A great maintenance department is a cohesive unit of staff with different technical skills. As the work environments continue to get more complex, the maintenance engineer role is an increasingly important position to fill.

Whether you are interested in maintenance engineering as a career path or looking to hire a maintenance engineer for your organization, we have something for you here. We discuss everything you’ll need to know about maintenance engineers. We outline what they do, required skills, education and certifications, expected pay, and many other details.

Before that, we have to take a quick detour to define the concept of maintenance engineering.

What is maintenance engineering?

Maintenance engineering is a discipline that introduces engineering concepts to equipment maintenance. It enables companies to optimize maintenance procedures and improve machine performance in a cost-effective way.

As systems, machines, and infrastructure become more complex, there is an increased need to apply maintenance engineering practices to keep physical assets running smoothly and efficiently. Maintenance engineers, along with reliability engineers, are here to apply engineering concepts in an effort to increase the reliability, maintainability, and availability of systems and machines they are responsible for.

What is a maintenance engineer?

The end goal of any maintenance engineer is to ensure that industrial machinery and equipment runs smoothly and reliably. They are certified and trained to install, troubleshoot, and repair different types of equipment. They can use specialized technologies (like SCADA or remote telemetry units (RTU) to monitor equipment and diagnose machine failures. If there are complex breakdowns, they help to restore faulty equipment to optimal condition.

Depending on the type of facility where they are employed and its size, maintenance engineers may also be required to perform the duties of a maintenance technician. However, both positions are unique.

Maintenance engineers have specialized training to be “big picture” strategic problem solvers. While they will participate in major repairs, installations, and diagnostics of critical equipment, the rest of their day will often be focused on more managerial tasks. In contrast, maintenance technicians will do most of the required hands-on work, performing generalized repairs and a wide range of routine maintenance activities.

While writing this article, we reviewed dozens of maintenance engineer job posts to see the common skills required and common duties listed. We noticed an interesting trend. A big chunk of those job posts seem to be more in line with skills and responsibilities of a maintenance technician than an engineer. It seems that businesses looking for maintenance workers have trouble distinguishing between maintenance roles. It is an important thing to keep in mind during the hiring/application process.

Maintenance Acronym Guide

Confused by PMs, MTTR, and DFMEA? This maintenance acronym guide will have you talking the talk in no time.

Maintenance engineer job description

Certain factors like the employer’s niche and size of operations will shape the final job description that an organization will use to recruit a maintenance engineer. But in all, their responsibilities will typically revolve around the following:

- Ensuring that machinery, systems, infrastructure, and equipment run optimally with minimal downtime

- Conducting and overseeing maintenance process audits

- Diagnosing faults

- Undertaking planned maintenance

- Establishing different maintenance procedures and protocols

- Training staff on equipment operating and maintenance procedures

- Responding to major equipment breakdowns

- Forecasting and strategic planning for system overhauls and upgrades, while taking into account long-term maintenance costs

- Supervising other engineering and technical staff

- Procuring, testing, and commissioning specialist components, fixtures, or fittings

- Working with the maintenance director and other executives to manage budgets

- Setting and tracking maintenance KPIs

- Playing an active role in helping the organization set up and execute preventive maintenance, predictive maintenance, or any other preferred maintenance program

Whatever the case may be, experienced maintenance engineers can expect to be at the frontline of all things maintenance-related. They are expected to execute these responsibilities in a responsible and organized manner.

A maintenance engineer can expect to work 40+ hours a week. Although, on occasion, they could be asked to work well outside business hours (on weekends, public holidays, etc). For better or worse, overtime work is a shared reality for all maintenance staff.

Maintenance engineers in plants and facilities that run their operations 24/7 will have to work shifts that cover nights, weekends, and early mornings. The pace of work can vary and will often spike when there is a push to meet production deadlines or to quickly resolve breakdown emergencies.

Maintenance engineer salary

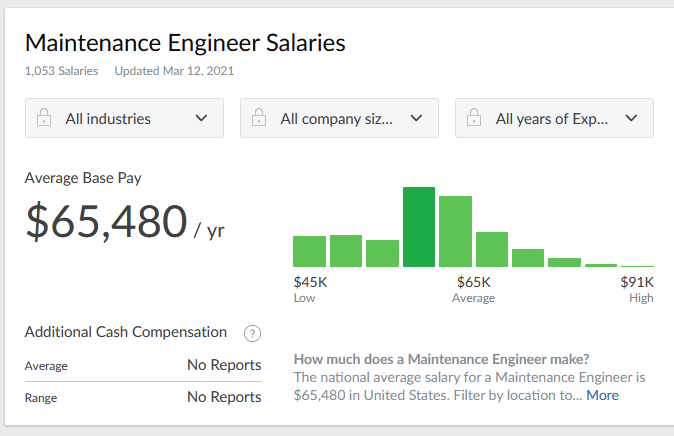

How much does a maintenance engineer makes in a year is not a straightforward question to answer. It depends on the size of the organization they are working at, the type of facility they maintain, and years of experience. Nonetheless, with a big enough sample, it makes sense to look at industry averages.

The data we pulled from major job platforms reveal that maintenance engineering jobs pay the following figures:

- Indeed states that the hourly wage for a maintenance engineer is $14.95, which comes to a $59k annual salary. They also put average additional compensation (overtime) at $6.7k per year.

- Salary.com tells us that the salary range falls between $64k and $83k, with the average hovering around $72k.

- According to Totaljobs, the average salary in the UK is £37k ($52k).

- Findcourses.co.uk estimates that the average engineering maintenance technician salary is closer to £44k ($61k).

- Glassdoor quotes the average base pay per year as $65k.

Our latest research shows that finding skilled maintenance workers is the biggest maintenance challenge plaguing maintenance departments right now. As we move forward, we might see a small boost to the maintenance engineer salary. Companies might use it as an incentive to attract experienced talent.

Maintenance engineering education and training

True engineers have had years of higher education, training, and certifications to make them proficient in performing advanced repairs and maintaining complex equipment. But, getting to this level requires an investment in continuous learning. Here’s what the educational and training background of a maintenance engineer typically looks like.

Basic educational requirements

Many future maintenance engineers display interests in science from a young age. After high school, they are expected to go on to earn a bachelor’s degree in one of the major engineering fields like:

This will give them an even stronger foundation in science, technical skills, problem-solving, and engineering fundamentals.

Training

Engineering is a wide area with a lot of practical applications. Hence, new engineers aspiring to the position of maintenance engineers will need to specialize at some point. To achieve this, it is advisable to work under the supervision of more experienced engineers for a while in addition to receiving company training. Gradually, as they become more competent, they are likely to receive more responsibility until they can work truly independently.

At the end of all this, these engineers would have acquired additional skills like good communication, project management abilities, stress management, team leadership, etc., in addition to their classroom studies.

Although we have established that aspiring engineers usually go straight from high school to an engineering degree, not all of them will follow this path. Some may work as maintenance technicians initially. Thereafter, they can:

- enroll at a university for a Bachelor’s degree in a related engineering field

- begin applying directly for engineering positions if they are confident of their abilities to demonstrate proficiency and skill in the field

- get promoted within the organization where they work to an engineer’s position

However, many employers will NOT consider technicians for engineering positions if they do not have a proper degree.

Recommended complementary certifications

In addition to their education and training, many potential employers these days look for candidates with specific certifications. The most popular ones for maintenance engineers include:

- Certified quality engineer (CQE certification)

- Lean Six Sigma certification

- American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE certification)

- Leadership in Energy and Environmental Design (LEED certification)

- Project management (PM certification)

- The American Society for Quality Certified Reliability Engineer (CRE certification)

You can also find a variety of maintenance and engineering courses at sites like Find Courses. They can connect you with training experts from specific industries so you can find very targeted courses and earn additional certifications.

While some employers will not insist on having these, they will appreciate relevant certifications when looking for candidates to fill senior engineering positions. Besides that, these certifications also help maintenance engineers broaden their career options.

Industries that employ maintenance engineers

Although many maintenance engineers work in plants, construction sites, or factories, all organizations with large facilities, complex machinery, and industrial plants will benefit from hiring maintenance engineers. Therefore, they can work in hospitals, large hotels and resorts, universities, public schools, and at different types of government establishments.

Still, some maintenance engineers may opt for self-employment, engineering consultancy, or freelance work especially those engineers that focus on specialist infrastructure (e.g. power generation, oil and gas, or the IT sector).

Skills to look for in a maintenance engineer

As the modern workplace continues to evolve, engineers are no longer expected to remain isolated in dark equipment rooms, laboring over machines and systems. Rather, they are playing more active roles in leadership and strategic planning.

Below are some pointers to help recruiters get the most suitable maintenance engineers for their organizations.

Technical skills

What’s an engineer without the necessary technical skills? Updated technical knowledge appropriate for the industry, plus evidence of competence for the job are still the main skillset employers are looking for.

A strong technical background helps engineers understand complex machines, perform RCM and RCA analysis, read OEM manuals and schematics, perform troubleshooting tasks, help with the creation of maintenance checklists and procedures, supervise preventative maintenance work, participate in equipment maintenance, and perform other technical work.

Leadership qualities

Businesses want to hire maintenance engineers who are willing to integrate with the rest of their staff, work their way up, and boost the organization’s general performance.

To that end, they’ll look for people who can help improve the work culture and will not shy away from being accountable for group or personal assignments and projects. Likewise, the ability to bring people together, influence them for good, and keep the team spirits up are welcome traits for maintenance engineers.

When things don’t go as expected – as will often happen – the engineer will be expected to manage stress well under pressure and still deliver results under unfavorable conditions. A typical scenario where such skills are key is when critical policies are being changed or revised (e.g. safety or financial matters), the organization needs engineers that they can count on to step up and carry their team along without too much of a ruckus.

Creative problem-solving

Maintenance engineers will need the ability to think outside the box, creatively solve problems, and suggest sustainable improvements. When tricky situations arise, a great maintenance engineer can innovate and propose alternatives that were originally not the most obvious solution.

The level of required creativity often correlates with the size of the maintenance budget. Well-funded MRO teams have less need to resort to improvised solutions. They do not have to work with ancient equipment, have the ability to purchase original spare parts, and do not hesitate to call in contractors to deal with specialized equipment and repairs.

Micro and macro-management

Accuracy and precision are critical for maintenance engineers. The inability to notice small but important details can result in costly miscalculations and mistakes or cause health and safety problems. When diagnosing complex faults or performing sensitive work on equipment, attention to detail is paramount.

Similarly, managing a team of diverse people and leading them to achieve common objectives requires a person that can track work orders and supervise day-to-day operations and maintenance activities. Fortunately, these days, tracking and managing maintenance work can be streamlined via the CMMS system.

While doing all of this, maintenance engineers should not get distracted from staying on the budget, warning about potential problems, and discussing long-term issues. Depending on their exact responsibilities, decisions they make today can have consequences months or years down the line. As such, they should work in tandem with maintenance managers and always try to think about the big picture.

Conclusion

There is a big gap between a maintenance engineer with little to no practical experience and an industry veteran. The difference in acquired skills, and subsequently maintenance tasks they can perform, is significant.

With that in mind, during the hiring process, both sides should be honest about their expectations, as well as what they can offer in return.

So this question was recently posed to me and I had to do some research on it. This is by far the most informative and succinct article I have come across. Nice work Bryan!

Comments are closed.