Mean Time To Failure (MTTF)

Learn how tracking Mean Time to Failure helps you understand the lifespans of your non-repairable assets and improve your asset management and maintenance strategies.

What is Mean Time To Failure (MTTF)?

Mean Time To Failure (MTTF) is the average time a non-repairable part or piece of equipment remains in operation until it needs to be replaced. It is a very basic measure that helps predict the lifecycle for components that cannot be repaired.

MTTF measures the average lifespan of non-repairable components and pieces of equipment.

Mean Time to Failure (MTTF) vs. Mean Time Between Failures (MTBF)

It’s easy to confuse these two important metrics. After all, their acronyms are nearly identical. Both provide insights that support effective reliability engineering, but they are different in a number of crucial ways. Here’s a quick guide to the differences between MTTF and MTBF:

Mean Time to Failure

- Applies to non-repairable systems or assets

- Measures the amount of time between a device’s first day of use and its last

- Represents the entire lifecycle of a component, piece of equipment, or system

- Applies to repairable items

- Measures the amount of time between each individual failure incident

- Takes failure rate or number of failures into account

- Predicts when an item may need to be repaired next

MTBF calculations involve dividing an asset’s total hours of operation by the number of failures it experienced during that time.

MTTR is another metric whose acronym can lead to some confusion. Like MTBF, it is used to assess repairable equipment. Maintenance professionals calculate MTTR by dividing the time they spend repairing an asset by the total number of repairs performed.

Why is tracking MTTF important?

Calculating MTTF helps organizations estimate the lifespan of non-repairable assets. Some common examples of non-repairable assets include:

- Fan belts in automobiles

- Light bulbs in our homes and offices

- The batteries used in vehicles and other large equipment

MTTF is particularly valuable as a reliability metric. Engineers can use it to estimate how long a component or critical piece of equipment may last. An awareness of your MTTF allows you to:

- Evaluate the effectiveness and quality of parts and components

- Forecast replacement needs and plan preventive maintenance tasks

- Perform proper inventory management to ensure resources and replacement parts are available when you need them

- Adhere to maintenance standards like those established by ISO

A smaller MTTF figure means more frequent replacements. And more replacements mean more downtime, less uptime, higher costs, and other impacts on productivity. Keeping an eye on the metric can help you avoid consequences like these.

When to use MTTF

First, MTTF helps you set capex and opex budgets for existing procedures. With dependable MTTF data, you can estimate how often you will need to replace non-repairable equipment and at what costs.

Second, MTTF can help you evaluate new procedures. If you are planning to invest in a new process that requires specific equipment, calculating MTTF can provide insights into how much the process would save or cost you in labor and parts spend.

You can sometimes find information about MTTF from the original equipment manufacturer. These estimates aren’t always accurate. It is best to track and report on MTTF internally to better understand your asset’s lifespans.

Calculating MTTF

Calculating MTTF for assets is simple. The only data you’ll need are the total number of hours your asset spent in operation and the number of assets you went through during that period of time.

The MTTF formula

You can calculate MTTF for critical assets by dividing their total operational hours by the total number of assets you used throughout that length of time.

Divide your operating time by the total number of assets you used during that period to calculate MTTF.

MTTF calculations in action

Imagine you’re calculating MTTF for three desktop hard drives. The first failure occured after 62,000 hours. The second hard drive didn’t last as long, failing after 28,000 hours. Finally, the third hard drive failed after spending 42,000 hours in operation.

In this instance, your calculations would look this:

MTTF = (62,000 + 28,000 + 42,000) / 3 units

MTTF = 132,000 / 3

MTTF = 44,000 hours

You can now reasonably assume that this particular make and model of hard drive will have a useful life of about 44,000 hours.

How to increase MTTF and productivity

Tracking your MTTF and other failure metrics will give you the knowledge and power you need to maintain a healthy maintenance budget and avoid unmanageable replacement costs.

Increasing your MTTF can greatly improve your productivity because you are ensuring that you get the longest lifecycle possible out of your assets, and that you are ready and prepared with a replacement when it fails.

Below are a few steps you can take to increase your MTTF:

Purchase high-quality equipment

High-quality products may cost more, but you may save more in the long run by avoiding costly repairs and frequent replacements. Make sure you keep long-term benefits in mind when you’re purchasing critical components and assets to reduce failure rates and save on maintenance.

Use your assets appropriately

Ensure all of your parts and components are used only for their intended purpose and only in the conditions they’re designed for. Check humidity, heat, pressure, voltage and other factors against the guidelines provided by the OEM. Store documents related to operating and maintaining assets for easy reference. That way, you’ll ensure each piece of equipment is properly installed every time to maximize its useful life.

Evolve your maintenance program

Preventive maintenance helps to improve MTTR. With a preventive program, you will address issues before they cause serious trouble. Over time, this will extend the useful life of assets and reduce maintenance costs.

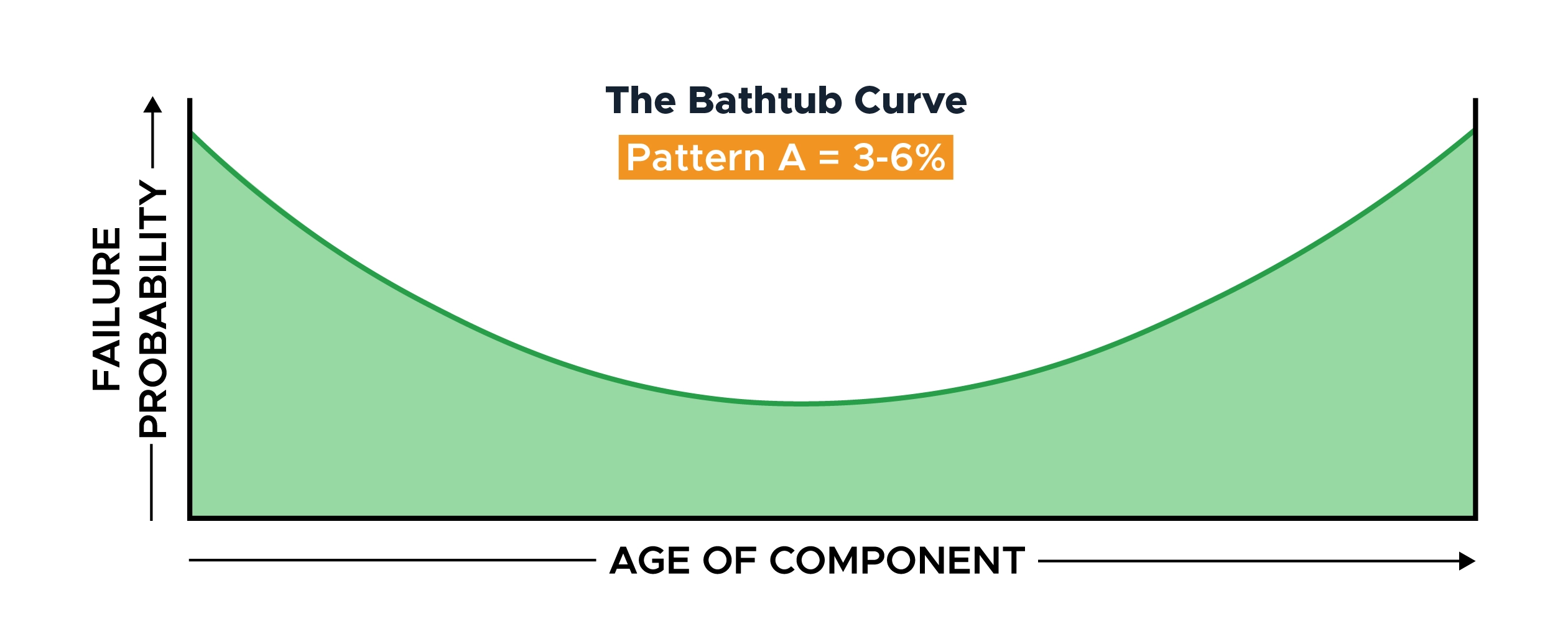

With MTTF data at your disposal, you’ll recognize common failure patterns like the bathtub curve.

Want to see Limble in action? Get started for free today!

Calculating MTTF with CMMS software

Calculating MTTF by hand is tedious and spreadsheets offer only slight improvements. CMMS software changes the game.

With a CMMS, equipment failures are logged automatically and metrics like downtime are tracked round the clock. You can start calculating failure metrics as soon as you begin using the system. You’ll gain easy access to valuable insights with a dashboard of useful key performance indicators (KPIs).

A good CMMS will do much more than simplify tracking against key metrics. The right platform can optimize your processes for issuing work orders, tracking technician performance, conducting root cause analyses and much more.

Check out our guide to CMMS platforms for more information on all the benefits of evolving your approach to maintenance.

FAQ

Why use CMMS software to track maintenance metrics?

Using CMMS software simplifies tracking complex maintenance metrics, fosters data-driven decisions, enhancing efficiency, reducing downtime, and aiding in regulatory compliance all in one.

Is Limble Mobile CMMS app user friendly?

Limble is consistently rated Easiest-to-Use CMMS on review sites like G2, Capterra, and Software Advice. And our customers agree. With our mobile CMMS app, teams experience 30%+ better productivity, on average, requiring little to no training or ramp-up time. Our CMMS app can travel with your team, no matter where they go! Visit our App Store or Google Play for more information.

Can I connect to other systems?

Limble provides seamless, pre-built CMMS Integrations with the most widely used software systems. That means no help from a developer or your IT team is required. Learn more about our integrations.

How secure is the Limble CMMS platform?

At Limble, our world-class data security practices ensure your account information is safe. We use state-of-the-art technologies and industry best practices to maintain a secure infrastructure, including SOC-II Type II certification, regular penetration testing, and continuous security training for our staff.