Oil analysis is the process of testing oil-based lubricants to help determine oil health, contamination, and machine condition and wear. It is an integral part of “tribology” which is the study of wear and tear of machinery and is a common element of condition-based maintenance programs.

Oil analysis uses various tools and techniques to reveal the properties of lubricating oil. It is important because the condition of the oil reflects the condition of the machine. It is like a blood test for your machinery.

Types of oil analysis

There are many different types of oil analysis that evaluate a variety of oil characteristics. Each type provides its own insight into equipment health. Here are some of the most common routine tests.

Viscosity

Viscosity is the most critical characteristic of a lubricant. A reading that is too high or too low can be the symptom – or the cause – of various problems.

A sub-optimal viscosity can result from using an incorrect lubricant or contamination from antifreeze or other solvent. Changes in viscosity can lead to problems such as oxidation or thermal stressors.

Elemental Analysis

Elemental analysis tests are used to detect specific elements, chemicals, or wear metals that may exist in oil due to machine wear, oil contamination, or additives. This test measures the concentration of elemental metals in oil.

This test uses a spectrometer to measure the concentration of specific elements present in an oil. Because the spectrometer can only detect the smallest particles – typically 5 microns or less – this type of analysis cannot detect all kinds of contamination.

Ferrography

Where elemental analysis falls short, analytical ferrography can fill in. This type of test is used to examine particles, wear debris, and solid contaminants in engine oils without any particle size limitations.

A ferrograph is used to apply a magnetic field to the oil, separating and sorting the wear particles from the oil to allow for inspection and further analysis.

FTIR

FTIR or “fourier transform infrared” spectroscopy is another efficient way to test for contaminants such as fuel, water, and soot. Infrared lights are applied to oil samples so that particles can be identified and their properties observed.

Acid number and base number

The acid number (AN) test is performed by mixing an oil sample with chemical solutions to determine its acidity level. The AN then represents an estimate of the amount of additive depletion, acidic contamination, and oxidation in the oil.

Similarly, the base number is used specifically for combustion engines and represents the ability of the oil to neutralize acids that occur as a result of combustion and oil degradation.

Particle Counting

A particle count is a method of testing that uses lights and microscopes to detect particles in all kinds of samples like air, water, and chemicals. In oil and grease, it is used to measure the contamination ratio of oil and determine its suitability for continued use.

Moisture Analysis

Water contamination in oil can cause accelerated wear and corrosion in machines. To conduct moisture analysis, oil samples are distilled so that any moisture content is vaporized, collected separately, and measured to determine moisture levels.

Why perform oil & grease analysis?

Oil analysis reveals important information about the health of a machine without the need to cut open, destroy, or disassemble it. In this way, oil analysis is similar to other forms of non-destructive testing (NDT). It provides useful information on the condition of the machine without having to damage the machine in the process.

When combined with other test methods, maintenance teams can gather enough information to plan and perform corrective maintenance. In the end, incorporating regular oil and grease testing can provide many benefits:

- Maximized oil service life

- Minimized waste and maintenance costs

- Extended equipment life

- Fewer malfunctions, catastrophic failures, and unplanned downtime

- Improved asset performance and productivity

- Increased asset resale value

Selecting a lab to perform oil analysis

Oil analysis requires specialized equipment and qualified professionals. Most organizations do not have the budget or resources to build an in-house lab and instead work with a specialized off-site laboratory.

The International Council for Machinery Lubrication (ICML) is a widely recognized non-profit organization that regulates everything related to machine lubrication. ICML conducts certification exams and accredits lubrication professionals across the globe.

Oil analysis certifications issued by ICML adhere to the International Organization of Standards (ISO) guidelines and include:

- Machine Lubricant Analyst (Level I, II, III)

- Machinery Lubrication Technician (Level I, II)

- Laboratory Lubricant Analyst (Level I, II)

- Machinery Lubrication Engineer

Another body that trains and issues certification to lubrication professionals is the Society of Tribologists and Lubrication Engineers (STLE). They issue two certifications related to oil analysis:

- Certified Lubrication Specialist (CLS)

- Oil Monitoring Analyst (Level I, II)

STLE has its own set of standards and procedures to certify oil analysis professionals and analysts.

How to perform oil analysis

While you won’t be performing the test yourself, it is still important to know how to collect and send your samples to the lab and interpret your results. To ensure the oil analysis results you receive are accurate and useful, it is essential that you follow some key steps.

Obtain a test kit

Contact the lab you will be using for your oil analysis and request a test kit. They will provide the materials and instructions you need to collect your sample and ship it to the lab.

Warm the engine

The sample needs to be representative of the oil flowing through the machine during operation. That is why, ideally, oil samples are taken after the engine has warmed up and while it is still running.

If it is not possible to draw the sample during operation, it can be pulled right after the machine has been turned off. Time is of the essence – if the lubricating oil is allowed to rest, any sediment or contaminants will separate and potentially ruin the accuracy of the sample.

Collect the sample

Oil samples have to be taken in clean containers using equipment like a vacuum suction pump or other device. The equipment you need will often come as part of an oil analysis test kit provided by the lab. Common techniques are drop tube sampling, pressurized line sampling, and drain port sampling.

For additional information, here is an in-depth guide on how to take an oil sample.

Ship the sample

The oil analysis kit should have all the necessary labels and materials needed to mail an oil sample. Upon receipt, the lab will perform your requested tests.

Receive and apply the results

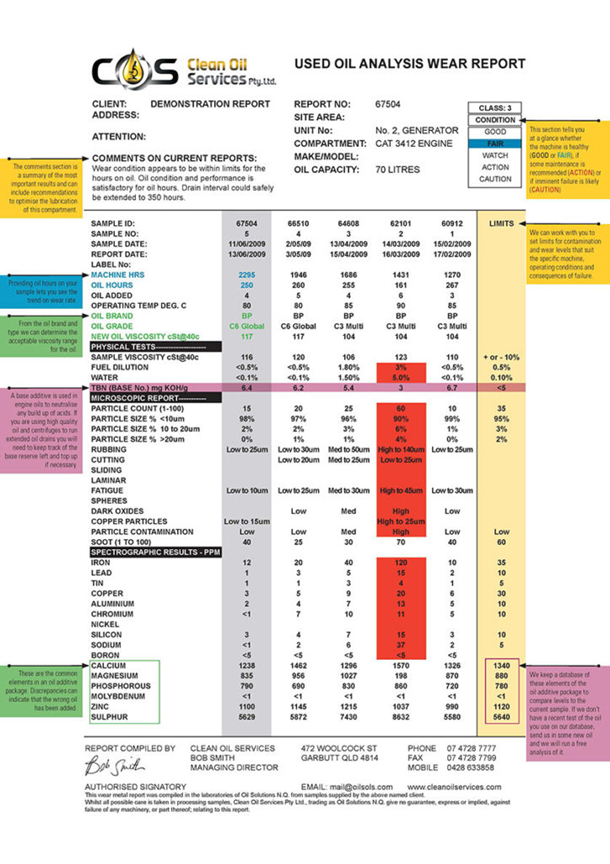

In most cases, results are available within days. The information included in an oil analysis report will depend on the test kit you chose. While it will not contain cut-and-dry recommendations, it will provide measurements that are very useful if you know what to look for.

What to look for in an oil analysis report and how to use it

While it can’t tell you what to do, an oil analysis report can provide important clues on your asset’s health and point you in the right direction for necessary maintenance. Here’s how to use it.

Identify abnormal readings

An oil analysis report will include ratings, readings, and chemical levels found in your oil sample. Whether those levels are good or bad depends on the ideal oil parameters for each machine you have tested.

Consult the manuals provided by the OEM to establish ideal levels and compare them to your baseline readings.

Plan maintenance to address abnormal readings

After identifying which of your readings fall outside of recommended levels, you will need to plan maintenance to address them. Here are some common oil tests and what their abnormal findings could mean for your equipment:

- Viscosity: Excessive oil viscosity can be the result of contaminants and elements present in the machine. It dampens machine performance over time.

- Elements: Spectral analysis or ferrography helps determine whether the present elements are contaminants or part of normal wear and tear. According to the number and quantity of materials present, expert oil analysts can determine the degree of deterioration and the maintenance measures that can be taken.

- Acid number: A high acid number indicates a high chance of corrosion. The acid number should be kept within the range advocated by the OEMs.

The real value of oil analysis lies in the maintenance actions taken in response to its findings. Common recommendations include oil filtration, oil changes, or further monitoring for readings that deviate from recommendations.

The long-term value of oil analysis

As with any other condition monitoring method, corrective maintenance should be applied based on priority, and testing should be conducted regularly to look for changes over time. Oil analysis along with various other forms of condition monitoring play a critical role asset maintenance and reliability.

To truly address issues identified in your fluid analysis and monitor signs of wear, it is best to leverage a CMMS. Using an CMMS software can help make the most of any oil analysis program by logging test results over time, triggering and assigning corrective actions and preventive maintenance work, and measuring their effectiveness.

thank you for giving your valuable information

Comments are closed.