Factory maintenance is complex and multi-layered, balancing the conflicting priorities of production efficiency with equipment longevity. Increased automation, shorter manufacturing runs, and greater customization have increased maintenance difficulty on the modern production floor.

To optimize manufacturing maintenance, you have to approach it with a strategic plan that avoids common pitfalls. Here’s everything you need to know to do that successfully.

Why is maintenance important in manufacturing?

Outfitting a modern factory with equipment requires considerable capital investment. Manufacturers must amortize that investment across each unit they produce to gain economic returns. Poor asset utilization reduces revenue, severely impacting competitiveness and profitability of your production facility.

Research suggests that 82% of manufacturers experience significant downtime. The outages last an average of four hours and cost an average of $2 million. We do not even have to discuss how much production time is lost there and how that erodes customer trust.

There is a better way. It comes in the form of a proactive factory maintenance program.

Common challenges of running maintenance activities on busy production floors

Maintenance departments encounter the following six challenges in production facilities.

Poor data collection and analysis

In general, factory auditors find it easy to uncover poor quality systems and incorrect data in maintenance departments. Systems are frequently a hybrid of spreadsheets, paper worksheets, separate defect lists, and standalone inventory programs. The volume of daily maintenance information can be overwhelming, making in-depth analysis and decision-making time-consuming, suboptimal, and often overlooked.

One solution centralizes the entire process, with all maintenance needs included, into a digital system. A modern computerized maintenance management system (CMMS) links the six key aspects of a maintenance program:

- Unique equipment identification

- Master maintenance plan

- Maintenance scheduling system

- Records of maintenance effected

- MRO inventory management

- Technician scheduling

While other modules such as analytics engines are available, the seamless intersection of these six factors maintains maintenance integrity, meets modern quality expectations, and eases data analysis.

Maintaining a one-team culture

Working as a maintenance technician requires a special individual. No one thanks the maintenance techs when a machine runs perfectly for weeks or months. But watch the blame fly when the machine stops.

In addition, technicians and mechanics work shifts in remote areas of the factory or co-located buildings, making cohesive teams difficult. Maintaining a one-team culture within a production facility takes understanding and hard work.

We’ve written an in-depth article discussing this topic here. However, here are a few tips for a unified workforce:

- Ensure production and maintenance plan all shutdowns as a team.

- Always get the maintenance team together regularly, regardless of shifts, to talk about their concerns while imparting important messages.

- Give insight into business economics to help techs understand both plant maintenance and their specific role in making the business successful.

- Do not accept us-and-them talk or behaviors; shut it down immediately.

- Make sure that the incentives for maintenance and production are aligned.

- Implement autonomous maintenance and train operators on using correct operating techniques.

Pay the same attention to the ‘soft skills’ of people management as you do to topics such as maintenance work and systems, metrics, and KPIs. Isolation and internal friction destroy competitive advantage and affect maintenance quality.

Lack of focused maintenance strategies

In the daily battle of production, it’s easy to lose sight of the bigger picture. Production demands can begin to skew equipment maintenance, subverting your maintenance program and destroying value. You become reactive, never catching up or returning to the original plan or maintenance schedule.

Every manufacturing facility (and business) should carry out a risk-based assessment of all its equipment. That assessment will drive strategies to optimize the effectiveness and efficiency of each machine within prescribed financial considerations and operational needs. While maintenance must always balance competing priorities, allowing short-term thinking to constantly overcome long-term goals is a hidden and expensive drain on the company.

The solution is education and alignment. Gain backing from the highest level in the company, and ensure everyone in production and maintenance understands the trade-offs made between meeting production targets and maintaining optimum equipment uptime and useful life.

Run toolbox talks, quick training courses, newsletters – whatever it takes to constantly reinforce this message. Devise case studies to show the true costs of missed maintenance, because these will send the most powerful messages.

Insufficient maintenance programs

Maintenance programs get dated rapidly. Production facilities are not static: equipment ages, it is removed and replaced, machines are repurposed, and the product mix changes. Line layouts change, as do equipment speeds, utilization, and cycle times. As a result, you find the maintenance program doesn’t deliver the expected overall equipment effectiveness (OEE) targets as it did last year.

A maintenance program is a live document needing regular review and adjustment, using a structured quality process. Any changes must increment a portion of the plan from a known state to a desired position. The reasons for the change should be recorded, highlighting the expected outcomes and leaving enough time for review.

If the change delivers the desired benefits, it should be incorporated into the new version of the program. If the change is unsuccessful, the program simply reverts to the original version until you devise a new initiative.

Outdated maintenance documentation

Planned maintenance (PM) tasks are a mix of multiple inputs: original equipment manufacturers’ (OEM) recommendations, third-party spares data, internal company techniques, and in-house frequencies. Establishing a current and relevant maintenance program, using the correct PM worksheets and data is critical.

Yet, step into many production facility workshops, and you’ll find uncontrolled data and improvised solutions: photocopied manuals, informal techniques and procedures, incorrect spares, or homemade fixes to equipment. All of those workarounds devalue the effectiveness and efficiency of a maintenance program, costing money and negatively impacting OEE.

The most straightforward way to control maintenance data is to implement mobile CMMS software. CMMS helps you enforce strict data quality control. Such enforcement includes stamping copies from manuals as uncontrolled, requiring all printed data to be returned or destroyed, educating technicians, and penalizing the use of non-approved methods.

These actions reduce the risk of performing actions that are not aligned with your current maintenance program.

Arbitrary maintenance budgets

A maintenance budget often bears no relationship to the returns expected from the department and is, at best, an arbitrary figure. The sum appears large and the strategic benefits it provides are long-term, making the maintenance budget contentious and vulnerable to short-term thinking.

In the modern production environment, a one or two percent reduction in operating costs or increased revenue makes the difference between growth and stagnation. When plant managers are pressed for savings, there’s usually one place they look.

Such short-term and destructive thinking is well-known. Many plant managers have made a name for themselves by cutting maintenance services and being praised for their great financial figures. They are promoted and moved, with the next manager left with a failing plant, high equipment downtime, and falling output.

The solution to this problem is in data, analysis, and education. Understanding the financial implications of achieving only 90% equipment availability instead of 92% is not too complex. You can simply asses how cost-effective the move was by measuring the lost revenue and the reduced client goodwill.

While managers sometimes trade off long-term losses against short-term gains, they seldom do so with a true appreciation of the business impacts. Using a CMMS linked to the organization’s accounting system allows a granular understanding of cost/benefit trade-offs, making short-term thinking harder to justify.

Checklist for Creating a Preventive Maintenance Plan

Following a consistent Preventive Maintenance Plan can make life easier. Use this checklist to create your own!

How to choose an appropriate maintenance strategy for your manufacturing plant

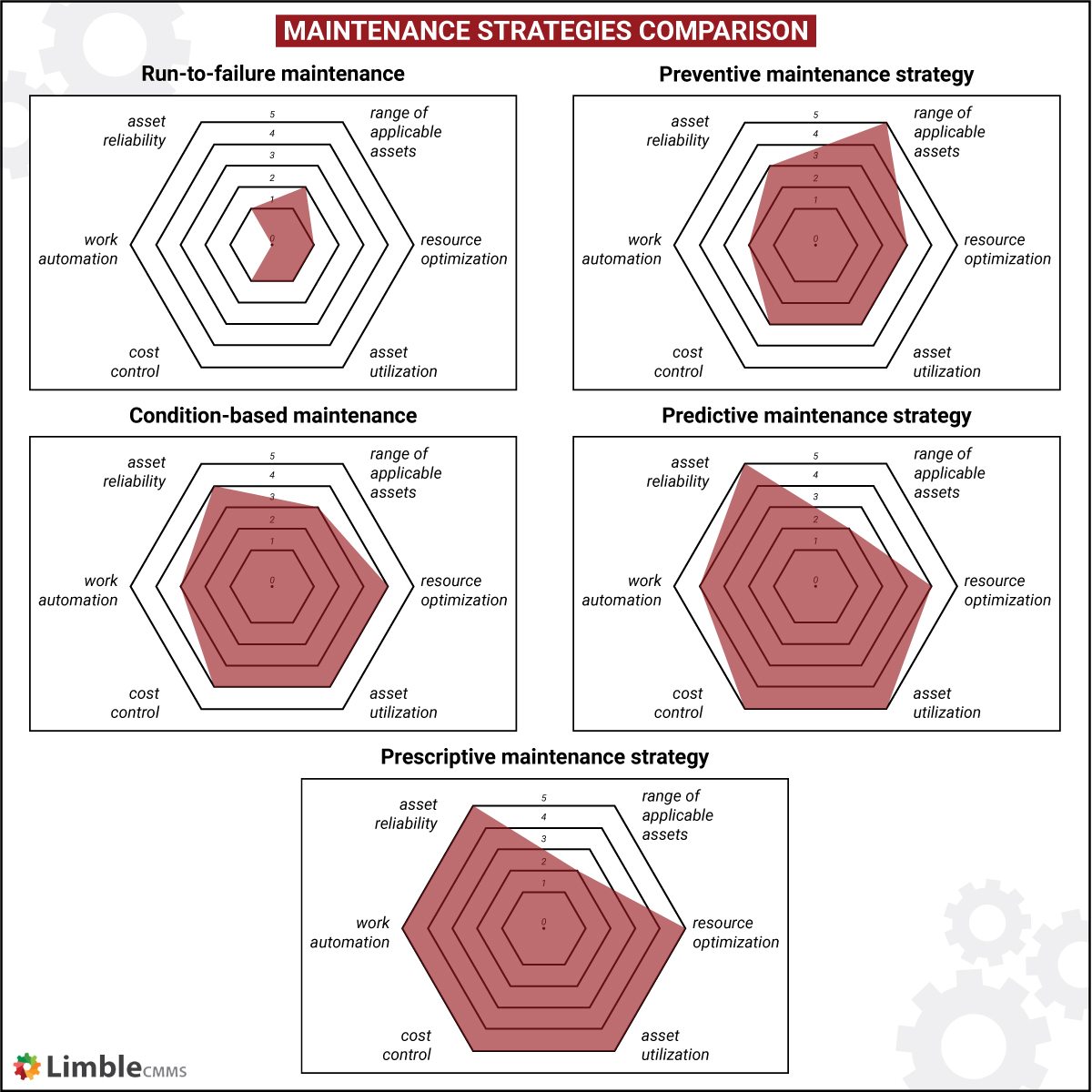

There are five main maintenance strategies employed in manufacturing maintenance:

- Run-to-failure maintenance strategy

- Preventive maintenance strategy

- Condition-based maintenance strategy

- Predictive maintenance strategy

- Prescriptive maintenance strategy

It’s important to understand that these strategies form a hierarchy. Each type of maintenance comes with its own set of benefits and disadvantages.

Reactive maintenance requires the least ongoing resource investments but causes poor equipment availability, high emergency maintenance costs, and inflates the capital expenditure budget. As you progress through the hierarchy, these cost implications change.

Condition-based maintenance costs more in ongoing maintenance expenses but greatly reduces emergency maintenance costs and lowers capital expenditure requirements. Prescriptive maintenance requires high up-front costs but provides a good return on investment through considerable maintenance savings and reduced downtime.

A healthy and targeted maintenance program combines these strategies to maximize equipment availability and longevity while minimizing maintenance budgets. Selecting the appropriate strategy for each machine requires a risk-based consideration, following the completion of a failure mode effect and criticality analysis (FMECA) and RCM.

Here are some additional notes that can help you select the most appropriate maintenance strategy for specific assets and use cases.

Assets with very high or very low MTBF

Preventative maintenance inspection tasks waste time and money if the equipment has a historically high mean time between failures. A run-to-failure or a predictive maintenance strategy may be more suitable, depending on the criticality of that asset.

In contrast, replacement at given cycles or calendar times may better suit unreliable items than including them on a costly predictive or prescriptive maintenance program.

Low-cost, disposable assets

Spending maintenance resources on regular inspections is inefficient when an asset is inexpensive to purchase. Reactive maintenance lets the asset run to failure, doing only regulatory test-and-tag, cleaning, or lubrication, assessing wear and tear. The item can be replaced once it ceases to function.

When items are designed to be disposable or have a fairly short lifespan, there is little point in investing time and money in expensive maintenance strategies. Inventory should hold sufficient spares of the item (and spare parts) to allow rapid replacement.

That being said, if the impact of the failure actually stops production, a condition-based or cycle time/calendar-based approach could be more efficient. You can simply schedule changeouts during planned downtime for regular maintenance.

Equipment redundancy

Equipment redundancy refers to using additional equipment to maintain operations. An example might be a configuration of two sump pumps, one operates while the other is idle (or both operate at 50% capacity).

Such a setup reduces duty cycles while providing backup in case of unplanned downtime or failure. In this scenario, carrying out preventative or predictive maintenance wastes resources. Allowing a pump to fail and trigger an alert is a low-cost maintenance strategy. The other pump will pick up the load until the failed pump is replaced.

Critical or unique equipment

If the failure of an item might cause environmental harm, a regulatory breach, or stop production for a considerable time, predictive or prescriptive maintenance is a viable option. Such strategies have a setup cost but provide early warning of impending failure, allowing early and planned intervention. The costs of implementation are usually well below the costs of breakdowns.

Long lead-time for spares

Modern equipment can have expensive sub-assemblies that are too expensive to keep in inventory but require extensive lead-time for supply. In such cases, condition-based, predictive, or prescriptive maintenance strategies can ensure early warning of deterioration to allow spares purchase and planned intervention before failure occurs.

Factory maintenance best practices

The following five practices are key to building efficient and effective industrial maintenance programs.

1) Develop standard operating procedures

Variability in completing maintenance tasks makes asset management difficult. If each technician applies their own rules, techniques, and depth of maintenance, how can you calculate the cost of a maintenance intervention or measure the effectiveness of a task?

Standard operating procedures (SOP) are official company documents outlining the step-by-step process to be followed when completing specific tasks (often in the form of checklists). They force a consistent approach to maintenance optimization. New hires are clear on expectations, information is current and approved, no step in a task is missed, and everyone executes the task in the same way.

An SOP also allows you to apply incremental changes and measure their impact as a part of the continuous improvement process.

2) Implement a CMMS

Paper-based and spreadsheet-powered maintenance systems are labor-intensive, prone to error, hard to analyze, and do not support rapid action.

A modern CMMS software centralizes and automates many aspects of maintenance management while providing modular extensions for complex analytic engines. They are cloud-based maintenance solutions, so they do not require in-house servers. You only need to provide technicians with appropriate tablets or smartphones.

CMMS solutions can capture and store all historical maintenance data, and can even integrate with other business software. As an example, Limble CMMS offers integrations with Quickbooks accounting software and SAP.

3) Implement sensors for data collection and analysis

Sensors for vibration, heat, or sound monitoring are becoming more common in factory maintenance. Recent advances in sensor miniaturization, robustness, and wireless technology support remote monitoring of critical equipment at more affordable prices. The captured data allows a timely identification and analysis of developing trends, supporting spares purchases and planned interventions at times suitable for production.

Coupling sensors to a CMMS enables you to establish real-time data feeds to its analytics engines, which can then spew out warnings for trends that lead to equipment degradation or failure.

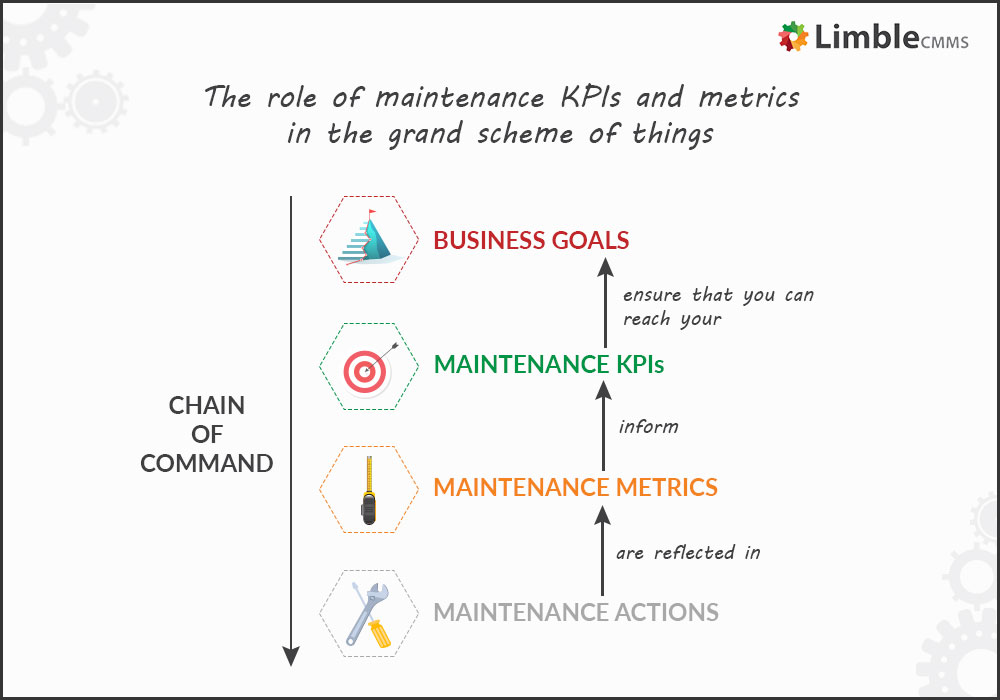

4) Develop and track key maintenance metrics

How do you know you’re hitting your maintenance targets without defining what success looks like for your organization? Maintenance exists to support business goals, and those goals require the maintenance department to achieve certain actions.

You can measure progress by developing key metrics to identify when those actions have been successful. Metrics also allow you to make incremental changes to maintenance systems and gauge their impact.

An example of a standard maintenance and production metric is OEE, which compares ideal equipment performance to its actual performance. Other measures might include inventory turnover, reported accidents, planned maintenance percentage, etc.

5) Ensure regular maintenance training

Maintenance training should be an ongoing process. Maintaining a technician’s skill at a peak level reduces the time needed for maintenance and supports safer work practices. A breadth of training also creates flexibility in your workforce, reducing the need for expensive specialists, and reducing risk when individuals are unavailable.

Use a mix of classroom, on-the-job, workplace secondments, and self-paced learning.

Do not forget that creating a lifelong learning culture in your workforce offers many secondary benefits. Your investment will mark you out as an employer of choice, reducing staff turnover rates and absences, and improving worker morale.

Taking manufacturing maintenance to the next level

Factory maintenance requires much more than fixing things when they break. It demands an understanding of business economics, strategy, quality systems, leadership, and technical skills.

The careful selection of maintenance strategies, combined with a desire for continuous improvement, timely data, and measurable results, offers businesses maximum asset life and equipment uptime.

Support that process with a capable maintenance software, and you’ve got yourself a strategy for success. Request a demo or start a free trial to learn how Limble CMMS can help you optimize maintenance in your manufacturing plant.