Simplify and streamline heavy equipment maintenance management

Heavy equipment operates in tough conditions, often pushed to the limit. Limble helps you anticipate maintenance needs and schedule downtime proactively, keeping your equipment running smoothly and helping you avoid costly repairs.

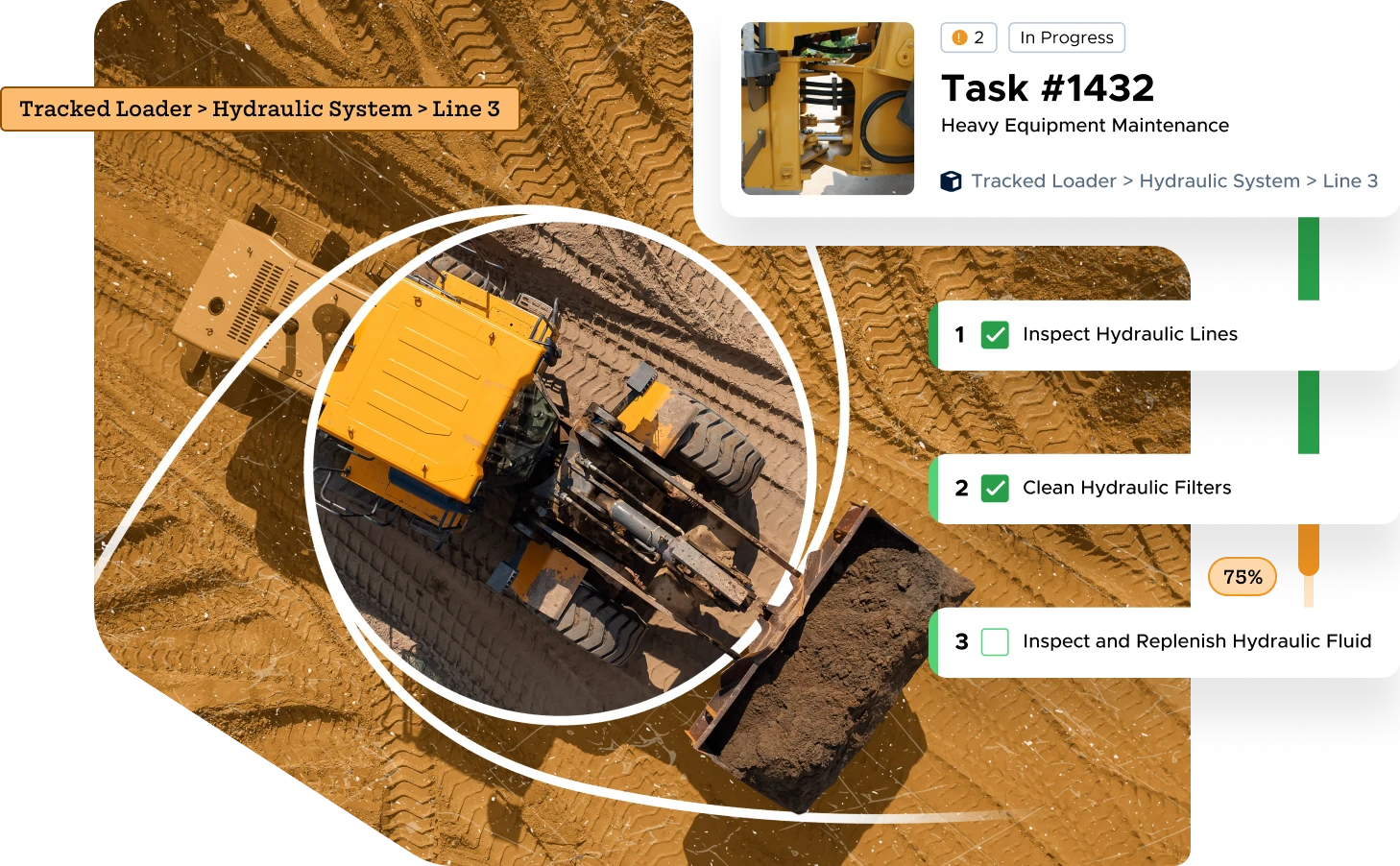

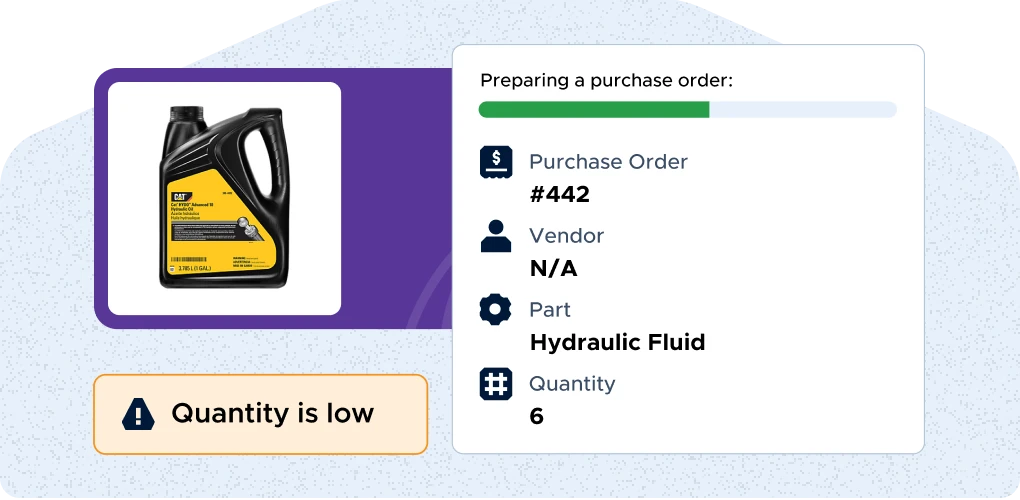

Preventive maintenance

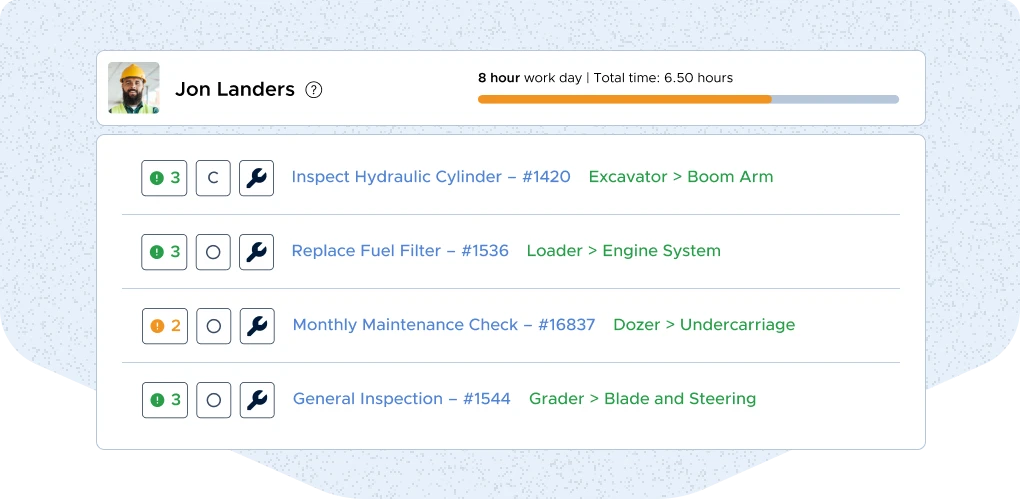

Stay ahead with automated PM scheduling based on time, usage, or condition. Build intuitive, customizable PM checklists with all the information and functionality your technicians need.

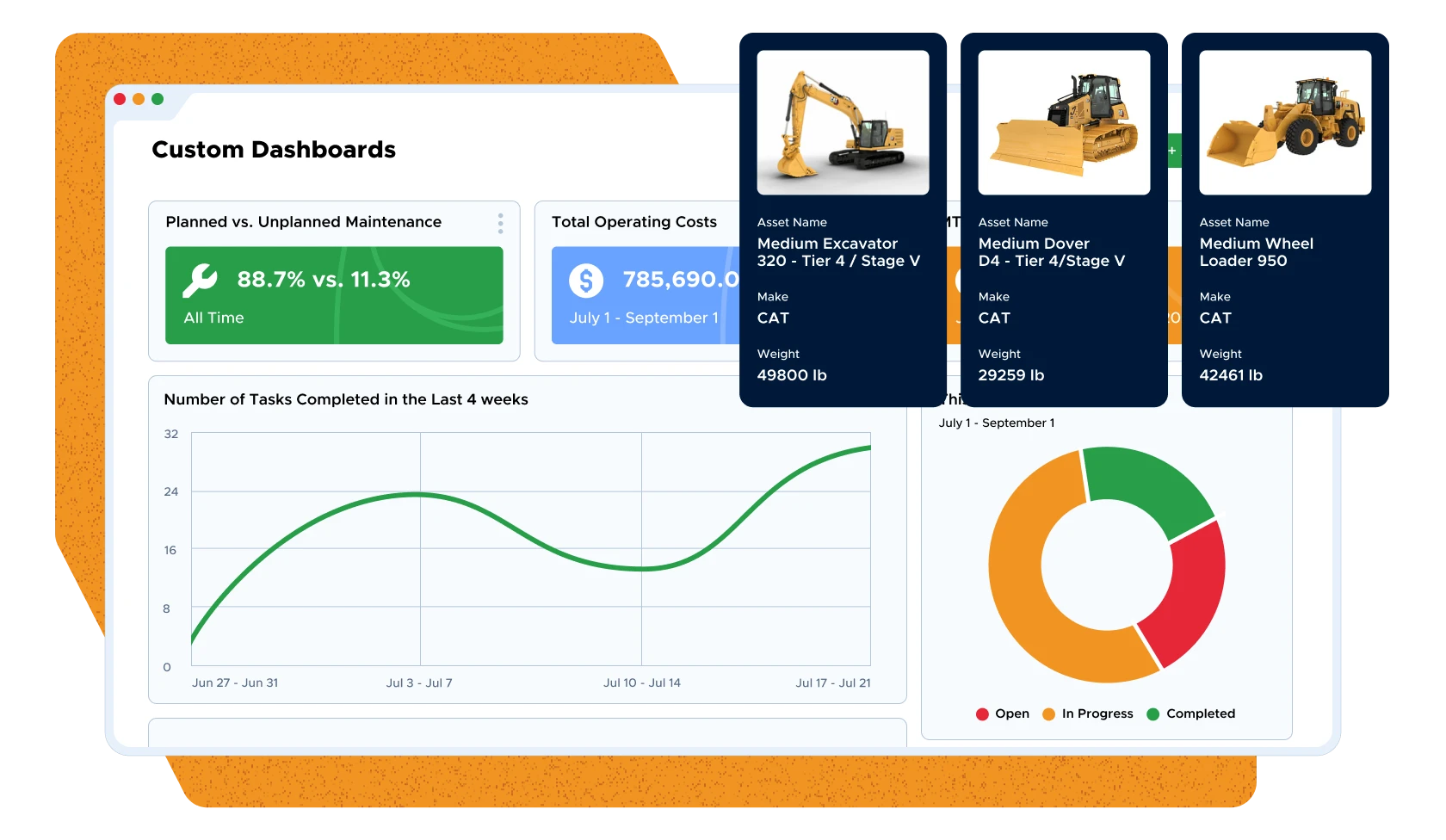

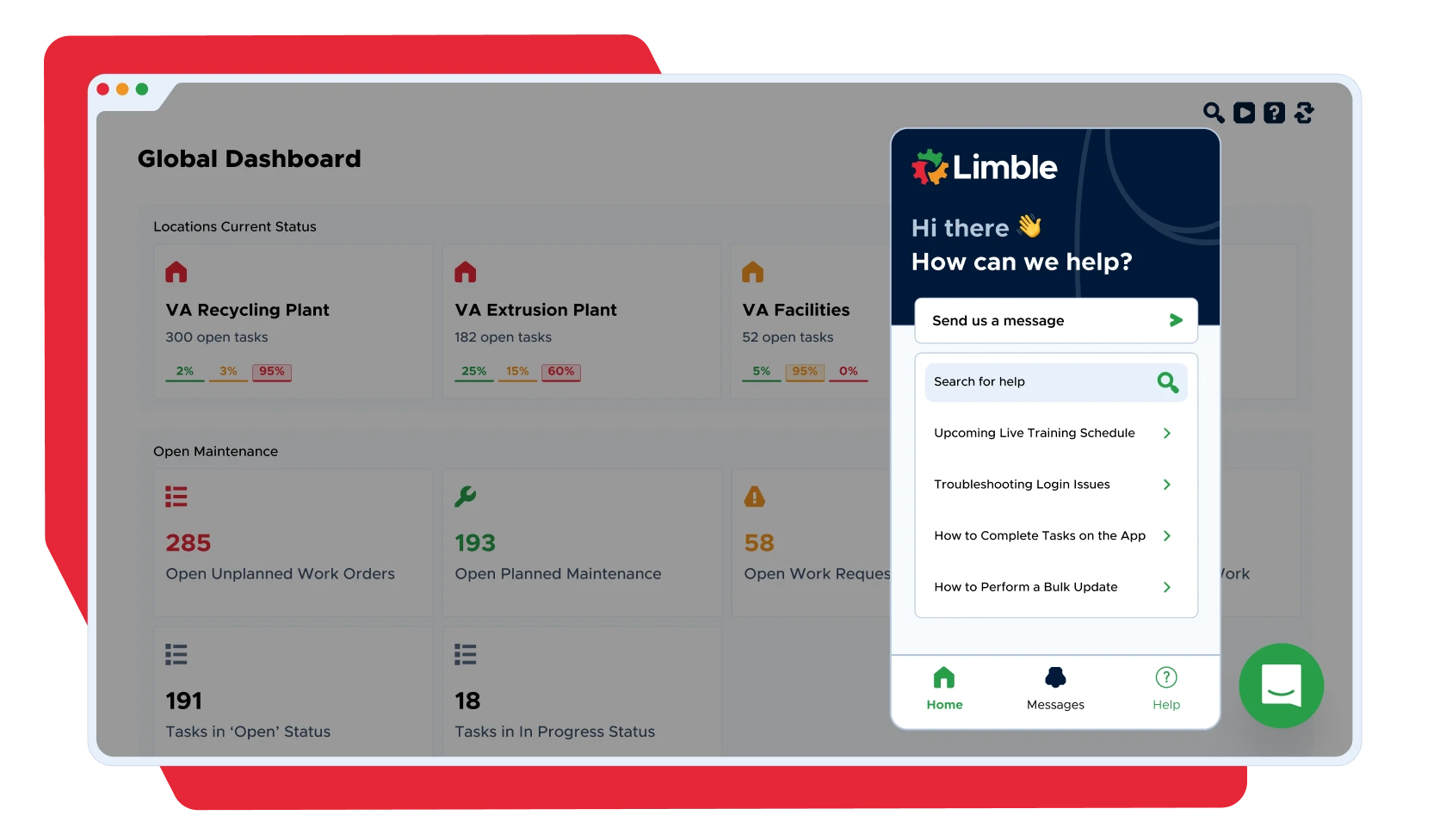

Actionable insights at your fingertips

Make informed decisions with detailed dashboards that provide a complete overview of your equipment's performance. Track key metrics such as maintenance costs, downtime, asset utilization, and repair histories in real time.

- Tailor reports to focus on key data—cost, compliance, or efficiency.

- Easily monitor team productivity and maintenance schedules.

- Export reports or share dashboards with stakeholders.

Responsive, easy-to-reach customer support

We know how important fast support is when you’re managing heavy equipment. Limble customers get 24/7 phone, chat, and email support and a dedicated onboarding team to ensure success from day one.

Hear it from our customers

Reducing unplanned work

Aztec Construction cut their unplanned work percentage nearly in half after an easy transition to Limble.

Optimizing for efficiency and safety

Limble helps Rimex standardize operations, improve safety, and increase efficiency across manufacturing plants.