Retirement is inevitable. This is why HR departments exist – to find new workers and replace the veterans. While technical schools can churn out recruits with a reasonable knowledge of basic maintenance, they cannot replicate actual work experience.

Nowhere is this skill gap felt more acutely than in maintenance. The industrial sector as a whole is suffering from a skill gap crisis, with millions of positions lying vacant due to a lack of qualified candidates. This is why intra-organizational knowledge transfer is so vital for maintenance teams.

In this blog post, we will explain everything maintenance managers need to know to capture, document, and share maintenance knowledge inside their department.

First, what is a knowledge transfer?

Departments and organizations acquire a ton of information over years and even decades of functioning. This includes data about processes, procedures, people, and physical assets.

Much of this knowledge is unique and irreplaceable. And while some may be well documented in files and databases, a lot of it is stored in the heads of the most experienced and skilled workers. Now, if employees stayed in the organization perpetually, this wouldn’t be alarming.

But that doesn’t happen in real life. People retire, quit, or move on to other jobs at a rival firm. Smart, professionally managed organizations find ways to retain their knowledge not just for the sake of future generations of workers but for the future of their company as well.

To summarize, proper management of maintenance knowledge is important because:

- Without the planned transfer of maintenance knowledge, a firm risks losing vital intellectual capital when experienced technicians retire or leave.

- The void left behind by skilled workers can lead to production delays, inefficiencies, and a myriad of other disruptions.

- Knowledge transfer is the only reliable way to ensure the long-term stability and flexibility of a maintenance department in the face of a high employee turnover.

Core concepts in knowledge management

The knowledge management theory deals with three main concepts found within an organization. Here are all three, explained in the context of maintenance management.

1) Intellectual Property (IP)

For an equipment vendor, the IP would include designs, blueprints, and patents for any in-house technologies, as well as technology licenses leased from other companies.

From a maintenance perspective, in an industrial or manufacturing setting, intellectual property could involve a patented manufacturing process, vendor guidelines, performance data from machines, etc. It can also include any insights or skills gained by the staff in the course of their work.

2) Organizational culture

Effective capture and transfer of knowledge within the organization can’t happen without built-in systems and philosophies. The initiative has to come from the top, encouraging a collaborative environment within the entire organization. Projects like mentorships, training classes, documentation initiatives, and skill augmentations are essential.

3) Information technology

The intellectual property can be present in raw or unmined data. You need technology to capture it, store it, and convert it into information that can be used to train other members of your team.

There are various digital tools to capture relevant maintenance knowledge. We discuss the most popular ones later in the article.

What does “knowledge” mean from a maintenance perspective?

Maintenance is a highly specialized job in modern manufacturing and other asset heavy industries.

The job description of a maintenance technician can include a diverse array of responsibilities, from the installation of industrial equipment to the usage of tools like borescopes, lathes, hand-held vibration meters, and welding equipment, to troubleshooting complex on-site and off-site machines.

Many of those tasks benefit from having a well-defined procedure technicians can follow. Some have to be executed in a specific way to satisfy OSHA requirements and other industrial safety guidelines. Even within these frameworks, organizations will often have their unique ways of getting things done.

Old equipment will often develop unique quirks that can’t be addressed by looking at operating manuals or vendor blueprints. During an unplanned maintenance job, a beginner technician may end up wasting hours of valuable time trying to troubleshoot issues that someone who is familiar with that piece of equipment could solve in a matter of minutes.

You know full well that speed and accuracy are critical in maintenance. You need skilled workers to handle expensive, mission-critical machinery. Maintenance knowledge transfer here focuses more on equipping new hires with the insights and skills distilled over years of hands-on work on the production floor.

In short, knowledge in the maintenance context is focused on the following aspects:

- Capturing and documenting insights derived from years of experience

- The knowledge that enables fast and accurate troubleshooting

- Transferable skills that help optimize all facets of repairs and maintenance work

Explicit vs tacit knowledge in maintenance

The industrial environment provides perfect conditions for the creation of both explicit and tacit knowledge:

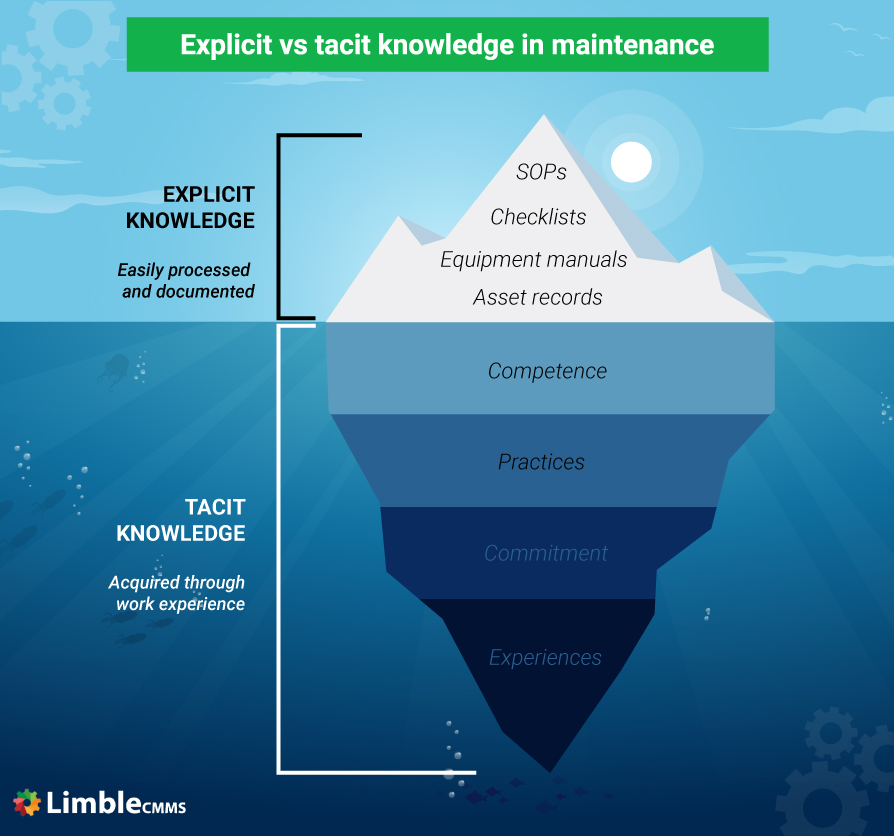

- Explicit knowledge: Refers to information that is easily processed, stored, organized, and interpreted. Think SOPs, checklists, asset records, technical books, O&M manuals, etc.

- Tacit knowledge: Refers to information, skills, and practices technicians and mechanics slowly acquire as they spend more time working on different machines and systems.

In other words, explicit knowledge provides the foundation, while tacit knowledge enhances it.

For the success of any intra-organizational knowledge transfer initiative, you have to find ways to transfer both explicit and tacit knowledge.

Building a centralized maintenance knowledge repository

These days, thanks to cloud technology, you can create and store all such data in one easy-to-access place. In a maintenance setting, a modern CMMS solution has everything you need to serve as your maintenance knowledge library.

While they are not built for the industrial environment, if you do not have access to a CMMS, you can look at popular knowledge management apps. As a final alternative, you can also look into Google Workspace.

Here are some suggestions on the types of documents and knowledge worth capturing.

Create and store important procedures and other maintenance documentation SOPs, checklists, and safety procedures

There are a lot of different types of documents worth creating, storing, and making available to all workforce. The main ones include:

- Standard Operating Procedures (SOPs)

- Preventive maintenance checklists

- Troubleshooting checklists

- LOTO procedures and other safety guidelines

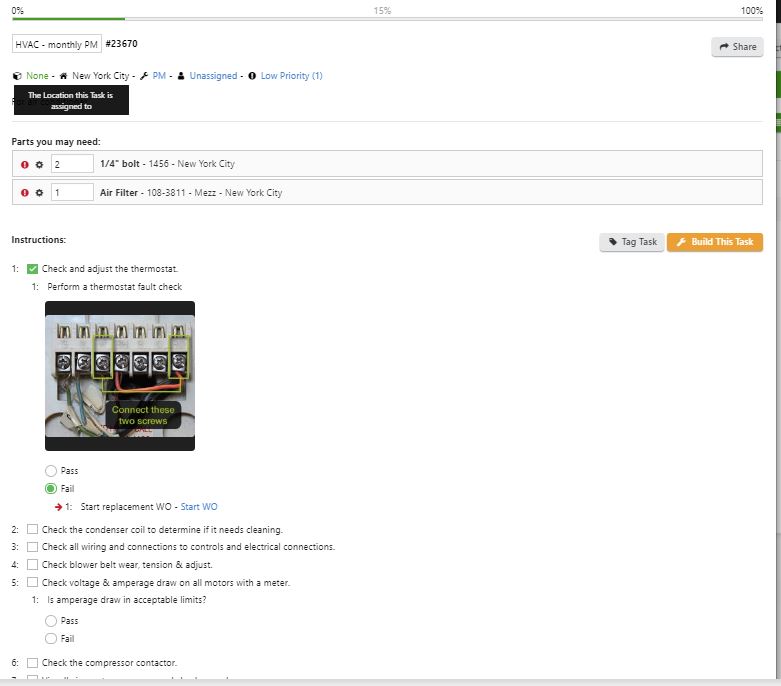

An example of a PM checklist built using Limble’s PM builder

An example of a PM checklist built using Limble’s PM builder

All of those documents can be stored inside a CMMS and accessed in the field via quick search.

Gather and publish general info

Here is a list of general maintenance documentation you should make available to the whole department, as well as some other information your team might find useful:

- Your maintenance policy

- Contact information for each team member (email, business phone number…)

- OSHA documentation

- General policies and procedures

Find and store all relevant asset-related information

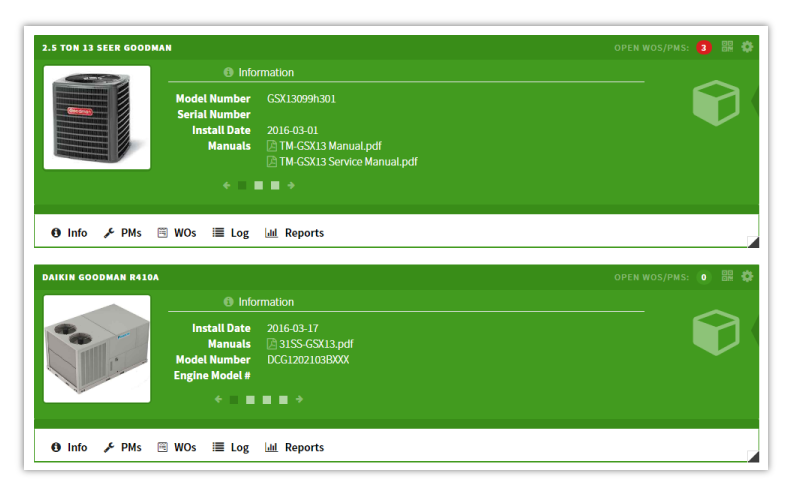

Having a repository of all relevant asset information is great. Having that info tied to its respective asset is even better.

This is why Limble CMMS categorizes asset data in the form of centralized asset cards. Each asset is represented by its own asset card that features the following information:

- Make and model of the asset

- Serial number

- Installation date

- Equipment manuals

- Troubleshooting checklists/LOTO procedures/PM checklists

- The history of PMs performed on that asset

- The history of WOs performed on that asset

- Maintenance log for that asset

- Reports generated for that asset

- Custom variables that can contain basically any info you deem necessary

Example of asset cards inside Limble CMMS

Capture data using videos and photos

Many maintenance-related skills can be easily demonstrated using instructional videos. These days, you can easily create short instructional videos with minimal expense, using just a decent phone camera. Involve your senior technicians as instructors. You can also use high-definition photos in how-to guides to create more effective training manuals.

Other ways to transfer maintenance knowledge

Apart from creating a knowledge base, you can also rely on the following methods for on-the-job knowledge transfer. In general, these are the best ways to transfer tacit maintenance knowledge.

Mentorship programs

At any given time, an organization is bound to have some veterans working on its payroll. The simplest form of knowledge transfer involves using these individuals as tutors or mentors to help new hires get up to speed.

Training sessions

Informal toolbox talks, as well as more formal training sessions, can also be used. If necessary, you can also explore the idea of bringing in outside experts or retired technicians in a training capacity. This is a great way to bridge the skill gap when there is a sudden generational shift in your workforce.

Maintenance tech entry programs

In a tight job market, you will often face significant challenges in finding skilled workers. Entry programs and in-house certification programs can serve a dual purpose – attract new talent with technical aptitude and also ensure that organizational knowledge is retained and put to good use.

Obstacles to effective knowledge transfer

Maintenance knowledge management should be a continuous process. Unfortunately, many organizations do it haphazardly or do not bother with it at all, often because of the challenges listed below:

- Absence of company culture: If the maintenance directors and other organizational leaders are not committed to the project of knowledge management, the initiative is unlikely to succeed.

- Shortage of time: In the highly demanding and challenging market, firms may not have time for anything other than meeting production quotas and other deadlines. Poorly organized maintenance departments can’t take a breather due to an insane amount of equipment failures resulting from a reactive approach to maintenance. That needs to be solved first.

- Limited incentives (for both technicians and management): Technicians may resent the extra burden of training rookies, while management is reluctant to commit precious resources to the project.

- Lack of adequate infrastructure/know-how, especially in IT: This is often a factor in smaller and medium-sized enterprises where they don’t have expertise at the management level to helm this type of project.

None of these obstacles are insurmountable, especially now that you know what you should be watching out for.

Use CMMS to facilitate effective knowledge transfer

A modern CMMS is built to give you a 360-degree view of the entire maintenance process – from when a Work Request is submitted to when the respective Work Order is marked as complete; from when an asset is installed to when it is disposed of.

One of the main benefits of using a mobile CMMS is its ability to capture that entire process and automate data collection. Furthermore, it gives you the ability to create and attach SOPs, checklists, and safety guidelines to each respective asset, making it easily accessible from any mobile device. When used correctly, CMMS will quickly become an invaluable repository of maintenance knowledge.

If you want to learn more about how Limble can simplify maintenance knowledge management contact us using this form. If you’re more interested in other features and the general workflow, schedule a personalized demo!