Machine efficiency is a critical aspect of modern manufacturing. It cuts down on operating costs, improves throughput, and reduces environmental impacts.

Inefficient machines lead to poor ROI – something any business should actively try to avoid. If you are a maintenance or a plant manager, we do not have to tell you how expensive manufacturing equipment can be and why efficiency can’t be just a footnote in your daily work.

Below are several approaches you can use to measure and calculate machine efficiency.

The basic concept of efficiency

In manufacturing, efficiency is the ability to produce something without wasting any time, materials, or energy.

In reality, 100% efficiency is unattainable – there will always be some kind of wastage. Nonetheless, it is still the ideal which manufacturers attempt to get closer to, through principles like lean manufacturing, “just-in-time,” and continuous improvement (Kaizen).

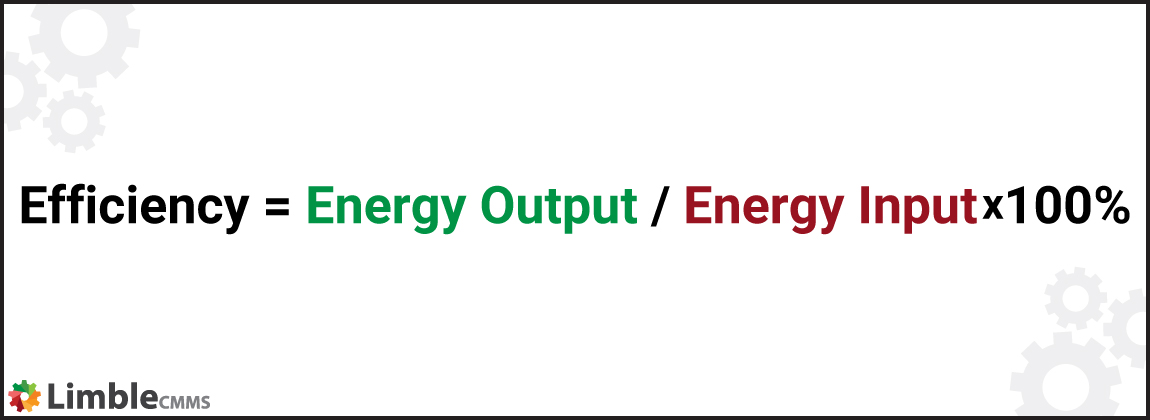

Physics is a great starting point to understanding the concept of efficiency. It defines the basic formula for efficiency which looks like this:

When you divide the output from a process with the inputs and express the result as a percentage, you get the efficiency rating for that specific process.

Efficiency has an upper ceiling of 100% – it cannot exceed that limit. Any process, manufacturing or otherwise, with an efficiency rating of 100%, can be considered as a perfect process.

Checklist for Creating a Preventive Maintenance Plan

Following a consistent Preventive Maintenance Plan can make life easier. Use this checklist to create your own!

Ways to calculate machine efficiency

There are numerous inputs in a manufacturing process. Using the basic formula, you can examine the efficiency of a machine from different angles, depending on the input under consideration. This gives us several different ways to measure machine efficiency.

The three approaches worth noting are:

- Energy production

- Energy consumption

- Productivity

Energy production

The term energy production is a misnomer as energy can neither be produced nor destroyed – according to the Law of Conservation of Energy. Here, energy production refers to the conversion of available energy into a more “usable” form of energy.

A great example would be a solar panel converting light energy into electrical energy, or a generator that converts mechanical/chemical energy into electrical energy.

The formula for calculating the energy production efficiency would have the same format as the basic efficiency formula:

Efficiency = usable energy/available energy x 100

Take the example of a diesel generator. If one gallon of diesel has 40,000kWh of energy, and the generator converts it into 10,000kWh of electricity, efficiency can be calculated as:

Efficiency = (10,000/40,000) x 100 = 25%

Energy consumption

Given the high cost of energy inputs and the impact fossil fuels have on the environment, energy consumption efficiency has acquired more importance in recent decades. According to the US Department of Energy studies, energy (electricity) costs make up a whopping 96% of the total life-cycle cost of a motor.

And in manufacturing, machines with motors account for almost half the electrical energy consumption. So, any changes in industrial energy consumption efficiency will have a massive impact on power grids and the environment in general.

We can use the same basic efficiency formula we’ve used so far.

Consider the example of a power tool that consumes 500kWh in electricity and outputs kinetic energy to the tune of 320kWh. Its efficiency can be calculated as:

Efficiency = (320/500) x 100 = 64%

The Essential Guide to CMMS

The Essential Guide to CMMS

Production efficiency (productivity vs efficiency)

There is a significant difference between “productivity” and “efficiency” in manufacturing. Productivity focuses on increasing the quantity of goods produced. This can often come at the cost of efficiency.

An increase in the percentage of defective units is a common example. Firms that ramp up production beyond the optimal limit often face this issue, due to factors like lower-quality materials, operator fatigue, etc. While the actual number of units created went up, the efficiency went down.

In contrast, production efficiency focuses less on quantity and more on quality. It wants to produce more units by reducing the number of defects and waste. When executed properly, improving manufacturing efficiency will increase productivity.

A simple way of calculating production efficiency would be to consider the actual output rate versus the standard/maximum output rate possible on the machine.

Consider the example of a printing machine that delivers an actual output of 650 units per hour, as opposed to a maximum rate of 900 units per hour. Using the efficiency formula we get the following results:

Efficiency = (650/900) x 100 = 72.22%

OEE: The gold standard in manufacturing efficiency

OEE stands for Overall Equipment Effectiveness. It is an industry-standard metric and a widely accepted Key Performance Indicator (KPI), applicable in a wide range of industries.

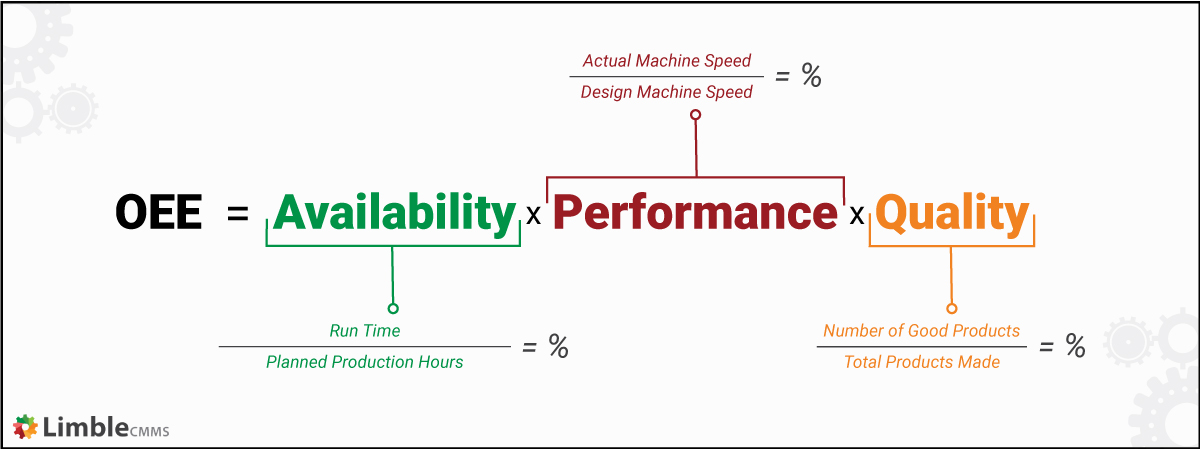

This metric is popular due to its comprehensive focus. It looks at three key aspects of equipment on the production line:

- Availability

- Performance

- Quality

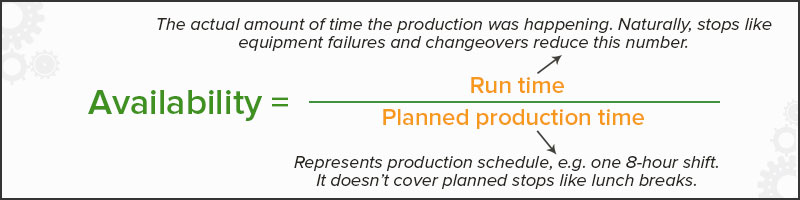

Calculating Availability

All assets have a scheduled working time of X hours per week/month. Availability displays the actual working time of a machine as a percentage of the scheduled working time.

The formula for calculating Availability is:

Availability is very rarely at 100%, as downtime can occur due to a wide range of factors. Equipment failure, adjustments, repairs, unplanned maintenance, and other factors contribute to reduced availability.

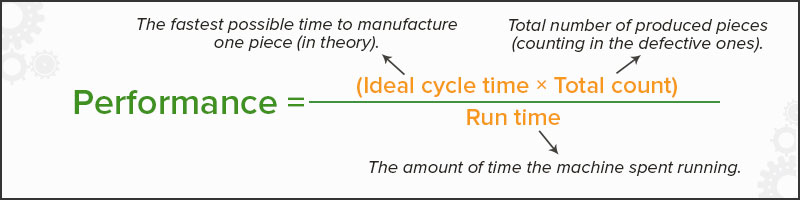

Calculating Performance

The performance depicts the actual number of units produced by a machine, as a percentage of the maximum number of units it could have produced at maximum speed, during the actual working time on the floor.

The basic formula for Performance is:

Performance can be affected by minor stops during the production process. Machine defects and untrained operators can slow down production speed, leading to lower performance.

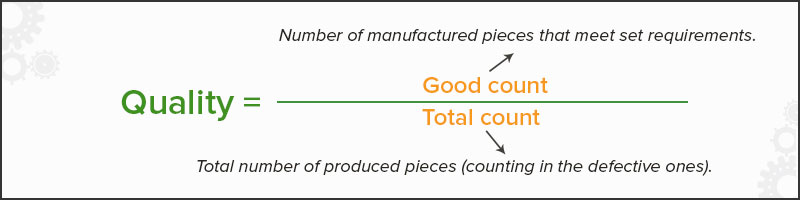

Calculating Quality

Quality shows the percentage of “good” products vs defective products in any batch. Defective products lead to waste, as they have to be either scrapped or reworked.

The formula to calculate Quality is quite simple:

Quality can be affected by many factors, both direct and indirect. Defects in the production process can result in lower quality or defective products. Operator mistakes, low-quality raw materials, and machine faults can also lower the percentage of quality in production.

How to calculate OEE

Once you have Availability (A), Performance (P), and Quality (Q) metrics for a machine/plant facility, calculating OEE is a relatively simple process.

The basic formula for OEE is:

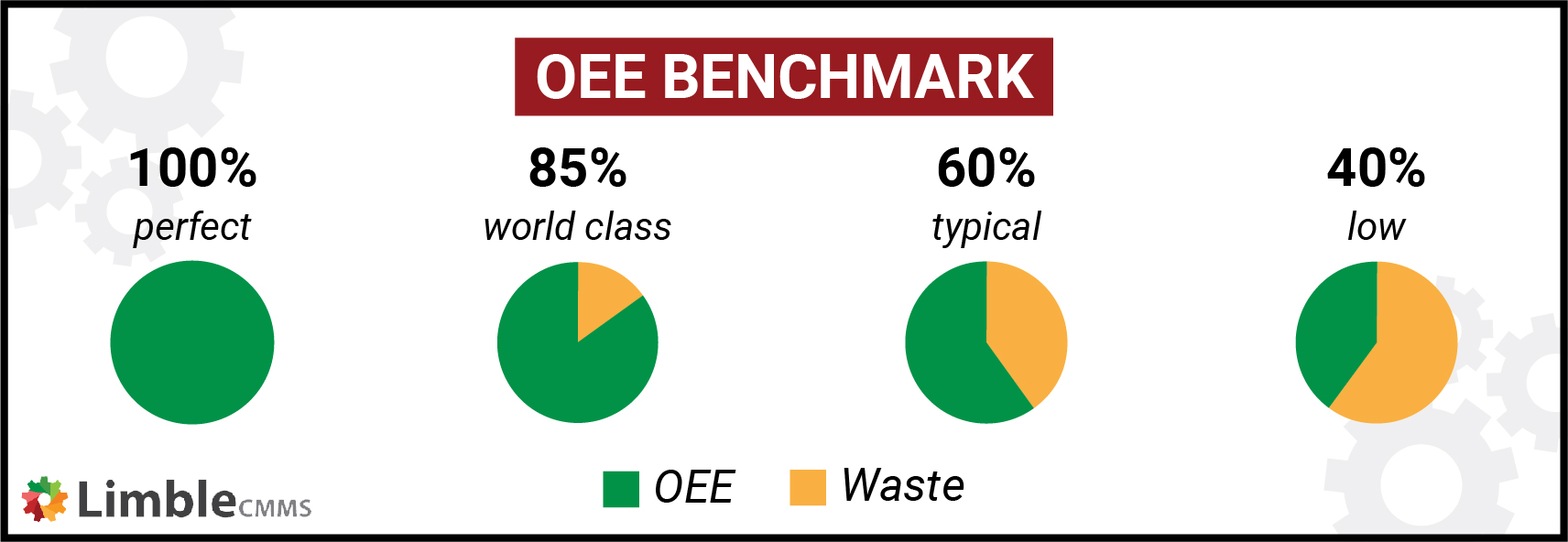

An OEE score of 100% is considered as “perfect production.” It has three main characteristics:

- The machine is producing no defective parts

- The machine is producing parts non-stop (during scheduled run time)

- The machine is performing at maximum speed

Just to give you some context, average production facilities have the OEE score at around 60%.

How to implement and use OEE at your facility

As already explained, the formula for OEE is fairly straightforward. Managers seeking to calculate OEE must compile data on Availability, Performance,, and Quality.

The following steps can improve the chances of successful implementation of OEE:

- Pick a pilot: Start simple, with a machine that is relatively easy to review. Choose eager operators who have a positive attitude and are receptive to feedback. Assign a competent maintenance technician to the project as a contact person. Entrust leadership to a line manager/department manager with clear oversight of the production process.

- Define OEE parameters: Set limits on the data that needs to be collected. Select the time category for measurements, products to be tracked, the maximum speed of the machine, and so on.

- Organize data collection: Pick the best way for an operator to easily collect the relevant data defined in step 2. Keep forms and procedures as short and as simple as possible for maximum effectiveness and accuracy.

- Train the personnel: Explain the OEE basics and benefits to all participants on the pilot team. If needed, provide additional training for data collection and reporting.

- Collect data: Avoid the mistake of not trusting operators with this task. They are best positioned to track the metrics necessary for calculating OEE. If that is an option, you can provide a supervisor with OEE experience to improve accuracy and avoid errors.

- Process data: Have the team leader review and process the data as soon as it is readily available, preferably before the next round of data collection. Create readable charts and reports for easy communication of OEE measurements.

- Give feedback to operators: Share OEE results with operators to help them gain insight into areas that need improvement. Prompt communication is essential as the feedback can be incorporated into production before the next round of OEE data collection.

- Involve the management: OEE results may reveal weaknesses that require high-level intervention into the production process. Only management is capable of addressing some of these issues. Report all OEE results to top-level management for successful implementation.

For the maximum chance of success, OEE must be a concerted effort involving everyone – operators, mid-level management, and C-suite oversight.

Battling machine inefficiencies

Machine inefficiency is a major headache for manufacturers. What makes things worse is that many organizations are not even fully cognizant of the losses they are suffering due to low efficiency.

Equipment downtime is one of the major culprits that hinders the production process. Timely, proactive maintenance can be employed to minimize the risk of unplanned downtime.

If you need help tracking and organizing maintenance activities on the plant floor, Limble CMMS is here to help. Do not hesitate to schedule a demo or contact us directly if you have any questions about the software.

it is very nice

Comments are closed.