Testing is an integral part of equipment maintenance. It is essential to evaluate the materials, components, design, and structure of your products and assets. Based on the state of the tested component after the testing is done, the procedures can be classified under either destructive testing or non-destructive testing.

If the component gets damaged or destroyed during the testing process, the testing method employed is described as destructive testing. In contrast, non-destructive testing is carried out without causing damage to the tested piece of equipment.

In this article, we will focus on different applications of non-destructive testing methods.

What is non-destructive testing?

Testing methods that do not compromise the structural integrity of the parts being tested are called non-destructive tests (NDT). NDT employs various inspection techniques to evaluate the components, individually or collectively. It uses different principles in scientific fields (physics, chemistry, and mathematics) to test the components.

NDT can also be referred to as non-destructive evaluation/examination (NDE) or non-destructive inspection (NDI).

Let’s imagine a piston in operation inside an engine that is tested for defect or material degradation. The piston can be cut open to check whether there are any defects inside. However, once tested, the piston cannot be used in the engine anymore, even if it was found not to be defective. This is a form of destructive testing.

Instead of cutting it open, the piston can be tested with radiography. We can use ionizing radiation (X-rays, gamma rays) to detect defects or material degradation in the component. If it passes the test, the component can still be used. This is a form of non-destructive testing.

Where is NDT used?

NDT is used to test the quality of components and machine condition before or during their active use. Non-destructive testing is used for condition assessment and quality control in a wide range of industries, which include (but are not limited to):

- Aerospace – testing castings

- Automotive – to test the durability of piston heads

- Manufacturing – to test the quality of components before it goes into production

- Medical devices – to test the durability and composition of stents

- Military and defense – ballistics testing and analysis

- Packaging – to test the structure and chances of leakage for packages

- Marine industries – to identify corrosion

- Power generation – to test welding-related defects

- Waste management – to identify redeemable metals in waste

- Petrochemical industry – to test pipelines used to transport oil

Maintenance Acronym Guide

Confused by PMs, MTTR, and DFMEA? This maintenance acronym guide will have you talking the talk in no time.

Why is NDT used?

The distinct advantage of NDT is the reusability of the tested components. On top of that, non-destructive testing can often be employed on components that are still in operation. Devices and testing equipment used to conduct most methods of NDT are compact and portable. This makes it easier to test components in a working machine.

Additional benefits of conducting non-destructive testing are listed below:

- Conducting NDT ensures the safety of working components. Components suffer wear and tear, which inevitably leads to malfunctions and failures. NDT helps to spot early signs of degradation and helps identify the causes of equipment failures. The maintenance team can use that info to perform corrective maintenance and adjust their preventive maintenance efforts. All of this leads to improved asset reliability.

- Quality assurance purposes. NDT methods can be used to assure the quality of the output of production. The quality assurance team will be able to quickly analyze whether the product is within the tolerance limits.

- Assessing the remaining useful life of machines. The wear and tear of machines is a natural byproduct of their operations. They have to be replaced after their useful lifetime. But all machines do not degrade at the same rate due to the different operating conditions and other factors. An NDT inspection can help estimate how long the machines can be used before it is better to purchase a replacement.

All non-destructive testing methods have unique use cases and requirements. Let’s discuss those next.

Non-destructive testing methods

There are a plethora of non-destructive testing options available. Which method you’re going to use depends on the type of component you are testing and what exactly you are looking for.

Some NDT methods have applications only in niche categories. Below, we discuss the most common NDT methods that have a broader application.

1) Visual inspections

Remote visual inspection (Image source)

Visual inspection is by far the simplest non-destructive testing method. It is often classified as a part of routine maintenance work. Maintenance professionals use it on a daily basis to check for common signs of wear and tear. Depending on its application, it may or may not be conducted while the machine is in operation.

In scenarios where direct access to the test object is not available, robots and drones fitted with cameras can be used to perform visual inspections remotely.

In its most advanced application, visual testing is combined with machine learning algorithms. This is only economical for product quality testing where there is a large volume of standardized components that need to be inspected.

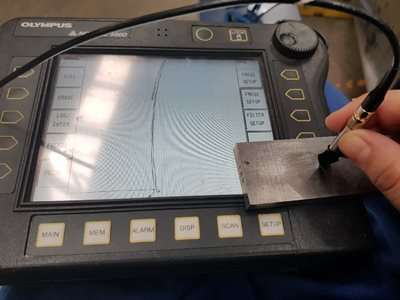

2) Ultrasonic testing

Ultrasonic testing (Image source)

Ultrasonic testing is based on the principle of propagation and reflection of high-frequency sound waves. It can be used for flaw detection/evaluation, dimensional measurements, material characterization, and more. Testing is performed with an ultrasonic receiver and transmitter.

Ultrasonic soundwaves are transmitted through the tested material. The sound propagates through the component and reflects off the rigid surface placed at the opposite end of the transmitter. The time required to transmit and receive the sound waves is measured. The variance in the time at different sections of the component can be used to identify the defects in the material.

Different types of ultrasonic testing modes can be used to identify different defects, cavities, material deterioration, etc. Mechanical components that operate with heavy workloads are regularly tested with ultrasonic testing. A good example of ultrasonic testing is testing to identify defects and deformation in the wheels and axles of railway carriages.

3) Vibration analysis

Vibration monitoring testing (Image source)

Vibration analysis is a commonly used method to monitor the condition of rotating components in operation. The underlying principle of vibration analysis is that different materials have different vibration signatures.

Aside from a vibration meter device, there are different types of sensors that can be installed to measure vibrations. They are designed to measure displacement, velocity and acceleration, misalignments, looseness, and similar faults that rotating equipment can experience.

Vibration analysis, like every other technique we are discussing here, provides valuable data that is used for condition monitoring and predictive maintenance.

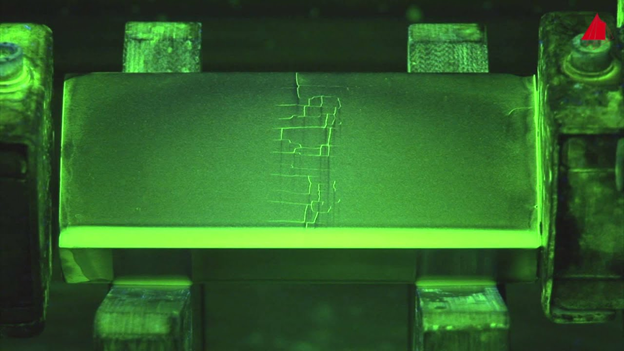

4) Magnetic particle testing

Magnetic particle inspection (Image source)

Magnetic particle testing is used to detect near-surface defects in ferromagnetic materials. The test piece is kept between the two poles of an electromagnet and a suspension of magnetic particles is poured over the test piece. This testing method is based on the effect of a magnetic field on ferromagnetic materials.

The defects on the surface of the material will be highlighted as the magnetic particles cluster near defects and cracks. For better visibility, ultraviolet light is used to observe defects.

Magnetic particle examination can be performed with a wet horizontal MPI machine or handheld devices like magnetic yokes. National Board Inspection Code (NBIC) specifies MT may be used for the inspection of items such as:

- internal and external surfaces of boiler and pressure vessels

- components subjected to fire damage

- locomotive and historical boilers

- yankee dryers

- cargo tanks

- vessels in LP gas service

- weld repairs and alterations to pressure-retaining items

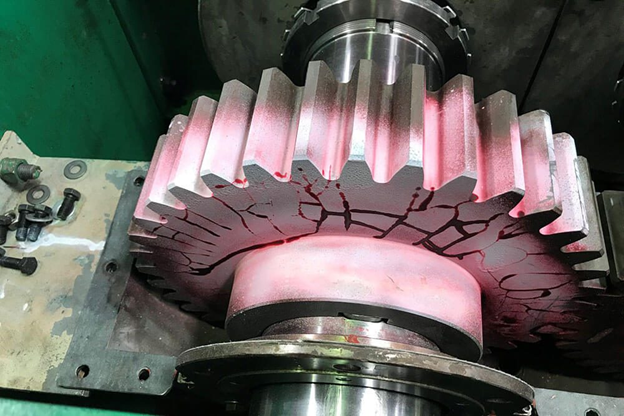

5) Penetrant testing

Liquid penetrant testing (Image source)

Penetrant testing can be used where magnetic particle testing is not feasible. A clean work surface is required to conduct penetrant testing.

During a penetrant inspection, a liquid dye penetrant is sprayed over the area to be tested and left untouched in the open air. The time required to leave the penetrant to work (a.k.a. dwell time) on the surface could be anywhere from 10 minutes to an hour. It depends on the characteristics of the tested material.

The liquid penetrant is removed from the work surface with a dry lint-free cloth. A light application of developer liquid is sprayed over the tested work surface. If there are defects on the tested surface, the liquid dye will be brought to the surface after the developer liquid is applied.

Liquid penetrant testing is commonly employed to test welded surfaces and works on the principle of capillary action.

6) Eddy current testing

Eddy current testing (Image source)

Eddy current testing is a common NDT technique used in both manual and automated testing scenarios. It is based on the principle of electromagnetic induction.

When electric voltage is applied across a coil, it generates a strong magnetic field. When metal is introduced inside the coil, the magnetic field fluctuates and the current flowing through the circuit increases. This is due to the eddy current flow inside the metal.

When there is a defect or cavity in the material, the current consumption increases. The eddy current has to travel a longer distance – increasing the resistance that manifests as increased current consumption. The variance in current consumption across different cross-sections of the material can be used to identify the location and the dimensions of the defect.

This type of nondestructive examination is performed with eddy current testing equipment, which can include electromagnetic probes, current flaw detectors, ECT conductivity meters, and other accessories. These tools are used to perform different types of electromagnetic inspections, such as surface scanning, subsurface inspection, weld inspection, fastener hole inspection, tube inspection, heat treatment verification, and metal grade sorting.

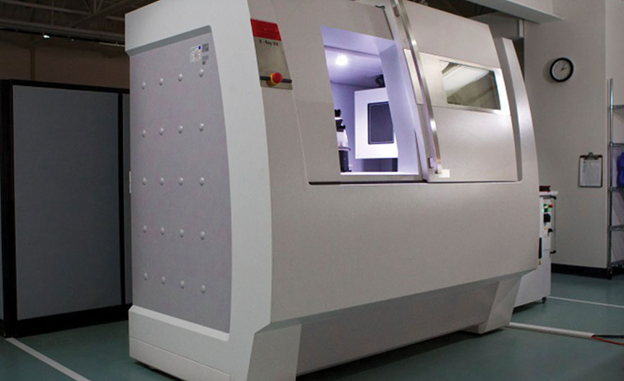

7) X-ray inspection and industrial computed tomography

Industrial CT scanning (Image source)

X-rays and other tomography techniques are widely used in the medical field. However, some of the same techniques are also used in industrial applications as a part of non-destructive testing.

X-rays and CT scans can be used in industrial radiography to see the detailed images of the tested material. X-rays are passed through the components and the image can be imprinted on film or viewed in real-time using a computer.

Computed tomography technology can also color-code the various objects according to the composite metals or the cavities present. X-rays can be sent from different angles on the test object to gain images with higher details. X-ray testing and computed tomography fall under the broader category of radiographic testing, where different types of ionizing radiation can be used.

8) Honorable mentions

The seven types of NDT described in the previous sections are commonly used across different industries. However, there are many more NDT techniques employed in scientific laboratories and industry operations like:

- Guided wave testing: identifying defects by controlled excitation of multiple ultrasonic waves sent in different directions.

- Laser testing: laser beams are used to detect defects in materials. Three laser testing techniques used are holography, shearography, and profilometry.

- Leak testing: testing leaks through different methods like bubble, pressure change, halogen diode, and mass spectrometer testing.

- Magnetic flux leakage: identifies defects from the varying magnetic flux patterns in ferrous materials.

- Neutron radiographic testing: low energy neutrons are sent across the work surface instead of x-rays.

- Thermal/infrared testing: mapping the temperature of the surface, based on the infrared radiations emitted.

A while back, we compiled a complete list of condition monitoring techniques for MRO magazine, for those who want to learn more.

Who performs non-destructive testing?

As you can imagine, the different NDT methods require technicians with different skill sets and experience.

For instance, with a little bit of training and a good PM checklist, some visual inspections can be performed even by novice technicians. In contrast, industrial computed tomography requires technicians with specialized knowledge of radiology and equipment used in the testing process.

Who conducts the testing will also be determined by what is being tested – the condition of machines/components or product quality.

When the output quality of a production line has to be tested, the quality assurance team might be responsible for conducting NDT.

In most other scenarios, testing is performed by the maintenance team. In some instances, OEMs can be responsible for conducting NDT tests according to a predefined schedule. In both scenarios, organizations can use CMMS software to schedule testing intervals and record testing data. When testing is performed by retrofitting machines with sensors, CMMS can be used to analyze incoming real-time data and automatically trigger alerts when it spots any deterioration signs.

The American Society for Nondestructive Testing (ASNT) is the pioneer in providing accreditation to qualified technicians. They offer various NDT training courses, conduct exams, issue certificates, and accredit different organizations. The details are provided on the ASNT website.

The future of non-destructive testing

The sheer number of non-destructive tests that have been developed over the years speaks about the utility of these methods. Checking machine condition without damaging it and without necessarily needing to shut it down are two huge perks – especially in a production environment.

As the adoption of predictive and prescriptive analytics continues to grow, so will the usage of NDT. Algorithms need a high volume of accurate machine condition data to predict failures and offer solutions. There are no better ways to do that than through condition-monitoring sensors and non-destructive testing.

What about to use the laser radiation as a new method in NDT.

This is not a complete list of NDT methods, just the ones we found to be most popular. We might update the article at a later date with more NDT methods!

Comments are closed.