Maintenance Window

Everything you ever needed to know about maintenance window

What is a “maintenance window”?

The term “maintenance window” has generally been associated with IT. In this context, system administrators use maintenance windows to push important updates that require system downtime.

This can be applied to the factory setting as well: maintenance teams also need to look for the right time to schedule and complete important maintenance tasks. Instead of losing access to software and functions, manufacturers lose access to machines and production.

These factory maintenance windows can often take the form of a scheduled production line shutdown and upgrade. In extreme cases, they become plant shutdown weekends or month-long turnarounds.

Checklist for Creating a Preventive Maintenance Plan

Following a consistent Preventive Maintenance Plan can make life easier. Use this checklist to create your own!

When to schedule a maintenance window?

Be it a server room, a construction site, or a production floor, finding the perfect time to perform required maintenance work is never easy. This especially rings true for systems and assets that require high availability.

Part of the problem is that everybody connects downtime with lost profits. And while that is not always the case, it is true to a big extent.

Long story short, the timing of a maintenance window is an important consideration. For the sake of this discussion, there are two main options:

- Scheduling maintenance during regular business hours

- Scheduling maintenance outside of regular business hours

Let’s briefly go through their pros and cons.

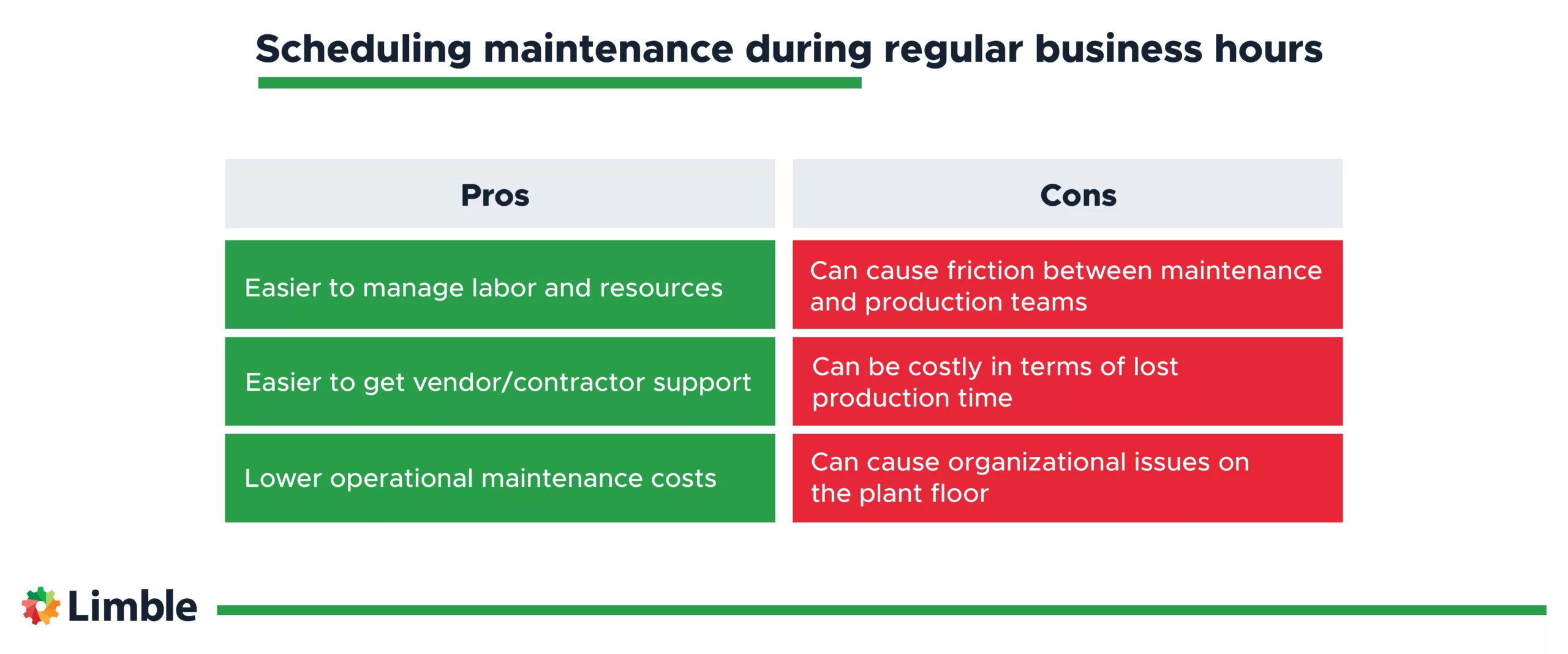

Scheduling maintenance during regular business hours

The first option is to schedule the maintenance window during core business hours. This is often the simplest and most straightforward way to set up a maintenance window.

On the plus side, you will typically have more resources at your disposal. Your team should be fully staffed during this time. Furthermore, vendor and contractor help is much easier to obtain during the day. This is critical if you require specialized assistance during your maintenance window.

All of that comes with an obvious tradeoff: if the shutdown has to happen during main hours, the service that relies on that hardware will be unavailable.

In a manufacturing setting, things get significantly more complicated. Not only do you have to sacrifice some production time to perform planned maintenance, you also have to figure out what to do with machine operators and other non-maintenance personnel that normally work during these hours.

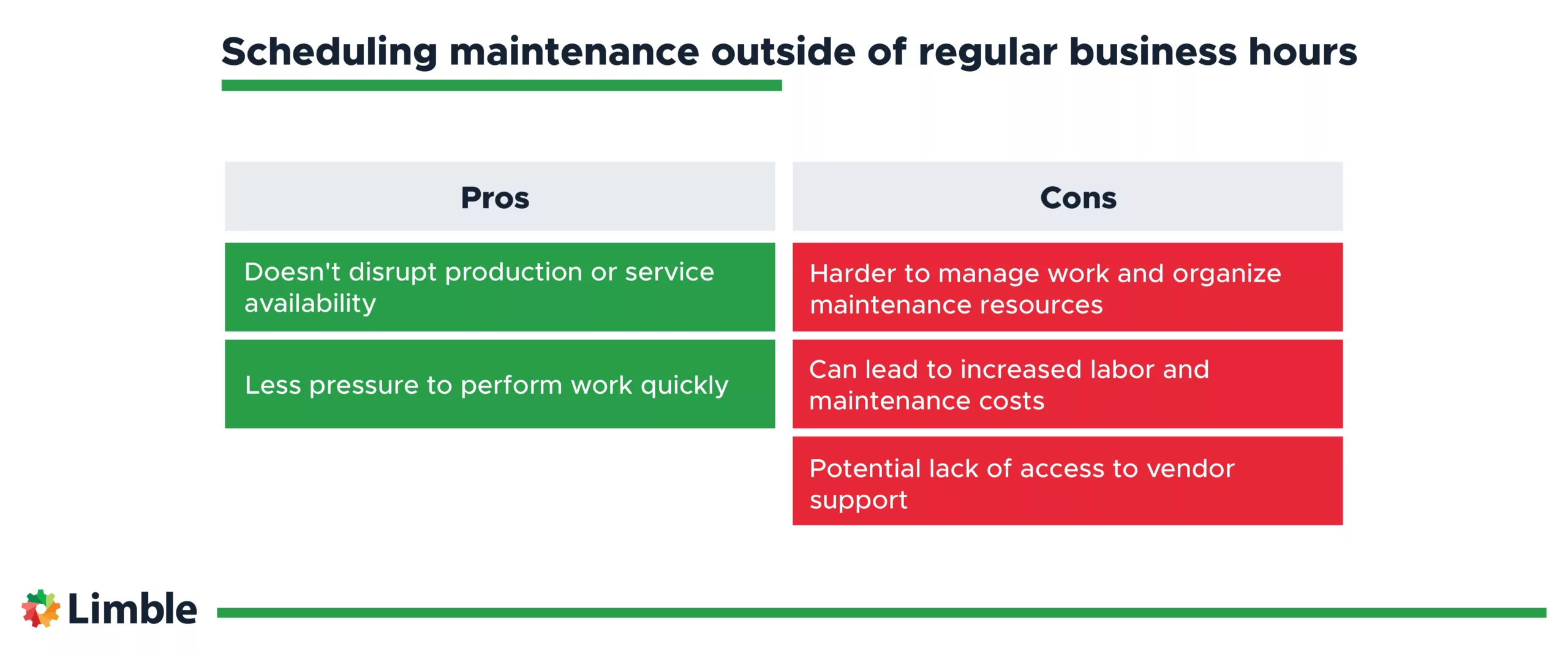

Scheduling maintenance outside of regular business hours

The alternative is to schedule your maintenance window after standard hours. This comes with its own pros and cons.

The biggest benefits of this approach are the limited disruption to the operation and less pressure to execute work as quickly as possible. Plus, when the maintenance is complete, your core team will be back to start up the equipment and ensure it is running smoothly.

A serious drawback to this schedule is a potential lack of access to vendor support.

Not everyone is available outside of the standard working hours. Even when they are, the cost of contractor help could also increase substantially.

Bonus: Finding surprise maintenance windows

On a busy manufacturing floor, maintenance teams should always be on the lookout for surprise maintenance windows. They can come in the form of a power outage, production bottlenecks, safety incidents, prolonged downtime caused by spare unavailability, etc.

The reason why the production stopped doesn’t necessarily matter. What matters is that a machine is not in use at this very moment. Instead of stopping production again on Friday to perform scheduled maintenance, you can just do it right now.

It takes great organization to catch these maintenance windows. Maintenance teams that use a CMMS software have a much better chance of reacting on time.

How to get the most value out of your maintenance windows

Maintenance windows are a necessary evil. However, they are also an investment in your future. It’s like sleeping. Yes, you could have done more work this week if you slept 4 hours a day instead of 8. For better or worse, that is not sustainable, and it will have a detrimental impact on your long-term health.

Still, you will want to make efficient use of the necessary downtime, so that you can get back to making products/delivering a service, and generating profit.

It is no real surprise that the key to a successful maintenance window is proper planning. To accomplish this, start early and involve all stakeholders. Communicate the window in multiple formats to all parties, and do it more than once.

Have a contingency plan for when servicing or equipment upgrades do not go as smoothly as planned. Consider what you will do when milestones are not hit in time. It is much better to have this laid out before the problem occurs.

For exactly these reasons, a CMMS is invaluable for scheduling maintenance windows — whether planned or unplanned. It can help in so many ways, from scheduling and delegating work to making sure that the required resources are available, and that relevant parties are notified of the work progress.

The Essential Guide to CMMS

Download this helpful guide to everything a CMMS has to offer.

How to reduce reliance on maintenance windows

While some maintenance windows are necessary, others can be avoided.

There are many different strategies to reduce your need for planned downtime. It’s a very deep and complex topic. A few common methods include:

- Redundancy

- Asset upgrades

- Condition monitoring and predictive maintenance

Equipment redundancy

One way that IT staff will mitigate maintenance windows is by adding redundancies — backup servers in an array, for example.

This concept is also applicable in manufacturing and used for critical equipment.

One simple example is an inline pump. Two pumps could be installed in a parallel configuration, where one of them can take over the full load when needed. Be it for a repair, an upgrade, or routine maintenance, the maintenance team can always stop one of them, without any visible impact on the performance of the whole system.

Often this is simply not feasible — financially nor practically. A more rudimentary way of employing equipment redundancy is by holding necessary spare parts. The swaps can be made quickly, ensuring minimal downtime.

Equipment upgrades

In many cases, upgrading or replacing old machines can dramatically reduce maintenance needs. Newer equipment is made with a maintenance-conscious design in mind, which vastly improves its maintainability.

On a side note, avoid upgrading a machine during a surprise maintenance window. The urgency is turned up in these situations, damaging morale, racking up costs, and leaving more room for errors.

Condition monitoring and predictive maintenance

The main selling point behind condition monitoring and predictive maintenance is that they will help you catch early equipment deterioration signs and allow you to schedule maintenance only when it is actually needed.

With these tools in your back pocket, you will be able to plan downtime based on the actual condition of your equipment instead of more arbitrary metrics like calendar time or cycle count.

This should allow you to get by with fewer maintenance windows, without an increase in unplanned downtime caused by equipment breakdowns.

Want to see Limble in action? Get started for free today!

Schedule your way out of tight spots with Limble CMMS

Whichever way you look at it, the quality of your maintenance windows will depend on two main factors:

- How capable is your maintenance team

- Your ability to schedule and organize maintenance work

Both factors can be improved with a modern CMMS like Limble. You can use it to access maintenance history and build checklists and procedures your maintenance teams can follow during a maintenance window to complete work in a faster and safer way, with less room for mistakes.

On top of that, CMMS software is a centralized digital platform whose main purpose is to help you schedule work and organize your maintenance resources. So there’s that.

If you are ready to take your maintenance to the next level, reach out to our CMMS specialists or schedule a quick product demo.