Functional failures are a problem in every industry. It’s a silent way to lose money, waste time, and squander precious manpower. You need to understand it — so you can prevent it.

We’ll show you what functional failure is, explain the difference between functional and partial failures, and share the most common causes behind equipment failures.

What is functional failure?

Simply put, an asset has experienced functional failure if it can no longer perform its function.

The term “functional failure” can refer to a wide range of problems, symptoms, and impacts.

The most extreme example is a machine that won’t turn on or run at all. A lighter version of functional failure is when a machine doesn’t have the same yield, speed, or throughput it used to have.

In fact, anything short of peak performance is considered a functional failure.

The Essential Guide to CMMS

Download this helpful guide to everything a CMMS has to offer.

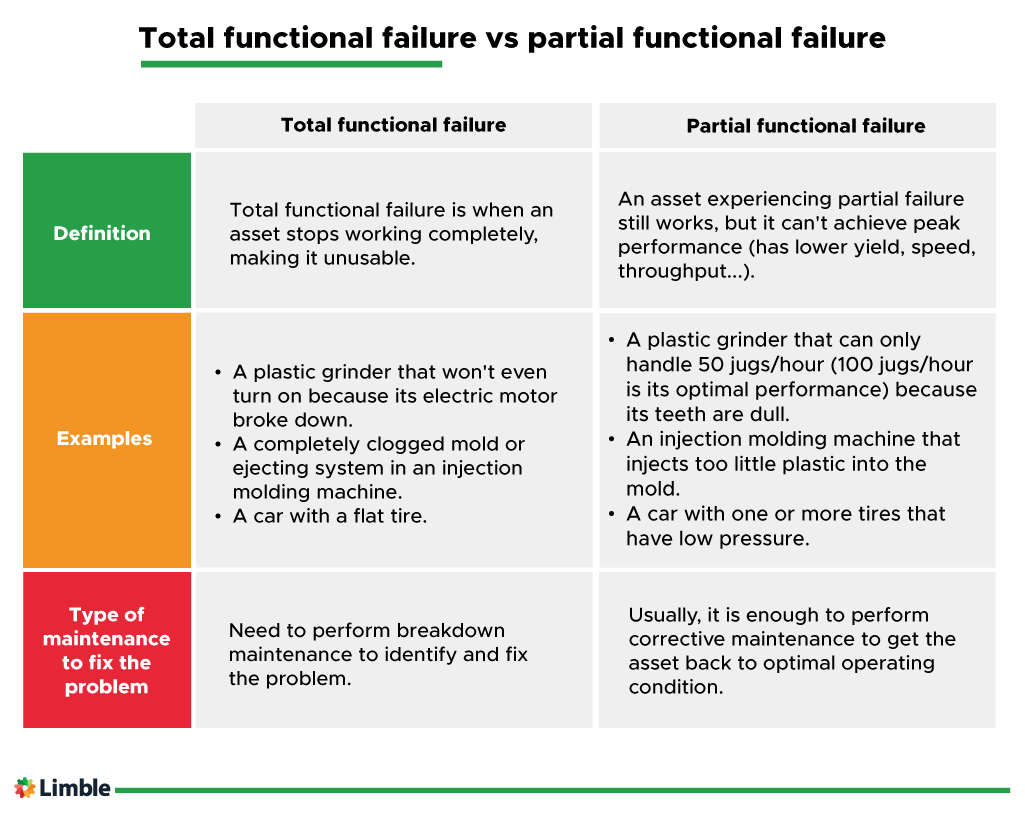

Total functional failure vs partial functional failure

We can break down a functional failure into two distinct categories:

- Total functional failure: The machine doesn’t work at all.

- Partial functional failure: The machine still works, but it can’t achieve peak performance.

Total functional failure is impossible to miss as it makes the asset unusable.

On the other hand, without tracking production metrics, spotting a partial failure can be tough.

Imagine a metal skiver that needs to consistently cut your product into slices of 1.00 inch, plus or minus 5 mils (5 thousandths of an inch). A partial functional failure could manifest as a dull blade with wider tolerance, sending the product outside of your predefined specs.

If you don’t measure the thickness of your product regularly, it might be a while before you figure out that your asset needs corrective maintenance.

Examples of functional failures in industrial equipment

To understand functional and partial failures better, let’s go through a couple of examples.

This time, imagine you’re working in an injection molding facility. There, you have:

- A plastic grinder, which uses large teeth to shred plastic bottles.

- A large injection molding machine that takes molten plastic, pushes it into molds and creates solid plastic parts after they cool.

What do different failures look like for these two assets?

Functional failure examples for a plastic grinder

If your grinder can handle 100 empty plastic bottles an hour, that is its peak performance standard. If your grinder doesn’t turn on or doesn’t chop up any bottles, then you’re experiencing total functional failure.

However, if the grinder runs but can only handle 50 bottles an hour, then you have a partial functional failure.

What could be slowing down or stopping the grinder? There are a lot of factors:

- You might need to grease or replace your bearings that make the grinder spin and cut up plastic.

- You may need to sharpen or replace the teeth of the grinder, as they wear down over time.

- Ensure that there is nothing stuck between the teeth of the plastic grinder. This will either slow down or stop the operation altogether.

- Most grinders use an electric motor to drive the movement. If the motor is due for replacement, you’ll experience some loss of function.

Functional failure examples for an injection molding machine

For a complicated machine like an injection molder, there are a lot of potential failure modes:

- Failure to lubricate bearings will cause deterioration of all rotating shafts. When parts stop rotating, so does your production.

- Failure to clean hoses leads to clogs, a buildup of pressure, burst lines, or too little plastic in each mold.

- Adding the wrong plastic can degrade the lines and lead to leaks.

- A clogged mold or ejecting system can cause finished parts to get jammed in the machine.

- Making too many parts with a single mold will damage the cavity, ruin the tolerances you can achieve, and result in defective parts.

- Failure to lubricate interfering parts will accelerate wear and tear that leads to breakdowns

- When bolts are out of torque, pieces will not be appropriately fastened together. They can vibrate and become loose over time.

Some causes of failure are obvious. When that isn’t the case, you should perform a failure analysis.

Checklist for Creating a Preventive Maintenance Plan

Following a consistent Preventive Maintenance Plan can make life easier. Use this checklist to create your own!

Preventing breakdowns with functional failure analysis

The idea behind failure analysis is to use the data you have available to find the root cause of a specific functional failure. The same analysis can also be used to roll out fixes that may prevent similar failures in the future.

Take a nail gun as an example. Recently, an operator at your site had a nail gun jam. Through failure analysis, you found debris in the nail chamber that became wedged in the barrel, completely jamming the tool.

After some digging, you found the root cause. Operators had been storing the tool in an area filled with gravel, sawdust, and debris.

To avoid this in the future, you choose to store the tool in a separate area.

This approach can be applied to machines of any size, criticality, or complexity, as long as you use the right methods. For an in-depth dive, check our full guide on failure analysis techniques.

Common causes of functional failures

What causes equipment failures in the first place? Here is a list of major culprits:

- Lack of routine maintenance: Routine maintenance tasks can include cleaning, replacing, lubricating, or inspecting parts. Doing this can minimize the impact of a faliure, or prevent it altogether.

- Installation errors: If machines aren’t installed correctly, it could lead to unmanaged vibrations or other issues that hurt the machine’s performance. Installing parts of a machine incorrectly might lead to a breakdown after just a few cycles.

- Design errors: If the shaft in a design is undersized, it can snap during operation and lead to total functional failure.

- Regular wear and tear: Wear and tear are inevitable — materials will degrade, parts will wear out due to friction, and components can cyclically fail. This can be postponed with regular routine maintenance, but it becomes impossible to avoid when the asset is near the end of its useful life cycle.

- Operator error and maintenance mistakes: Using a machine incorrectly, skipping maintenance steps, or misunderstanding how a process works is a quick way to break or damage parts.

Improve equipment reliability with Limble CMMS

Equipment failures come in different forms and sizes. Using a routine maintenance strategy and failure analysis are the most effective ways to prevent both partial and total functional failures.

A modern computerized maintenance management system (CMMS) is your best partner for identifying and solving reliability issues. It ensures preventive maintenance is performed on time and provides all the data you need to perform effective failure analysis.

For a great CMMS partner, consider Limble. Request a free demo today or contact us to learn more.