Original equipment manufacturers (OEM) are an integral part of modern industrial production. Most of the products we use in our daily lives are comprised of OEM parts. Yet, most consumers tend to be unaware of the role played by these companies, since they exist largely in the B2B market.

The same cannot be said about industrial maintenance professionals – they cannot afford to ignore OEMs! In this post, we will explore how to use the OEM as an indispensable resource in your maintenance strategy, and how and when to consider alternatives. But first, let’s take a closer look at OEMs in general.

What does OEM mean?

Before industrialization, most products only had a few moving parts. Manufacturers created basically everything they needed in-house.

These days, products are infinitely more complex. Cars, computers, heavy machinery, TVs, mobile phones – everything contains hundreds, sometimes thousands of different components.

Even the largest of corporations don’t attempt to keep everything in-house. Outsourcing and relying on third-party vendors for specific parts is not only cheaper, but far more convenient as well.

This is where original equipment manufacturers come into the picture. It is almost impossible to envision modern industry without OEMs. They provide many benefits, some of which we take for granted:

- OEMs allow other manufacturers to cut production costs

- They enable competitive pricing of products through economies of scale

- Through specialization, they encourage technology innovation

- They help maintain high-quality standards in industrial production

OEMs provide components for finished products

This is the classic definition of an OEM – a company whose products are used as components in the creation of a finished product by another company.

For instance, Brembo is a famous Italian manufacturer of high-performance brake pads. They are the OEM for the brakes used in many sports cars from manufacturers like Ford, Chevrolet, and Dodge.

OEMs provide equipment

Manufacturing involves the use of specialized CNC machines, foundries, cranes, loaders, hydraulic presses, drills, and a wide range of other advanced machinery. In many instances, companies buy them from OEMs that specialize in the design and manufacturing of industrial equipment.

A good example here would be Lincoln Electric, a global leader in the production of CNC machines and welding equipment.

OEMs can supply software and hardware

Another example comes from the tech industry. Many companies in the software space work as OEM suppliers for other companies. In this arrangement, the OEM will give out licenses of their software products to other companies.

Microsoft is one of the biggest examples of a software OEM – their Windows OS and MS Office suites are bundled on laptops and PCs sold to end-users by computer manufacturers like HP and Dell.

The hardware part of the computer industry is even more famous for OEMs – hard drives, graphics cards, and processors for retail products are manufactured by a handful of companies, with giants such as Intel leading the market.

The relationship between VARs and OEMs

A Value Added Reseller (VAR) is any company that buys components from an OEM and sells it to customers with additional features that enhance the original. A VAR is similar to a reseller but distinguishes itself from the latter by adding tangible value to the OEM product.

A company specializing in custom PC building can be considered as a VAR – they source all components from OEM brands like Intel, Nvidia, Asus, Samsung, Corsair – do the assembly, take care of the operating systems and apps, and deliver a finished product built to the specifications of the buyer.

A car dealership can be also considered as a VAR – they source the cars from the automaker and add features/services and additional components – a service plan, insurance, finance options, entertainment systems (from other OEMs) before selling to the final customer.

VARs act as a worthwhile distribution and marketing channel for OEMs, leaving them free to focus on their core activities like production and R&D.

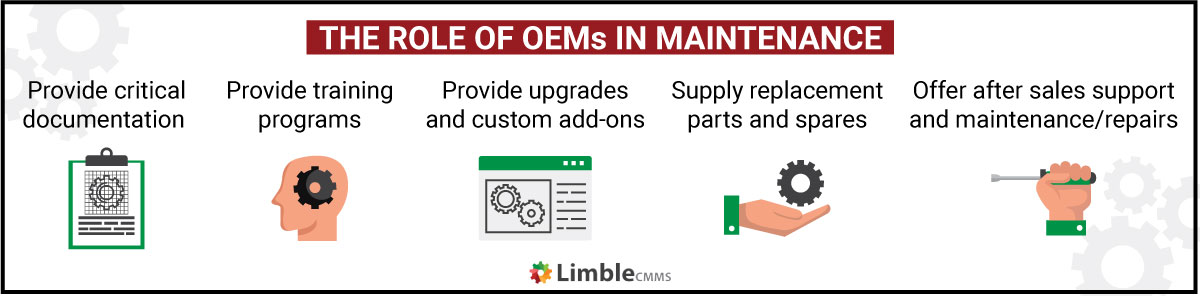

The role of original equipment manufacturer in maintenance

OEMs that supply machinery and equipment have a much larger bearing on industrial maintenance than those that supply components for the final product. The reason is quite obvious – it is the job of the maintenance department to conduct regular servicing and repair of all company assets on the production floor.

When the equipment is sourced from an original equipment manufacturer, its reliability and quality will have a huge bearing on the long-term productivity and the potential ROI of the procured asset.

The impact of an OEM partner does not end at the time of asset acquisition. It extends throughout the service life of the asset.

OEMs provide critical documentation

Access to proper documentation is essential during the asset acquisition process – it allows firms to zero in on products that match their needs and specifications. Furthermore, user manuals and vendor guidelines help staff get familiar with the equipment. This is especially important for the maintenance team.

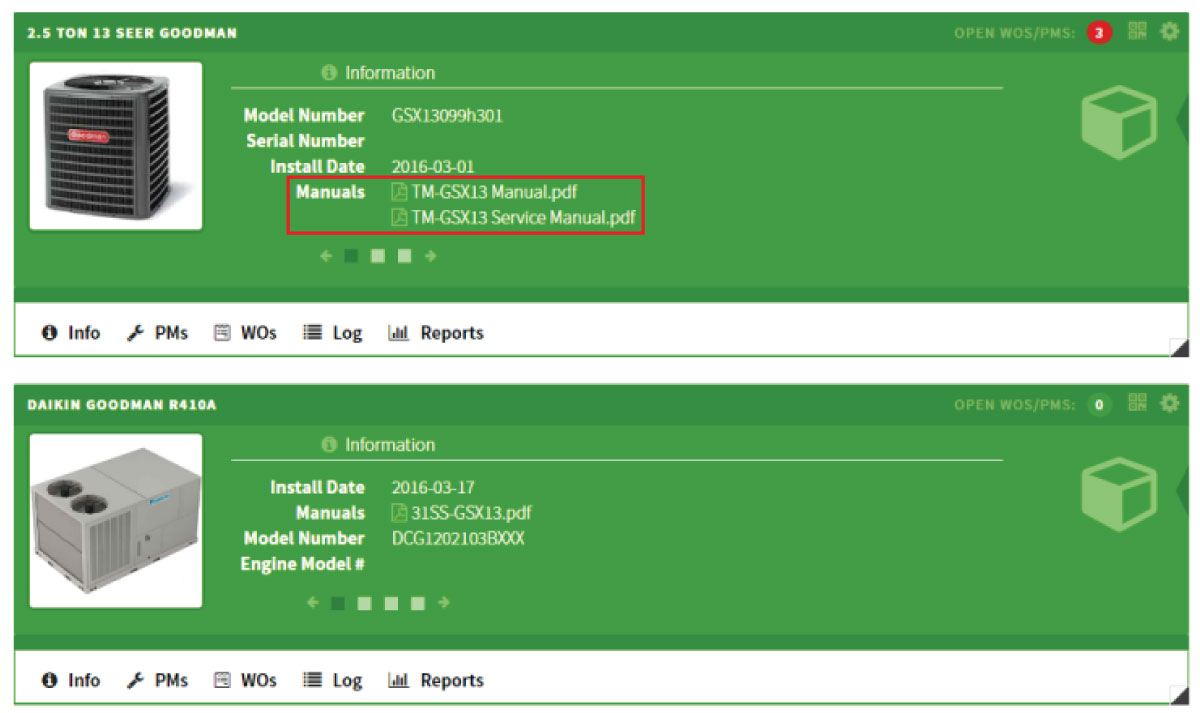

With modern CMMS like Limble, user manuals can be attached to respective assets.

An example of an asset card inside Limble CMMS (which can include user manuals)

This way, maintenance techs and operators can access it from anywhere with just a few simple clicks. Combine that with quick access to maintenance history and checklists and you have created an environment where maintenance techs have everything they need to minimize downtime and spend the least amount of time troubleshooting failed equipment.

OEMs can provide training programs

If the product is a highly technical or sensitive piece of equipment, OEM vendors often provide additional services in the form of maintenance training programs. These may include modules focused on operations as well as repairs, troubleshooting, and advanced equipment maintenance.

Maintenance Inventory Tracking Template

Begin tracking your maintenance and parts inventory with this free and easy-to-use template.

OEMs provide upgrades and custom add-ons

In the IT and software fields, frequent software updates and security patches are common features provided by OEMs. OEM software improves end-user experience and helps neutralize potential security threats.

Similarly, when it comes to equipment, OEMs might offer optional upgrades, expansions, and customized add-ons, depending on the changing needs of your business.

OEMs supply replacement parts and spares

In all pieces of hardware, some parts are more prone to degradation than others. Companies often keep a constant stock of essential spares for their critical assets. These stocks have to be replenished regularly.

Naturally, OEMs are usually the best (if not the most economical) sources of equipment spares and replacement parts.

OEMs offer after sales support and maintenance/repairs

Some OEM vendors may also offer ongoing maintenance services as part of an after-sales support program. When dealing with highly-specialized equipment, the on-site maintenance team may not have the necessary expertise or tools to perform the required maintenance actions.

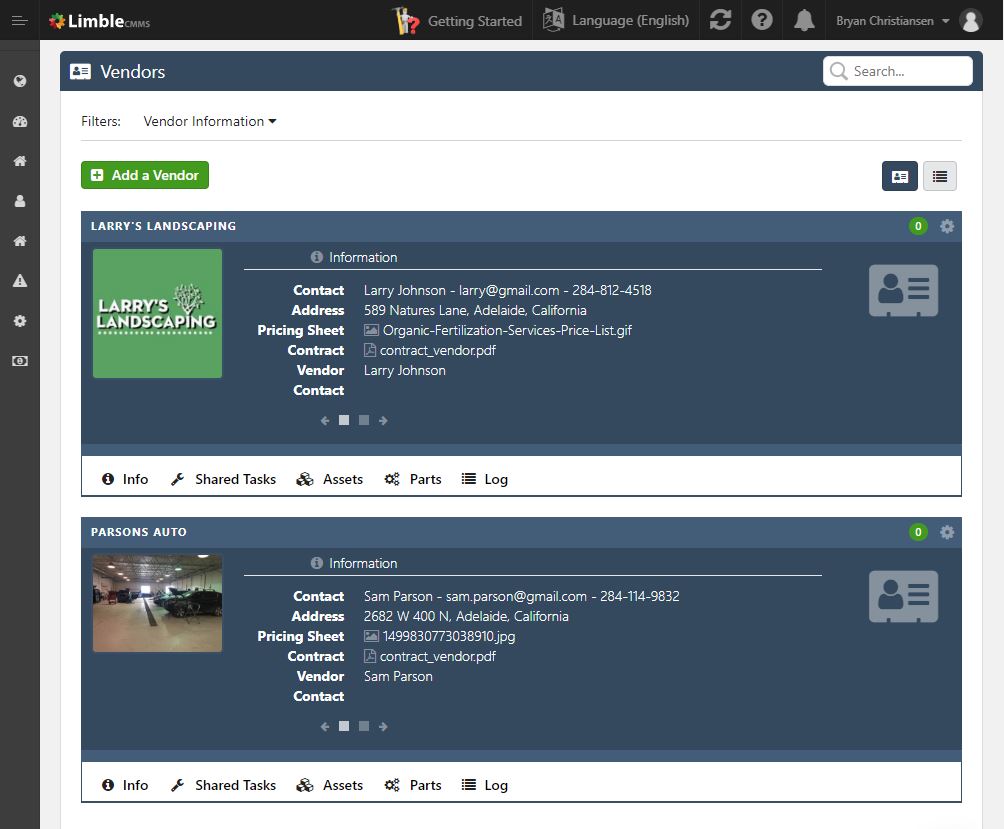

The cost of these services depend on the signed maintenance contract. You can use the Limble CMMS vendor management module to track costs associated with each vendor, as well as keep track of their work.

A vendor overview screen inside Limble CMMS

Keep in mind that there are many OEM vendors who don’t provide all of the aforementioned services. Picking vendors who don’t provide adequate documentation or a reliable supply of spares can increase your maintenance costs and risk of unplanned downtime. Be sure to do your homework when picking your maintenance vendors.

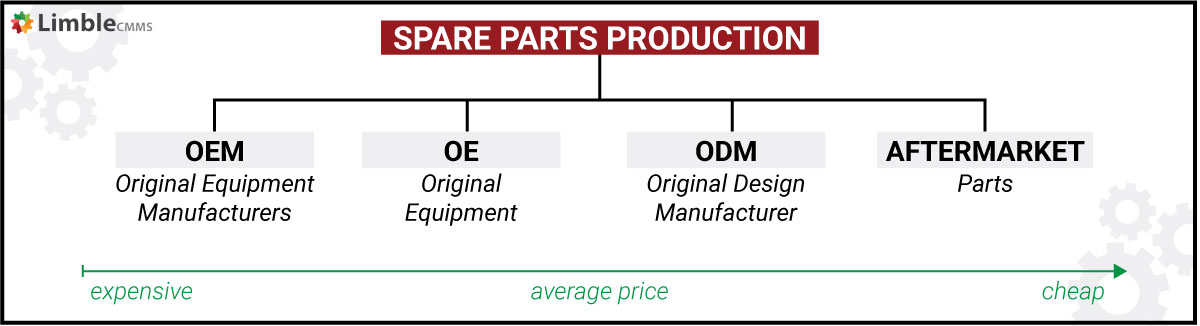

The alternatives to OEM parts – OE, ODM, aftermarket

The supply of affordable spares is an important concern for any industrial enterprise. Managing spare parts inventory is a major unavoidable expense for any business using industrial equipment.

Now, OEMs may seem like the natural choice as the source of all spares and parts. But other options do exist in the market, in the form of OE, ODM, and aftermarket spares. Let’s see how they stack up against OEM spares.

OEM vs OE parts

OE stands for Original Equipment, the same as in “OEM.” Both OE and OEM parts are identical as they are made based on the same factory specifications. The only difference – a different company makes the OE parts.

For example, consider an OEM car component for a Mercedes manufactured in-house by the company. The OE variant of the same component may come from licensed auto parts subcontractors of Mercedes – companies like Hella Behr.

The OE component will come with the authentic Mercedes logo, and the same build quality and reliability as the original product. OE spares tend to be cheaper than their OEM counterparts.

OEM vs ODM

ODM is an acronym for Original Design Manufacturer. ODM and OEM are often used interchangeably and cause a fair bit of confusion. An Original Design Manufacturer is any company that manufactures a new product based on exact specifications and designs provided by a client that owns all the license and branding.

A great example of ODM – client relationship involves the new Nokia mobile phones. The phones are developed and designed by the Finnish firm HMD Global. They own the Nokia brand, but the production is handled by ODMs like Taiwanese electronics manufacturer Foxconn. The name of the ODM does not appear on the retail products – the phone carries the Nokia brand name.

Since ODMs rely on the design and specifications provided by the brand owner, you can expect the same quality and reliability as on the original company’s product, probably with cheaper costs as well.

OEM vs aftermarket parts

Aftermarket parts are manufactured by companies that are generally not connected to the OEM in any way. There are numerous firms out there, especially in the automotive segment, involved in the production of aftermarket alternatives for OEM spares.

Aftermarket parts come with considerable appeal – they can be 60% less expensive than OEM or OE parts. But that affordability does come with major caveats in terms of quality and reliability.

OEM/OE spares from different sources will offer a similar level of reliability. But with aftermarket parts, you do not have this guarantee. There are numerous options from obscure manufacturers, with wild variations in quality.

Some expensive aftermarket solutions do offer performance and durability comparable to (or better than) OEM parts. Unfortunately, that is more of an exception than a rule. The vast majority of low-priced spares come with a limited warranty and low quality.

If you can find a consistently reliable brand, aftermarket spares can be a great way to cut down maintenance costs on your lower priority assets. For critical assets, it is better to stick with OEM/OE parts.

Cheaper is (almost) never better

From a pure maintenance perspective, picking the right OEM for critical assets will depend on several factors. The level of support offered by the OEM through training, manuals, and after-sales service will have long-term implications on asset reliability and longevity.

The availability and pricing of OEM spares, and the price/quality balance on aftermarket spares, can easily complicate vendor selection.

Ultimately, the decision should be based on a long-term outlook. Cheaper parts and products will need to be replaced more often, forcing you to expend more maintenance resources in the long run. More work also means more downtime.

Keep that in mind while choosing your original equipment manufacturer and OEM parts provider.