Optimizing the maintenance workload and inventory relies on efficient maintenance scheduling.

Nested preventive maintenance is a feature of modern CMMS software that lets you merge recurring maintenance tasks in a way that reduces administrative burden and simplifies maintenance planning.

Let’s see how it works in practice.

What are nested PMs?

Preventive maintenance is built on time-based and usage-based schedules. With a CMMS, such recurring tasks can be automatically scheduled months ahead of time.

When you have weekly, monthly, quarterly, and yearly PMs for a single piece of equipment, it is only a matter of time before some of those PMs overlap. In many cases, you want them to overlap so you can perform all of the work on that asset during a single planned shutdown.

In these scenarios, you want to schedule one big PM which includes everything that needs to be done on the day, without messing up future due dates for any of those recurring tasks.

Nested preventive maintenance function — if your CMMS supports it — lets you do exactly that.

The Essential Guide to CMMS

Download this helpful guide to everything a CMMS has to offer.

Who uses nested PMs?

Nested PMs are very useful if you manage a large number of assets, with a lot of recurring tasks you can merge together. Instead of creating two or three separate PMs and asking technicians to close them in a specific order, you can schedule all of the work via a single task.

If you run a small operation with just a few assets on your preventive maintenance plan, you can live without this feature.

An example of nested preventive maintenance

Nested PM functionality assumes that you want to include all activities and tasks from more frequent cycles into less frequent cycles. You want to perform all of the daily tasks alongside a Weekly PM, all of the daily and weekly tasks alongside a Monthly PM, and so on.

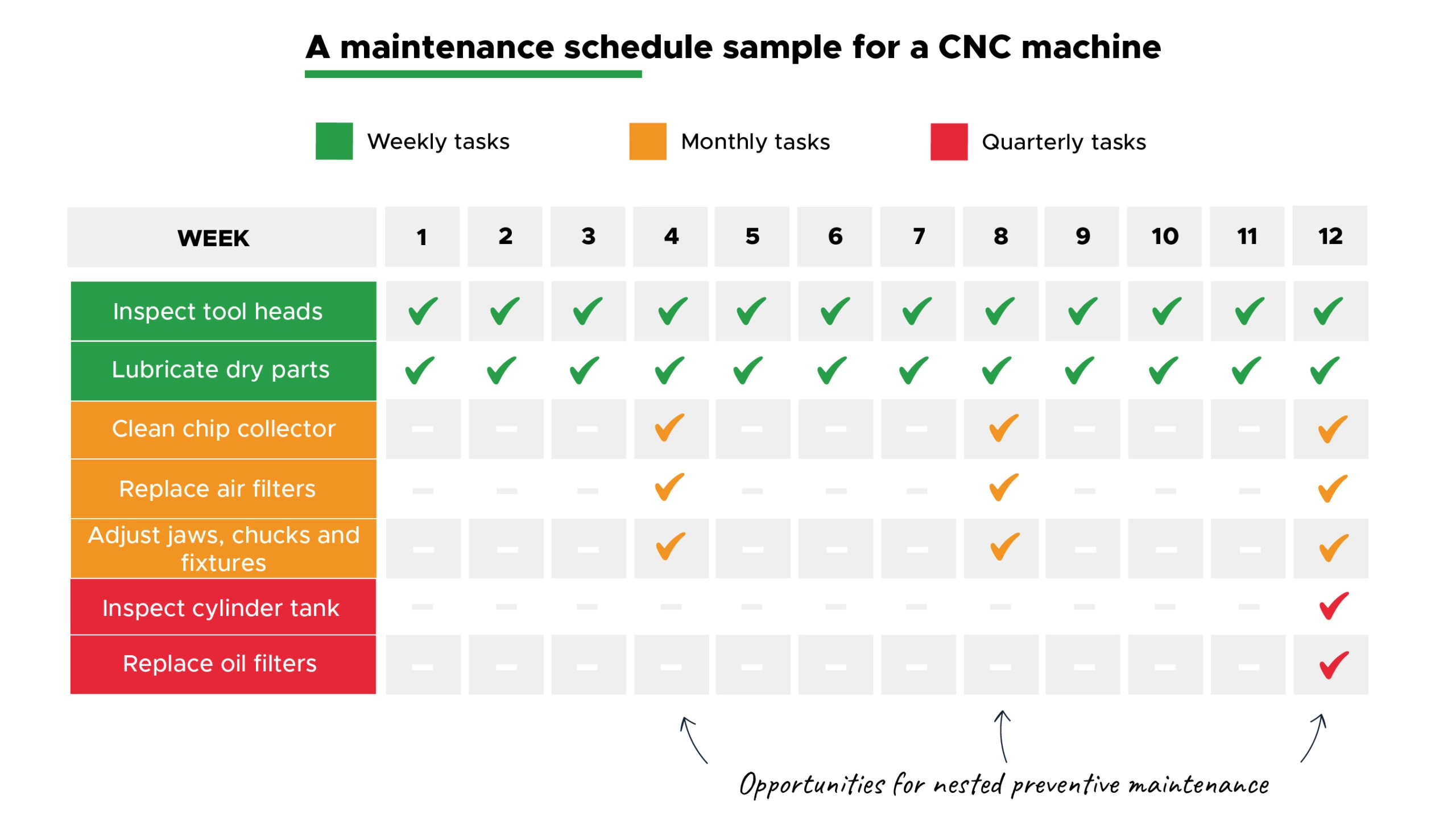

Let’s take a CNC machine as an example, and put it on a simple, time-based calendar outlined in the image below.

In the first 3 weeks, everything goes as planned. Every Thursday, your CMMS software triggers a PM to inspect tool heads and lubricate dry machine parts.

Then week 4 comes along. You have to trigger at least two PMs — one for the weekly tasks and one for the monthly tasks. On week 12, you would have to schedule, assign, and manage at least three different PMs to cover all scheduled tasks in this example.

Nested preventive maintenance functionality allows you to automatically merge those overlapping preventive maintenance tasks into a single PM, simplifying work for both maintenance planners and technicians.

How does nested preventive maintenance work inside Limble CMMS

Using Limble CMMS, you can create a nested PM in five simple steps we outline below.

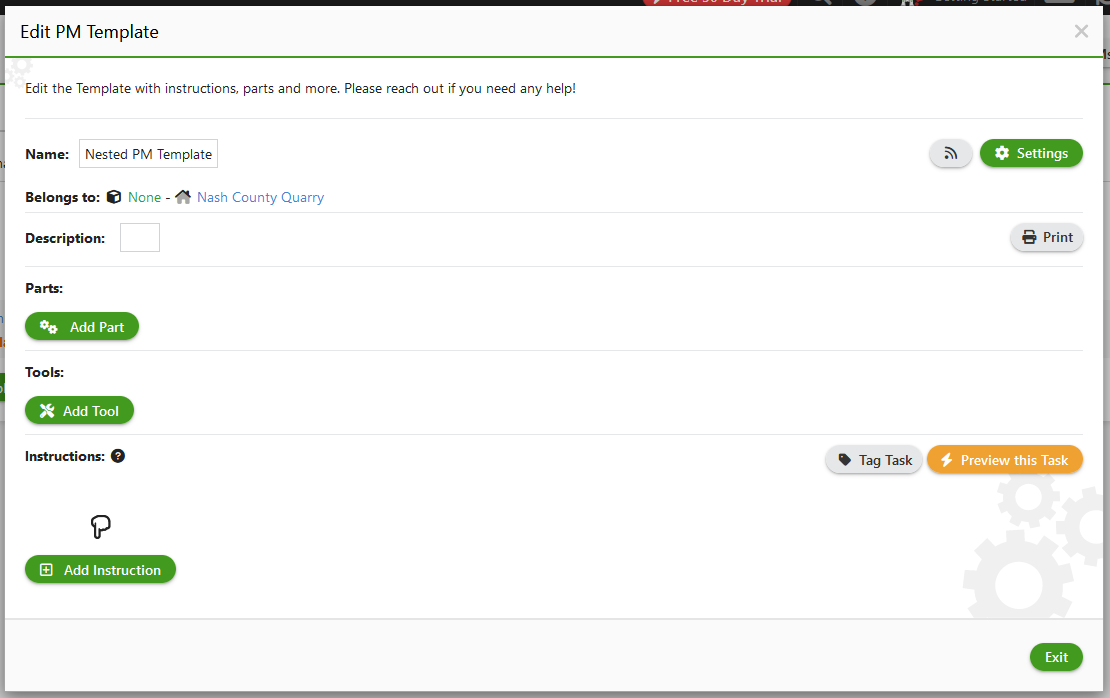

Step #1: Select an existing PM template you want to modify or create a new template from scratch.

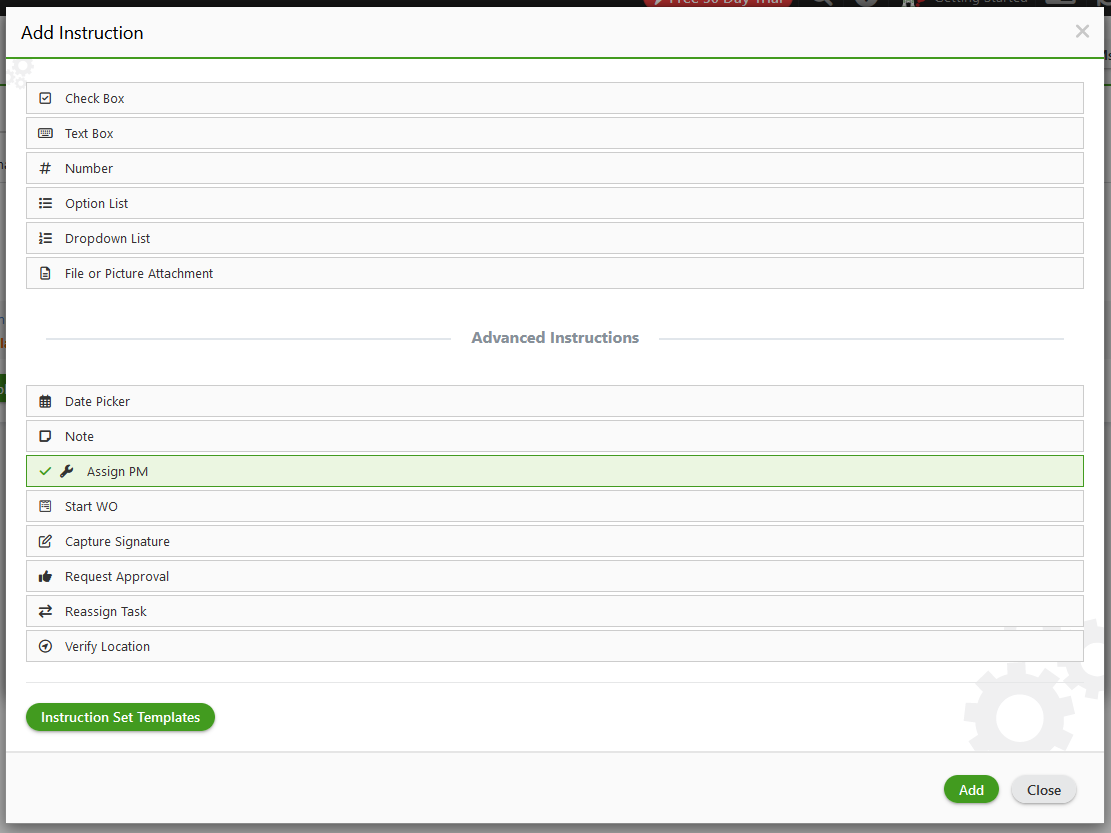

Step #2: Select “Add Instruction” in the bottom left corner.

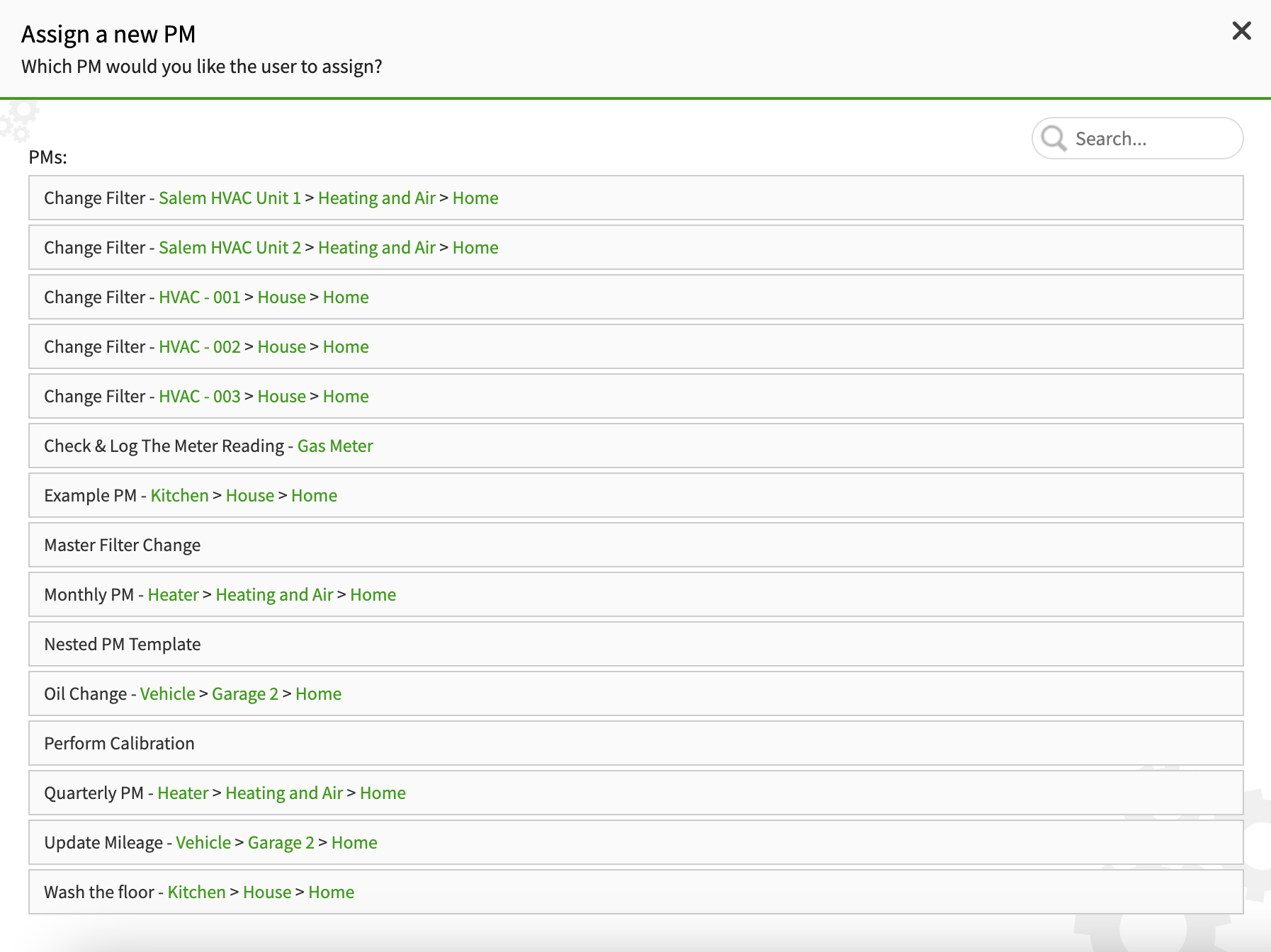

Step #3: From the advanced instructions list, choose “Assign PM”.

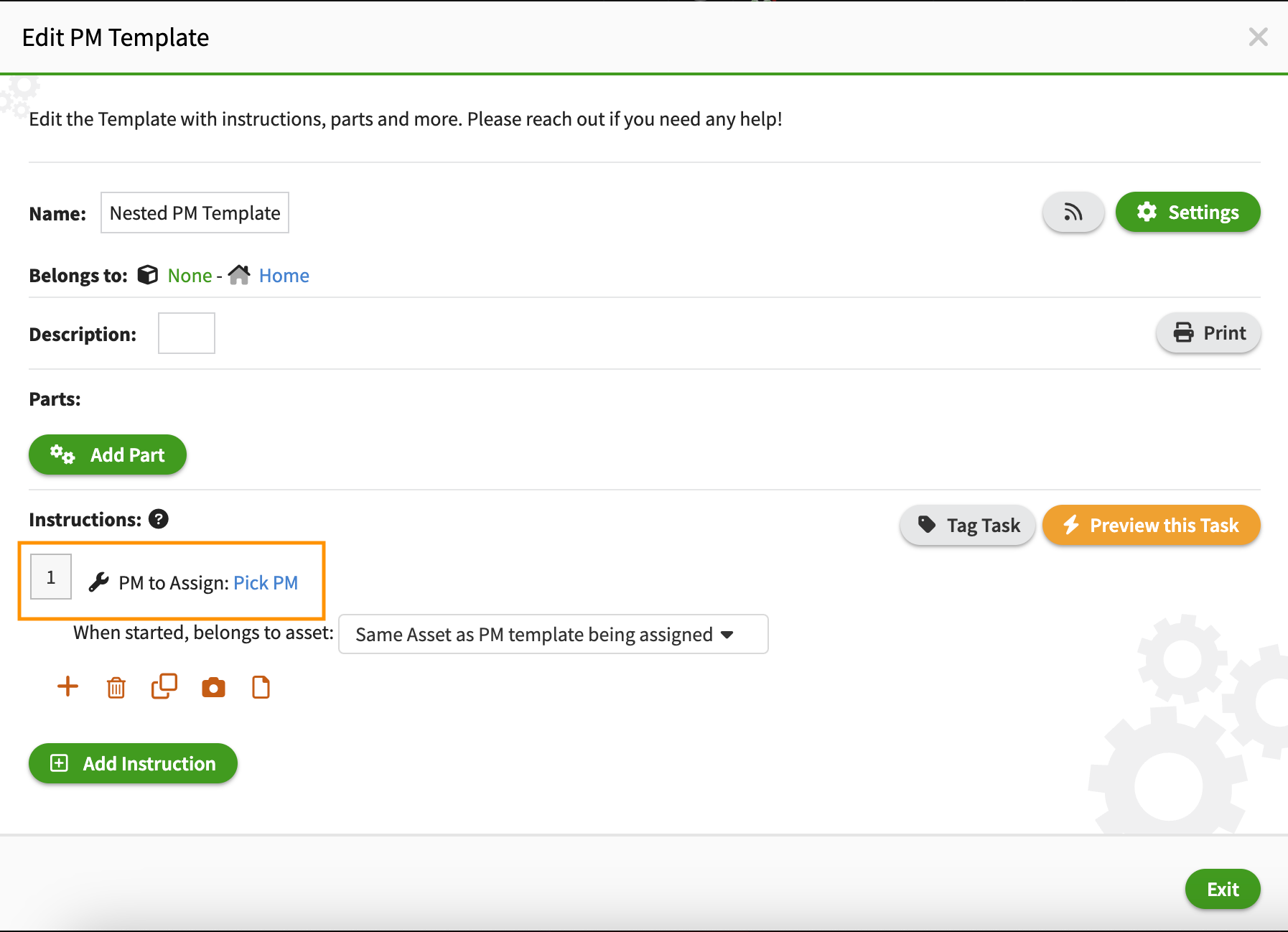

Step #4: Now that the instruction is added, click “Pick PM” to select an existing PM you want to nest.

Step #5: The PM you choose from the list above is now nested under another PM!

This way, you can nest your Weekly PMs under Monthly PMs, Monthly PMs under Quarterly PMs, etc. Since each PM comes with its own Parts and Instructions, Limble will still track all of that for you in the background.

After you’re finished, you can open the calendar for that specific asset and check if everything is scheduled as intended.

Things to keep in mind when using nested preventive maintenance

Automating maintenance scheduling is a huge time saver, but only if the system triggers everything correctly. Here are some things to keep in mind while using the nested preventive maintenance functionality.

Different implementation methods

Different CMMS vendors have different approaches to nested PMs.

Without going too much into technical details, the most common implementation methods include:

- Suppression method: You have to create multiple PMs for different cycles. The CMMS will trigger only the major PM that includes all of the work that needs to be done and skip minor ones or automatically mark them off as closed.

- Additive method: The software lets you build one PM that shrinks or grows, depending on your PM cycle. For example, tasks included in a Weekly PM can be automatically added to the Monthly PM when it gets triggered.

- Hybrid method: A combination of the above. You can build one PM that will change based on the PM cycle.

Ask your preferred CMMS vendor to demonstrate how to best use the nested preventive maintenance functionality inside their software.

How do the delays impact overarching tasks

Using floating schedules — where your next due date is automatically scheduled based on when the previous task was completed — can quickly run you into trouble.

If your monthly PM is just three days late on average, that will push your annual PM 36 days (3×12) past the initial schedule!

When you are trying to be diligent and stay in compliance with warranty and regulatory requirements, this can be a big problem.

How to adjust the schedule to handle exceptions

Imagine the following situations:

- You have postponed a monthly PM because one of the replacement parts was not in stock. The rest of the items on the PM were completed.

- Your weekly and monthly PM don’t align because it is February and you are short on days.

- There was a major equipment breakdown that completely messed up your schedule.

- There was a perfect maintenance window you used to perform Quarterly PM ahead of time.

In some of these scenarios, you will have to do manual tweaks to adjust the schedules.

The good news is that most CMMS vendors have thought of such issues and have developed very simple workarounds you can use to get back on track.

Optimize your maintenance schedules with Limble CMMS

Nested preventive maintenance is a tiny function compared to everything else that a cloud-based CMMS like Limble can offer.

Maintenance history, work order management, parts inventory management, vendor management, and schedules based on condition monitoring data and predictive algorithms are all integral features you need to simplify, organize, and automate your maintenance work.

To take Limble for a spin, request a free product demo, start a free trial, or play around in our self demo. No strings attached.