O&M manuals are an essential resource for world-class organizations. They contain all the instructions necessary for managing and maintaining specific types of facilities. Think of them like user guides to your facilities. They guide professionals through all the routine maintenance procedures and emergency protocols necessary

Though O&M manuals aren’t mandated by law, many organizations require them to ensure in-house technicians and contractors can perform their work effectively. Some contractors may require you to submit certain types of documents before handovers.

What types of professionals create O&M manuals?

- Plant executives

- Plant engineers

- Operations managers

- Original equipment manufacturers (OEMs)

- Maintenance personnel (managers, supervisors, engineers, technicians)

- Safety managers

- HR representatives

- Finance professionals

Why are O&M manuals important?

Armed with operation and maintenance manuals, professionals across industries can extend the life cycles of their equipment, keep facilities safe, avoid unexpected shutdowns, and mitigate the cost of all types of downtime. Some additional benefits of maintaining detailed, up to date O&M manuals include:

- Collecting lots of maintenance data in one place: These manuals bring together all the information necessary for maintaining a facility in one central location. Imagine how much time and stress that will save. Employees won’t need to dig through filing cabinets or wander aimlessly throughout your facilities to find the information they need.

- Establishing clear standards and protocols: Operation and maintenance manuals include well-defined standard operating procedures (SOPs) and protocols for all types of scenarios. Laid out in clear, unambiguous terms these offer guidance to technicians and reduce inefficiencies.

- Speeding up training and on-boarding: By centralizing relevant information and addressing common questions, high-quality O&M manuals help bring new hires or contractors up to speed as quickly and efficiently as possible.

Types of O&M manuals

Some organizations maintain a single large document that covers all of their operations and facilities. Other organizations maintain a number of O&M manuals in digital repositories or as hard copies. You may, for example, prefer to create manuals for different subsystems or types of equipment and keep them separate. You might also categorize manuals based on their purpose. Different manuals might cover areas like maintenance, operations, installation, administration, decommissioning, or support.

Some common types of O&M manuals you may encounter include:

- Emergency and safety manuals

- Human resources manuals

- User manuals from OEMs

- Software and data administration manuals

- Installation and maintenance manuals

- Manuals for help desk support

- Quick reference guides

Whatever their contents and context, O&M manuals should include enough crucial information to ensure its users can confidently make decisions and perform their tasks.

What should you include in an O&M manual?

Here’s some of the specific information you may see in the table of contents for a high-quality O&M manual:

- Background information on your organization

- Details on the scope of the manual

- A guide to any revisions you’ve made to your manual

- Definitions for key terms and acronyms necessary for understanding the document and following its instructions

- A fixed asset register or digital asset register with technical specifications for all the machinery included in the document

- Vital information for each of your assets, including the names of manufacturers, model numbers, and estimates related to their expected productive life cycle

- Detailed engineering drawings and diagrams for critical pieces of equipment and their components

- As-built drawings, maps, and floorplans for your facilities with details on locating key assets

- Comprehensive walkthroughs for each routine maintenance procedure

- Descriptions of corrective and preventive maintenance programs, including plans, maintenance schedules, and requirements

- Health and safety information

- Details related to any relevant equipment warranties

- Contact information for all relevant internal and external stakeholders

- Answers to frequently asked questions

- A troubleshooting guide

- Instructions for decommissioning, demolishing, or otherwise disposing of assets

It’s ultimately up to you to decide what to include in your O&M manuals. You should make sure to consult all relevant stakeholders and take their feedback into account. Anyone responsible for carrying out maintenance tasks or overseeing technicians should get a chance to offer their insights.

Do your O&M manuals and O&M manual templates include all the information you’ll need? Download our helpful checklist to assess the quality of your documents and set yourself up for success.

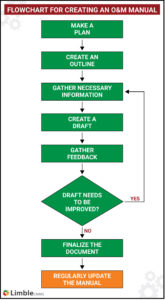

7 steps to create and optimize an O&M manual

Not sure how to get started? Here’s a quick guide to building and refining your O&M manual.

1. Select the right platform

Managing all the data and documents necessary to create effective O&M manuals and oversee a world-class maintenance program is much simpler with the help of a cloud-based platform like a computerized maintenance management system (CMMS). Limble’s suite of facilities management features and robust reporting capabilities make it a must-have resource for modern maintenance professionals.

2. Make a plan and begin outlining your manual

You’ll need a plan in place before you begin to create your manuals in earnest. Start thinking about the stakeholders who should be involved in this process and the steps you’ll take to ensure your manual is tailored to its target audience.

3. Gather the necessary documents and information

Now, it’s time to compile the wealth of information that will make your O&M manual a useful document. Observe technicians and operators at work to better understand their responsibilities and the best practices they’ve developed. Conduct interviews to help supplement your takeaways from this process and gain a sense of what end users would like to see from this document. Don’t forget to round up user manuals, warranties, OEM guidelines, flowcharts, and other documents that belong in your manual.

4. Create an initial draft of your O&M manual

Using the outline you created during the planning stage, begin to formally draft your manual. Make sure you clearly outline all relevant procedures and don’t forget about drawings, maps, and diagrams to bring the words to life.

5. Gather feedback from stakeholders and end users

Next, share your first draft with all relevant parties. It’s possible that you created an appropriately detailed manual on your first try. In other instances, you may need to collect additional information to deliver on their recommendations.

6. Finalize and distribute your new O&M manual

Finally, it’s time to polish your document, publish it in the appropriate places, and distribute it to anyone who’ll need to use it. Make sure it’s always readily accessible to end users.

7. Update the manual over time

As time goes by, you’re bound to come across new information that will affect the contents of your manual. You’ll also purchase new assets, witness changes to existing workflows, and experience growth across the organization. You’ll need to update your manual to ensure it stays relevant for your evolving team.

Don’t forget: some O&M manual tips

You don’t want to waste time and effort putting together an O&M manual that nobody will use. Make sure to structure your document logically, include plenty of visual aids, simplify complexities wherever possible, make the document easily accessible, and educate end users on where to find it.

O&M manual templates and examples

Here are a few examples of O&M manuals from various industries that may offer some inspiration:

- Construction industry O&M manual example

- A nursing home’s O&M manual

- The South Australian Water Corporation’s standards for O&M manuals

You’ll notice that these documents all follow a similar structure while including details that are specific to their use cases.

Maximize the value of your O&M manuals with a CMMS platform

Implementing the right CMMS can dramatically simplify the creation, distribution, and long-term management of essential documents like O&M manuals. Customers in a range of industries trust Limble to make their teams as productive, efficient, and connected as possible. They love it enough to make it a top-rated solution on G2. You can learn all about why customers choose Limble by checking out some customer testimonials or scheduling a demo with our team.

Not ready for a demo? Check out our essential guide to CMMS platforms to learn more about the transformative potential of cloud-based maintenance solutions with features like mobile applications.

Great piece with many insightful points to take away, thanks for sharing.

Are there any legal requirements of contents that an O&M manual must contain?

Since O&M manuals aren’t mandatory by law themselves, we can only conclude that the answer is no. There might be some special cases, but we are not aware of any.

This was very very helpful to me ,thank you so much for sharing this example, you literally saved me from submitting late

Awesome, glad to hear it helped!

thank you for your support that helped me to compare how I prepared my small draft before circulating it to comment.

Comments are closed.