Preventative maintenance is the most popular maintenance strategy because it provides many benefits with a low level of cost and difficulty to implement.

That being said, preventive maintenance does have its downsides.

One of the most cited objections is that it may require excessive maintenance. In other words, some worry that technicians will waste time on unnecessary inspections of assets that might not (yet) require attention.

If we dig a little deeper, there is a more significant concern. When you are doing preventive work on an asset, in many cases, that asset needs to be shut down first. In translation, you need to schedule planned downtime.

Nobody wants to shut down an asset during peak production time or for maintenance work that isn’t immediately necessary. That means you will need to develop a maintenance schedule that takes an asset’s productivity into account, and minimizes overall downtime. We will show you how.

Checklist for Creating a Preventive Maintenance Plan

Following a consistent Preventive Maintenance Plan can make life easier. Use this checklist to create your own!

What is planned downtime | scheduled downtime?

Simply put, planned downtime is a period of time you reserve for scheduled maintenance and upgrades during which your assets have to be shut down.

Since proactive maintenance is often done on critical assets that are important to production, you don’t have any other solution than to pause normal production operations until the repairs/inspections/upgrades are done.

Organizations look to avoid these problems by scheduling maintenance during night shifts (or other times when the machines are not in use). However, if your maintenance department isn’t running night shifts or if you have a 24/7 production cycle, finding the right time to schedule planned downtime can get really complicated, really fast.

Quick note: For the rest of the article, we will use the terms “planned downtime” and “scheduled downtime” interchangeably as they refer to the same thing in practice.

Planned and unplanned downtime

The difference between planned and unplanned downtime is self-explanatory: you decide when you want to have planned downtime, machines decide when they want to take a break, and they don’t bother asking whether that fits your schedule.

All jokes aside, unexpected equipment failures that lead to unplanned downtime can be very costly, which is one of the key reasons why many businesses are switching from reactive to preventive maintenance.

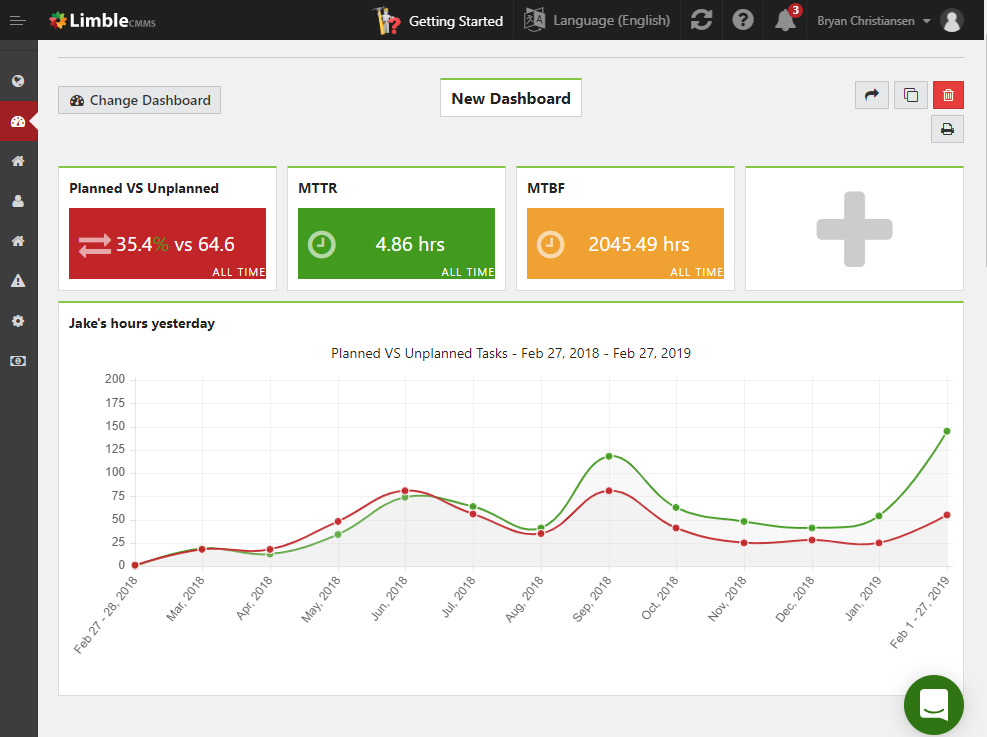

Knowing how much time you spend on planned vs. unplanned maintenance is essential, so it is one of the many things that Limble keeps track of for you.

Here is an example of how you can use Limble to track how much time you spend on planned maintenance tasks vs. how much time you spend reacting to unexpected issues:

Let’s see how to schedule planned downtime so you can conduct proper maintenance with a minimum impact on your production speed and volume.

How to manage planned downtime

#1) Understand your production

Throughout the year, you will more than likely have an ebb and flow in a day to day production. Know each machine you run, and discern how different seasons affect production cycles, and in turn, machines’ daily use.

During peak production, plan to find the best time that affects the bottom line the least. Finding time to prepare may mean after hours. If you’re running a 24/7 shop, it might mean the slowest hour of the day.

The key is knowing when production slows down and when it speeds up to plan.

#2) Reduce excessive maintenance with a CMMS

One of the principal ways of running a successful maintenance plan is being able to organize, manage, and track large amounts of information across various sources.

Having a modern CMMS software can greatly help you track and make sense of all of that data. Here are just some of the things you do with a CMMS:

- Record machine performance and asset history

- Track the progress of all tasks (read work orders)

- Track the usage of all inventory and spare parts

- Track technician’s performance

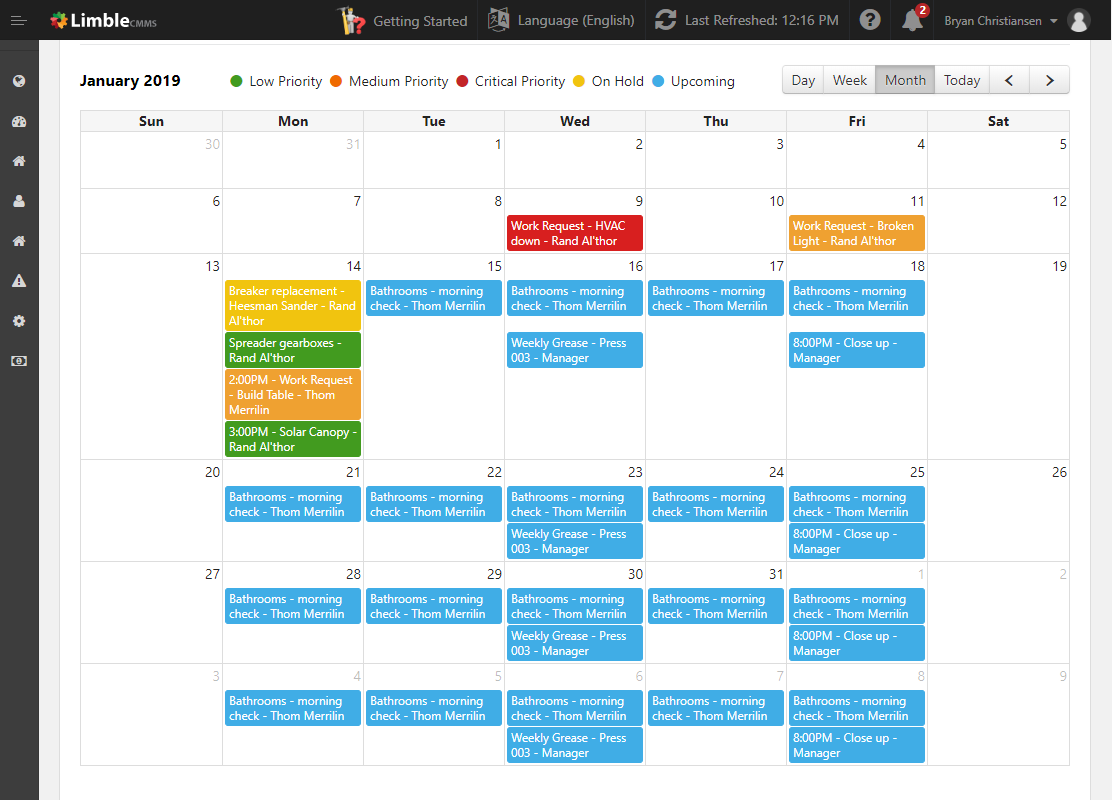

- Schedule and oversee your complete preventive maintenance schedule

By having all of this data at your disposal, you can reduce excessive maintenance by:

- Spacing out the frequency of maintenance work on assets that can handle it

- Cutting the length of the downtime event by speeding up diagnosing and team communication

- Ensuring all spare parts are available when you need them

- Having a well-organized maintenance department in general

For an in-depth look at CMMS, check out our What is a CMMS System and How Does it work guide.

#3) Narrow the focus of your maintenance plan

A great way to know where to begin your maintenance scheduling is by listing all of your assets and assigning a rank to them. It might seem obvious, but knowing which machines are of the highest priority in your factory will give you a north.

Once you have listed your important machines, list the more minor assets that might be so secondary they do not need to be included in routine maintenance.

Individual machines, for example, take less strain with use. One might not need oil or lubrication; another might be less involved than other devices, with far fewer moving parts.

Either way, specific machines need less overall maintenance. And it should be clear which machines fall under this category. After all, it is often not worth having all of your machines on a preventive maintenance plan.

In addition to everything mentioned, understanding how long each maintenance task should last and when the machine is used the least will be crucial in creating an effective preventive maintenance plan so that you can schedule planned downtime at the most opportune moment.

#4) Have a clearly defined SOP

Having clearly defined standard operating procedures for every operation that has to be repeated often is a great way to streamline your maintenance operations.

As planned downtime is something you will have to schedule reasonably regularly, having clear guidelines will help technicians perform their work faster, which means that your assets will need less time to get back to work.

Keep in mind that the speed and quality of the performed maintenance work are equally important. While it is nice to keep scheduled downtime at a minimum, poorly performed maintenance work will almost certainly lead to an increase in unplanned downtime.

And I think we can all agree that two additional hours of scheduled downtime are much more acceptable than a whole day of an unplanned shutdown or outage.

#5) Understand your bottlenecks

Frequent delivery delays make it hard to keep a stock of needed spare parts? Some senior maintenance technicians retired or left the firm, so you are working with a younger team that lacks experience and training? Working with older assets that need a lot of attention and like to break down unexpectedly?

In the context of minimizing planned downtime for preventative maintenance, spare parts, inexperienced/unskilled technicians, and aging assets are the 3 most common bottlenecks you need to schedule around.

The good news is that these bottlenecks are avoidable with a little bit of workaround and foresight.

If your spare parts aren’t getting to you promptly, consider ordering them earlier or switching to a new provider when possible.

When you know you have inexperienced technicians, you can:

- Pair them up with more experienced colleagues

- Have a clearly defined SOP we just talked about

- Provide them with the necessary training

- Have a more rigorous hiring process

And lastly, you have to find a way to account for aging assets. In most cases, this will mean that you will need to pay special attention to those assets as they can be very troublesome and be the cause of many unscheduled downtimes. Some ways you can do that is by:

- Carefully tracking asset history to extrapolate common breakdown patterns so you can look to address them during planned downtimes

- Scheduling additional inspections that can be performed while the asset is in function

- Installing sensors to perform condition-based monitoring

#6) Reduce the duration of scheduled downtimes through effective collaboration

Departments that interact with maintenance personnel should be on the same page and coordinate routine tune-ups and repairs. As long as everyone understands where the maintenance team will be for every planned shutdown, machine operators, cleaning staff, and other workers can start preparing the environment to focus only on what they need to do and ensure minimal downtime.

When the opposite occurs, and there is poor communication between departments, it is not hard to imagine different mistakes and accidents that can occur and prolong the time your assets spend on standby.

Do not allow poor organization and communication to be why your planned shutdowns caused production delays.

The Essential Guide to CMMS

Download this helpful guide to everything a CMMS has to offer.

When to schedule planned downtime

As a facility maintenance manager, it is clear that only you can find the right time when to schedule planned downtime at your facility.

That being said, we have a few tips that could help:

- Schedule planned maintenance work after business hours

- Immediately before major holidays

- Before highly anticipated severe weather

- One every two years simulate a blackout and test all critical equipment at once

It’s all about planning ahead

As you can see, with enough planning and organization, you can greatly minimize the amount of downtime during planned maintenance.

Whether it’s during a peak production season, or the slowest season of the year, being organized and having an exact maintenance schedule will ensure your production runs at the highest level and that your machines are in peak operating condition.

If you are interested in fully exploring how Limble can help you keep the amount of time spent on planned downtimes to a minimum, leave a comment below or send us a message.