Continuous Manufacturing/Production

Everything you ever needed to know about continuous production.

What is continuous manufacturing?

Continuous manufacturing, also known as continuous production, is a method of manufacturing where material flows through a series of steps without pause to manufacture a large quantity of products with few variations.

To support continuous production, the workforce on the floor must operate 24/7 which is achieved through rotating shifts of staff using highly standardized processes, tools, and equipment. In order to implement continuous manufacturing and achieve high output, procedures and material use are studied and optimized to ensure high quality and low product waste. Manufacturing technology is often an integral part of continuous production in order to ensure production lines stay up and running to avoid uniquely high costs of stoppages.

Continuous production examples in different industries

Continuous production systems are used by operations that can maximize the advantages of continuous production flow. Below are some specific examples.

Automotive

With automotive manufacturers better known for process production, Toyota Motor Manufacturing Indonesia is a good case study in continuous production. Comprising three integrated plants, the facilities work as one, casting metal, stamping it, building engines, assembling vehicles, and packing in one long and complex example of a continuous production line.

Pharmaceuticals

Companies in the pharmaceutical industry were long known for batch processing. However, many have started to move towards continuous production.

Pharmaceutical manufacturing systems produce coated tablets from raw powders in a continuous production stream in accordance with FDA standards. This allows several continuous streams of roll compaction or wet granulation that offers specialized solutions to clients’ needs. GlaxoSmithKline recently opened two new continuous manufacturing facilities in Singapore and expanded a third following a $95 million investment.

Mining and metals

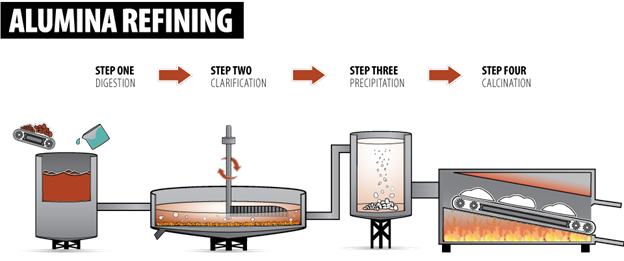

The mining and metals industries use continuous production to extract and transform raw materials. A global leader in aluminum production, Rio Tinto mines the mineral bauxite, transforms it into alumina, which is the key constituent of aluminum. It is sent to aluminum smelters for conversion to metal.

Alumina refining process – Source: Aluminimum.org.au

Biotechnology

Biotechnology uses living organisms and molecular technology to produce various products including genomics, food production, medicine, and biofuels. In 2019, Sanofi opened the world’s first digital facilities using continuous biologics production to manufacture new products in accordance with strict regulatory requirements.

The Essential Guide to CMMS

Download this helpful guide to everything a CMMS has to offer.

Continuous process versus batch manufacturing

Many small to medium-size manufacturers begin as jobbing shops. These shops provide end-to-end services, producing a diverse range of customized products from start to finish before beginning the next.

Eventually, as these businesses scale-up and strive to improve their products and services, they eventually need to focus on efficiency and specialization. By committing to one type of manufacturing, these organizations are better able to meet product demand, efficiently use raw materials, and maximize available resources.

Depending on the level of service and specialization required, manufacturers must choose which type of manufacturing process best meets the needs of their customers and clients.

Batch manufacturing process

Batch manufacturing uses a stop/start manufacturing process where products are manufactured in groups or batches. Such production may be:

- Demand-led: Smaller production runs for a specific product and volume.

- Quality-led: Production runs that require conformity to specific standards.

The period between batches is known as cycle time, and it is used to make any changes required in materials, processes, or maintenance interventions and prepare for the next batch or product.

Batch manufacturing is less disrupted by machine breakdowns because jobs can be shifted between workstations. This method also limits financial losses from quality issues by minimizing scrap and waste. However, lower machine utilization rates can also offset the gains in quality and flexibility.

Continuous manufacturing process

As the name implies, continuous production goes on indefinitely. This method allows for high yield, specialization, and efficiency. While it maximizes output by using all available time for production, there are tradeoffs.

In order to produce continuously, the machines, processes, and materials themselves are designed to be in continuous motion. As a result, any stops and starts can pose more significant risks and unique problems like settling of suspended solids or crystallization and hardening of materials in piping and tanks. Unintended stoppages also increase cycle times, thermal cycling, and pressure cycles on equipment which increases fatigue and shortens the equipment’s useful life.

This lack of flexibility and high machine utilization also significantly impact maintenance procedures. Unlike batch production, maintenance and equipment upgrades on continuous manufacturing facilities will occur annually – at best. Some plants operate two to three years without stoppage, and high-temperature transformation systems such as blast furnaces run without pause for five to ten years.

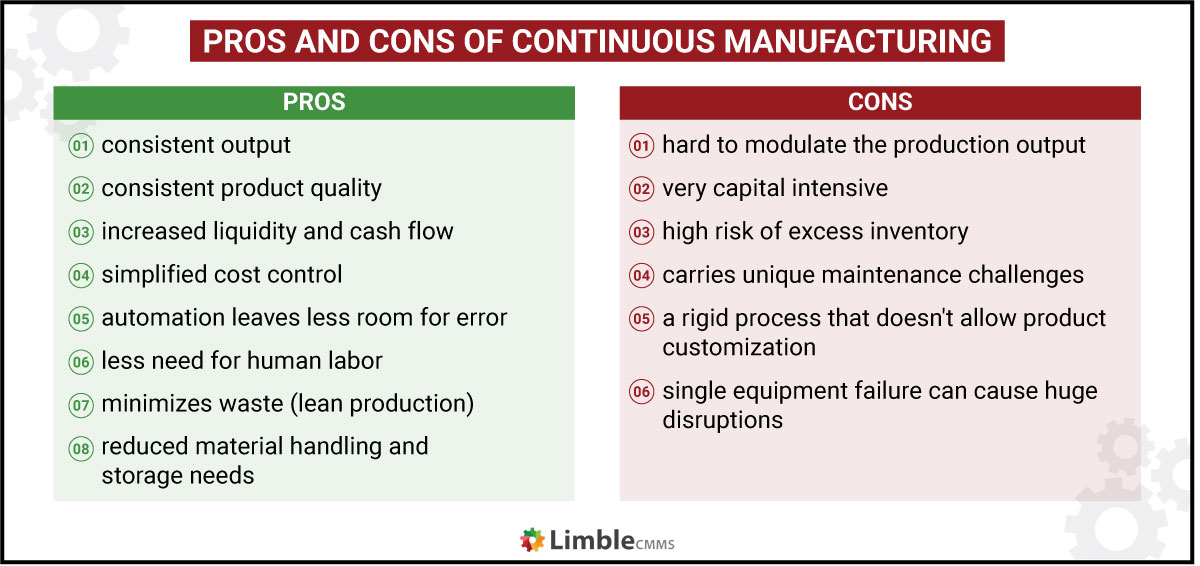

The pros and cons of continuous manufacturing

Transitioning to continuous production impacts everything from quality control strategies to investments in manufacturing equipment. With the high investments involved, it is important to clearly understand the pros and cons.

Advantages of continuous production:

- Strict process control and monitoring ensure consistent product quality.

- Balancing just-in-time delivery of raw materials and manufacturing sequences reduces work-in-progress, increasing liquidity and improving cash flow.

- Reduced material handling and storage areas lower overhead costs.

- Material cost control is simplified.

- High production rates allow a lower capital cost per unit.

- Improved opportunity to leverage automation and reduce human labor per hour.

Disadvantages of continuous production:

- The need for standardized procedures makes it harder to customize products to changing customer needs.

- The interdependence of each step in the process reduces fault tolerance, with a single equipment failure stopping or creating severe disruptions to product volumes.

- There is little ability to adjust production flows when demand falters or drops.

- Investment in advanced, expensive, and often customized equipment makes the production process very capital-intensive.

- Carries a high risk of excess inventory holding in the event of a downstream disruption.

Continuous manufacturing is a process that comes with a big reward; high product output. However, the capital investment required along with a lack of flexibility make it an option that must be considered carefully and applied only in the right circumstances. In addition, the complexity and consequences of unplanned stoppages mean that a carefully planned monitoring and maintenance plan is required.

Want to see Limble in action? Get started for free today!

Summary

Continuous production manufactures large quantities of products with few variations, relying on standardized processes, procedures, tools, and equipment.

Maintenance shutdowns on a continuous production facility are always high-pressure events. In order to make this method a success, a comprehensive maintenance strategy supported by data and a modern computerized maintenance management system is the minimum required to create a sustainable continuous production system.