Industrial equipment is getting more complex, specialized, and expensive to acquire and maintain. Even routine maintenance can prove to be beyond the capabilities of an in-house team. For many firms, buying modern machines has become a high-risk endeavor.

Driven by these pressures, a new paradigm has gained traction in modern manufacturing – Equipment as a Service or EaaS for short.

What does it mean for OEMs and their potential buyers? Is it an option worth considering for your business? What are its pros and cons?

Let us find out together.

What is Equipment as a Service?

In the world of widespread digitization, the “as a service” model is extremely popular. You have companies working under various business models like Software as a Service (SaaS), Platform as a Service (PaaS), and Infrastructure as a Service (IaaS).

The basic idea across all these models is the same – instead of selling a product to the consumer, vendors will provide a package of ongoing services in exchange for recurring fees/subscriptions. This would include customer support, ongoing maintenance, and constant updates and tweaks.

This allows you to reduce CapEx and focus on your core business.

Limble CMMS is a perfect example of a SaaS. A centralized cloud-based maintenance platform you can access with any mobile device. Everything is taken care of at the vendor’s side. Your only job is to remember your login details and pay your monthly/yearly subscription.

Equipment as a Service is the same model brought over to the realm of industrial equipment. It is also called by other names such as Machine-as-a-Service (MaaS), or Pay-per-use (PPU). This model is directly at odds with the “classical” paradigm in the industrial equipment market.

The Essential Guide to CMMS

Download this helpful guide to everything a CMMS has to offer.

Equipment as a Service business model vs standard model

In the traditional system, original equipment manufacturers (OEMs) design and sell machines to their customers – usually a manufacturing company. There is an up-front payment for the transaction and the ownership and control of the equipment is transferred to you, the buyer.

The OEM provides a limited form of customer support and onboarding assistance, as well as advanced troubleshooting and warranty services. However, as the owner of the equipment, it is largely your responsibility to handle spare parts, maintenance, and repairs.

In contrast, in the EaaS model, your firm does not gain full ownership or control over the equipment. The vendor’s EaaS offering will usually place strict limitations on what you can and cannot do to the equipment by way of alterations, modifications, etc.

The role of the EaaS vendor is also significantly expanded when compared to the classical model. Instead of being just a seller, they have to provide other services which can include maintenance, repairs, software/hardware updates, and other on-site or field services – as well as customer satisfaction.

Equipment as a Service is industrial manufacturing’s take on the subscription or outsourcing economy that has become widespread in the modern era. With the increasing costs of owning and maintaining complex equipment, renting it begins to make sound business sense.

A brief look at the history and evolution of EaaS

Equipment as a Service is not a novel concept. Its origins can be traced back to the early days of the airline industry in the 1960s. The equipment in focus was the jet engine – and both the buyers and OEMs had problems with the classical model of equipment sales.

For the airlines, engine maintenance and repair/replacement costs were a huge drain on their resources. The vendors were selling a product with a long life cycle – which meant long intervals between sales.

In this context, Rolls Royce introduced the “power-by-hour” model. It was an “Engine as a Service” model, where the airlines would pay an hourly subscription for the flight time. In exchange, Rolls Royce would handle all aspects of maintenance and repairs.

The airlines were now free to focus on their core business of carrying passengers and cargo, while Rolls Royce unlocked a new recurring revenue stream. They also benefited greatly in future R&D from the additional experience and knowledge gained from regular engine maintenance and follow-ups.

The Impact of IoT and Industry 4.0 on the spread of the EaaS model

A revolutionary aspect of the power-by-hour model was the guarantee of productivity. However, there is a reason why this business model didn’t catch on much earlier. You see, airplane engines are a specific case study: it is fairly easy for an OEM and the airlines to track flight hours and achieve preset targets. In an industrial facility with complex production chains, this was not possible.

You simply did not have the 360-degree visibility over the production process to capture relevant performance data. This meant that buying any expensive new equipment represented a gamble to some extent – there was always a risk of it failing to deliver the expected results.

This changes with the rise of the Internet of Things and Industry 4.0. Firms now have ways to accurately capture a multitude of Key Performance Indicators. Using internet connectivity, smart sensors, and IIoT in general, combined with a modern Computerized Maintenance Management System (CMMS), manufacturers and OEMs can both keep track of equipment efficiency and productivity – in real-time.

This development has drastically improved the viability of EaaS in the industrial space. It equips OEMs with the confidence to include productivity parameters into service contracts. The data also reduces the element of risk involved, making it easier for CFOs to make a case for switching to EaaS.

Pros and cons of the Equipment as a Service model

In the airline industry, the adoption of power-by-hour was a mutually beneficial arrangement for both OEMs and their clients. The same continues to be the case in modern iterations of EaaS, but it is not all smooth sailing.

Switching to the new model does come with some not-insignificant challenges for OEMs and buyers alike.

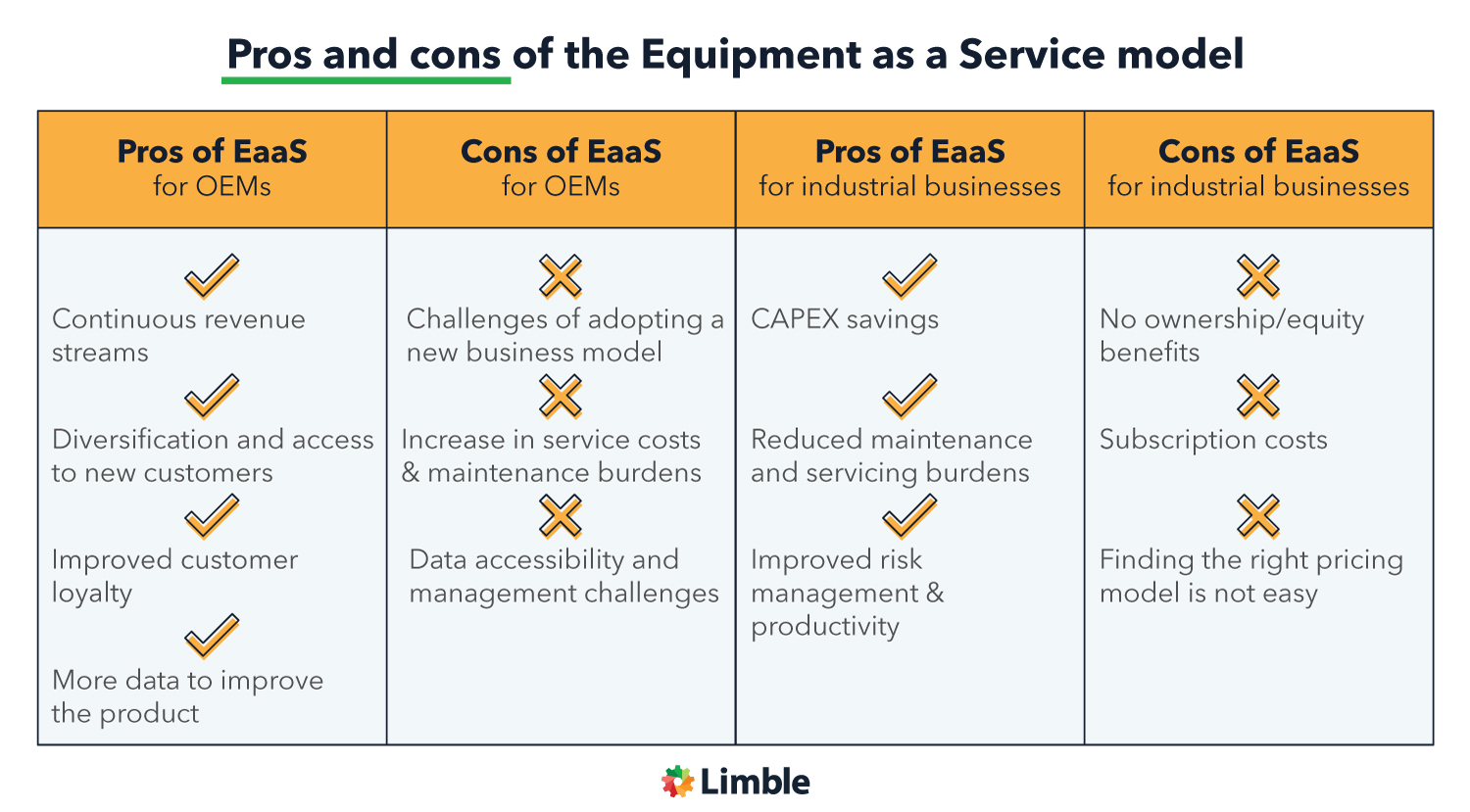

Pros of EaaS for OEMs

- Continuous revenue streams: The subscription model is widely recognized for its ability to generate a constant cash flow for businesses. It has the potential to provide increased financial stability to OEMs.

- Diversification and access to new customers: Not all manufacturing firms have the CapEx outlay to buy equipment outright. Using an EaaS model improves accessibility and can bring new customers to the OEMs.

- Improved customer loyalty: A continuous service model can create long-lasting business relationships. Service providers with quality customer service should have no trouble retaining existing clients.

- More data to improve the product: By performing regular servicing and tracking usage, condition and performance metrics, OEMs gain access to a lot of data that can be analyzed and used to improve the design of their future products.

Cons of EaaS for OEMs

- Challenges of adopting a new business model: An EaaS model requires system-wide changes across the OEM. It is not something vendors can test in stages – most modern clients expect a full-fledged service. Wholesale changes may be required in sales, maintenance, customer support, and invoicing. This can cause severe disruption to the business.

- Increase in service costs and maintenance burdens: The quality of service and maintenance can make or break a vendor’s EaaS business. This model puts a massive strain on vendors for field repairs, on-site maintenance, and ensuring the steady availability of spares – making them, in a way, responsible for avoiding production downtime.

- Data accessibility and management challenges: OEMs have to augment their network and IoT capabilities to make EaaS viable. Data and KPIs play a huge role in ensuring that key targets of the service agreement are achieved. Simultaneously, they also have to maintain adequate data safety and privacy safeguards.

Pros of EaaS for industrial business

- CAPEX savings: The option to avoid high-risk investments in CapEx is a major advantage of EaaS for manufacturers. You can reallocate the saved capital into other important areas like sales or HR for further benefits.

- Reduced maintenance and servicing burdens: With the responsibility of maintenance and repairs resting with the OEM, you can enjoy a significant reduction in general operating expenses. This has the potential to further improve the overall cash flow situation of the company.

- Improved risk management & productivity: With costly CapEx losses kept to a minimum, the EaaS model gives manufacturers a flexible way to reduce business risk and improve productivity.

Cons of EaaS for industrial businesses

- No ownership/equity benefits: Capital expenditure – when done right – can boost the valuation and equity of a business by adding highly productive physical assets. In a subscription model like EaaS, you get none of these benefits as the equipment is still the property of the vendor.

- Subscription costs: While large-scale investments in asset purchases can be avoided with EaaS, it is not a free service. The service offering usually includes a recurring fee, which – depending on the pricing structure – can still be quite taxing on your overhead.

- Finding the right pricing model is not easy: Last but not least, you also have the major headache of settling on a mutually agreeable pricing model. For the service contract in an EaaS agreement to work as planned, it must adequately address the expectations and concerns of both the vendors and the end-users. As you will see in the next section, this is all but easy.

EaaS pricing models

At the core of an EaaS agreement is a very expensive piece of machinery. This asset has two major aspects for the parties involved:

- Value of the asset: How much extra value will the asset generate in a manufacturing setting? Both OEM and the buyer should be on the same page when it comes to understanding the value added by the asset to the business.

- Risk management: The deployment of an expensive asset carries some risk. Sometimes, targets may be missed and unforeseen disruptions can occur. How will both parties quantify and share the elements of risk involved?

The success of an Equipment as a Service business model hinges on its ability to deliver clear value to both parties. For the buyer, the main concern is that machines are reliable and that they can justify their renting costs. For the OEMs, it is imperative to find a pricing model that, when all is said and done, delivers profits.

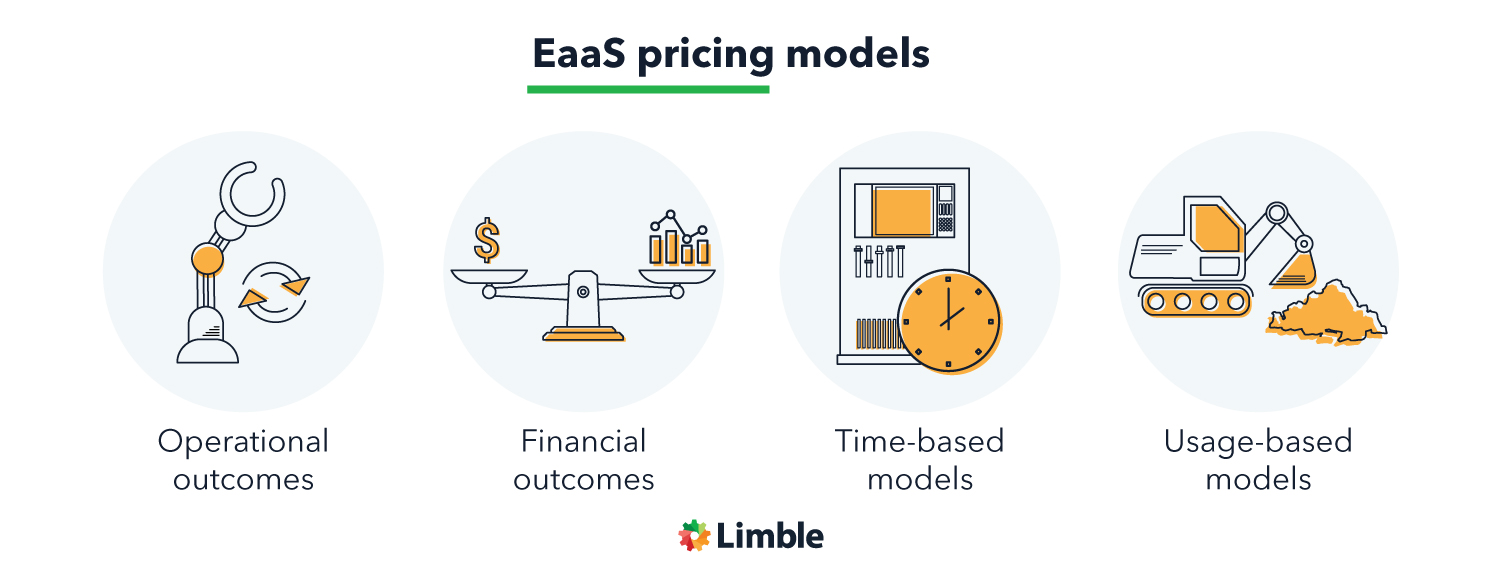

Several pricing models have found success in the nascent EaaS market in recent years. Of the four main models listed below, the first two belong to a category called “outcome-based models” – subscription fees are determined by outcomes that can be measured by the buyer:

- Operational outcomes: This model is ideal in industrial/manufacturing settings where the process involves well-defined and repetitive tasks. EaaS contracts involving robots are a great example, where the fees are charged based on fixed operational cycles.

- Financial outcomes: This model works best in a setting where the equipment involved has a direct impact on the financial performance of the firm. If the new machine from the OEM leads to a direct measurable increase in productivity/cost savings, it could be tied to a service contract based on the desired financial outcome. For instance, a new piece of equipment with a higher efficiency rating that results in lower power costs would qualify for this pricing model.

- Time-based models: The pricing and payment schedules are tied to the duration the equipment is used by the client firm. The Rolls Royce power by hour model is an apt example of this arrangement.

- Usage-based models: In some industrial settings like mining, fixed operating schedules cannot be guaranteed due to environmental factors. In this scenario, the pricing model for EaaS could be based on the relative intensity at which the equipment was used. Instead of paying by the hour, the OEM could base payments on actual work done by the machine in question.

The concept of maintenance in EaaS

The major defining factor of an equipment subscription model is the role of the vendor in maintenance. In traditional vendor–buyer relations, the OEM largely has a supportive or peripheral role in the regular maintenance of manufacturing equipment.

The opposite is true in EaaS, with the bulk of asset maintenance duties carried out by the vendor. When you lease/rent machinery, your main responsibility is to ensure that it is operated strictly under vendor specifications.

All other aspects like routine maintenance, emergency repairs, and other forms of troubleshooting are the responsibility of the OEM. Breakdowns and disruptions should be kept as close to zero as possible while keeping maintenance costs down as well.

This can only be achieved through a predictive maintenance approach, leveraging IoT and CMMS software. With the responsibility of asset maintenance across multiple clients, an EaaS vendor cannot rely only on traditional preventive maintenance tactics and expect positive results.

The future is now

With the global economy in a sustained cycle of disruption and recovery, firms across all sectors are feeling the pinch. There is less capital available for expensive asset acquisitions. Alternative models that prioritize cost savings and guaranteed productivity are more appealing than ever.

While the cooldown in the demand for equipment is a major challenge for OEMs, it also represents an opportunity for change. New revenue streams can open up with a pivot to an Equipment as a Service business model, providing benefits for both OEMs and their industrial clients.

Fresh advances in 5g connectivity and Industry 4.0 are creating the ideal conditions for the expansion of the Equipment as a Service model. Businesses that embrace digital transformation will have a first-mover advantage in this new paradigm.