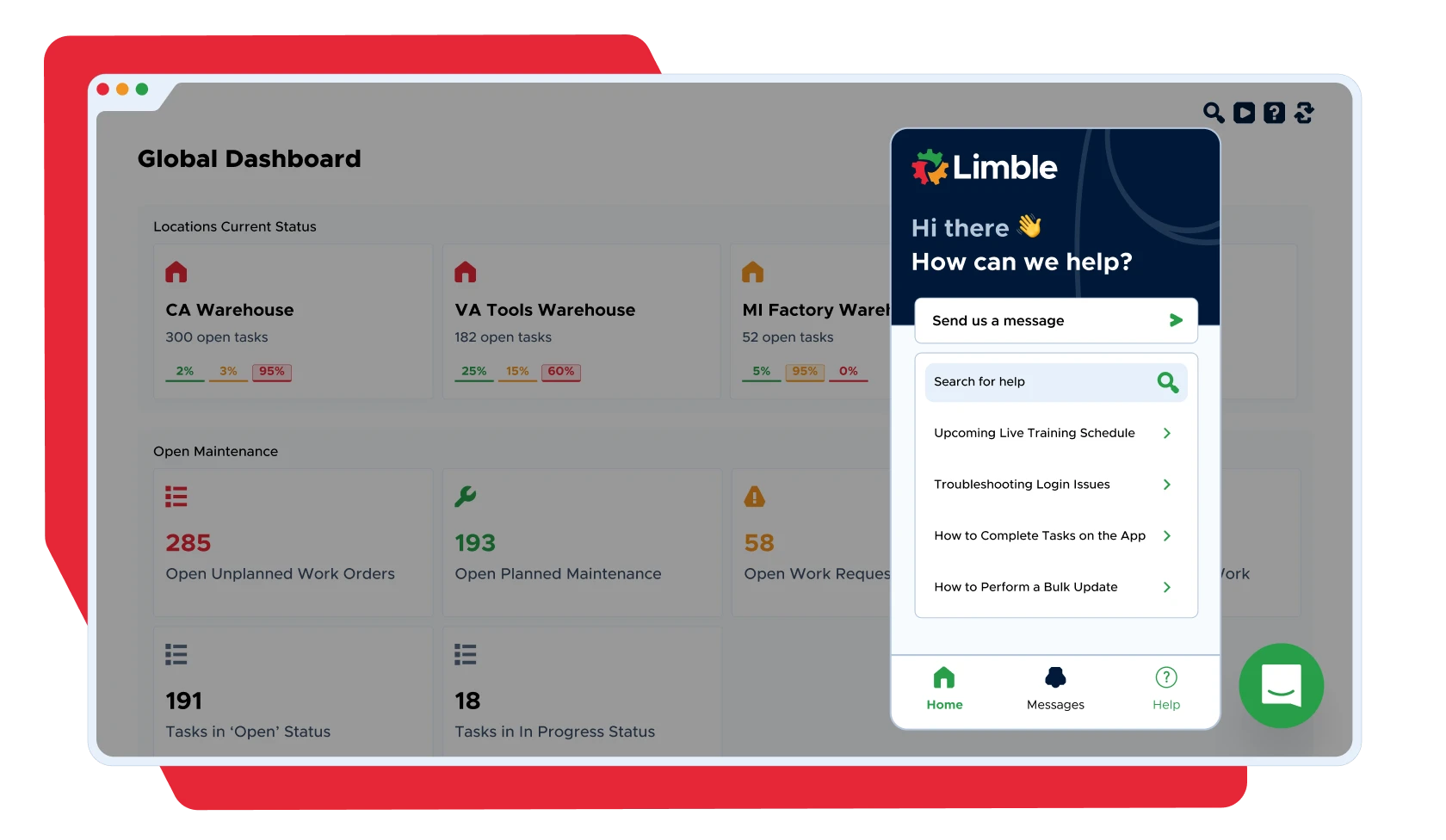

Dedicated support when you need it

We understand how important it is to resolve maintenance issues quickly in a fast-paced warehouse environment. Limble’s dedicated customer support team is available 24/7 via phone, chat, or email to assist with any questions or challenges. Our onboarding specialists ensure your team is up and running from day one.

Hear it from our customers

Reducing unplanned work

Serving 1,000+ stores and spanning 1 million square feet, Rite Aid’s flagship distribution center used Limble to hit an on-time completion rate of 90%.

Optimizing for efficiency and cost

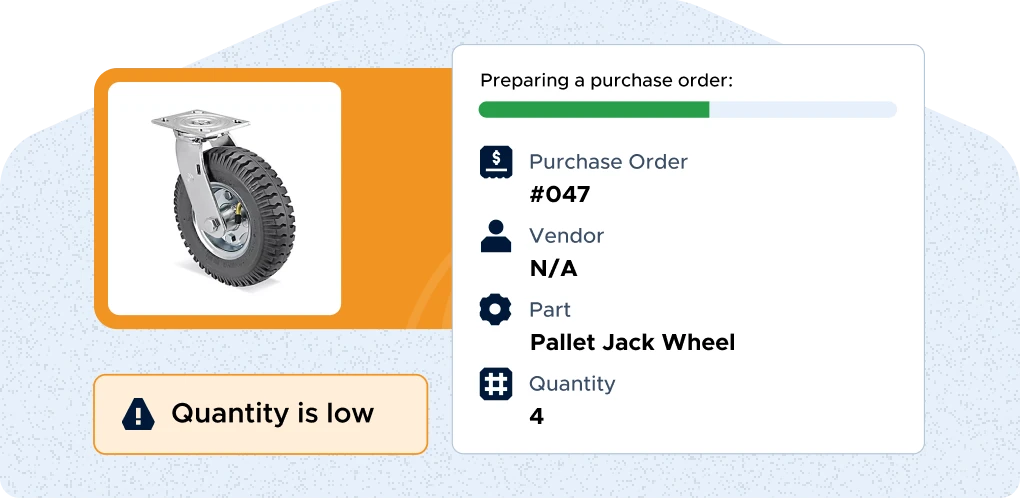

MidWest Materials reduced overtime by 80%, cut PO turnover time, and started managing parts inventory in real time.