There is one thing in common between the modern armed forces, athletes, HR departments, and Silicon Valley tech firms – they all use tactics and strategies inspired by Frederick Winslow Taylor, often referred to as the “father of scientific management.”

Taylor’s ideas, like improving work ethics, reducing waste, and creating improved production standards, continue to apply. One of those ideas, one that is critical for improving efficiency on the plant floor, comes in the form of a time study.

Conducting time and motion studies is no ordinary task. It requires careful preparation with a well-thought-out plan. In this post, we will outline the process and share important considerations for getting things right on the first try.

What is a time study?

British Standards Institutions (BSI) is the premier body tasked with the creation of engineering and industrial standards of production in the UK. This is how the BSI defines time study:

“Observing, recording, and rating of human work to establish the times required by a qualified worker to perform specified work under stated conditions at a defined rate of working.”

The “work” it refers to involves all activities on the factory floor that contribute to the production process – the use of manual labor or machines, machine operators making decisions on the fly, and similar.

Time studies are best suited for activities that involve a set of predictable and repetitive actions. They are ideal in factory settings, where the production process can be broken down into a series of sequential tasks and operator movements.

In such a context, you measure the amount of time taken for a particular task done by multiple workers to find the standard time (we will show the calculation later in the article). In industrial engineering and manufacturing, standard time is the average time a properly trained worker takes to complete a specified task.

A time study is a work measurement activity, usually conducted by a trained observer, with the aid of basic equipment like a stopwatch and a clipboard to note down the time recordings. In modern factories, observers can use more advanced tools like video cameras, computers, and specialized software.

The Essential Guide to CMMS

The Essential Guide to CMMS

Why conduct a time study analysis?

When performed properly, with due planning and careful analysis, a time study delivers a granular view of how efficiently work is being conducted on your plant floor. The standard time is an invaluable metric for managers looking for ways to improve production efficiency and productivity in general.

It can also be used to find hidden flaws and weaknesses in other aspects of the plant floor, like sub-optimal layouts and placement of machines and workstations. Using standard time, you can locate inefficiencies in the allocation of manpower, machines, and other production inputs.

Apart from cost and efficiency improvements, time studies can be vital for worker welfare. It can help in the creation of better, safer workspaces. Managers can identify and remove unnecessary and potentially dangerous movements and actions on the plant floor, thereby reducing the effort required to complete specific tasks.

There are plenty of other benefits to conducting a time study:

- required for realistic planning of production schedules

- helps in the optimal allocation of manpower on the plant floor

- can be used for comparison with alternative processes

- necessary for balanced work distribution among employees

- helps create target times and wage incentives

- helps eliminate inefficient or unnecessary operations and minimize worker effort

- if done for maintenance workers, it can help maintenance planners and managers to better plan and organize routine maintenance work

Standard time is a very useful metric for industrial engineers and production managers. It allows them to compare their plant’s efficiency with industry standards. The metric is also valuable from a future planning perspective in estimating the following key aspects:

- delivery times of future product batches

- future manpower requirements and labor costs

- future machinery/production equipment investment requirements

- future raw material procurement needs

- inventory management

- overall production cost and selling price per unit

There are plenty of reasons to conduct time studies. Let’s see what you should have in place before you start the stopwatch.

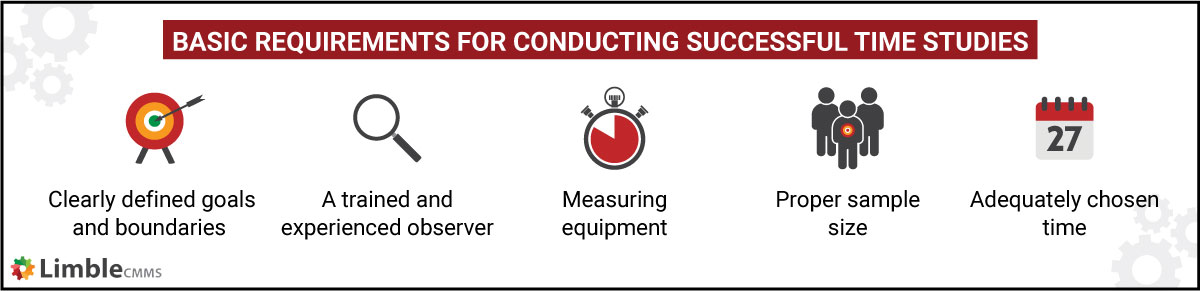

Basic requirements for conducting successful time studies

Regardless of the industry or production processes involved, a time study will have the same basic requirements.

We can classify them into the following 5 areas that you need to address when you prepare your time study:

1) Clearly defined goals and boundaries

Before you conduct your time and motion study, you need to establish clear boundaries.

First, determine and specify the goals of the study – speeding up the production process, removing wasteful actions, etc.

Next, pick the processes that will be the core focus of the study. See if your sector already has established standard times that you can use as a reference point for comparison.

2) A trained and experienced observer

This is the person who will conduct the time study. In most instances, industrial engineers with relevant experience and training are preferred for this job.

Ideally, they should have certification in workplace optimization. The observer should have a safe and comfortable vantage point from which he/she can watch the workers as they conduct regular tasks.

There are companies out there, such as Industrial Time Study Institute, that offer consulting and training services. They can help you execute your time studies and answer any technical questions.

3) Choice of equipment (basic vs advanced)

The role played by time study equipment has changed dramatically in recent years. In the past, studies were conducted with a simple stopwatch and time study boards, with the observer close to the workers.

This had some major disadvantages, the most important of which was the “Hawthorne Effect” – workers may put in more effort than normal when they know they are being watched.

Modern technology allows observers to watch and record times from a distance and in secret, using video equipment (CCTV), and specialized software platforms that can replace a stopwatch and the basic time study recording tables.

4) Proper sample size

Due care should be taken when picking the labor sample size. If it is not adequately large and representative of your existing workforce, your work measurement will be practically useless.

The quality and competence of the workers are also critical. A common mistake is to pick the best-performing individuals. Instead, pick a balanced sample size that favors workers who are well trained, but whose work output does not put them at either extreme of low or high productivity.

5) Adequately chosen time

To reduce the margin of error, a time study usually involves taking measurements across multiple production cycles. In manufacturing plants, there will be periods of production with shorter deadlines and more intense activity on the plant floor.

Care should be taken to pick a period that is representative of the general workflow in the facility, within predictable limits. Unless you have a specific goal, avoid those peak seasons of demand when conducting time studies.

An outline of the process: how to do a time study?

A time study is conducted linearly, with several clearly defined steps. The qualified observer will take the following course of action once the study commences:

- Select the tasks to study: this will depend on the goals of the study and the basic boundaries established by the firm. The type of manufacturing business and the current state of the production systems will have a defining role here.

- Analyze the individual tasks: is the production using already established processes and standards in the industry? If yes, the observer can select baseline standards and calibrate the measuring process to reflect them. If no standards exist, the observer will have to use his/her experience and judgment to plot the best baseline.

- Select eligible workers: it should be a representable sample of adequately trained average workers.

- Estimate the number of cycles to be observed: more data samples will result in less margin for error, but requires more time and effort. There is a balancing act required here, based on time and budget limits.

- Communicate the details of the study to workers: time studies can have a disruptive influence on the workforce. People will worry about the potential implications the study can have on their future job security. It is very important to communicate the purpose of a study beforehand.

- Observe and record the worker performance and times for each element: many techniques are available to observers. If using a basic time watch, timing methods include the continuous method, snapback method, and accumulated method. More advanced tools and software allow these measurements to be automated.

- Use the observed data to calculate standard time: the formula and calculations will be explained in detail in the following section.

Finally, based on the calculations and the initial goals of the study, the company should be able to come to some actionable conclusions.

How to calculate standard time

Once the observer has recorded the actual time readings of all the workers in the sample group, it is time to calculate standard time. The process follows this order:

- calculate Average Time

- calculate Normal Time using Average Time and Rating Factors

- calculate Standard Time using Normal Time and Allowances

1. Calculate Average Time

As the name indicates, this is the amount of time taken by the worker to complete the task, from start to finish. When multiple workers are being observed as part of the study, an average value of observed time is generated by calculating the average of all the recorded time readings, after the removal of any abnormal values.

2. Determine rating factors

The actual recorded performance of a worker may not always conform to the “normal” standards of the task. The observer has to apply an adjustment to the observed time to deduce the time an average operator would have taken to complete the task.

Using his/her judgment and experience, the observer can determine the performance rating of individual workers. Popular rating systems used for this purpose include:

- Pace/Speed Rating

- Westinghouse System

- Objective Rating

- Synthetic Rating

These rating systems use factors like speed, skill, effort, and consistency of the worker to evaluate their performance. The rating factor is calculated as a percentage figure like 90% or 120%. This shows any deviations from the expected performance, which is represented as 100%.

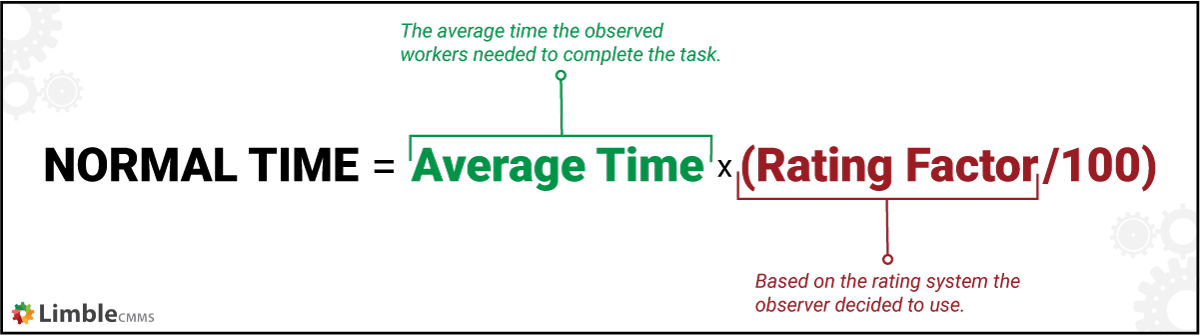

3. Calculate Normal Time

When you multiply the average time by the rating factor in decimal format, you get the “normal time” value for a task. Here is the formula:

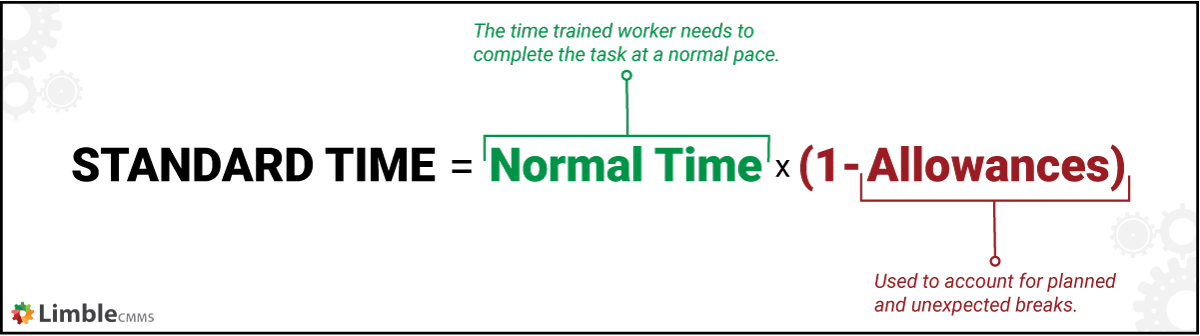

To arrive at Standard Time, Normal Time is adjusted with additional values called “allowances.”

4. Provide allowances

Real-world working conditions can have a massive impact on the productivity of workers on the plant floor. These conditions will vary drastically from one production facility to another. Observers have to provide allowances for these differences.

They have a wide array of factors, which can be divided into 5 major categories:

- Relaxation allowance: it includes personal needs (time taken for meals, water and bathroom breaks, etc.) and fatigue (includes things like standing duration, level of illumination, air quality, use of force, physical and mental strain, etc.).

- Interference allowance: if the worker has to operate multiple machines or tools, this allowance is used to factor the downtime on a machine when the worker is busy on other machines.

- Process allowance: it accounts for any downtime that comes as part of a process, or due to power failure, faults in the machines, etc.

- Contingency allowance: this will account for all irregular and unpredictable breaks or delays (like emergency maintenance) that may come up during the production process.

- Special allowance: some routine activities – such as a start-up, cleaning, shut-down, and changeover of equipment – are encouraged by management, to improve equipment safety and longevity. The disruption caused by these breaks is factored in using this allowance.

Allowances are given in the form of percentages, so they can be used in the final calculation of standard time.

5. Calculate Standard Time

Finally, we arrive at the key metric which gives us the time taken by a normal worker for a particular task, when it is performed under average/standard conditions, after taking into account various allowances for legitimate and unavoidable disruptions.

To arrive at the standard time, you have to multiply normal time with an allowances rating factor. The formula goes like this:

Now, let’s show how this works in an actual example.

Manufacturing time study example

Let us consider a basic manufacturing setting where workers are producing backplates for car brake pads, in a brand-new facility. Imagine that these workers take an average of 33 minutes for a batch of backplates.

The company wants to conduct a time study to find how the factory floor efficiency compares to the industry average and, if possible, identify areas that can be improved upon.

For the sake of this example, let’s assume that the expected time value for the task of producing one batch of backplates is 30 minutes.

The measurements show that workers are about 10% slower than the expected norm. So, the observer can safely assign a performance rating factor of 90%, using the simple speed rating method.

To accommodate for the different breaks observed during the work cycles, the observer adds a relaxation allowance of 7%, an interference allowance of 5%, and another special allowance of 8%, for a total of 20%.

So we have the following known variables:

- Average Time = 33 minutes

- Speed Rating = 90%

- Allowances = 20%

To calculate Standard Time, we first need to calculate Normal Time using average observed time and speed rating:

Normal Time = Average Time X (Speed Rating/100)

Normal Time = 33 x (90/100)

Normal Time = 29.7 minutes

We can round that off to 30 minutes – this is the baseline speed at which workers are expected to complete the production of a batch of backplates when working without any breaks or interruptions.

Next, we combine this normal time with the allowances to arrive at the Standard Time for producing a batch of backplates in the factory:

Standard Time = Normal Time ÷ (1 – Allowances)

Standard Time = 30 ÷ (1 – 20/100)

Standard Time = 37.5 minutes

As we can see from the above calculations, the standard time taken by workers in the facility to produce a batch of backplates, after taking into consideration various factors like speed rating and break allowances, is around 37 and a half minutes.

The time study shows several areas where there is room for improvement. For instance, the 33 minutes of observed time shows that workers are not performing – on average – to optimum levels. Management may need to identify the reasons for inefficiency and apply remedial measures.

Allowances are another area where the facility can make improvements. Cutting down on relaxation allowance may have negative effects – reduced employee morale, compliance violations (employee rights), etc. However, interference allowance and special allowance could possibly be tweaked to further improve productivity.

Equipment failure is one of the most common causes of interruptions on the production floor. The best way to battle them is to use a modern CMMS system to develop a proactive maintenance management culture.

The key to success is in continuous improvement

If you want to eliminate waste from your production floor, you have to adopt concepts like lean maintenance and continuous improvement.

The first step towards improving efficiency is acquiring specific data points on performance metrics. With machines, it is easy to predict performance. But the humans operating them are far less predictable.

A time study helps fill this critical void for manufacturers. With the advent of modern technology, it is now easier than ever to conduct accurate time and motion studies. Still, if you do it the old-fashioned way, all you need is a stopwatch, a clipboard, and some patience!

Comments are closed.