-

Uptime, all the time

Avoid emergencies and keep production running with a streamlined process for tracking and completing PM tasks.

LEARN MORE -

Fully compliant

Maintain a strong PM program with audit-ready historical data on assets and maintenance activity.

LEARN MORE -

Built for growth

Take advantage of Limble’s flexibility and scale to create an enterprise-worthy PM strategy.

LEARN MORE

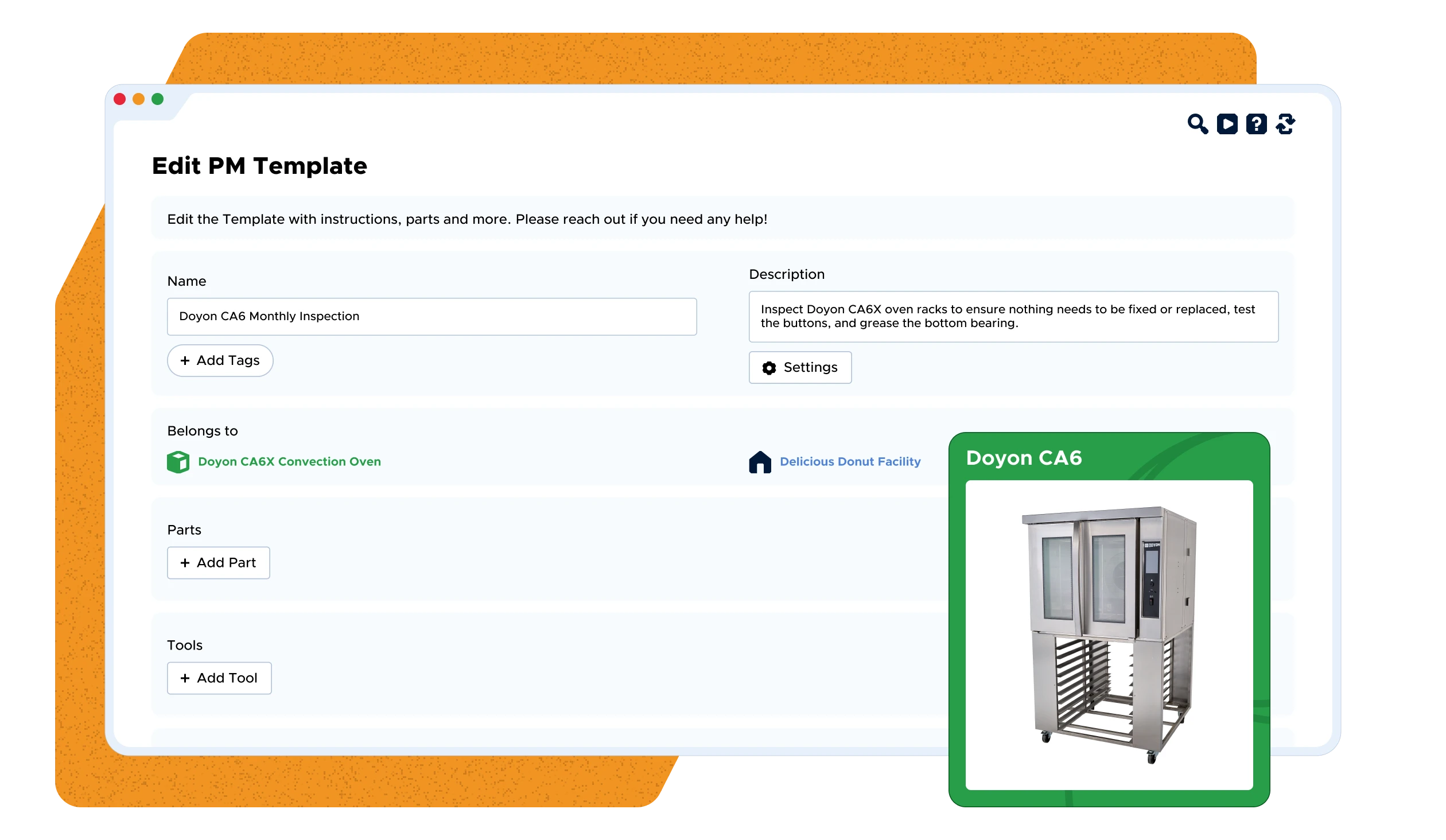

Create PMs in a few clicks from desktop or mobile

Manage your PMs without dealing with spreadsheets or back-and-forth emails. Limble’s user-friendly preventive maintenance templates can be easily customized with your own SOPs, photos, and checklists based on conditional logic.

Automatically assign tasks and notify their owner

Configure your preventive maintenance processes to automatically get assigned to a specific team, location, or individual employee. If you want to make changes to an existing task, all it takes is a quick drag and drop to reschedule.

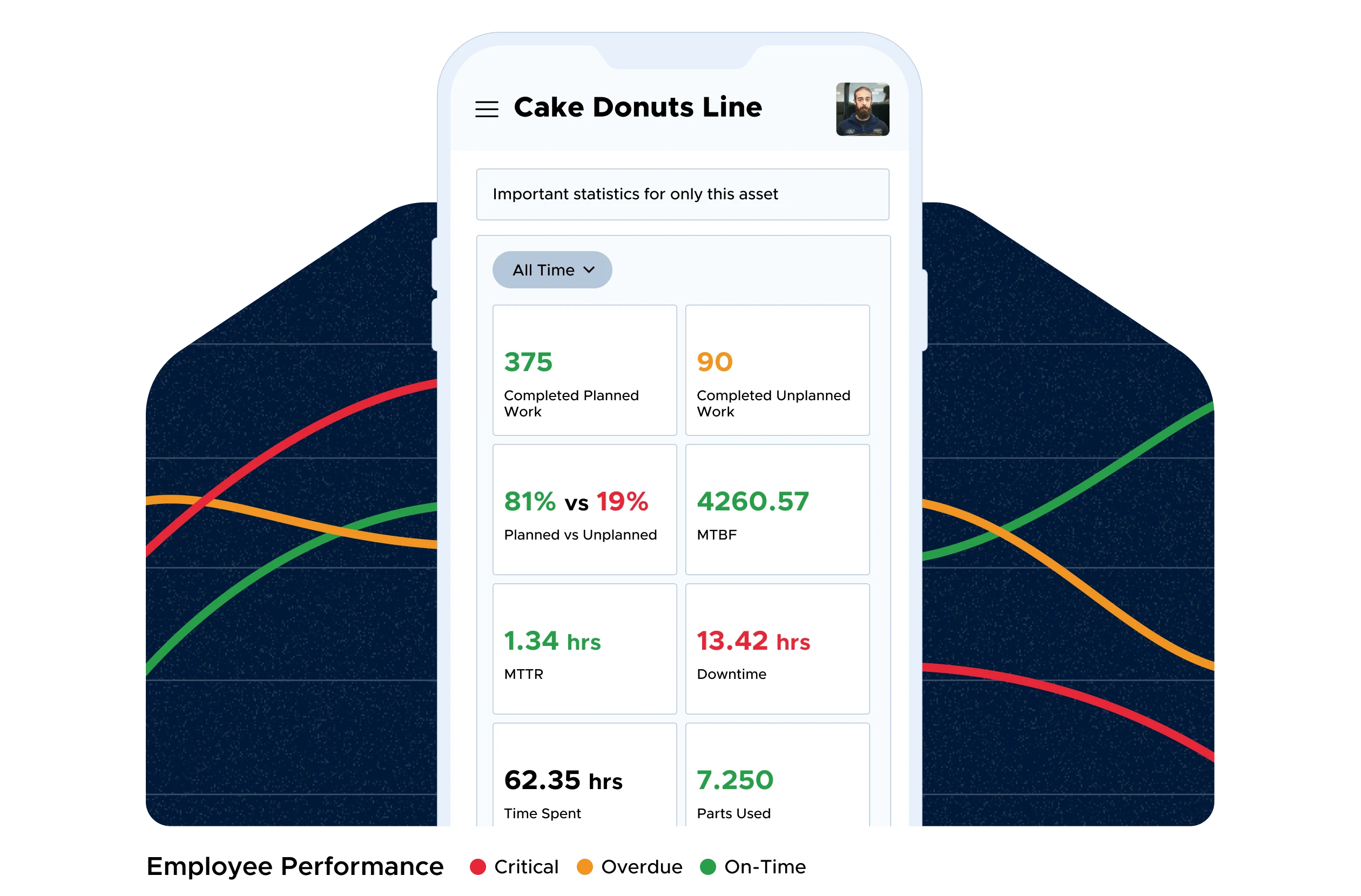

Track completion and outcomes of preventive tasks

Monitor preventive maintenance tasks, track completion rates, and measure planned vs. unplanned maintenance to understand the health of your program. Limble helps you schedule PMs more efficiently and see where your work is paying off, with intuitive reporting on top PM metrics.

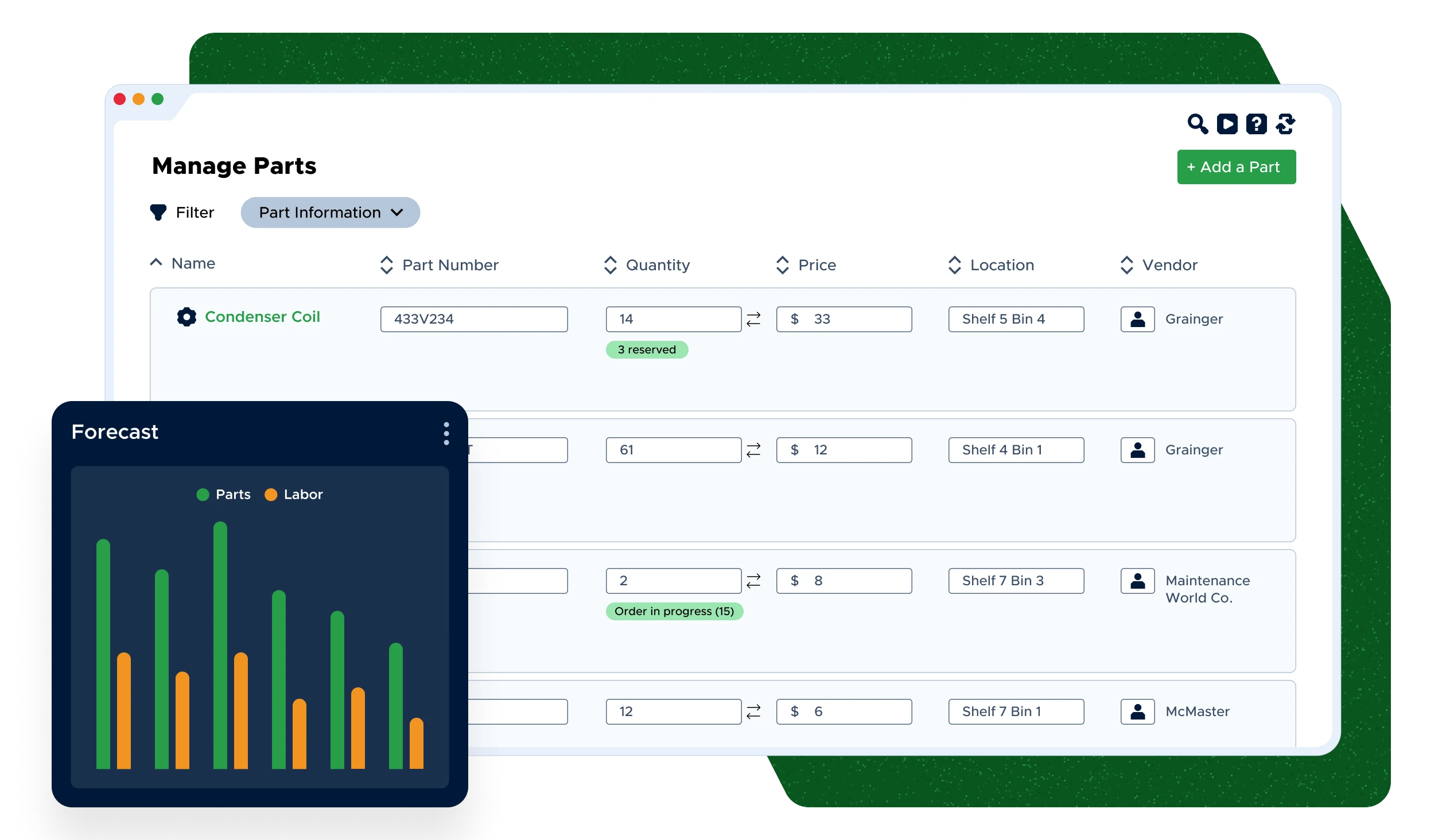

Easily order parts for routine upkeep

Associate parts with specific vendors and quickly create POs when spare parts inventory falls below a certain threshold, ensuring you always have them on hand for preventive maintenance.

“As we put more and more data into Limble, including labor hours and the cost of parts, we're getting more and more out of it, which can generate better budgeting for the next fiscal year.”

Sean Diffley Director of Engineering VIEW CASE STUDY