Effective Lockout Tagout procedures prevent injuries and fatalities while helping organizations avoid the costs of unplanned downtime. The Occupational Safety and Health Administration (OSHA) estimates that following lockout tagout procedures prevents 50,000 workplace injuries and over a hundred deaths each year.

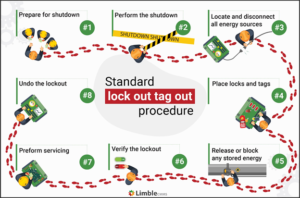

OSHA requirements compel businesses to maintain lockout tagout procedures tailored to their specific needs. Your industry and the types of equipment your team uses will determine your approach, but all LOTO procedures should follow the same basic structure.

The LOTO procedure you establish at your organization will be tailored to your specific needs. However, it should at a minimum include the following important steps.

Step 1: Notify relevant employees

Locking out equipment disrupts the workday of employees within your organization. It is imperative that all affected employees know which equipment you are taking out of operation, why you’re doing it, and for how long. Ensuring that all impacted employees are filled in on these details is an essential piece of any LOTO procedure, helping to promote compliance and safety. In addition, it helps machine operators plan for these interruptions in a way that minimizes the impact on productivity.

Step 2: Review the unique LOTO procedure for the asset

Before proceeding, ensure all responsible team members review the asset-specific lockout tagout procedure so everyone understands the process from beginning to end, and the role they play in it. LOTO procedures should clearly describe all the necessary steps for shutting down, isolating, blocking, and securing equipment to control potentially hazardous energy while also detailing the processes for placing, removing, and transferring lockout tagout devices. You should also take this time to conduct any necessary pre-shutdown inspections.

Reviewing the best practice guides with plenty of photos and posting them for employees to see can help simplify the procedure review process.

Step 3: Perform the shutdown

If the equipment is powered up and in operation, follow the standard shutdown procedure to take it out of commission. The shutdown procedure should include clear instructions for how to stop and power down the specific asset. This will be different for each individual piece of equipment so documenting these steps individually will ensure that the proper steps have been taken to safely proceed.

Step 4: Locate and disconnect all energy sources

Once you’ve powered down the asset, disconnect it from all energy sources. The authorized person performing the shutdown will follow the procedure’s guidelines to locate all sources of electricity, steam, water, gas, or compressed air and safely shut them down. Again, you can make their lives much easier (and their jobs much safer) by including pictures and diagrams in your documented LOTO procedures.

Step 5: Place locks and tags on the asset

Now that you’ve isolated the equipment from all its energy sources, install lockout devices on its switches and controls and mark them with the appropriate lockout tags. The authorized person should be the only employee capable of removing these devices. Tags must include information on who locked out the device, when they locked it, and why.

LOTO tag and lock. Source: Ara University.

Step 6: Release or block any stored energy

Though you’ve isolated the machine from its primary energy sources and safely locked it down, residual energy could still pose a safety risk. Dangerous fumes, condensed air, and tension from compressed springs may need to be released to avoid injuries. This is an essential step in the lockout tagout procedure. Ensure that you’ve accounted for all energy sources before moving to the next step.

Step 7: Verify the lockout

Now that the equipment is fully isolated, you’ll need to ensure it is locked correctly. The best and easiest way to conduct this test is to attempt the normal start-up process. If you’ve followed the previous steps in your LOTO procedure correctly, nothing will start, move, or change. Following this test, make sure to return the machine’s controls to their neutral or off position.

Step 8: Perform scheduled servicing

It’s time for the maintenance technicians to step in and perform the necessary work. Without sacrificing safety or thoroughness, they should move quickly and efficiently to service the locked-down equipment, keeping downtime to a minimum.

Step 9: Restore the equipment to service

Just as the LOTO procedure provides clear steps for the shutdown of equipment, it should also include the process to restart it. After the scheduled maintenance is complete, you will need to restore the equipment to its usual operating conditions by “undoing” the lockout and reconnecting the equipment to its various energy sources. Before removing lockout tagout devices, thoroughly inspect the machine and ensure the area is clear. Finally, ensure that this step in your LOTO procedure includes a notification to impacted employees that the machine is operational again.

Maintaining and Refining Your Lockout Tagout Procedure

Organizations do not have to choose between safety and productivity. In fact, they can go hand in hand. Implementing LOTO procedures and enforcing compliance can benefit more than just the meeting of OSHA requirements. By following these tips to develop and improve your procedures over time, you will also be positively impacting your company’s legal risk and workplace culture.

- Conduct LOTO training and regularly check for understanding: Whether they’re playing an active role in lockout procedures or not, all employees should understand the what, why, and how of safely shutting down machinery.

- Invest in good LOTO equipment: Purchasing safety equipment isn’t the time for bargain hunting. Look for LOTO hardware that’s built to last and customized to suit your specific machinery.

- Standardize wherever possible: It’s easier to scale LOTO procedures across an organization, promote compliance among the workforce, and conduct audits when processes are standardized as much as possible. Keep it simple, keep it safe.

- Refine your lockout tagout procedure over time: OSHA recommends auditing your LOTO procedures at least once a year, but more regular assessments establish a culture of safety and awareness.

Comments are closed.