Often misused and misunderstood, the word policy is a generic term. Yet, its application and effectiveness to business management and maintenance governance are without question. Read on to find out what a maintenance policy is and how it applies to and supports efficient and effective maintenance strategies.

What is a maintenance policy?

A maintenance policy is a document produced, owned, and managed by senior management. In the hierarchy of business governance, all policies flow from and sit below the company’s vision, mission, and values.

As a factual statement of intent, a maintenance policy is a formal document. It establishes what top management expects from the maintenance department. The contents of the maintenance policy must support and enable the mission, values, and business objectives.

You will find confusion around policies versus strategy, so let’s set the record straight. A maintenance policy sits below business strategy and asset management policy – yet above the maintenance department strategy and maintenance plans.

Why do you need a policy for maintenance?

A maintenance policy sets the boundaries for maintenance strategy development. Think of it as the mission and values for the maintenance department. By setting clear, objective and quantifiable maintenance expectations, the policy focuses maintenance department actions toward necessary and desired outcomes, such as making business processes cost-effective, reducing maintenance costs, reducing unplanned downtime and breakdowns, etc.

The very act of writing a maintenance policy requires a fair bit of analysis. It forces decisions on risk analysis, the desired extent of regulatory compliance, maintenance costs and expenditure commitment, and the extent of workforce safety. Such a process combines thinking, creating consensus, and collaboration between senior management and maintenance workers.

It is also a clear, auditable commitment from the owner or senior team. When a maintenance engineer or other maintenance expert writes the maintenance strategy, their document must deliver on the intent and commitments required by the maintenance policy. Basically, they are held to account by the policy.

Standard Operating Procedure (SOP)

Create your own routine maintenance SOP with this customizable template.

Who writes the maintenance policy document?

The act of writing a maintenance policy document is less important than who formulates it.

At a minimum, you could expect an HR Director, Operations Director, and Engineering Director to be present. This senior team should formulate all policies, based on the impact they will have on their departments. The team usually is led by the CEO or Managing Director.

The writing will usually be passed to the engineering manager or a maintenance manager. Submitted to the senior management team for review and challenge, the CEO and maintenance department heads will sign off on the document once everything is polished and agreed upon.

The exact division of responsibilities between the roles will depend on the size of your organization and your maintenance department.

What defines a good maintenance policy?

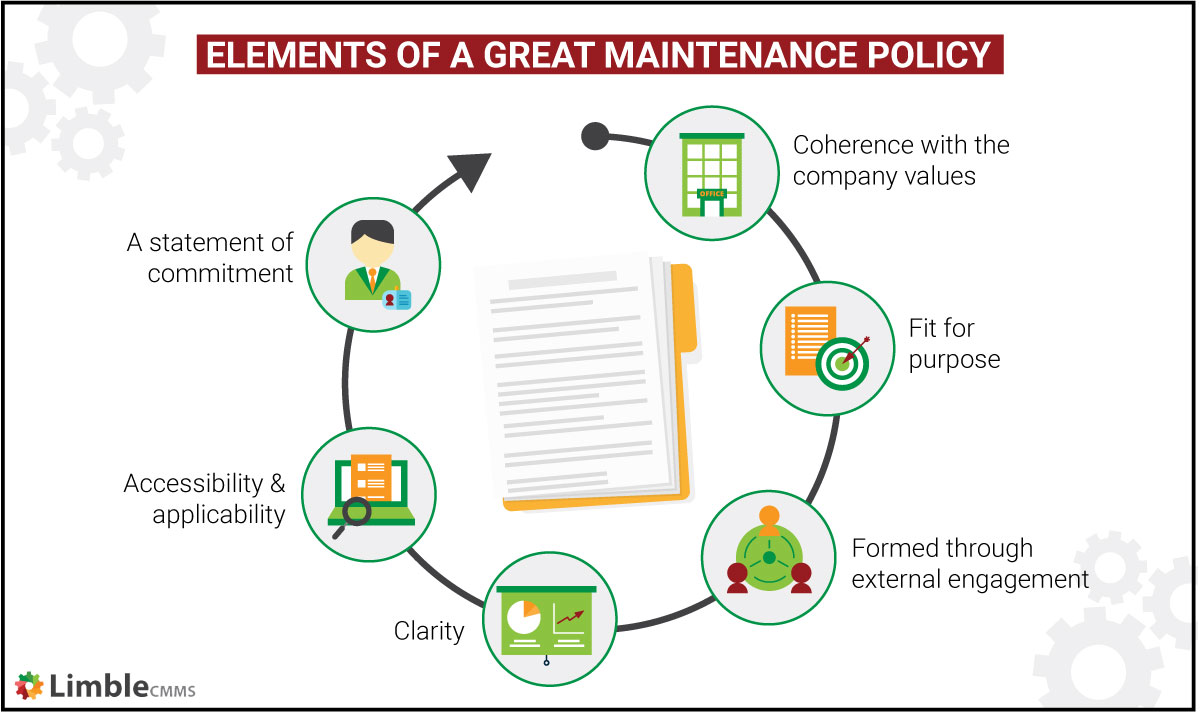

The easiest way to explain what a good maintenance policy looks like is to review its desired characteristics. We identified six of them.

1. Coherence with the company values

If the company values speak of the right for all employees to return home safely from work each day, it would be remiss not to highlight the health and safety expectations of the maintenance department.

Where sustainability and environmental concerns are valued, a high-level expectation on waste disposal would be appropriate, pushing maintenance managers to be more eco-friendly.

The best way to lose the support of your employees is to show inconsistency between words and deeds.

2. Fit for purpose

Design your policies according to company size and activities, keeping appropriate maintenance in mind. A six-person maintenance organization may have 4 or 5 one-page policies covering HR, Operations, Health & Safety, and Finance. The policies of a large multi-site manufacturer will have a suite of comprehensive documents.

Write policies to support clear guidance, good decision-making, and publicize where your company sits in regard to maintenance. Write them to inform and include realistic guidelines.

3. Clarity

The maintenance policy must clarify the role and goals of maintenance and how it supports the company vision. It should set clear boundaries beyond which the maintenance department must not operate. It will also clearly articulate the obligations and support expected of the broader organization toward the maintenance department.

4. Formed through external engagement

Gone are the days when a CEO wrote a policy document as a way of policing their staff. Discuss policies with those who will be affected, and consider their input and concerns. An impractical policy will be ignored, begging why it was written in the first place.

5. Accessibility & applicability

Policies are not dry, dusty documents, written to please an auditor once every couple of years. They exist to inform and guide everyday decisions. All personnel should be able to access and read any of the company’s policy documents.

Limble CMMS users have the option to create a digital asset and attach the newly written/updated maintenance policy to it. This way, any employee with Limble user account can quickly access the document on any PC or mobile device. Why does this matter? Because documents that are hard to find will simply stop being used.

Company size, strategy, or practices will change throughout its life-cycle. The maintenance policy should undergo regular updates to ensure applicability to current operations. In that way, it is similar to standard operating procedures.

6. A statement of commitment

The policy must be signed and supported by the CEO and departmental head, signifying a formal commitment from a person of accountability. As individuals change in their roles, the review and signature of the documents by the new incumbent should occur.

What does a typical maintenance policy contain?

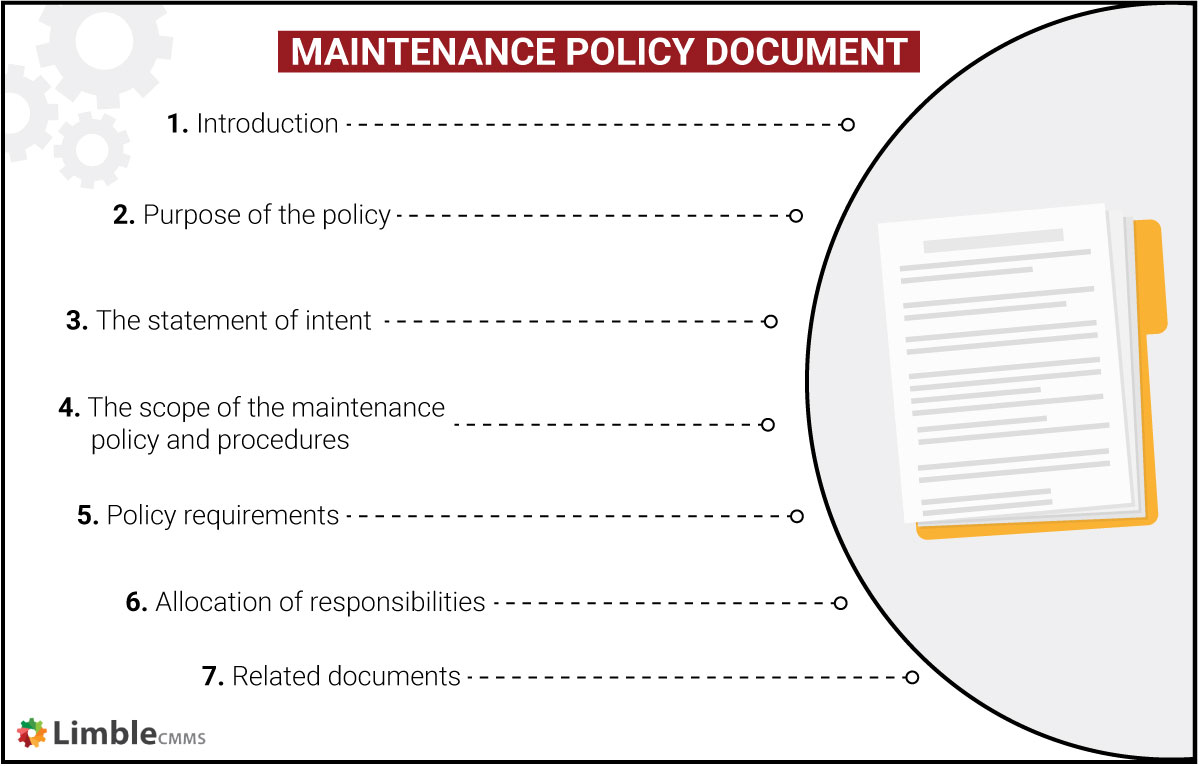

Every maintenance policy you read will be different, but good policies should address the following areas:

1. Introduction

The introduction is a general, short, high-level overview for someone who has no maintenance knowledge. It talks about what maintenance is, why it’s done, and the benefits it brings to the organization.

It should explain how maintenance helps the company achieve its vision, mission, and purpose, addressing appropriate maintenance, preventive maintenance, and all other maintenance activities.

2. Purpose of the policy

Purpose explains the intent behind writing the document. Maybe you wish to provide a safe and healthy environment for employees and machine operators. You could wish to maximize equipment uptime to ensure effective and efficient use of assets. Perhaps component or service quality is an integral part of what you do, and you wish to maintain product excellence.

It may be that effective inventory management is part of your concern, or perhaps the reduction of rework. If the equipment you use is capital-intensive, you may wish to achieve the lowest total operating cost possible.

This paragraph should clarify the reasons for prescribing these maintenance expectations.

3. The statement of intent

This part of the policy is a commitment by the company. It should begin with a definite statement. No more high-level fluffy language here. What is this policy going to do? Examples include:

- Our Maintenance Policy will…

- This policy will ensure…

- The company’s approach to maintenance is…

Following this statement, there will be a bulleted list of commitments starting with action words: maintain, implement, ensure, prevent, assist, promote, provide. There should be no ambiguity in this statement, no room for misinterpretation.

4. The scope of the maintenance policy and procedures

This paragraph describes the first level of implementing and maintaining a comprehensive maintenance management process. It outlines the planning and development of activities associated with your company maintenance, and it should include as a minimum:

- developing a maintenance strategy

- assigning maintenance standards

- writing a strategic maintenance plan

- developing and writing maintenance procedures

5. Policy requirements

The requirements chapter is the meat of the maintenance policy document, being more tactical than strategic. Here, you write brief paragraphs explaining the company’s or department’s approach to important issues. Basically, you outline the scope of maintenance work required by prescribing the maintenance tasks required. Common topics are:

- Obligations concerning EHS regulations, quality assurance, risk management, and financial management.

- Preparation of a maintenance strategy addressing planned and unplanned maintenance.

- Writing and regularly reviewing a Strategic Management Plan (SMP) that addresses company maintenance needs in the short, medium, and long term.

- Budget development, to ensure the achievement of stipulated maintenance standards.

- Development of a maintenance management system utilizing original equipment manufacturer (OEM) data, in-service experience, and historical data.

- Implementation, monitoring, and ongoing review of maintenance performance against industry standards.

- Establishing processes for the capture, safe retention, and utilization of maintenance data, to meet company and regulatory reporting requirements.

- Procurement of maintenance contractors and maintenance services.

The policy requirements paragraph is a broad and deep explanation of the issues that require adherence from a company or department. The involvement of other departments in the development of this stage is advantageous and recommended.

6. Allocation of responsibilities

While brief, this is where you identify the roles affected by or responsible for this policy. Who will be held accountable by it? What consultation must take place, and with whom? Who will be informed of its contents?

To avoid constantly updating this portion, use roles rather than names. Address the maintenance requirements and outline the maintenance team’s responsibilities.

7. Related documents

List all the documents that affect the maintenance policy in some way. These may be external legislation or other internal policies.

Include internal documents that exist because of this policy. Examples include maintenance strategy documents, the strategic management plan, the maintenance management system, and maintenance standards.

Go only one level down in the document hierarchy: you don’t need to list all procedures, guidance notes, or safe work practices that sit below the standards.

Don’t know where to begin? Look at some maintenance policy examples

Below are some links to maintenance policy documents and guidance for different industries found in the public domain. These examples don’t necessarily contain all the recommended components; nonetheless, they are good enough to serve as practical examples.

Remember, taking these and copying them verbatim won’t help you. Your maintenance policy must reflect your company values, the industry you’re in, technology levels, and used equipment.

Instead, use these examples to focus on format and the type of included content:

- Medical Equipment Maintenance Policy #1

- Medical Equipment Maintenance Policy #2

- Information Security System Maintenance Policy

- Building Maintenance Policy

A top-down approach to maintenance

A strong maintenance policy is the first step for organizations to optimize their maintenance spend, improve equipment uptime, and align maintenance strategies and procedures with the company mission and values.

By setting objective and quantifiable maintenance expectations, the maintenance policy focuses the engineering and maintenance departments on delivering the intent and commitments required by the maintenance policy. When drafted and communicated correctly, it is expected to minimize production losses and breakdowns, improve product quality, and optimize maintenance equipment, spares, and personnel.

A coherent, auditable top-down approach to maintenance management starts with a clear and understandable maintenance policy that is aligned with your company’s objectives and backed by senior management.