Your maintenance team is responsible for a wide range of critical functions from routine equipment upkeep and preventive maintenance activities to regulatory compliance checks and safety inspections. Your maintenance program will take the lead role in ensuring that maintenance tasks are performed quickly and correctly, minimizing unplanned downtime, and extending the expected useful lifespan of your equipment.

Your maintenance team will also play a lead role in keeping accurate and up-to-date records of these activities. This is where maintenance logs come in.

Why are maintenance logs important?

A maintenance log is a valuable asset management tool. Your organization’s maintenance log plays a pivotal role in documenting the work performed, helping maintenance professionals track the health and status of their equipment while providing a foundation for making informed decisions that can enhance maintenance strategies.

What is an equipment maintenance log?

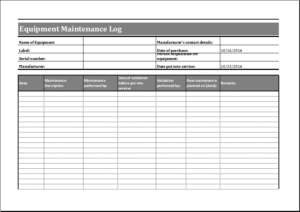

The equipment maintenance log (sometimes referred to as an equipment maintenance form or equipment maintenance sheet) is a simple document that records all maintenance actions that have been performed on a specific asset.

While the information it contains varies depending on the type of equipment/asset in question, a standard equipment maintenance log is often split into two sections:

1. General information used to identify the asset

- Location and movement tracking

- Make, model and manufacturer names

- Serial number, model number, and any other identifying numbers

- Warranty information

- Vendor contact information

2. Maintenance activity details including

- Date of maintenance

- Descriptions of the work performed

- Spare parts used or components replaced in completion of the work

- Names of the individuals who carried out the maintenance activities

- Explanation of equipment condition both before and after work

The purpose of compiling this information in a single log is to provide a comprehensive historical record of an asset’s maintenance history, which can be crucial for tracking the performance and condition of equipment, diagnosing recurring issues, planning preventive maintenance schedules, and making informed decisions about repairs or replacements.

Example of equipment maintenance log template

Types of maintenance logs

An effective maintenance program will often leverage a combination of overlapping machinery maintenance logs. This ensures a detailed, comprehensive, and multidimensional view of maintenance needs and activities. The following are among the most common types of maintenance logs:

- A basic maintenance log is a simple log that captures essential information about maintenance activities. These include the date of maintenance, a brief description of the maintenance action, and the names of the technicians and other personnel involved.

- A detailed maintenance Log is a more comprehensive log that includes additional details on equipment identification, location, movement, description of the maintenance performed, parts used or replaced, and observations or recommendations for future maintenance.

- A preventive maintenance log is specifically designed to aid in preventing equipment failure by logging scheduled maintenance tasks, date and time of each preventive maintenance task, specific procedures performed (e.g., inspections, lubrication, calibration), and details on the technician responsible for performing the proactive maintenance tasks.

- A predictive maintenance log is used to track maintenance based on the actual real-time condition of the equipment, often utilizing data from sensors and monitoring tools, including information such a equipment condition data (e.g., vibration levels, temperature readings), analysis results from condition monitoring tools, and maintenance actions performed based on predictive data.

- A corrective maintenance log documents repairs and corrective actions taken to fix equipment after a failure or malfunction has occurred. It will typically include a description of the issue or failure, the date and time of the failure report, corrective actions taken to resolve the issue, parts replaced or repaired, and details on the duration of downtime and its impact on operations.

What information should maintenance logs include?

- General equipment information, including equipment name, model and serial number, physical location within the facility, purchase date and, if applicable, purchase price

- Maintenance action details, such as date, time, and a detailed account of the work performed, including specific tasks such as inspections, cleanings, part replacements, calibrations, or repairs

- Index of spare parts used and components replaced during the maintenance activity

- Assessment of equipment condition both before initiation and after completion of maintenance activities

- Personnel information including the name or ID of the technician(s) who performed the maintenance, and, if applicable, the name of the person who supervised the project or inspected the completed maintenance work

- Operational metrics like Mean Time To Failure (MTTF), Mean Time Between Failures (MTBF) and other Key Performance Indicators (KPIs)

- Additional relevant materials including photos, videos, diagnostic reports, manufacturer guidelines and, where required, clear documentation of authorization or verification from technicians and/or supervisors

- Compliance checklists indicating the completion of activities related to industry best practices, safety standards, or regulatory requirements

Benefits of an equipment maintenance log

An equipment maintenance log is a valuable tool that carries a number of indispensable benefits for your maintenance program. An effective equipment maintenance log:

- Optimizes the preventive maintenance process by providing historical maintenance records of all past repair and upkeep activities, lending insight into the frequency and nature of past issues, and allowing maintenance teams to make data-driven preventive maintenance scheduling decisions.

- Facilitates predictive maintenance by enabling the identification of patterns and trends that can forecast potential failures and informs the type of preemptive maintenance plan and schedule that can improve the efficiency, availability and longevity of your equipment

- Improves Root Cause Analysis (RCA) of equipment failures by providing a comprehensive history of all issues and repairs relating to individual pieces of equipment, making it easier to diagnose recurring problems, and offering quick reference points on previously used solutions or recurring faults.

- Supports onboarding by functioning as a valuable training tool for new technicians unfamiliar with the equipment while offering current team members insights into common issues and best practices for repair.

- Improves resource allocation by making it easier to identify the critical assets that require the most frequent and demanding maintenance and upkeep and making it possible to streamline and automate aspects of your inventory management strategy to align with these needs.

- Reduces operational costs by improving equipment uptime, speeding up response and repair times, extending the useful life of your equipment, and helping your facilities manager make data-driven decisions about when to replace or upgrade aging equipment.

- Provides a detailed audit trail to help ensure regulatory compliance, adherence to current safety standards, and protection from legal liability.

Getting started with equipment maintenance logs

Here are some of the key steps involved in designing, implementing, and improving the functionality of your equipment maintenance logs over time.

- Define the purpose and scope of the log, identifying the types of equipment or assets to be tracked and the specific maintenance activities to be documented.

- Identify the key information fields that are necessary to support maintenance activities and decision-making including space for general equipment information, maintenance details, date of maintenance, personnel information, description of maintenance actions, parts used or replaced, and condition of the equipment both before and after maintenance.

- Design the maintenance log template, using the fields identified above to divide the template into logical sections (e.g., equipment information, maintenance actions, parts used, technician details), to ensure the format is user-friendly, and that your equipment maintenance log template can be customized based on specific equipment needs or organizational requirements.

- Implement the maintenance log, ensuring all team members are trained on how to use the log effectively and understand the importance of accurate and consistent data entry. You should also establish standardized procedures for filling out the log and take efforts to make the log easily accessible to all relevant personnel, preferably through shared access to an advanced Computerized Maintenance Management System (CMMS) platform or other maintenance management software solution.

- Regularly monitor the use of the maintenance log to ensure compliance, gather feedback from technicians on the usability of the log, and identify areas for potential improvement in the maintenance log’s functionality.

- Leverage data collected in the maintenance logs to analyze trends, diagnose recurring issues, and make data-driven decisions for continuous improvement or your maintenance program.

Equipment maintenance log best practices

Maintaining a well-organized and effective equipment maintenance log is crucial for ensuring the longevity, safety, and efficiency of your assets. Below, we spotlight some proven best practices for getting the most out of your maintenance logs:

- Standardize log entries, creating a user-friendly template for all items, establishing standard operating procedures (SOPs) for data entry, and making your template customizable for all relevant equipment types.

- Enable remote cloud-based access, ensuring that digital logs are accessible to all relevant team members, including those working in the field and offsite.

- Track Key Performance Indicators (KPI) such as downtime, MTBF, and MTTR. Use these metrics in order to identify recurring issues, schedule preventive maintenance, and plan for cost-effective replacements or upgrades.

- Integrate maintenance logs with inventory management in order to track parts and materials used in each maintenance task, link this information to your inventory system, and automatically update stock levels when parts are used.

- Digitize maintenance logs for centralized access, enhanced user controls, and advanced data analysis, preferably by leveraging a CMMS that makes it possible to track maintenance activities all in one place.

Digitize your maintenance log book with Limble

A leading-edge maintenance software like Limble can streamline maintenance log management by digitizing your entire maintenance workflow. This not only simplifies the process of record-keeping but also enhances your team’s ability to use this information for continuous improvement.

- Limble automates much of the data entry process, reducing the manual effort required to maintain logs and minimizing the likelihood of human error.

- With Limble, maintenance logs are stored in the cloud, providing easy, secure, and remote access from anywhere in the field or offsite.

- Limble enhances accountability by providing a clear audit trail of all maintenance activities, including time-stamped maintenance logs with comprehensive details about the technicians, supervisors, and inspectors involved in the completion of each task.

- Limble provides a comprehensive overview of an asset’s maintenance history so technicians can quickly review past maintenance data for trends such as recurring breakdowns or frequently replaced parts, and consequently optimize maintenance strategies to address underlying issues.

- Limble seamlessly integrates maintenance logs with other critical maintenance functions, such as inventory management, work order management, and preventive maintenance scheduling so that you can manage every dimension for your maintenance program through a single, centralized, user-friendly dashboard.

Ready to streamline everything about your maintenance program, from record keeping and audit trails to data analysis and inventory management? Take the Limble CMMS Product Tour at your convenience!

For the guided experience, reach out to our experts and schedule a personalized demo today!

Comments are closed.