-

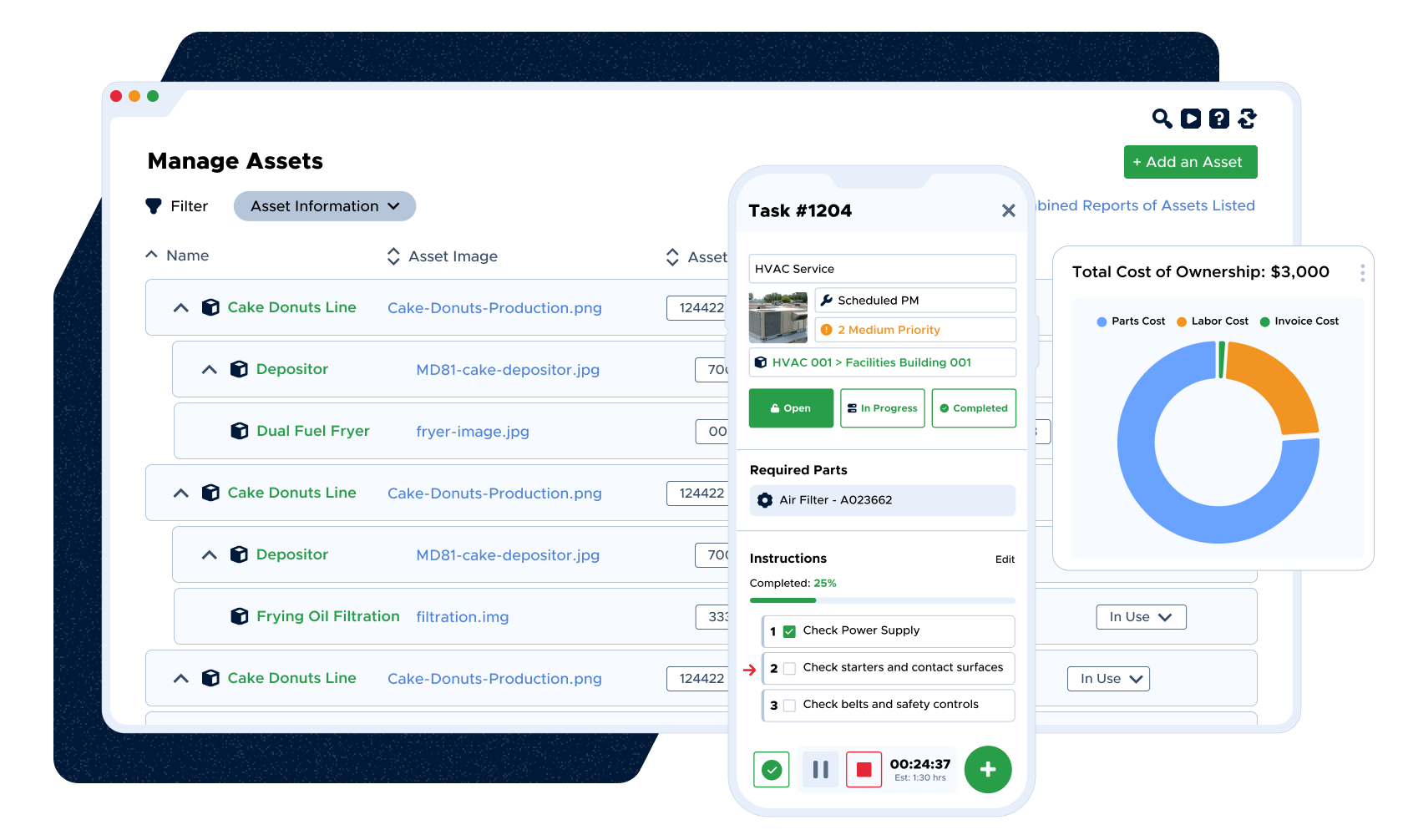

Increase uptime

Reduce unplanned breakdowns and increase asset reliability with predictive maintenance.

LEARN MORE -

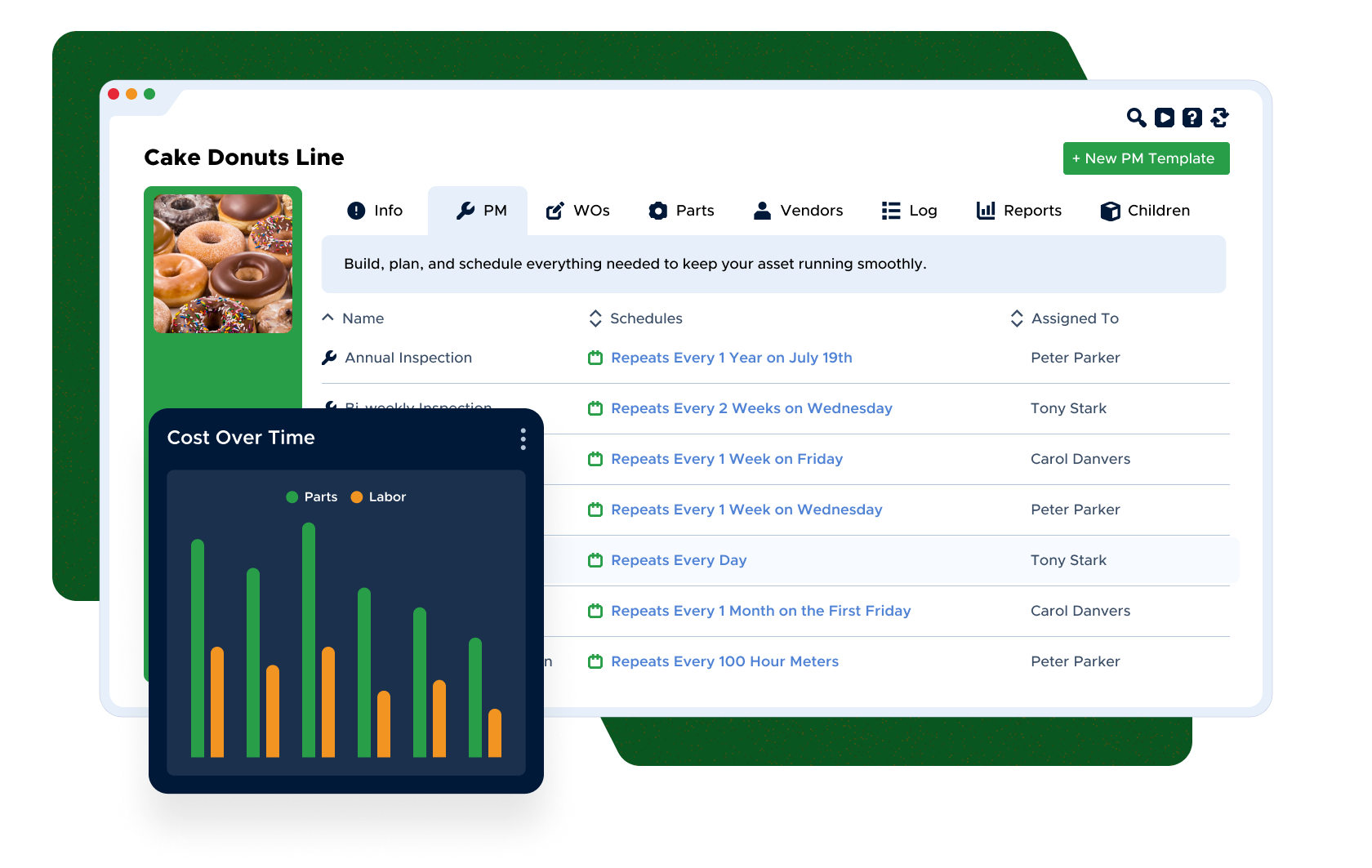

Increase productivity

Streamline your maintenance program with maintenance scheduling and automation.

LEARN MORE -

Increase connectivity

Integrate IoT sensors and EAM/ERP systems for a complete view of your data and asset performance.

LEARN MORE

“Everyone picked it up quickly and suddenly all our maintenance requests that had been up on the wall were now on our phones and laptops. It simplified the operation for absolutely everyone here”

AJ Popovic Maintenance Technician VIEW CASE STUDYLimble takes predictive maintenance to the next level. See how in a personalized demo from our team.

FAQ for a predictive maintenance software

What is predictive maintenance software?

Predictive maintenance software (key feature of CMMS), leverages data analytics, machine learning, and artificial intelligence to monitor equipment health. It predicts failures before they occur, enabling condition-based maintenance and proactive solutions tailored to your maintenance needs.

What are the benefits of using predictive maintenance software?

Predictive maintenance solutions reduce unplanned downtime, lower maintenance costs, extend asset lifespans, and enhance safety. They drive operational efficiency, enable digital transformation, and deliver significant cost savings.

What types of industries can benefit from predictive maintenance software?

Industries like manufacturing, energy & utilities, healthcare, and transportation use predictive maintenance to optimize equipment performance, manage maintenance workflows, and reduce operational disruptions.

Does predictive maintenance software integrate with existing systems?

Yes, predictive maintenance solutions integrate seamlessly with IoT devices, EAM, ERP systems, and work order management tools, enhancing functionality and data flow.

How much data is needed to implement predictive maintenance effectively?

Predictive maintenance hinges on quality and relevance of data rather than sheer volume. Typically, a few months of accurate sensor readings and maintenance logs can establish a solid baseline, but assets with longer operational cycles may require up to a year of continuous data to build reliable predictive models.