Farming is a multi-million-dollar, asset-intensive business relying on heavy planning for success. Poor farm equipment maintenance wastes money due to the weather and time-sensitive nature of farming and introduces a bunch of safety risks. Yet, it is a more common occurrence than we’d like to think it is.

Farm equipment breakdowns result in production loss, seed wastage, crop spoilage, and worker waiting time. Add these costs to emergency repair bills, and the total far outweighs the costs of a regular preventative maintenance program.

In this post, we’ll discuss farm assets that need regular maintenance, the benefits of proactive farm maintenance, as well as how to set up an effective farm equipment maintenance schedule.

Building Maintenance Checklist

Use this helpful template as a starting point for your building maintenance program.

What farm assets need regular maintenance?

Farm assets are items with an economic value used in income generation and consist of machinery, equipment, and structures. Comprehensive maintenance extends the useful life of these assets, improving the efficiency of daily operations and reducing annual operating costs.

Equipment and machinery

The range of equipment used in modern farming is staggering. While tractors, harvesters, balers, spreaders, slashers, and seeders get attention due to their size and complexity, there are huge numbers of smaller machines and important tooling to consider.

Motorbikes, ATVs, posthole diggers, chainsaws, welders, brush cutters, and pumps are common equipment often taken for granted on most farms. Step down again from powered equipment, and you’ll find hydraulic jacks, fence strainers, trailers, and yard scrapers.

These items’ failure, loss, or deterioration wastes capital, introduces delays, requires costly repairs, and may cause a safety issue. A comprehensive maintenance program may also prevent fines and criminal penalties following accidents due to unexpected equipment failure.

Structural Assets

Farm buildings and structures are renowned for their run-down state, with artists and photographers chronicling crumbling barns, rusty and damaged silos, and weeds growing through tanks and structures. However artistic, such neglect costs money. Asset life shortens, and contents within the structure, like grain in a silo or tractors in a barn, are damaged or deteriorate more rapidly.

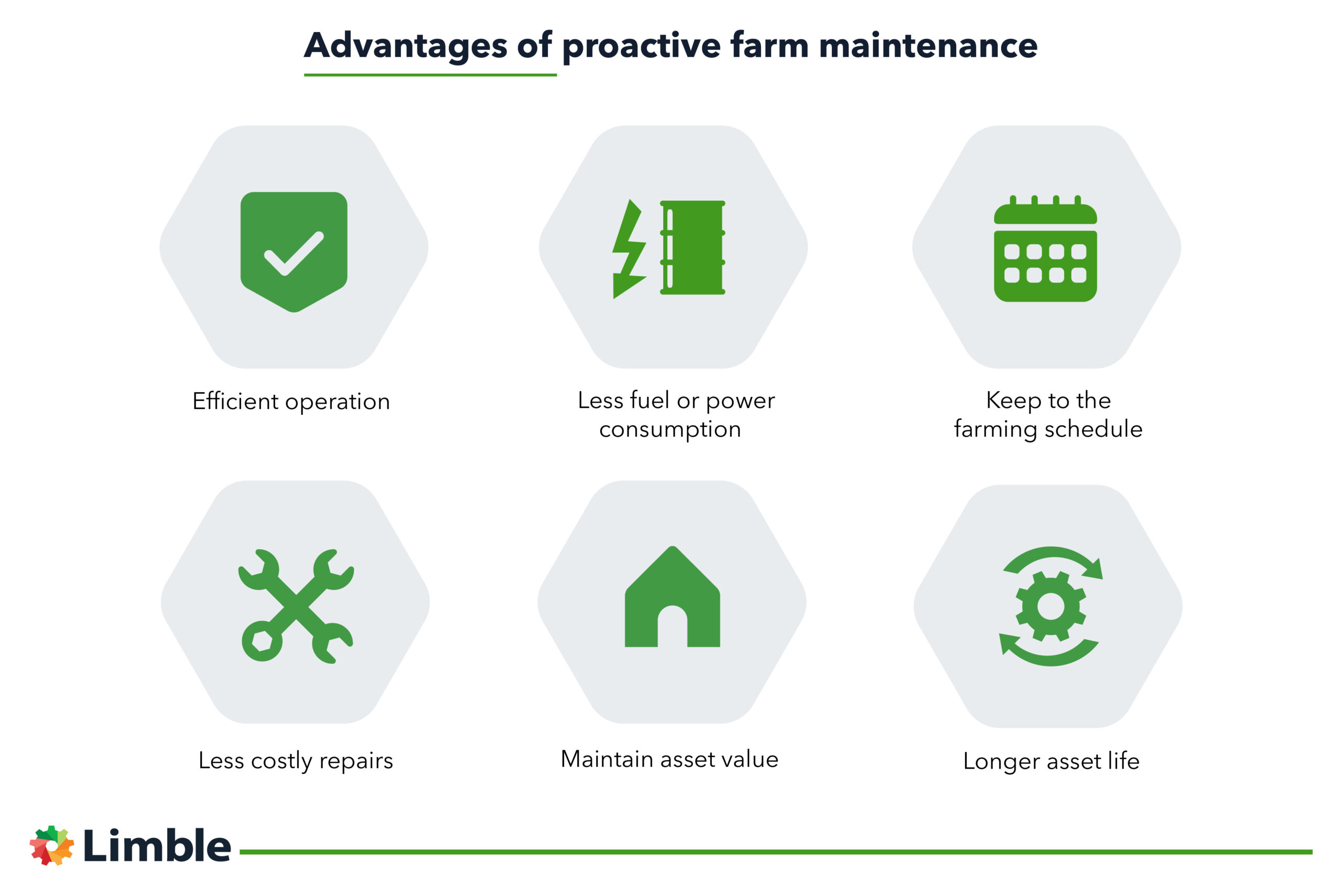

Advantages of proactive farm maintenance

We’ve touched on some benefits, but here are six advantages to implementing a comprehensive farm maintenance program.

1. Efficient operation

Partially blocked air or fuel filters, leaking hydraulic piston wiper and rod seals, leaking pump gland packings, and loose chainsaw chains. These, and many more faults, contribute to inefficient operation by reducing equipment performance. Not to mention how they also waste precious resources and create safety hazards.

2. Less fuel or power consumption

When cooling fans are not operating, bearings are unlubricated, filters are blocked, tire pressures incorrect, or pump bypass valves are in partial bypass, your equipment uses more energy to meet operating requirements. For every ten psi a tire is underinflated, vehicles lose 1% of their fuel economy. You can stay on top of these routine tasks with simple heavy equipment maintenance software.

3. Keep to the farming schedule

Unproductive time adds to farm operating costs. You’re loading your overheads when workers are engaged in anything other than direct production tasks. Traveling back and forth to get tools and equipment, waiting for an outsourced maintenance contractor, changing tires and repairing equipment in the field – these are all wasteful tasks.

Meanwhile, crops need to be harvested, sowed, or cattle fed or milked. If you’ve scheduled a job for four hours and it takes six due to maintenance issues, you’re already 50% over budget on that task.

4. Less costly repairs

Catching and addressing equipment deterioration early costs considerably less than repairing it only once the equipment breaks down.

The Virginia Polytechnic Institute and State University quote a study showing that farmers reduce maintenance costs by 25% after improving their maintenance procedures. The 2009 study cited one $80,000 tractor undergoing average maintenance requiring $24,000 in repair costs over 5,000 hours of operation. Improving the maintenance program decreased this cost to $18,000.

5. Maintain asset value

Maintaining the performance and appearance of our private car achieves a better price when it comes the time to sell. The concept is no different with farm equipment. Diligently maintaining your assets keeps them looking and running better, providing a higher resale value when you upgrade or replace the item.

6. Longer asset life

Assets have a useful life, a duration you can expect the asset to function and generate income. Spend $100,000 on a machine designed to last ten years, with an expected residual value of $20,000, and you’re consuming capital at $8,000 annually.

Do minimal maintenance, and your useful life may drop to eight years with a residual value of $18,000. You’re now spending $10,250 annually, increasing your capital spending on that machine by 28%.

Carry out proactive maintenance, and you might extend the useful life by two years and sell the machine for $21,000. You’ve reduced your annual capital spending to $6,600, gaining an 18% saving over its design life and a whopping 36% over our worst-case maintenance scenario.

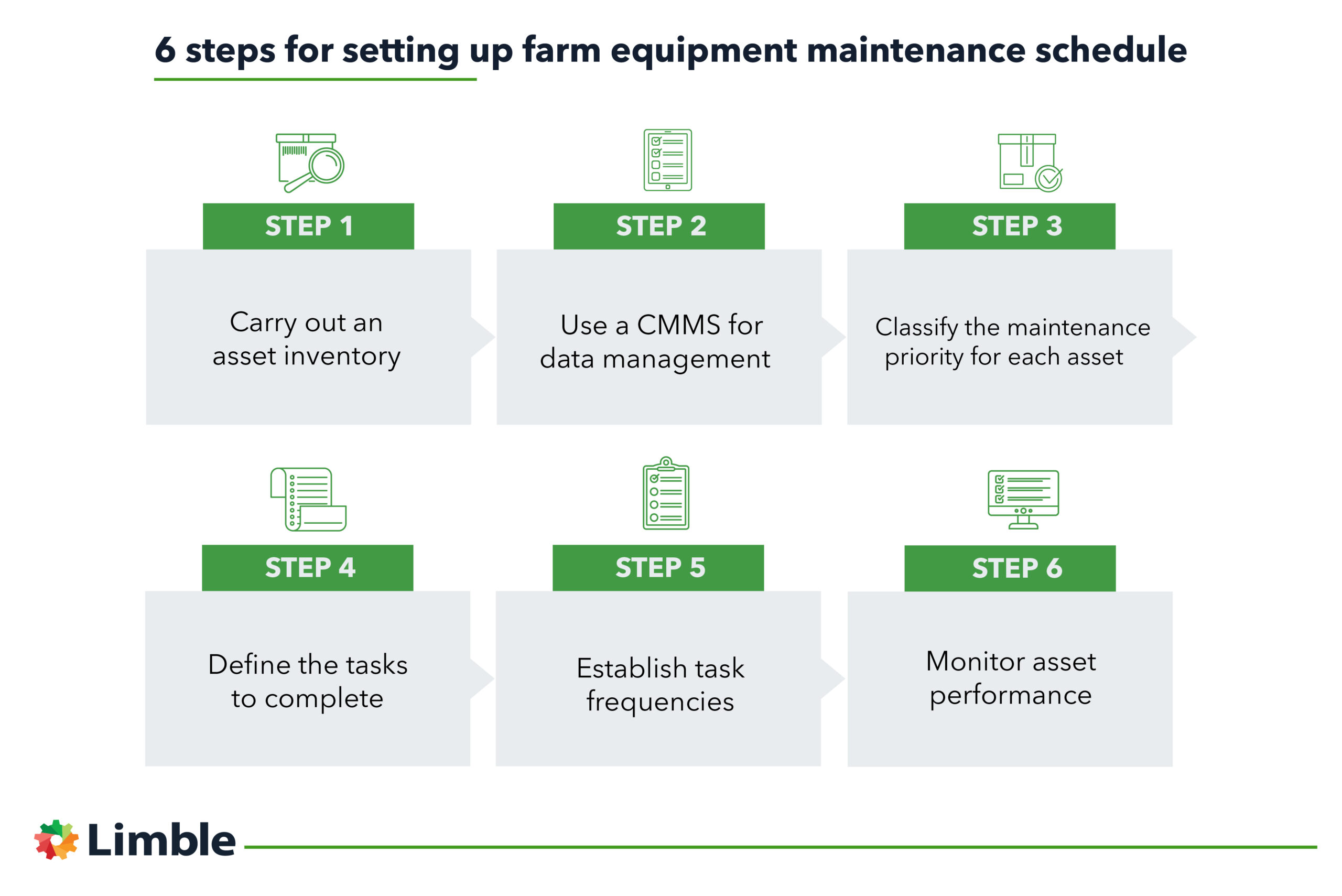

How to set up an effective farm equipment maintenance schedule

Here we’ll explain six steps to follow for an effective farm equipment maintenance schedule.

1. Carry out an asset inventory

You begin by cataloging all assets that will require maintenance during their useful life. You will want to capture the following data on each asset, where it is applicable:

- Make and model

- Serial number

- Location

- Is it a spare part or complete equipment?

- Serviceable or unserviceable?

- Include numbering systems for large equipment (in case you use them)

- Photo of equipment (especially if you have a lot of different equipment)

The easiest way to capture all the above information is to use CMMS software. If you don’t have a budget for a CMMS at the moment, manual tracking of your assets through spreadsheets will do the job.

2. Use a CMMS for data management

A computerized maintenance management system (CMMS) manages your maintenance by recording each asset, its maintenance tasks, and the frequencies at which you must complete each task.

It will track hours, dates, or equipment cycles and warn you of any maintenance items due in the next period. It can advise on the equipment location and maintenance resources required, including tooling, personnel, spare parts, and documentation.

On the day you plan the maintenance, the CMMS will output task cards that advise the technician/operator on scheduled tasks, required resources, and the expected time the task will take.

CMMS also lets you record any defects found during the maintenance to capture the remedial work or schedule corrective maintenance for a later date. Last but not least, it captures and retains all maintenance history to analyze equipment performance and calculate its total cost of ownership.

If you have just a few pieces of farm equipment to maintain, you can use manual management systems such as spreadsheets or large planning calendars on which you can easily note maintenance tasks that need to be performed in defined intervals.

3. Classify the maintenance priority for each asset

In this step, classify each asset into one of four categories:

- Run to failure: Used for non-critical assets, items of low capital value, high failure rates, or disposable items. There’s no value in spending resources doing regular maintenance on these assets

- On-condition: Assets you can easily monitor and replace, or repair once they reach a certain threshold. Many of your assets will fall into this category – air filters, tires, and similar.

- Condition-monitored: Applies to assets where visual inspections will not identify deterioration, the asset operation is critical or failure is costly. A good example is oil analysis.

- Finite life, or time life components: Have a fixed frequency at which you should remove the asset (for example, fuel filter) from service. It may then be sent for overhaul or scrapped.

4. Define the tasks to complete

Use original equipment manufacturer guidelines to create the list of maintenance tasks for each asset other than those you intend to run to failure. Each manufacturer will have servicing and maintenance tasks at recommended intervals. Add in any custom tasks you want to complete due to the specifics of your operation.

5. Establish task frequencies

This step requires applying a frequency for the completion of each task. Remember that one task may have multiple frequencies. For example, a filter change may have a hard limit of 5,000 engine hours and a calendar time of four years, whichever occurs first.

Many of these frequencies you can get from an equipment manufacturer or maintenance manuals. Some you’ll decide on yourself, based on your previous experience with the equipment.

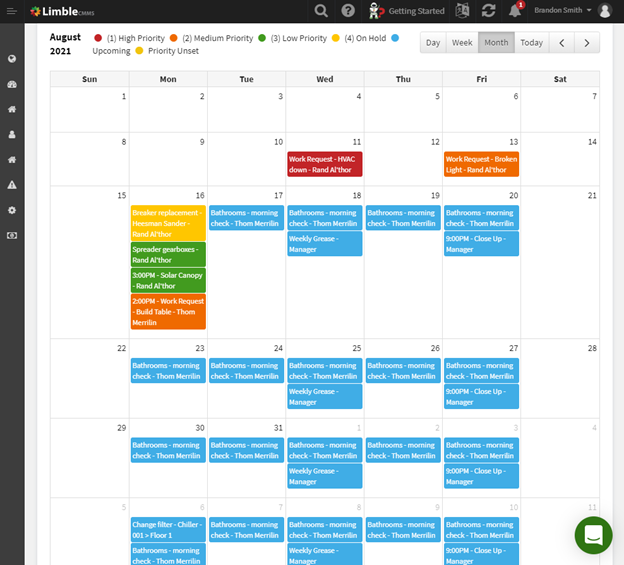

When you are done, you can enter all of that data into maintenance software like Limble CMMS and track everything via its simple-to-use drag-and-drop maintenance calendar.

An example of a maintenance calendar inside Limble CMMS

6. Monitor asset performance

As you begin using your maintenance program, you’ll see its effects on the equipment. You may find that each time you inspect a component, there is nothing wrong with it, with no visible deterioration. Extending the frequency of that inspection avoids wasting inspection resources.

However, suppose you see that the replacement of a component should have occurred earlier or equipment performance begins to suffer. In that case, you can increase frequencies on those inspections you feel will resolve the issue.

Additional practical considerations for farm maintenance

Let’s tackle some practical considerations you should also have in mind while conducting farm maintenance.

Tooling inventory

The tools you use for farm maintenance are assets in their own right. Be sure to keep an inventory and maintain them regularly. If you need specialist tools, buy or rent them. Using the wrong tools, or making do, is a primary cause of accidents.

Consider spares holdings for critical items

Consider creating a clean room that is temperature- and humidity-controlled to hold spare parts for critical equipment. Relying on urgent deliveries when something breaks wastes time and costs money.

Phase or level the maintenance workload

Your first farm maintenance plan will have peaks and troughs in the workload. Try to level the plan by shifting farm equipment out of phase with others and breaking large maintenance periods into multiple smaller maintenance blocks.

Farm equipment cleanliness and lubrication

Regularly clean your machinery, as accumulated dirt hides defects. The simple act of cleaning ensures someone is casting their eyes over all parts of the equipment regularly. If you use a pressure washer, be sure to lubricate all points immediately after.

Deciding on a maintenance provider

Deciding whether to do the farm maintenance yourself or outsource to others is always a dilemma. If you have a large farm and lots of equipment, there might be a case to employ your own maintenance person. However, many farms won’t have enough regular work to keep someone busy full-time. There will also be expensive specialist tooling it makes no sense to purchase. The answer is usually a hybrid solution.

Always ensure the daily checks, lubrication, and minor servicing tasks are done by you or the people operating the equipment. It drives ownership and an awareness of developing issues. Regular monthly maintenance using commonly available tools and mechanical knowledge can be adequately done in-house or by a local mechanic.

When you need to maintain advanced equipment requiring specialist knowledge and tooling, contact service people that have experience with that equipment. Trying to cut corners on this type of machinery will void warranties and potentially cause considerable downtime and cost if something goes wrong.

Use Limble CMMS as your farm equipment maintenance software

Having one centralized software that’ll help you manage all your farm maintenance tasks sounds like a marvelous idea, right? Crowded excel sheets and sticky notes that always manage to get lost can actually become a thing of the past.

With the features it offers, Limble can help you:

- Easily manage different groups of your assets and track how often they are breaking down and getting repaired.

- Quickly organize all your work orders and other tasks in a centralized database so your employees can easily access them.

- Track and optimize levels of spare parts inventory – you’ll get push or email notifications each time a part’s quantity is low.

- Integrate all your vendors into Limble and seamlessly keep track of all their information, invoices, work history, and schedules.

- Build custom reports and start using collected data to make smarter decisions about your assets.

If you want to find out more info about Limble CMMS and how it can help you with your farm maintenance, schedule a demo or start a free trial.