Eliminate unplanned downtime

Don’t let your machines dictate when downtime happens. Limble’s maintenance management software helps you shift from reactive fixes to proactive maintenance planning. Forecast maintenance needs and get everyone on board with scheduled downtime before breakdowns make the choice for you.

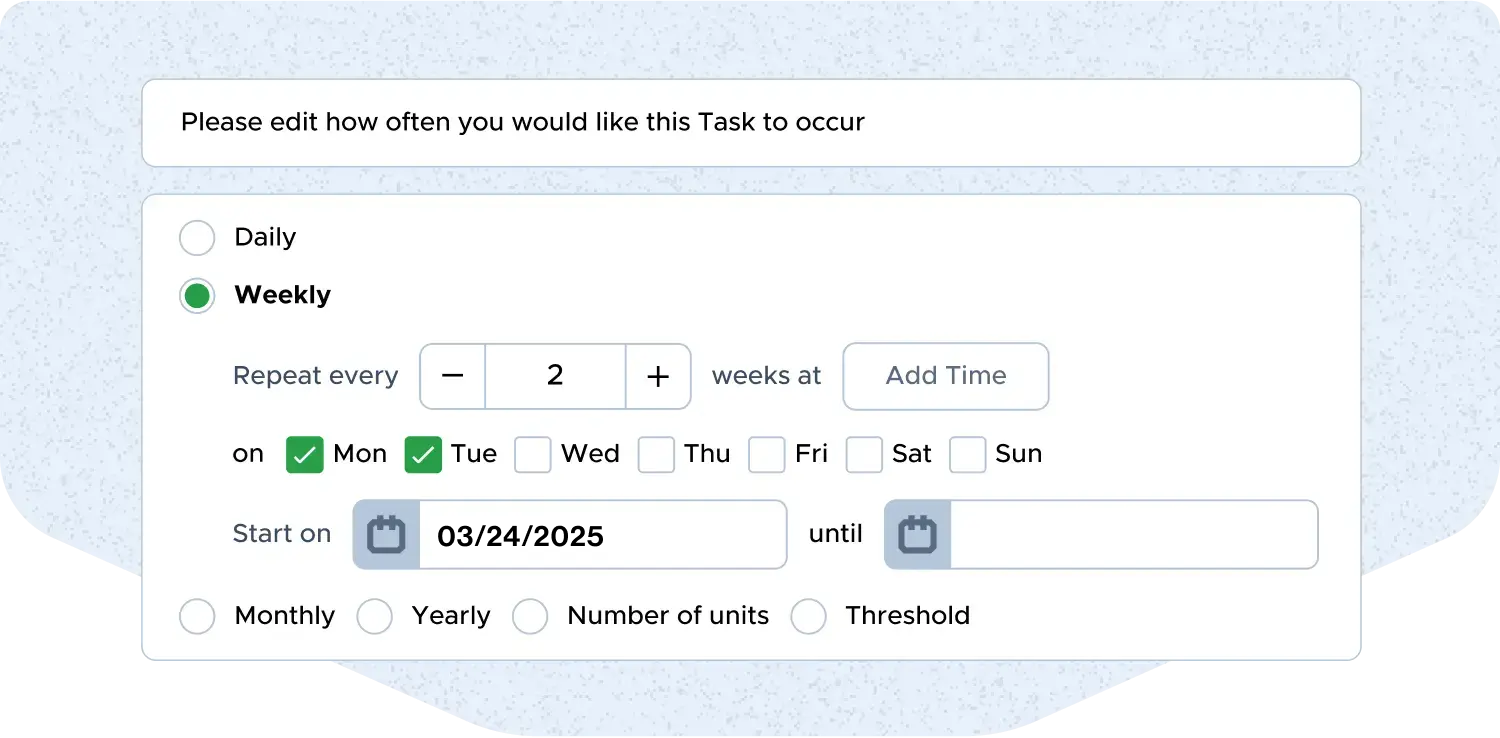

Preventive maintenance

Stay on top of preventive maintenance tasks with detailed checklists, automated scheduling, and clear maintenance schedules. Ensure routine maintenance happens consistently, keeping you operational during crucial production hours.

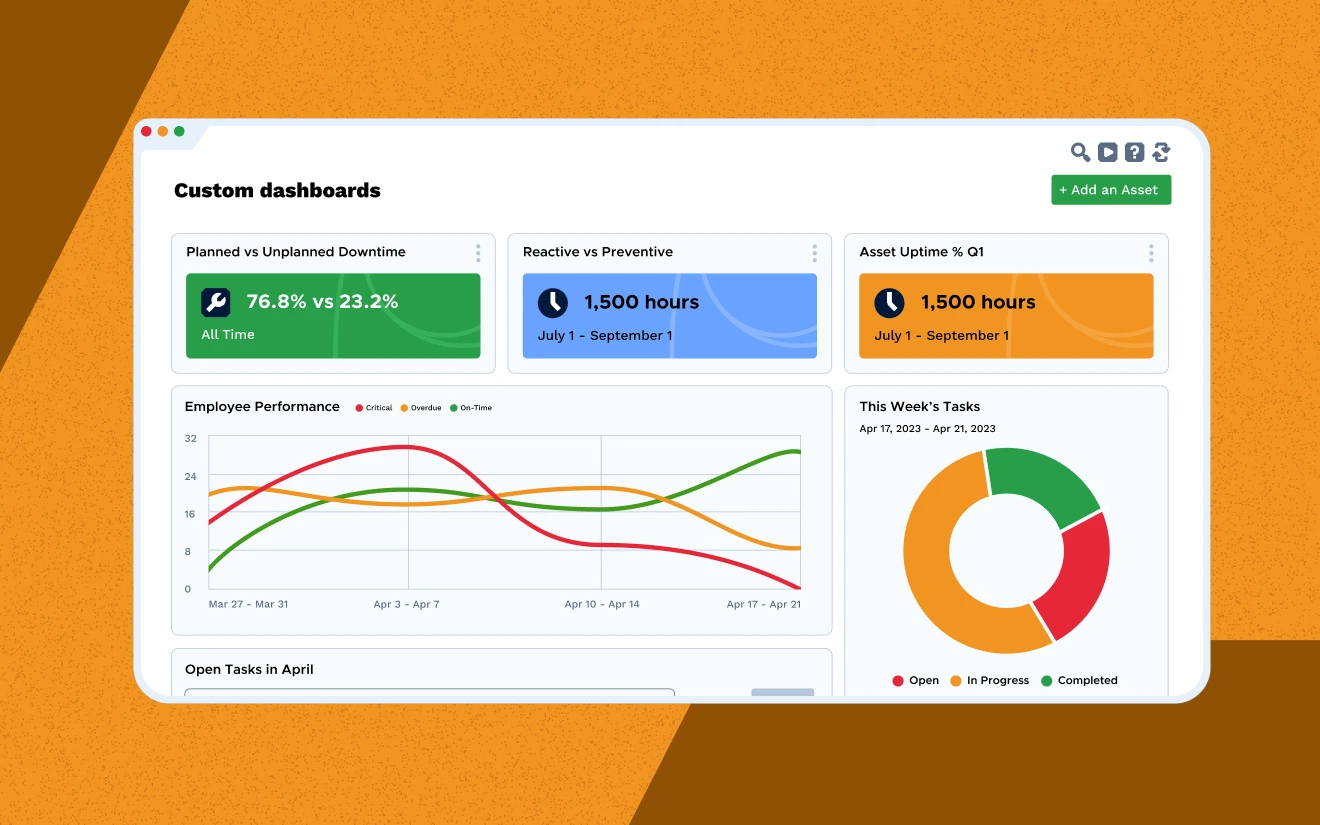

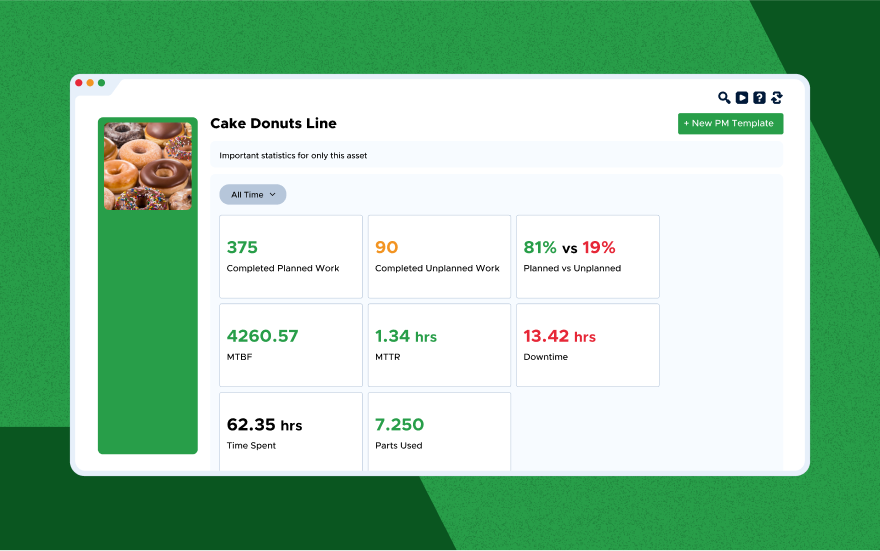

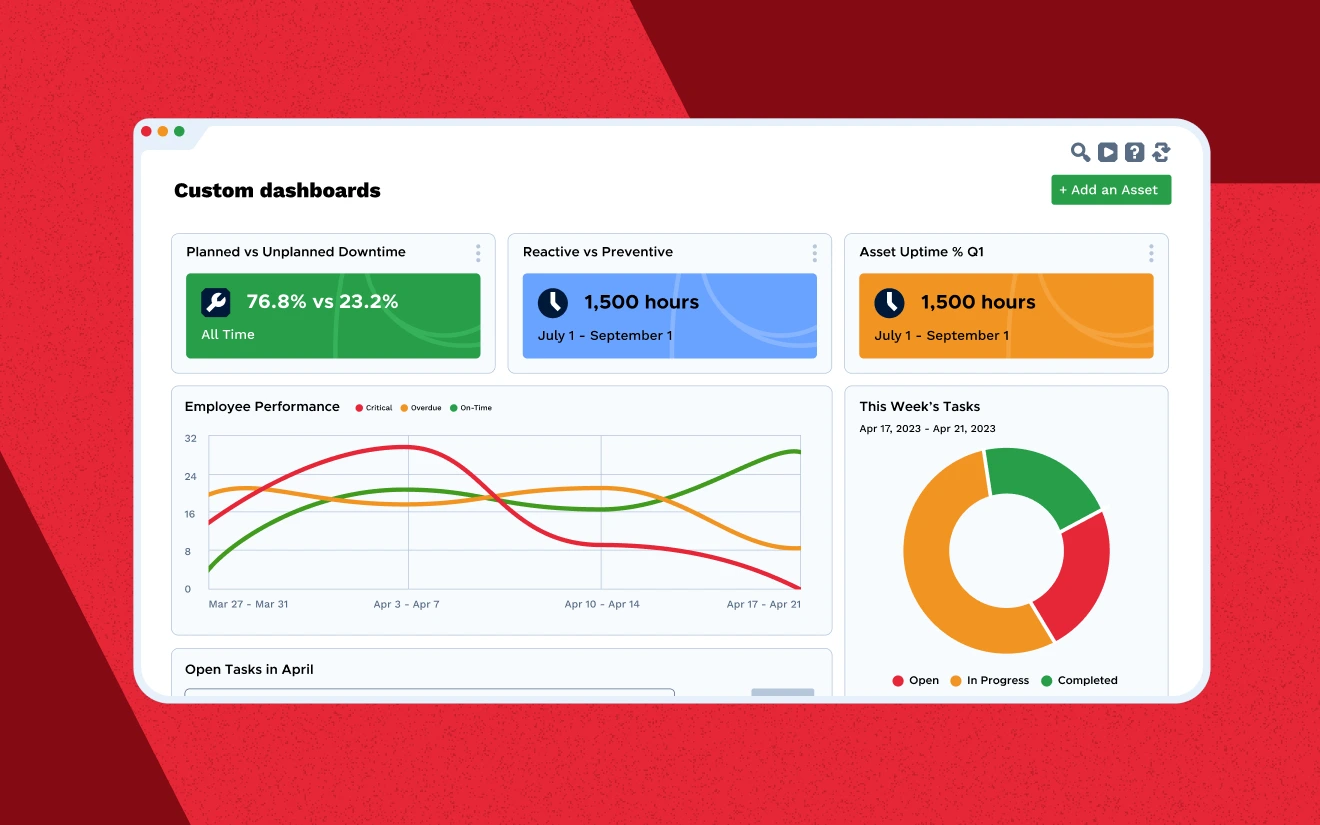

Automate your reporting

Gain actionable insights from real-time maintenance data. Use customizable dashboards to track maintenance activity, monitor asset performance, and review detailed maintenance history.

Tailor your maintenance processes for maximum efficiency

Limble puts the power of customization in your hands. Easily customize your work request portal, priorities, asset fields, QR codes, and more – with just a few clicks. From setting up workflows to creating custom reports, Limble’s customizability is unmatched.

Effortlessly scale your maintenance operations

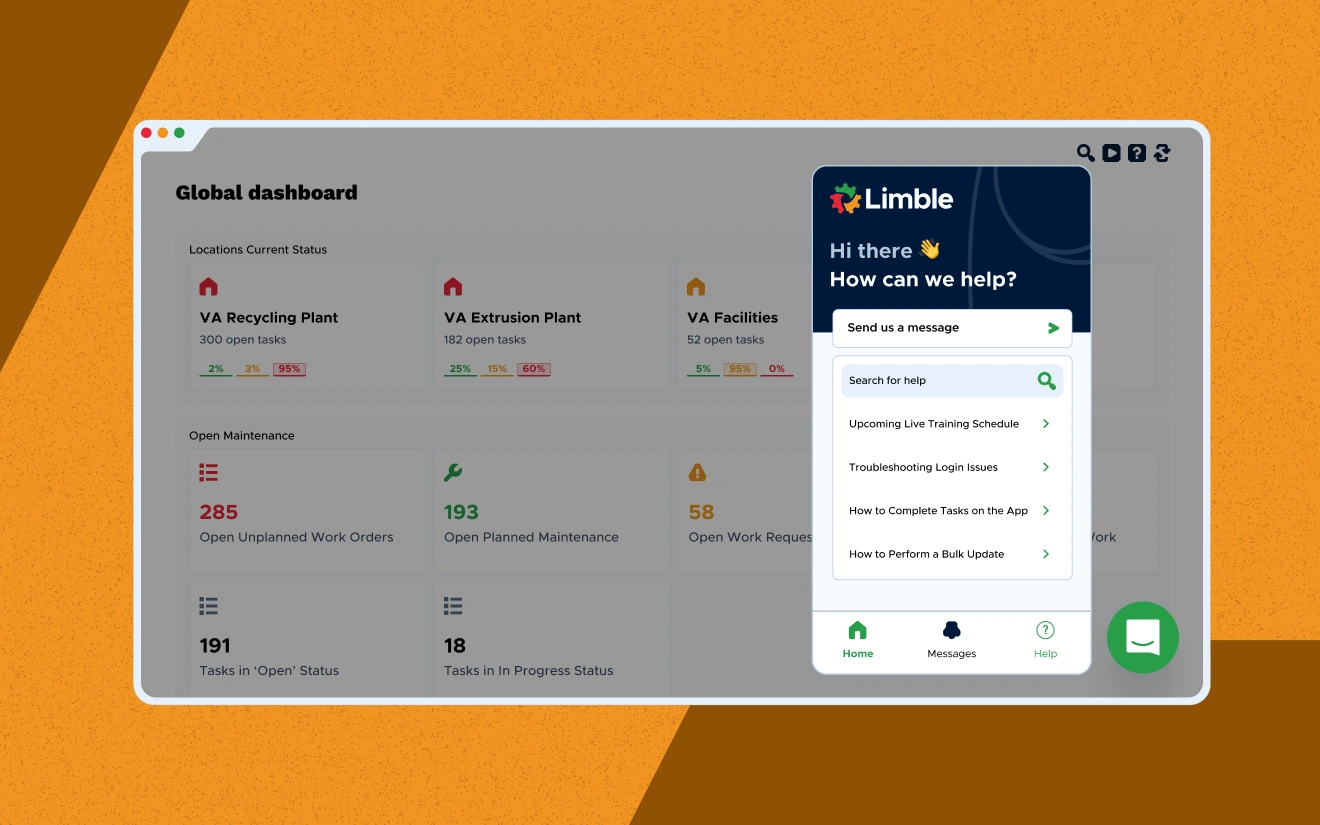

Whether you're a small team that plans to grow in the future or part of a larger organization, Limble is designed to scale seamlessly. It can be difficult to use a one size fits all system when your data is organized differently across various maintenance teams.

Unmatched support when you need it most

In addition to our robust help center featuring easy to follow 'how to' videos, Limble's fully US-based support team is ready to answer any questions you have in 60 seconds or less - no matter which plan you're on. Customer Obsessed is one of our core values and is at the heart of everything we do.

Hear it from our customers

Near-instant downtime reduction

Tara Manufacturing reduced downtime by 83%, with results in just a few weeks.

Justifying critical headcount

Allagash Brewery used Limble’s metrics to get buy-in for a technical role they knew they needed.