Conveyors are present in almost all manufacturing facilities. They often play a critical role in production and material handling processes. It is not an asset you want to see shut down, unless it’s for planned conveyor maintenance.

Stay with us as we discuss the significance of routine conveyor maintenance, common conveyor belt maintenance issues, and how to build a conveyor maintenance plan. Let’s dive straight in.

The importance of regular conveyor maintenance

Warehouses and manufacturing facilities can feature various types of conveyor systems. They are a great way to automate the flow of goods and materials in an industrial facility, leading to fewer bottlenecks and a more constant process flow.

The critical nature of conveyors is undisputable. However, we often act as if the smooth functioning of conveyors is a given. We allocate maintenance attention only when there is a problem.

The main culprits for the lack of maintenance is the fact that conveyor systems are designed to operate round-the-clock and have a lot of moving parts spread over a large area. To perform any significant maintenance work, the whole conveyor system has to be stopped. Oftentimes, this means that a portion of factory operations (or all of them) have to be halted.

It is no wonder maintenance professionals are hesitant to do that on a regular basis.

Unfortunately, this delay in maintenance often causes problems down the line. Small problems compound and result in major expensive breakdowns that could have been avoided.

This is why regular conveyor maintenance should never be overlooked. You need to plan and schedule it as part of regular plant operations. It is the only way to minimize planned downtime time for maintenance activities, as well as reduce the chance for a prolonged downtime due to an unexpected breakdown.

Checklist for Creating a Preventive Maintenance Plan

Following a consistent Preventive Maintenance Plan can make life easier. Use this checklist to create your own!

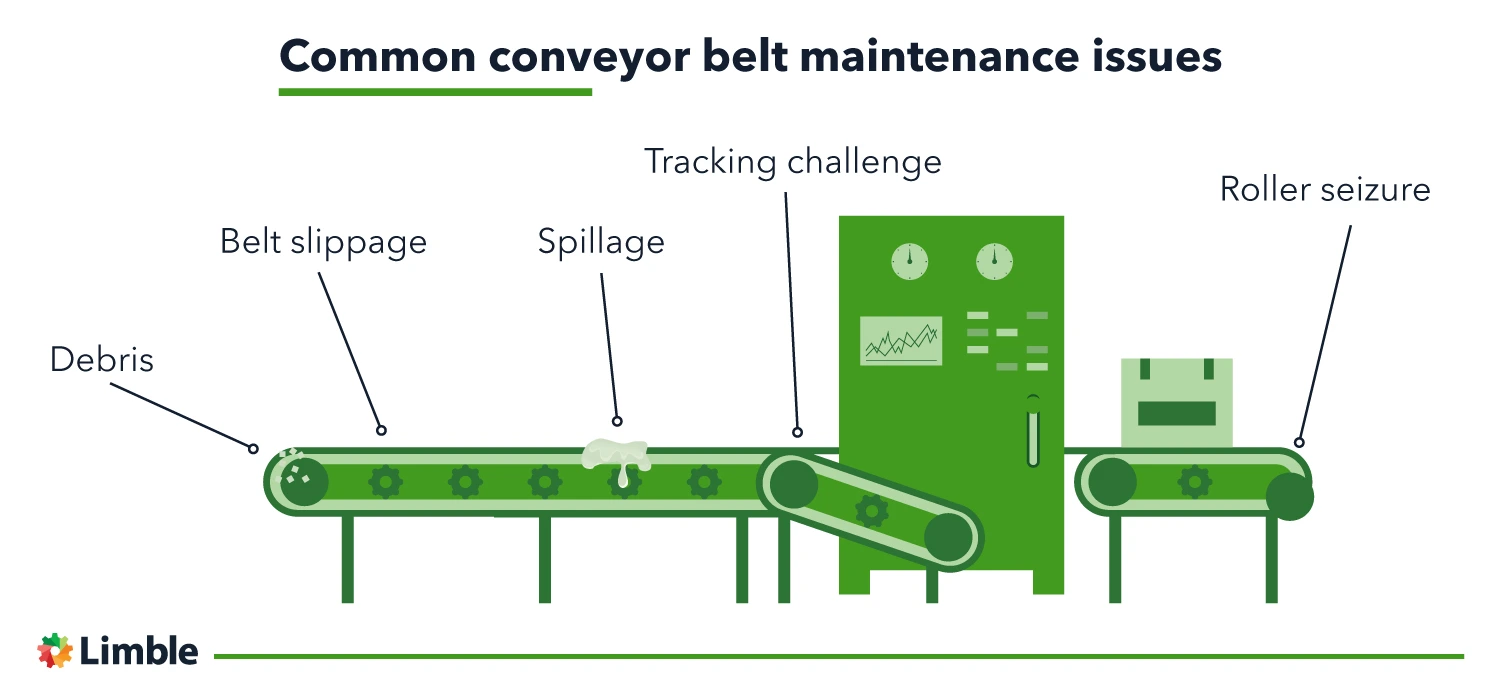

Common conveyor belt maintenance issues

Before we get into plans and checklists, let’s briefly go through the most common conveyor and conveyor belt issues you should be on the lookout for.

Debris

Conveyor systems carry different types of materials. The transported material could deposit debris. The environment in which the conveyor system operates also contributes to different debris, which can eventually find its way to the conveyor mechanism.

This can cause blockages, hampering the operation of conveyor systems. You should perform regular cleanups to avoid such a predictable problem. Inspection for debris buildup should be a part of your routine maintenance activities.

Belt slippage

Belts are used for conveyance in most conveyor systems. The belt needs just the right amount of tension to ensure smooth performance. When that balance is disrupted, it can cause a lack of grip, leading to belt slippage.

Regular checks have to be done to test the tension of the belt. When belt slippage becomes an intermittent problem, you can perform root-cause analysis to identify and eliminate the underlying problem.

Spillage

Material transported over the conveyor system can accidentally slide off or spill into the conveyor mechanism.

Material spillage commonly occurs at junction points where conveyor belts meet. Some factories take additional design measures to eliminate this material spillage. If it is a recurring problem, you will need to inspect the conveyor system for irregularities or imperfections that might cause said spillage.

Roller seizure

In most conveyor systems, rollers are part of the design. Individual rollers can stop rotating due to structural damage. This can also happen due to debris buildup, damage to drive motors, and various other reasons.

Your operators and maintenance tech should always be on the lookout for this type of problem. The first signs are sporadic roller seizures that cause spillage. Investigate these incidents promptly so you can eliminate the underlying causes.

Tracking challenge

Conveyor belts have to move in a predetermined path. In most instances, the path is a straight line. Any misalignment of conveyor belts can cause belts to drift side to side. This will cause wear and tear in the conveyor belt. When left unaddressed, the entire conveyor system can go awry. You have to keep an eye out for any tracing imperfections and rectify the underlying problem as soon as possible.

Build a comprehensive conveyor maintenance plan

As with any important physical asset, conveyor maintenance has to be done routinely. We recommend using a cloud-based CMMS system to ensure all preventive maintenance activities are performed on schedule and up to the required standard.

The following sections cover a broad range of recurring maintenance tasks involved in maintaining a conveyor system. Keep in mind that this is an illustrative overview. Some of these tasks may not suit your assets. Similarly, certain maintenance tasks essential for your system may not be enumerated in the following lists.

Take these checklists as an example you can build upon. Consider age, condition, and operating conditions before defining a preventive maintenance plan for your conveyor systems.

Daily conveyor maintenance checklist

Perform the following maintenance checks on a daily basis, during normal operation:

- Visually inspect for debris stuck in the conveyor mechanism.

- Check for unusual noise during normal conveyor operation.

- Visually inspect for cuts or bruises on conveyor belt.

- Take note of any belt slippage or material spillage.

Weekly conveyor maintenance checklist

Perform the following maintenance checks weekly, when the conveyor system is idle:

- Lubricate roller bearings.

- Scrape parts of the conveyor mechanism to remove debris and foreign objects.

- Check for damages to conveyor belt and rollers.

- Check whether materials are unloading properly from the conveyor mechanism.

- Retrieve and clean dust containment system (it can accumulate debris and other undesirable foreign objects).

Monthly conveyor maintenance checklist

Schedule planned downtime on a monthly basis to perform the following activities:

- Repair damages to conveyor belt according to the instructions from OEMs and vendors.

- Change oil or other lubricant in the gearbox and power module.

- Replace worn out brushes and scrapers.

- Have a detailed inspection of the belt and conveyor system when the conveyor is shut down and empty.

- Inspect electrical components for damages or faults. Replace/repair them if needed.

- Inspect the following mechanical components and replace them if necessary:

- Idlers

- Rollers

- Self trainers

- Belt tracking

- Tripper tracking

- Tripper spillage

- Tripper bends

- Head pulley

- Drive pulley

- Tail pulley

- Tripper discharge pulley

- Pulley cleaners

- Run drives

- Impact bed

- V-belts

- O-rings

- Sprockets

- Drive-chains

Annual conveyor maintenance checklist

The following are the maintenance activities to be performed annually:

- Replace heat insulation lagging.

- Drain gearbox reducers and flush them with kerosene.

- Inspect the motors of the conveyor system. Replace them if necessary.

- Replace electric contacts, fuses, and other similar electrical components.

- Operate the conveyor system without any load. Inspect for any irregularities in empty operation.

- Operate the conveyor system with standard load and check for faults in all conveyor system components.

- Test the emergency stop functionality on an empty load and full load.

For smooth conveyance

Using a mobile CMMS app like Limble is the easiest way to stay on top of your conveyor maintenance work. It helps you plan and schedule routine work, keep just the right amount of spare conveyor parts in stock, have all maintenance documentation and history in one easily accessible place, and much more.

Improve your plant operations by taking proper care of your physical assets and infrastructure. Test Limble CMMS today by starting a free trial, requesting a walk-through, or playing around in our self-demo.