The use of machine tools represents the backbone of any metalworking industry. A typical machine shop utilizes machining technology to perform operations such as milling, grinding, cutting, drilling, and turning.

The operators use sophisticated controllers in Computerized Numerical Controls (CNC) machines that precisely repeat machining operations without compromising output efficacy.

The problem is that, as the machine tools get more advanced, the requirements to properly maintain them also get more complex and require a greater degree of skills and expertise.

The purpose of this article is to outline must-know machine tools maintenance practices that are prevalent in the industry.

Maintenance Inventory Tracking Template

Begin tracking your maintenance and parts inventory with this free and easy-to-use template.

The essence of machine tools maintenance

Machine tools have many sensitive parts that need to be properly and regularly maintained. While the following maintenance practices might look basic at first glance, when it comes to machine tools, their execution leaves very little room for error.

1) Lubrication

As machine tools have moving parts, it is vital to minimize any friction in order to avoid excessive wear and tear at the point of contact. The simplest approach to avoid friction is through proper lubrication.

Most Original Equipment Manufacturers (OEM) will tell you that checking lubricant level is the central activity of machine tool maintenance. They will recommend inspecting lubricants in weekly, monthly, and annual maintenance cycles.

For maintenance to be effective, you need to monitor the quality, quantity, and nature or chemical composition of the lubricant:

- If there is too little lubricant, the tool is going to experience excessive friction.

- If it is too much, there might be chances of leakages at joints or pressure increases that may cause the premature failure of the bearing.

- The chemical composition of the lubricant should be specific to the requirement of the machine. Some of the common lubrication mediums for machine tools include greases, spindle oil, and hydraulic oils.

- Incorrect lubricant may result in inefficiencies and cause degradation of the machine tool due to overheating.

Some advanced machining tools come with an automatic alarm system that can be triggered as soon as the lubricant level in the main tank drops beyond a specified threshold.

2) Calibration

When the machine tool is first installed, it comes with a set of manufacturing tolerances within which it should function.

However, the use of machines over time often results in a steady displacement from manufacturing specifications. Reasons include:

- Inevitable wear and tear and increase in the vibration due to regular operation

- Mistakes or misuse by machine tools operators

- Transporting the machine from one place to another

- Prolonged operation in an extreme temperature or humid environment

To enable high-precision machining of an object, the machine tools should be regularly calibrated. It is the only way to ensure they operate at the intended specification and within set tolerances.

The first machine tools were fairly easy to calibrate. They required simple adjustments of the displacement error in the x, y, and z planes. However, as technology got complex and precision requirements got as stringent as the width of a hair, machine tool calibration became a very intricate process.

3) Cleaning

Cleanliness may sound trivial but it represents one of the most fundamental maintenance requirements of machine tools. Effective cleaning not only improves the health and well-being of workers but also improves the health of the machine.

The cutting and grinding operations produce machine dust and chips that can go into difficult-to-reach places inside the machine. This can cause interference in the precision operation.

Cleaning machine tools is a sensitive task that requires training and special tools.

While some portions of the machine can be cleaned simply by a piece of cloth or rags dipped in a degreaser, others require specialized tools suitable for precision components. If done carelessly, the cleaning activity can damage sensitive components of the machine (such as blowing compressed air into a spindle).

Before attempting to clean the machine, it is paramount to understand its functional requirements. For example, if the tool is used to machine an abrasive object, the cleaning requirement will be higher.

When scheduling preventive maintenance tasks for machine tools, a point worth considering is the operational uptime of the machine.

Upon cleaning, the machine may have to be shut down, which will reduce its availability and consequently its profit ratios.

Therefore, it is important to understand the maintainability requirements and outline clear cleaning instructions that are sufficiently simple and effective. You can do it by building a preventive maintenance checklist.

This way, the cleaning process will be performed timely and adequately, without compromising operational availability.

4) Sharpening

Ensuring the sharpness of specific components is another key element of machine tools maintenance. If the cutting or grinding components are not sharp enough, the output will not only be out of specification but there is a higher chance of damage to the machine tool itself.

The consistent use of unsharpened machine tools may result in the wastage of the product and can cause accelerated degradation of the machine tool – such as breaking the punching edge and/or chipping or shredding of the tool.

The general practice is to adjust the frequency of sharpening with the level of usage of the machine, the material being processed, and its thickness.

Sharpening of the tool is often performed through a grinding process which can be manual or automatic. Automatic grinding is more precise and effective but comes with an added cost.

Some industries use more advanced technology – such as infrared thermography – to track equipment degradation. The right approach is usually to look at the degree of precision required and sharpen the tools accordingly – while keeping the cost and operational downtime in mind.

5) Managing spare parts and accessories

Having the right spare parts and accessories when needed is a cornerstone of any effective maintenance program. The lack of said items will result in the rescheduling of important routine maintenance tasks or prolong downtime when corrective work is already in progress.

To avoid this scenario, the critical spares for the machine tools should be carefully studied by the maintenance planner who can then decide on the acceptable stock level for different parts.

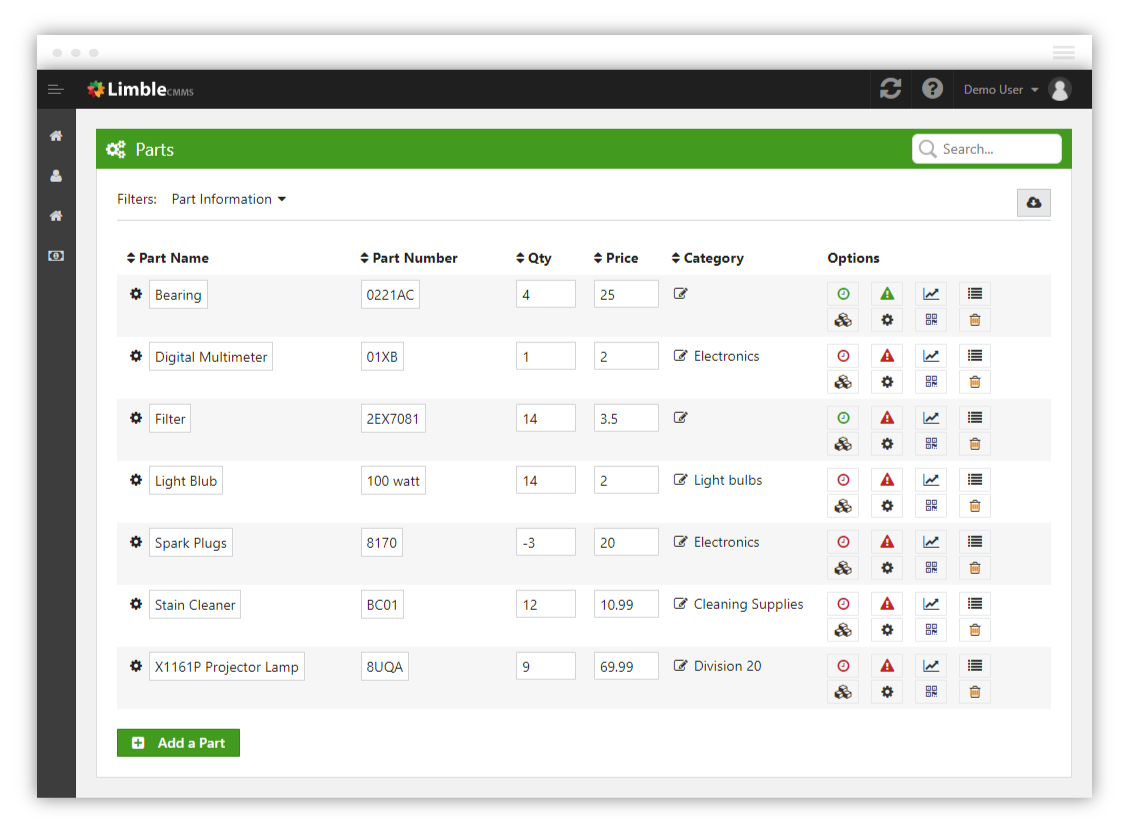

A Computerized Maintenance Management System (CMMS) can be particularly useful here as it can provide planners an overview of historical maintenance activities and insights on emerging failures in machine tools and their associated parts. They can use its automatic tracking features to track stock levels and make more accurate inventory forecasts.

Limble CMMS helps you stay on top of your spare parts inventory at all times

The historical information can be leveraged to pre-order critical parts and accessories that could sometimes take several weeks (if not months) to arrive.

Industrial businesses often use a part kitting process where you put all parts, accessories, and tools you need to perform a specific maintenance task in one bag (maintenance kit).

Since each kit has its own Stock Keeping Unit (SKU), this process not only improves the effectiveness of the maintenance process but also speeds up the ordering of necessary parts – ordering all parts as a kit under one SKU as opposed to tracking and ordering individual items separately.

Optimizing machine tool maintenance

The implementation of a proper maintenance regime, with a focus on precision maintenance, will not only prolong the life of machine tools but also improve the quality of the product that is being processed.

As machine technology gets more sophisticated, the complexity of maintenance requirements grows proportionally. Moreover, the increasingly strict tolerance requirements are also pushing manufacturers to calibrate and sharpen machines more frequently and efficiently.

Limble CMMS is designed to help you stay on top of your machine tool maintenance schedule by optimizing inventory, labor, parts, vendors, and costs. Learn more by scheduling a demo or starting a free trial.