To get digital asset management right, you need accurate asset data. It is the key to any good asset management program and it all starts with identifying assets using a standardized asset naming convention.

Uniform asset names may sound basic, but they are the foundation for seamless asset tracking and data analysis.

Let’s see how.

What is an asset naming convention?

An asset naming convention is a standardized way to name assets that makes them easy to track, manage, and identify. It’s a great way to maintain an organized and efficient asset inventory system and streamline future asset audits.

Here are some asset characteristics commonly used for easy asset naming and categorization:

- Descriptive elements: Names can be based on descriptive information about the asset, such as its type, function, or location.

- Unique identifier: Many assets come with a unique identifier, like a serial number. Using this in the asset name is a simple way to avoid confusion and facilitate precise tracking.

- Date/Time information: Including date/time information can be useful for tracking the age of the asset, its warranty period, or other time-sensitive information.

Versioning: If your assets undergo frequent changes or upgrades, incorporating a version number reduces the chance of creating duplicate entries.

Breaking down different asset naming convention methods

Function and serial number

Combining an asset’s function with a unique number makes identifying assets based on their name clear and self-explanatory. This is a great option for organizations – such as those with strict regulatory requirements – that need to organize maintenance activities depending on an asset’s workflow or job function, rather than its make or model.

1. AssemblyLine01Machine005

- AssemblyLine01: Descriptive name indicates the function and the specific line number

- Machine: Asset type specifies the general category of the asset

- 005: Unique identifier clearly identifies the asset

2. QC02Device018

- QC02: Descriptive component indicates the quality control function and the specific control area number

- Device: Asset type specifies the general category of the asset

- 018: A serial number uniquely identifies the asset

Department/location and asset type

Using the location and/or department for each type of asset provides a holistic snapshot of where the asset is situated and the department it belongs to. Adopting this naming system might be helpful for large manufacturing plants with multiple departments or units spread across different locations.

By knowing both the asset’s specific location or departmental affiliation, technicians and inventory personnel can swiftly locate the resources and assets they need, improving efficiency and coordination.

1. WeldingRA014

- Welding: Indicates the department where the asset is located

- RA: Specifies the type of the asset (a robot arm)

- 014: A serial number uniquely identifies the asset

2. Plant2Forklift007

- Plant2: Indicates the location of the asset

- Forklift: Specifies the general category of the asset

- 007: A serial number uniquely identifies the asset

Manufacturer and model

Incorporating the manufacturer’s name and model provides instant clarity on the asset’s origin and specifications. This naming convention is ideal for organizations that have a lot of assets sourced from different manufacturers. By having such detailed naming, it becomes easier to manage warranties, work orders, spare parts inventory management, and specialized maintenance procedures, as everything ties back to the exact make and model of the asset.

1. BDP3000004

- BDP3000: Specifies the manufacturer, type, and model of the asset (an abbreviation of Bosch Drill Press 3000)

- 004: A serial number uniquely identifies the asset

2. SiemensAR5001020

- Siemens: Specifies the manufacturer of the asset

- AR: Specifies the type of the asset (an assembly robot)

- 5001: Specifies the model of the asset

- 020: A serial number uniquely identifies the asset

Each of these examples demonstrates a slightly different approach to organizing and naming assets, depending on the specific criteria that are most important for the organization’s asset tracking and management needs.

Key asset naming convention best practices

Here is a list of 11 simple guidelines you should follow to establish strong and effective asset naming convention standards:

- Keep it simple: Standardized naming conventions work best when they are simple and easy to understand. Unnecessary complexity leads to confusion and mistakes.

- Apply logical categorization: Categorize assets logically based on their type, function, department, or other relevant criteria to make it self-explanatory for users.

- Enforce consistency: Create a structured format for naming and stick to it across all asset categories. This promotes familiarity and ease-of-use.

- Be descriptive: Each name should be descriptive enough to convey key information about the asset at a glance.

- Use unique identifiers: Assign unique identifiers to each asset to prevent duplication and ensure precise tracking and identification.

- Use abbreviations and acronyms: Use common and universally understood abbreviations and acronyms to save space and maintain clarity.

- Standardize Date/Time Format: If including dates, use a standard format (like YYYY-MM-DD) to prevent confusion and facilitate sorting and filtering.

- Avoid special characters: Avoid using special characters or underscores in asset names which can cause various data management issues.

- Document naming guidelines: Write down the asset naming guidelines and train new employees to adhere to those conventions.

- Implement tools: Utilize asset management software or dedicated asset tracking tools to automate the application of the asset naming convention wherever possible.

- Review and update: Periodically review your standardized naming convention to ensure it continues to meet the organization’s needs and make adjustments as necessary.

A well-thought-out asset naming convention will help you streamline set up and management of new assets, reduce errors, and help your maintenance team members quickly and easily pull required asset information.

Simplify asset tracking with Limble CMMS

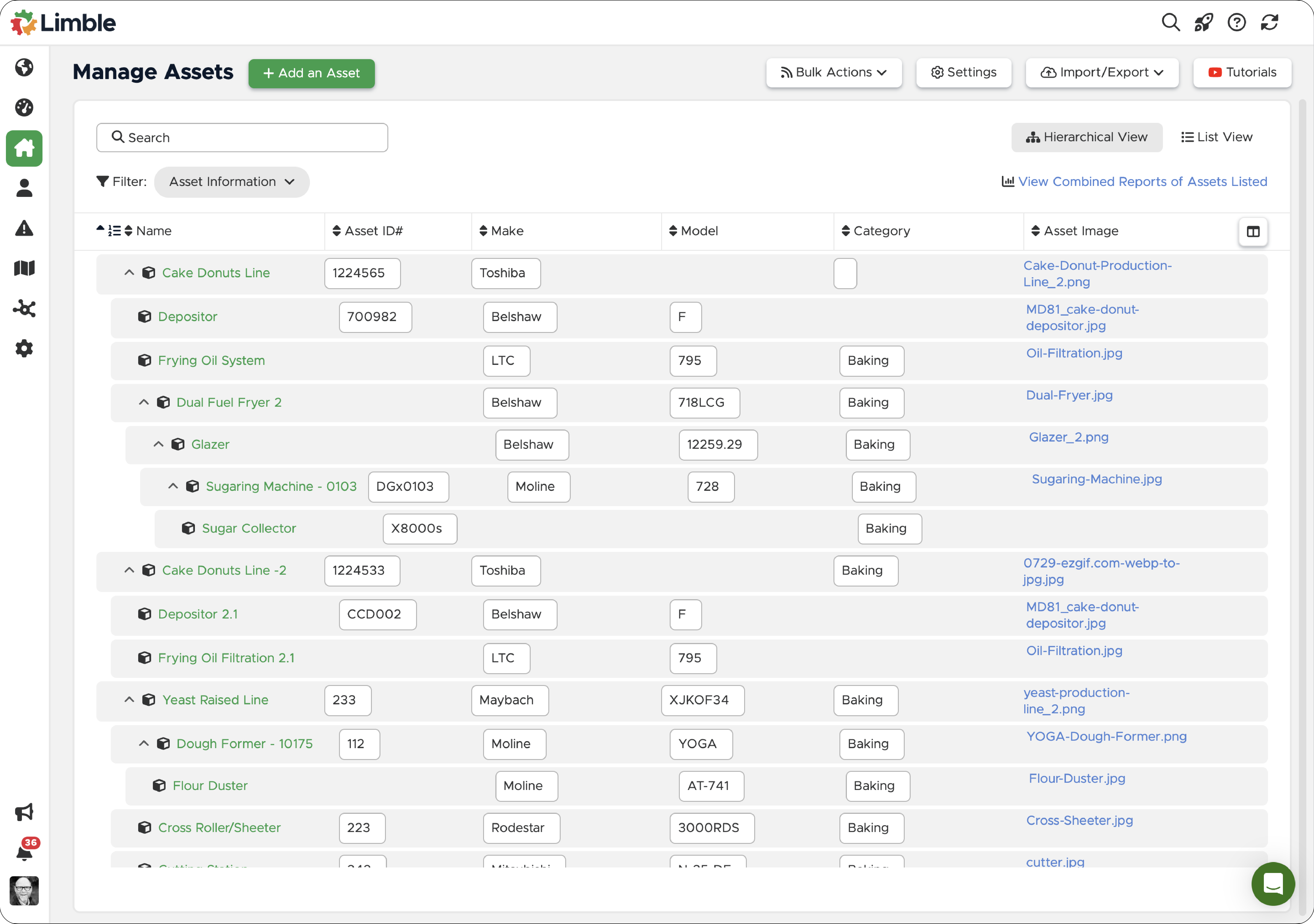

Asset tracking and management don’t have to be laborious processes. With a computerized maintenance management system in your corner, you can effortlessly implement a cohesive asset naming convention across all of your operations and locations.

Limble offers tools that facilitate easy categorization and asset tracking, saving you time and minimizing errors. Our user-friendly interface allows you to seamlessly create and manage thousands of assets with functionalities that guide the implementation of asset naming best practices.

Give Limble a try by starting a free trial.