Deferred Maintenance

Everything you ever needed to know about deferred maintenance.

What is deferred maintenance?

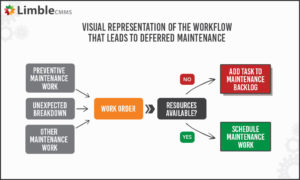

Deferred maintenance is postponing maintenance work to a later date due to the lack of necessary resources.

Whether it is an unexpected issue or a routine preventive maintenance task, if a company does not have sufficient resources to perform the task, it will have to wait.

Contrary to popular belief, deferred maintenance can be a useful strategy in any maintenance program. It just depends on how a company utilizes it.

If used strategically, deferred maintenance can help businesses prioritize maintenance tasks, helping their team achieve more.

Examples of deferred maintenance

Deferred maintenance is used in a wide variety of industries and maintenance applications. Let’s look at a few examples.

Deferred maintenance in real estate

Deferred maintenance in the real estate sector can have real financial impacts.

Selling a home that has been neglected becomes a challenge, negatively impacting the home’s value and the seller’s ability to close on it.

Deferred maintenance in production manufacturing

In production manufacturing, deferred maintenance can have serious impacts on entire production lines. A machine operator error can halt production altogether, resulting in current work and preventative maintenance tasks that team members have to put on pause.

As downtime and financial losses accumulate, it becomes an all-hands-on-deck situation for a maintenance team until the breakdown is resolved.

All other pending preventive maintenance tasks become a lower priority and are therefore added to the backlog.

Deferred maintenance in facilities

Let’s say a facility has a scheduled preventive maintenance reminder to change all the HVAC filters in a 10-story building every three months. While they have ordered the necessary filters, they did not all arrive on time for the maintenance team to complete the change as scheduled. Therefore, replacing the remaining filters gets added to the deferred maintenance backlog.

Checklist for Creating a Preventive Maintenance Plan

Following a consistent Preventive Maintenance Plan can make life easier. Use this checklist to create your own!

What is a maintenance backlog?

A maintenance backlog is the list of tasks and work orders postponed to a later date due to the emergence of higher-priority work and a lack of maintenance resources.

Many of the tasks in the backlog end up being preventive maintenance tasks. They are not urgent when scheduled, but they are essential to the safety and functionality of the equipment.

Preventive maintenance tasks are not optional, but other priorities can easily supersede them for a team with slim resources. And if the backlog grows too big, it can be challenging to catch up.

Common causes of deferred maintenance

All organizations face challenges unique to their situation. However, there are some common issues that lead to heavy maintenance backlogs.

Lack of a maintenance program or strategy

One of the main reasons a maintenance task may get pushed onto the backlog is because more urgent priorities get in the way.

If your organization relies too heavily on reactive or corrective maintenance, this becomes the norm. It is easy to get caught in the loop of constantly evaluating priorities in order to address the most urgent need and end up deferring the rest.

Save some trouble by implementing a preventive maintenance plan or a predictive maintenance program.

Poor inventory management

Whether a company has a proactive maintenance program in place or not, they must ensure they have the tools and parts on hand to complete maintenance work.

It is difficult to strike a balance between having enough resources on hand and not wasting money on unnecessary parts. Implementing an efficient spare parts management process can help mitigate this issue and prevent maintenance backlogs from growing too unmanageable.

Lack of needed skills

If maintenance technicians don’t have the skills they need to complete their work, it will lead to inefficiencies or repetitive work.

Ensure they have the right tools to do their job by providing:

- Maintenance training

- Maintenance checklists

- Other information, like equipment maintenance logs

For jobs or equipment that require specialized skills, make sure to establish relationships with the right vendors so they can jump in when needed.

Lack of needed manpower

Sometimes, the issue is as simple as not having enough people to do what needs to be done. If maintenance tasks and overtime hours keep piling up, it is likely more manpower is needed.

A company should leverage any maintenance reports in their CMMS to accurately determine their team’s workload. Alternative strategies can help improve efficiencies and make up for some lack of resources, but ultimately the company may need to look into hiring more team members or outside help if they can’t get on top of their maintenance tasks.

Lack of funding

Lack of funding is often a common thread that ties all other maintenance issues together. If top management is unwilling to budge and provide more resources, maintenance managers are left trying to optimize their workflows to cut costs.

A good CMMS can increase productivity and reduce maintenance costs while helping teams stay on top of their maintenance backlogs.

Costs and consequences of a poorly managed deferred maintenance backlog

Regular maintenance ensures the safe and efficient functioning of facilities and equipment. Therefore, putting off or postponing regular maintenance will have the opposite effect.

Research from The Geaslin Group suggests that deferred maintenance will often result in exponential costs that can quickly escalate out of control.

Rick Biedenweg, the President of Pacific Partners Consulting Group states that “every dollar of deferred maintenance will eventually cost $4 in future capital renewal.”

Here are some of the most common reasons why a poorly managed deferred maintenance backlog can be so detrimental:

Reduced efficiency

If an organization calculates metrics like overall equipment effectiveness (OEE) or machine efficiency, they generally find that slacking on regular maintenance reduces how well their equipment works.

Increase in breakdowns and repairs

Continuing to use equipment without giving it the regular maintenance it requires is a surefire way to accelerate deterioration. It is a poor way to handle asset management.

Compounding damage will ultimately lead to the need for increasingly frequent and costly repairs, lost production due to downtime, and a shorter asset lifecycle.

Risks to health and safety

Maintenance isn’t just about efficiency and avoiding breakdowns or complete system failures.

It also ensures that equipment doesn’t pose safety hazards or health risks to team members. Employee safety should always be an organization’s highest priority.

Legal and regulatory risks

If a company does not maintain their equipment or facilities properly and the unthinkable happens as a result, the fines and lawsuits that follow are an incredibly costly worst-case scenario.

Even when not facing a disaster, simple non-compliance with maintenance regulations can result in unpleasant consequences, too. Fines and other penalties, such as loss of licensure, should be major considerations when managing deferred maintenance tasks.

Good versus bad deferred maintenance

Too much deferred maintenance can be costly. But some is okay — beneficial, even. So, how much is too much?

Let’s explore what separates the bad from the good before reviewing some steps companies can take to get from one to the other.

When deferred maintenance is a problem

Here are some signs deferred maintenance may become a costly long-term problem:

- An increasing frequency of deferring maintenance activities

- Deferring essential maintenance or maintenance of highly critical equipment

- Deferring repairs or other reactive maintenance tasks in addition to preventive maintenance activities

- A deferred maintenance backlog that grows over time or becomes too large to ever resolve

If any of the above sound familiar, you may be in the danger zone.

An escalation in the frequency or type of maintenance that gets pushed onto the backlog should be a sign that some additional resources or efficiencies could benefit a company’s maintenance strategy.

When deferred maintenance is a solution

When used constructively, deferred maintenance can be a valuable tactic.

It gives companies the freedom to apply a more nuanced prioritization to their maintenance work. It can be a way to make the most of limited resources.

Here are a few characteristics of a productive deferred maintenance strategy.

- Tasks are added to the deferred maintenance backlog primarily as a result of unexpected issues that take time away from regular tasks.

- Maintenance backlogs are reviewed, prioritized, and assigned regularly.

- A maintenance backlog strategy exists to ensure tasks are reviewed and completed within a reasonable timeframe.

- Items on the maintenance backlog are mostly preventive maintenance tasks.

Want to see Limble in action? Get started for free today!

Consistency is key

A deferred maintenance backlog won’t disappear overnight, but with consistent work and a smart maintenance strategy, you should be able to keep it under control.

If you are interested in other ways in which Limble can help improve your maintenance department, don’t hesitate to get in touch.